Method of V-shaped welding of solid carbide drill and solid carbide drill thereof

A solid carbide and drill technology, which is applied in drilling/drilling equipment, components of boring machines/drilling machines, and drill repairing, etc. Great economic and social benefits, and the effect of reducing tool prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

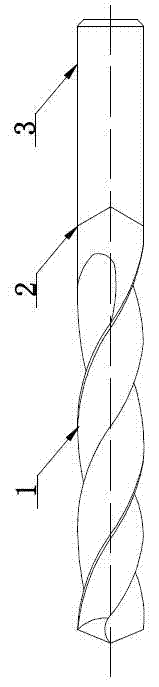

[0021] The method for V-shaped welding D16X165 welded solid carbide drill bits comprises the following process steps:

[0022] 1. Select the corresponding cemented carbide bar K40 (German blue trifoliate), and the cutter body material is 9Crsi;

[0023] 2. According to the process requirements, determine the length of the drill bit blade 1 from 100mm-103mm, and the length of the drill bit shank 3 from 65mm-70mm;

[0024] 3. Coreless grinding the alloy bar material of the cutting edge 1 of the drill bit, to D16.5mm;

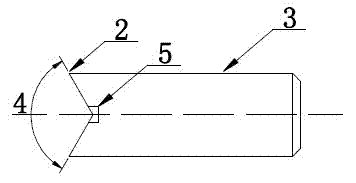

[0025] 4. The stress relief groove 5 on the shank 3 of the milling bit, the groove length is 13.5mm, the groove width is 5mm, and the groove depth is 5mm;

[0026] 5. Use a wire cutting machine to cut the drill bit edge 1 and the "V"-shaped welding part 2 on the alloy bar;

[0027] And use a special welding fixture to ensure that the position of the "V"-shaped welding part 2 is concentric with the center of the alloy rod material, and the eccentricity is ≤0.05mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com