Rotary drill bit shank, rotary drill bits so equipped, and methods of manufacture

A drill bit and bit body technology, applied in drill bits, manufacturing tools, drilling equipment, etc., can solve problems such as undesired stress, dislocation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

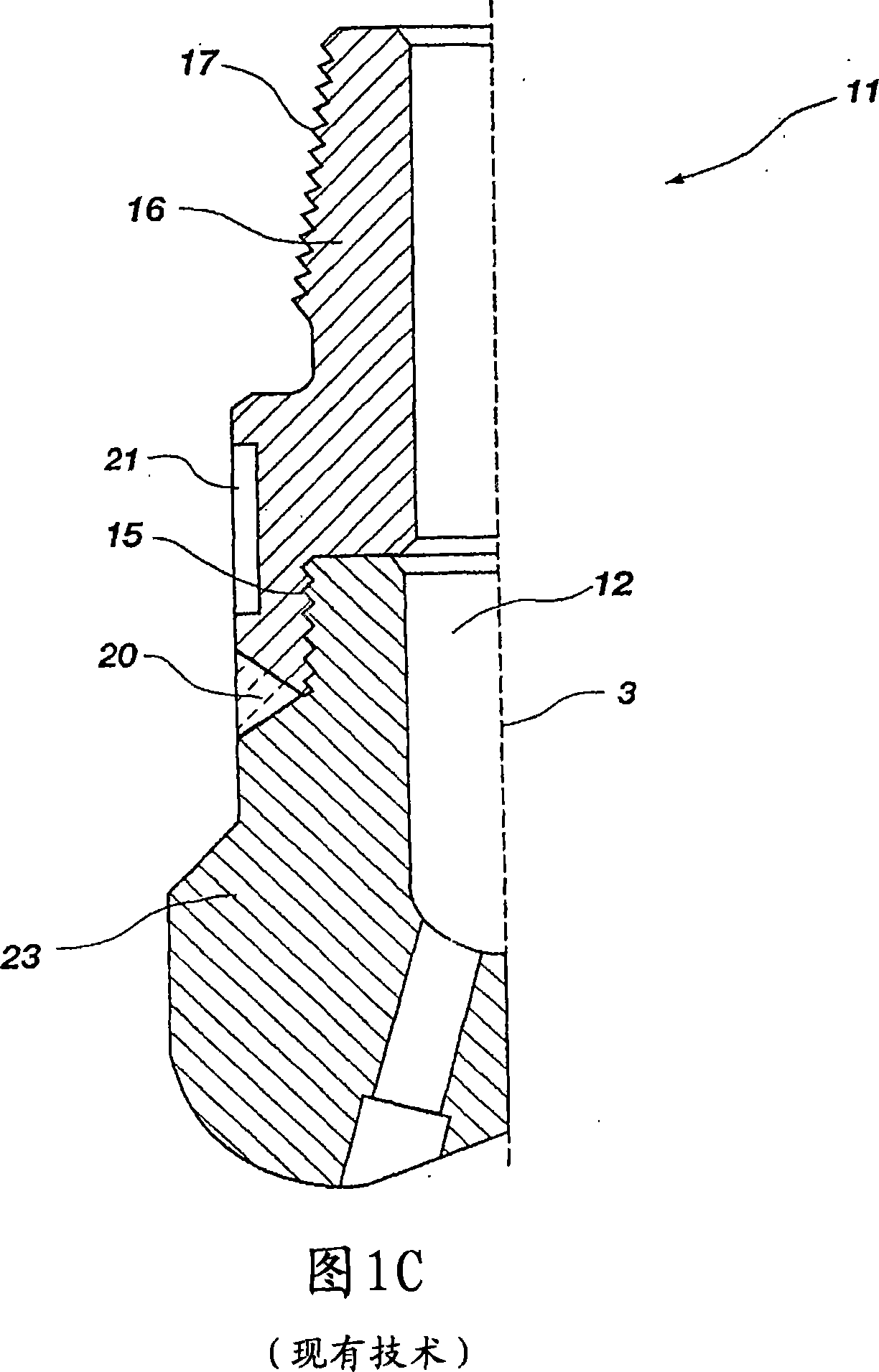

[0030] FIG. 2A shows a partial cross-sectional view of a matrix type rotary drag bit 110 according to the present invention. Rotary drag bit 110 includes a central longitudinal axis 103 about which holes 112 are generally arranged. Rod 116 may be made of a material having a carbon equivalent of less than about 0.35%, such as, but not limited to, AISI 4130 steel or AISI 4130MOD steel, and may include any known in the art for attachment to a drill string (not shown). The threaded pin connection portion 117 and the drill bit handler surface 121 for fitting onto or removing from the drill string, respectively. Desirably, the rod material has a carbon equivalent weight of even less than about 0.35%, such as less than about 0.30%. One of ordinary skill in the art will recognize that the material selected for rod 116 exhibits at least a minimum yield strength, a minimum ultimate tensile strength, and a minimum impact strength suitable for conditions encountered during drilling with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com