Shock absorber for drilling tool in oil-gas drilling

A technology for oil and gas drilling and shock absorbers, which is applied to drilling equipment, drill pipes, drill pipes, etc. It can solve the problems of complex structure, inconvenient maintenance, and different technical solutions, so as to reduce potential safety hazards, facilitate maintenance, and reduce wearing parts Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

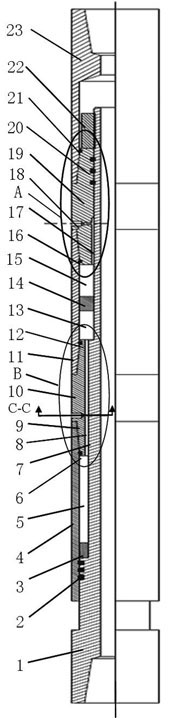

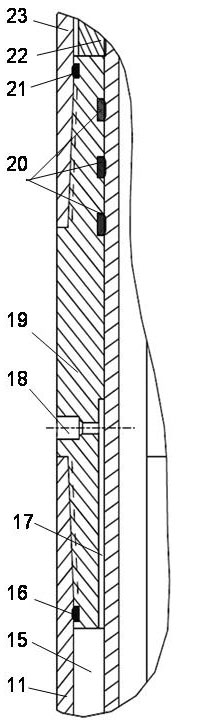

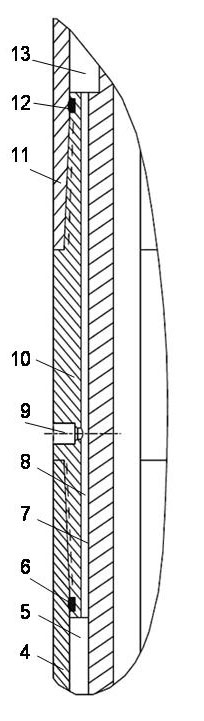

[0024] see Figure 1-Figure 4 The present invention comprises a mandrel 1, which is provided with a spline 7, and a fixed piston 3 is also installed on the mandrel 1. The spline 7 is provided with a spline outer cylinder 10 constituting an axial movement pair, and the movement pair is completely immersed in silicone oil, that is, the movement pair is always lubricated by silicon oil. Ten damping flow channels 8 are axially formed between the spline 7 and the spline outer cylinder 10, and each damping flow channel 8 is arranged at the bottom of the keyway of the spline outer cylinder 10, and the keyway of the spline outer cylinder 10 is in a "U" shape The groove, the spline 7 is gear-like, and the spline 7 is embedded in the groove of the spline outer cylinder 10, and the cross section of each damping channel 8 formed by the spline outer cylinder 10 and the spline 7 is semicircular. The number of damping flow passages 8 is consistent with the number of key grooves of the splin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com