Hot melting drilling tapping thread forming tap

A technology of extruding taps and hot-melt drills, which is applied in the direction of drilling/drilling equipment, drill repairing, drilling tool accessories, etc., can solve the problems of time-consuming, processing errors, etc., and achieve improved thread connection strength, excellent performance, Good thread quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

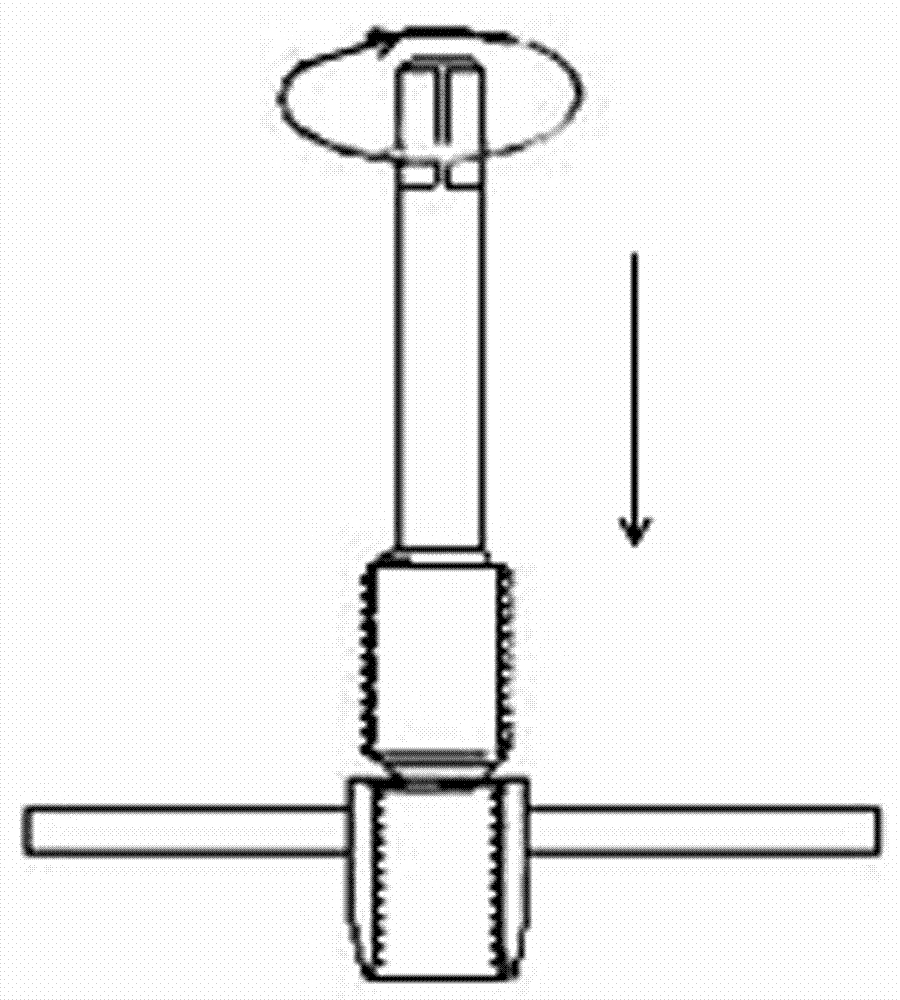

[0014] Such as figure 1 shown , The hot-melt drilling and tapping extrusion tap includes a shank 1, a tapping drill 2 and a hot-melt drill 3, the shank 1, the tapping drill 2 and the hot-melt drill 3 are integrally formed, and the hot-melt drill 3 is located at the front end, The tapping drill 2 is located in the middle, and the shank 1 is located at the end. The diameter of the tapping drill 2 is greater than that of the hot-melt drill 3 , and the diameter of the shank 1 is smaller than the diameter of the hot-melt drill 3 .

[0015] The tapping drill bit 2 is an extrusion tap. Forming taps are tools for chipless machining of internal threads.

