High-performance antiskid shank shrinkage drill bit

A high-performance, drill-bit technology, applied in twist drills, tool joints, etc., can solve the problems of reducing the work efficiency of operators, increasing the workload of operators, affecting the smoothness of the workpiece surface, etc., to improve the positioning effect, facilitate processing, and facilitate effect of connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

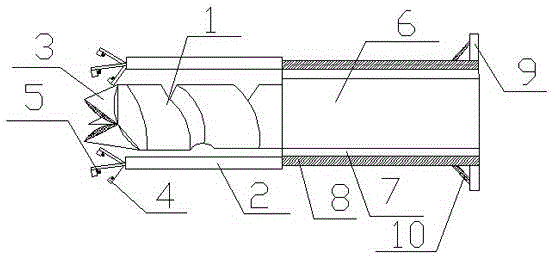

[0011] A high-performance non-slip shrinking shank drill bit, including a drill bit 1 and a clamping device 2, the drill bit 1 is a twist drill bit, the drill bit 1 is provided with cutting edges 3, the cutting edges 3 cross each other, and the drill bit 1 is provided with a clamping device 2, clamping The holding device 2 is a claw, and the claw is a four-legged claw. The claw is provided with a fixing piece. On the back of the drill bit 1 is provided with a connecting handle 6, the connecting handle 6 is hexagonal, the connecting handle 6 is provided with a sheath 7, the sheath 7 is made of thin stainless steel, and the sheath 7 and the connecting handle 6 are flexibly connected. The inner wall of the sleeve 7 is provided with a protective piece 8, the protective piece 8 is a rubber layer, the thickness of the rubber layer is 0.6cm, and the tail of the connecting han...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com