Screw Drilling Tool with Circumferential Rotational Impulse

A screw drilling tool and thrust technology, applied in the field of drilling, can solve the problems of low screw life, low ROP, and high cost, achieve high circumferential driving efficiency, eliminate stick-slip and drill sticking, and improve rock breaking efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

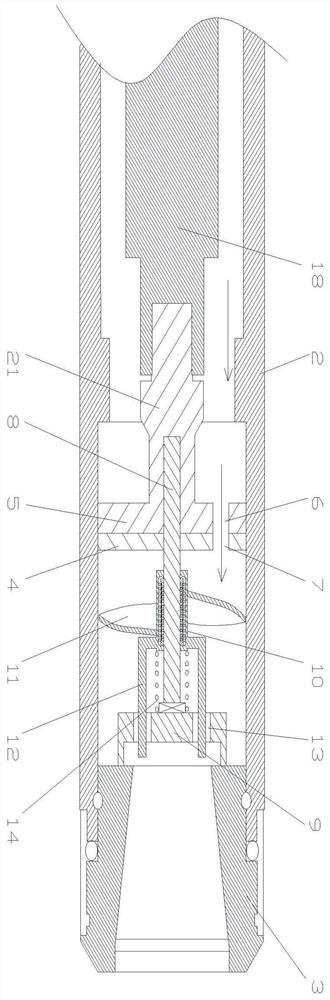

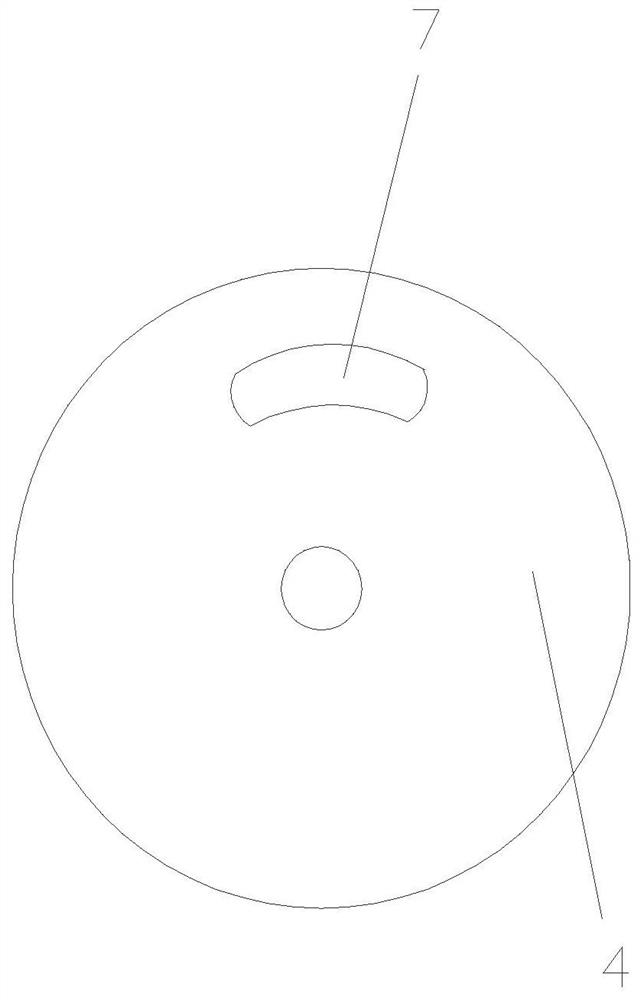

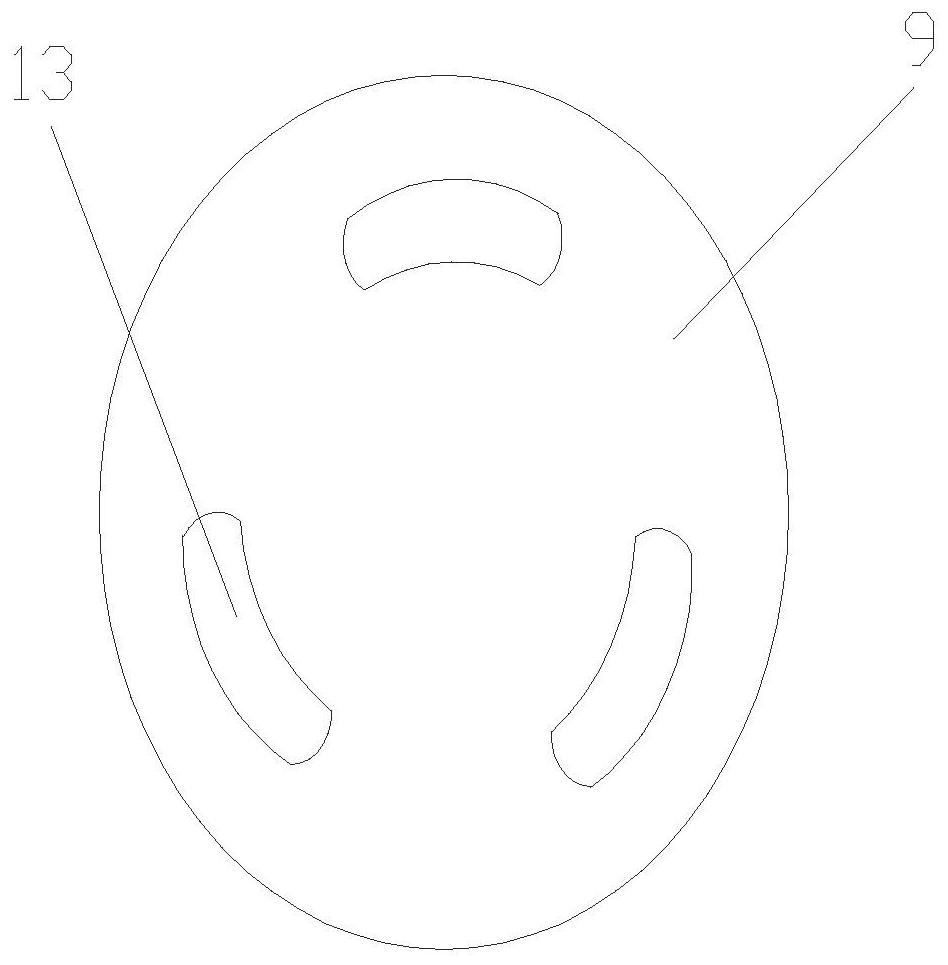

[0017] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is a structural schematic diagram of the front valve disc in the present invention, image 3 It is a structural schematic diagram of the driven disc in the present invention, Figure 4 It is a structural schematic diagram of the composite bearing in the present invention. As shown in the figure, the screw drilling tool with circumferential rotational impulse in this embodiment includes a drill body and a drill seat assembly connected between the drill pipe and the drill body and used to generate circumferential rotational impulse ; The drill head assembly includes a fixedly connected rear connection pipe, a middle pipe body 2 and a front connection pipe 3 from back to front, and the impact assembly and The power part driving and cooperating with the impact assembly; the power part is the screw rod 18 of the screw drilling tool; a disc valve assembly is also arranged between the power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com