Austenite stainless heat-resisting seamless steel pipe internal wall shot-blasting strengthening technique and device

A seamless steel pipe, shot peening technology, applied in the field of austenitic stainless heat-resistant seamless steel pipe inner wall shot peening process and its device, can solve the problem of low gas source pressure, inability to resist high temperature steam oxidation corrosion, steel Problems such as structural defects of pellets, etc., to achieve high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In the shot-peening strengthening process of the inner wall of the austenitic stainless heat-resistant seamless steel pipe of the present invention, the austenitic stainless heat-resistant seamless steel pipe with an inner diameter (ID) of 24mm≤ID≤60mm and a length not greater than 12M is selected for processing , and the chosen method is to use high-pressure air with P≥1.0MPa to drive the steel shot with a hardness of 45HRc to shoot at the inner wall of the steel pipe through the spray gun at an accelerated rate, and process it in a physical way of strain strengthening, so that the surface layer of the inner wall of the steel pipe can achieve the structure and stress strengthening. Purpose.

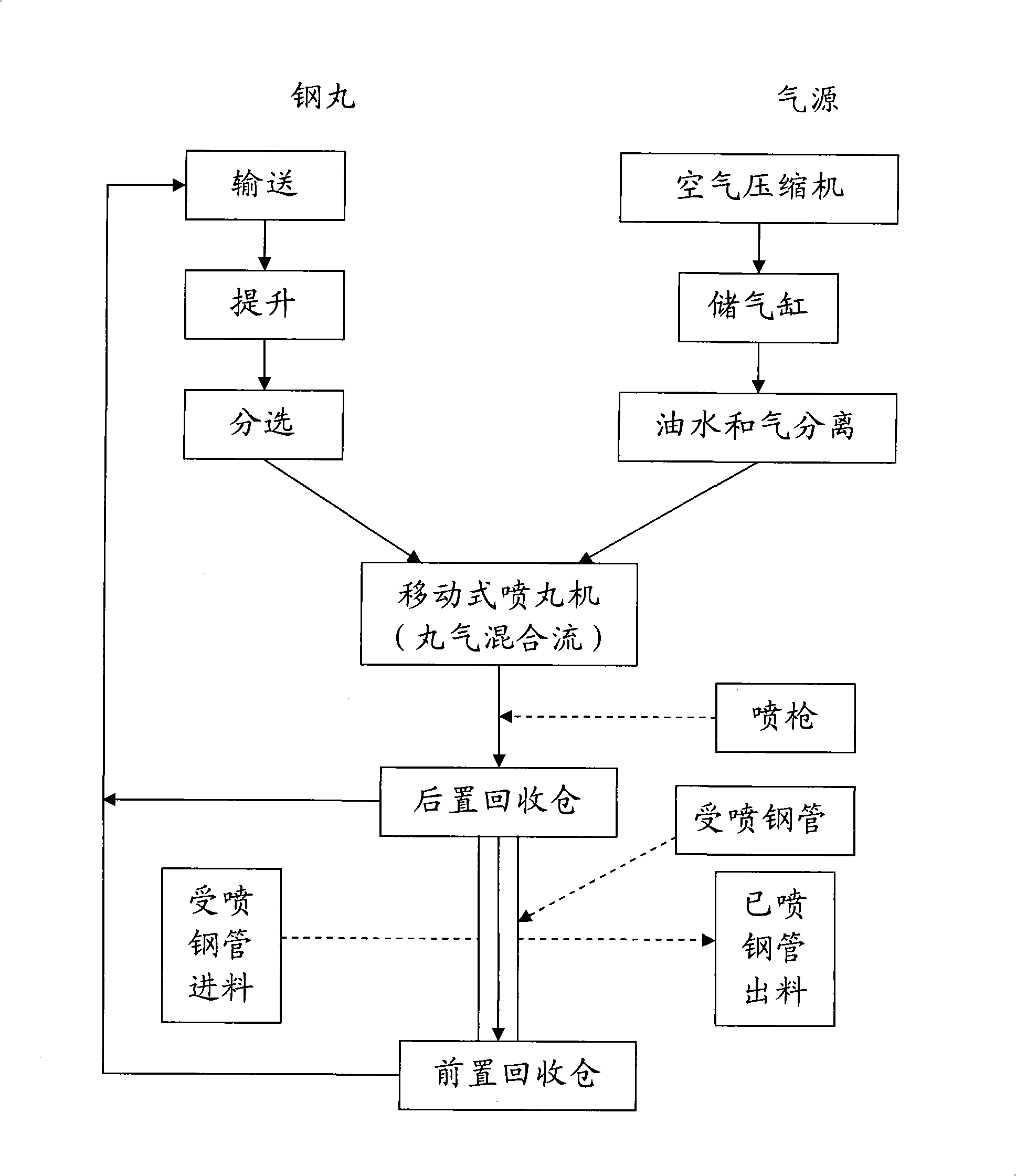

[0032] refer to figure 1 From the main flow chart of the process of the present invention, it can be seen that the present invention sends the steel shot into the mobile shot blasting machine after conveying, lifting and sorting. At the same time, the air source is pressurized by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com