Drill bit having increased resistance to fatigue cracking and method of producing same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

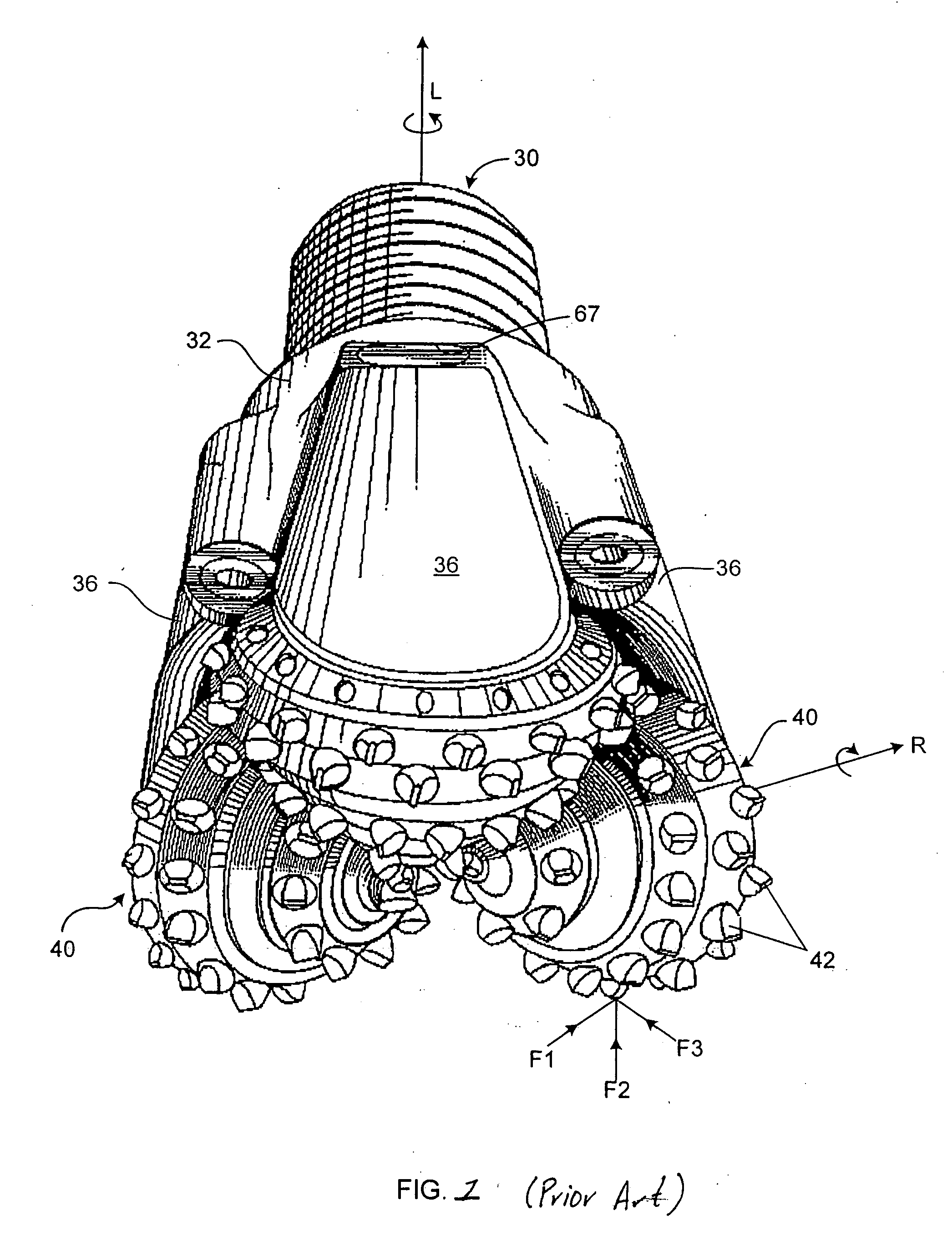

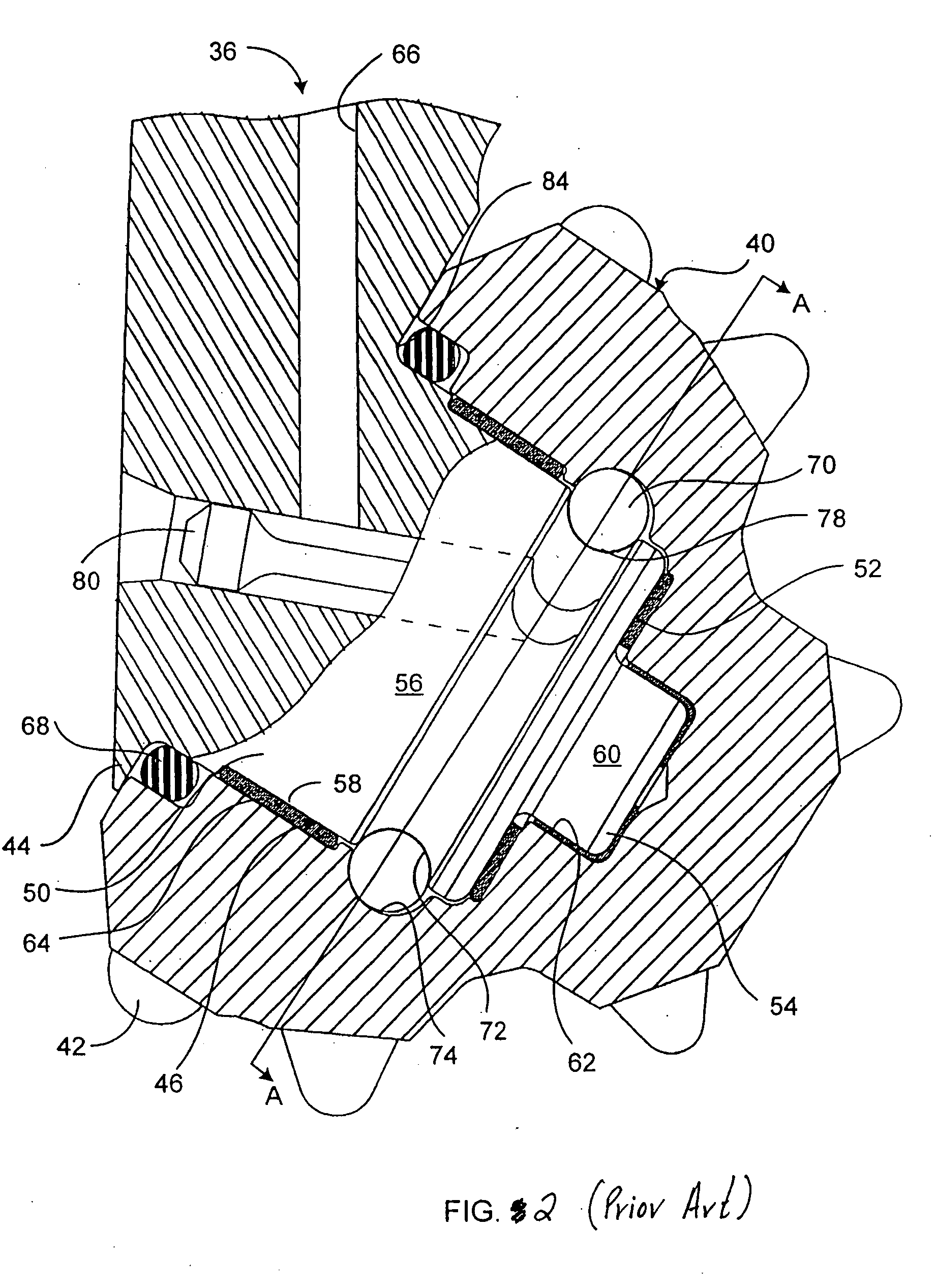

[0022] In one aspect, the present invention relates to a method for improving the durability of a roller cone bit. In another aspect, the present invention relates to a drill bit having improved durability when compared to prior art bit. In particular, the methods and bits of the present invention comprise treating at least a portion of a roller cone bit leg surface.

