Taper shank twist drill

A twist drill and taper shank technology, which is applied in twist drills, drill repairs, drill accessories, etc., can solve problems such as splashing workers, affecting the service life of tools, and dirtying the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

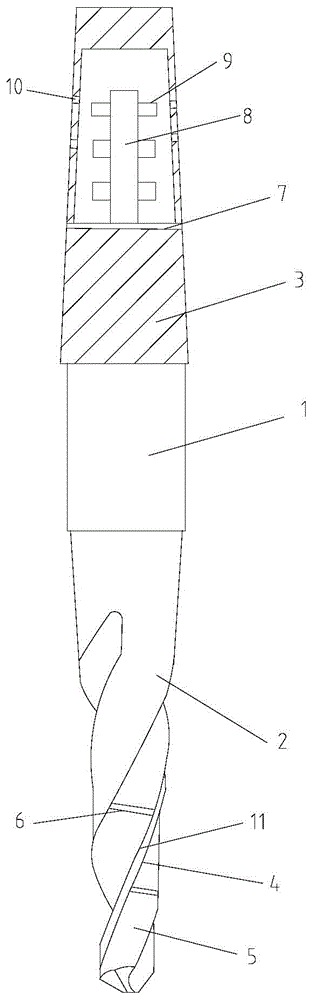

[0011] As shown in the figure, the taper shank twist drill includes a drill body and a taper shank 3. The drill body includes a drill working part 2 and a drill shank 1. The taper shank 3 is sleeved on the drill shank 1. The taper shank 3 is structured to facilitate utilization The principle of friction force can transmit a certain torque, and because the taper shank 3 and the fixture are taper, it can be easily disassembled. The working part 2 of the drill bit is equipped with three spiral cutting edges 4, and there is a row between the two spiral cutting edges 4. Chip flute 5, chip flute 5 is provided with a cleaning edge 11, chip flute 5 is equipped with a transverse chip edge 6, drill working part 2 is tapered, the lower end of the drill working part 2 has a diameter of 6mm and an upper end of 10mm, It can drill holes of different sizes, which expands the practical range of the drill. The drill shank 1 and the taper shank 3 are connected by threads, which facilitates the use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Upper diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com