Welded alloy drill

A technology for welding alloys and alloys, which is applied in the directions of repairing drills, twist drills, drilling tool accessories, etc., can solve the problems of high production and use costs, troublesome use, low rigidity of drill bits, etc., and achieve the effect of cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

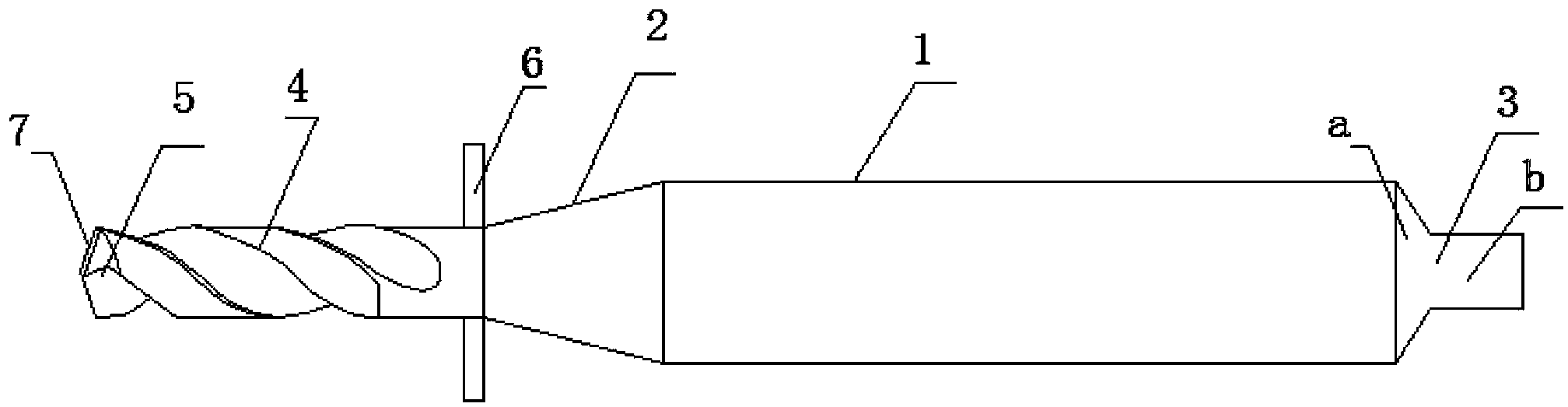

[0010] Such as figure 1 As shown, the welded alloy drill includes a drill shank 1. One end of the drill shank 1 is provided with a drill connecting portion 2, and the other end is provided with a drill positioning portion 3. The drill connecting portion 2 is welded with an alloy drill body 4, and the end of the alloy drill body A drill tip 5 is provided at the top of the drill bit, and a drill chip stopper 6 is provided on the peripheral surface of the joint 2 of the alloy drill body 4 and the drill bit joint.

[0011] An alloy blade 7 is arranged on the drill tip.

[0012] The drill positioning part is composed of a tapered part a and a cylindrical part b.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com