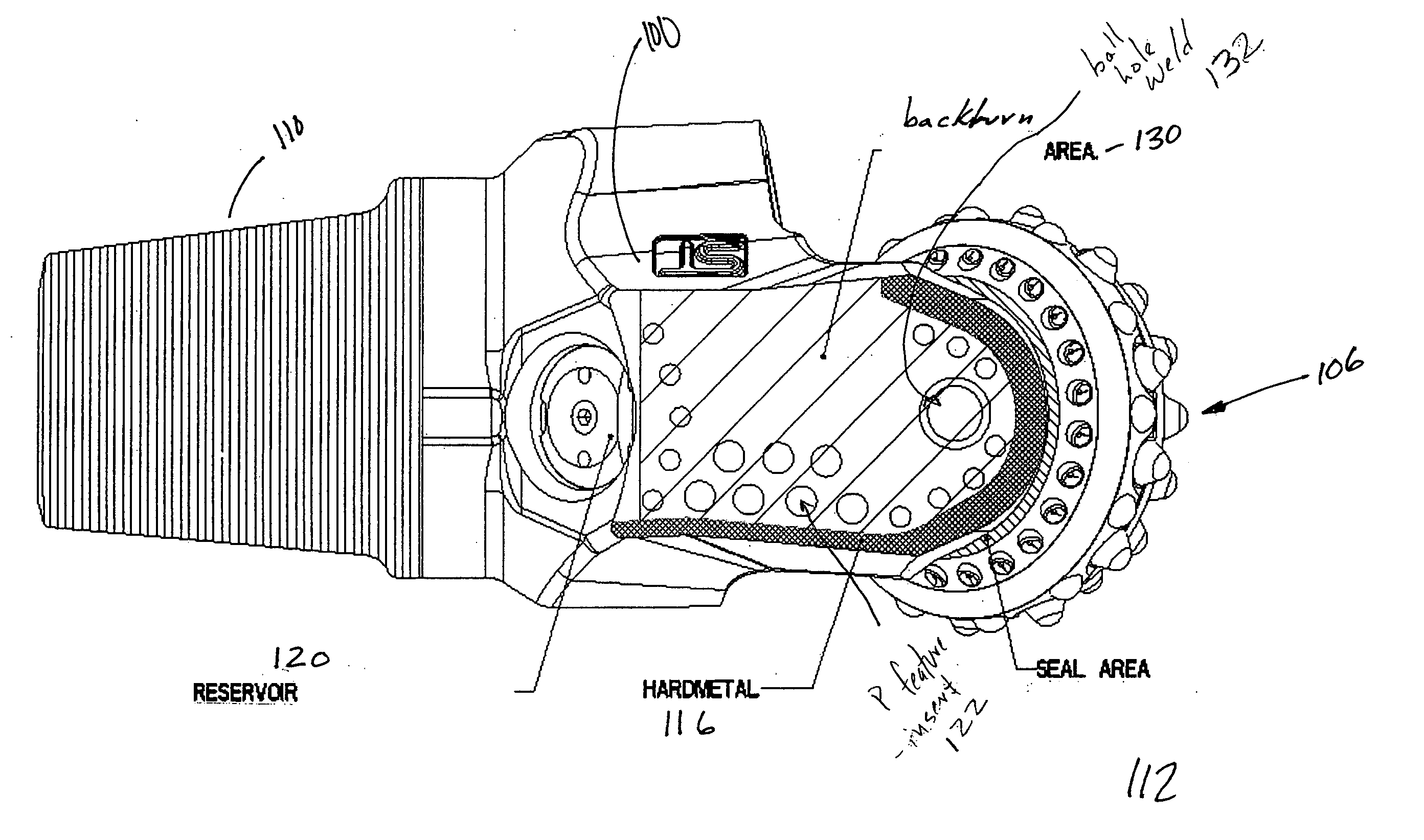

[0023] In one embodiment, the treating comprises inducing a residual compressive stress in a backturned surface of at least one roller cone drill bit leg. In one specific embodiment, inducing the residual stress comprises applying a shot peening process to the selected area (i.e., at least a portion of the leg backturn area). As those having ordinary skill in the art are aware, shot peening is a cold working process in which the surface of a part is bombarded with small spherical media called shot. Shot-peening is a controlled cold work process in which the surface of a part is bombarded with controlled impingement of a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Electric charge | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com