Shape maintenance shot peening strengthening and calibration method for preventing in-plane bending of wall panel

A technology of shot peening and correction method, which is applied in the field of shape-preserving shot peening and correction to prevent in-plane bending of wall panels, and achieves the effects of reducing parts scrap rate, avoiding major economic losses, and good technical and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

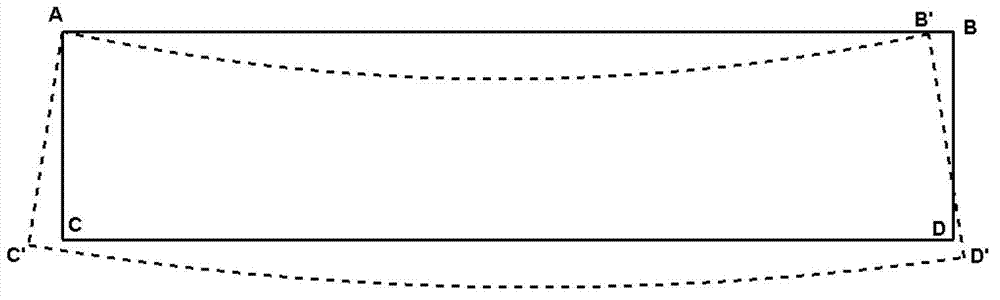

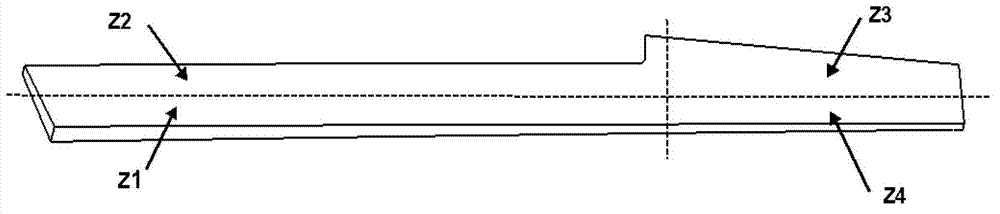

[0052] For shot peening of aircraft wing panels, first follow image 3 Divide the area, and the thickness is Z1, Z2, Z3, Z4 from large to small. The given shot peening intensity range is 0.15~0.2mmA, then it is divided into five equal parts, and the shot peening intensity of each level is:

[0053] Q1=0.2mmA; Q2=0.1875mmA; Q3=0.175mmA; Q4=0.1625mmA; Q5=0.15mmA

[0054] , the shot peening strength of the inner and outer surfaces of the four areas of the panel is shown in the table below.

[0055] spray position

Z1

Z2

Z3

Z4

The outer surface

Q1

Q2

Q3

Q4

The inner surface

Q2

Q3

Q4

Q5

[0056] Detailed process parameters include:

[0057]

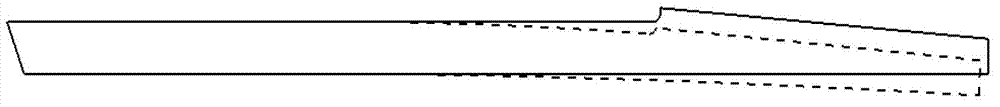

[0058] Shot peening was carried out on the MP15000 CNC shot peening machine of the French Wheelaborator company, and the wing panel after shot peening was deformed as follows: figure 2 , need to be corrected, according to Figure 4 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com