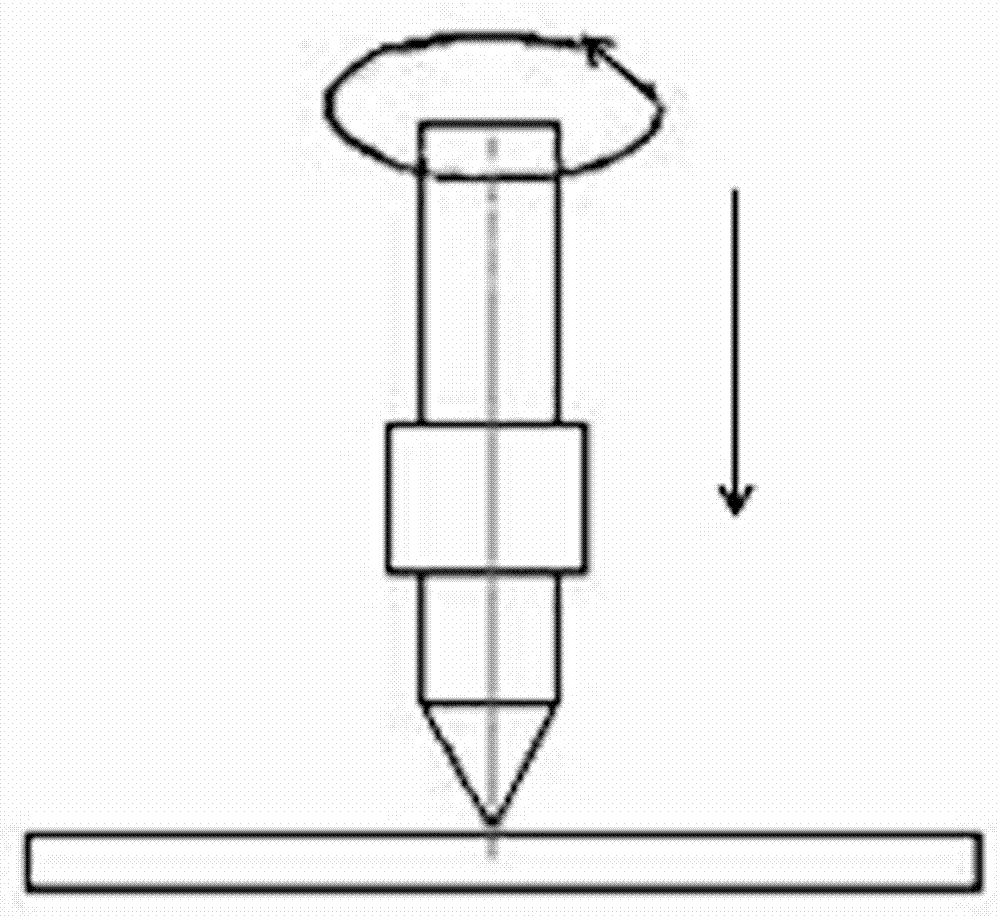

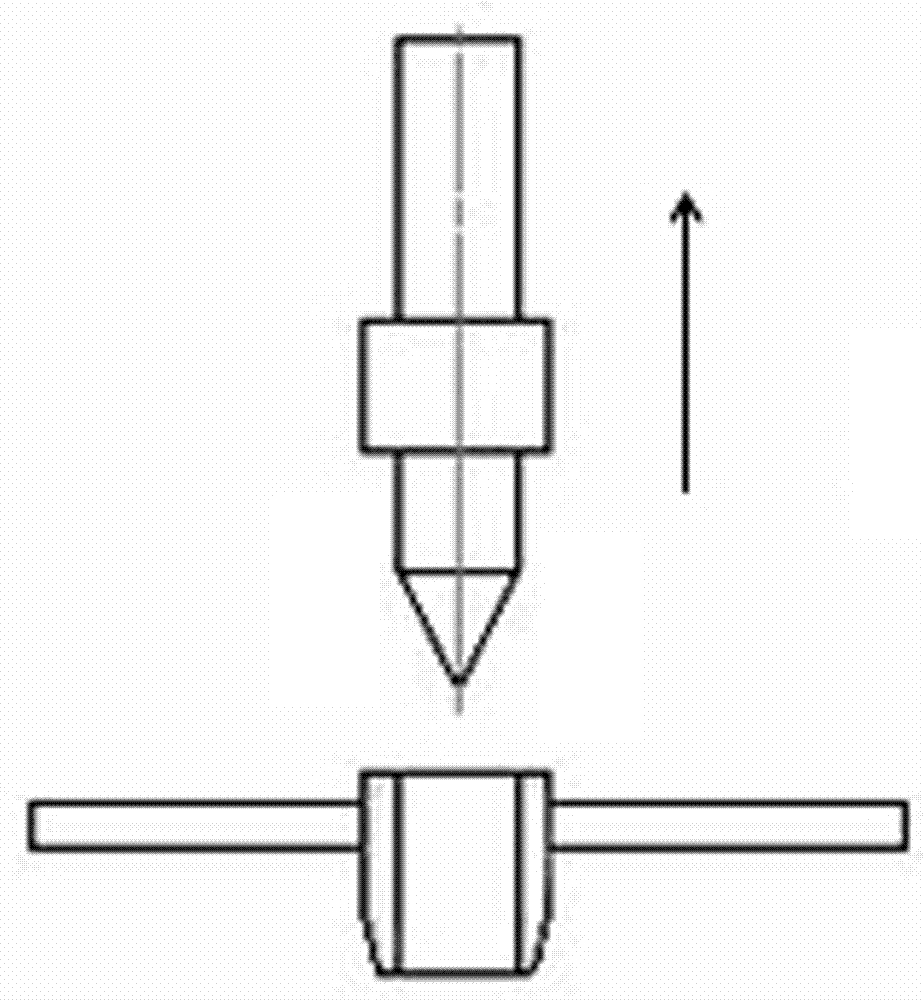

[0016] The present invention uses high-speed rotation and high axial pressure to generate a large amount of frictional heat on the metal material, and the temperature reaches about 750°C, so that the processing part of the workpiece 4 presents a plastic state, and forms a bushing 5 with the displacement of the drill bit (see Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com