Printing method and printing device for non-individual body sheet

A printing method and continuum technology, used in printing, printing presses, rotary printing presses, etc., and can solve problems such as wrinkling, sheet undercut, deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

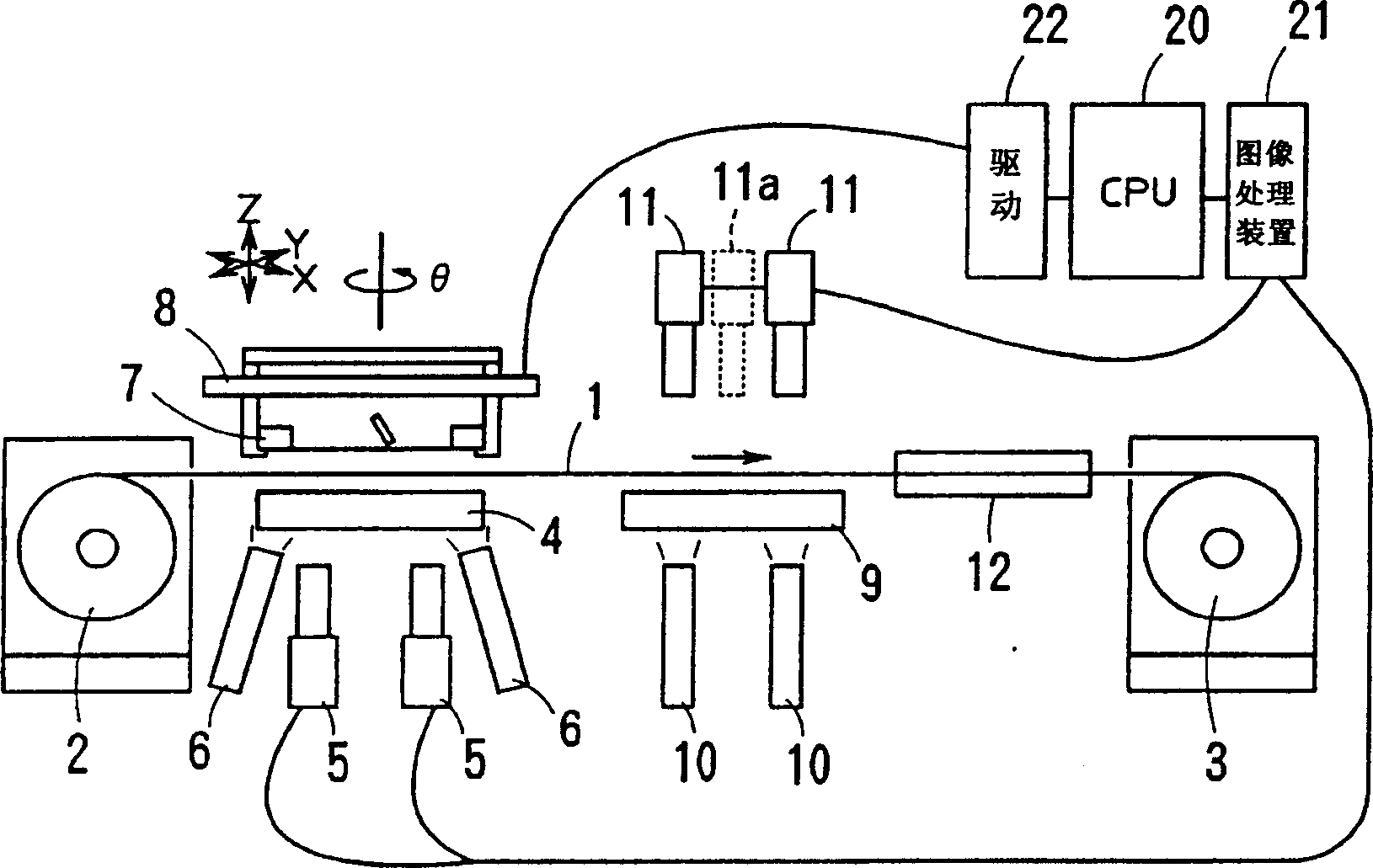

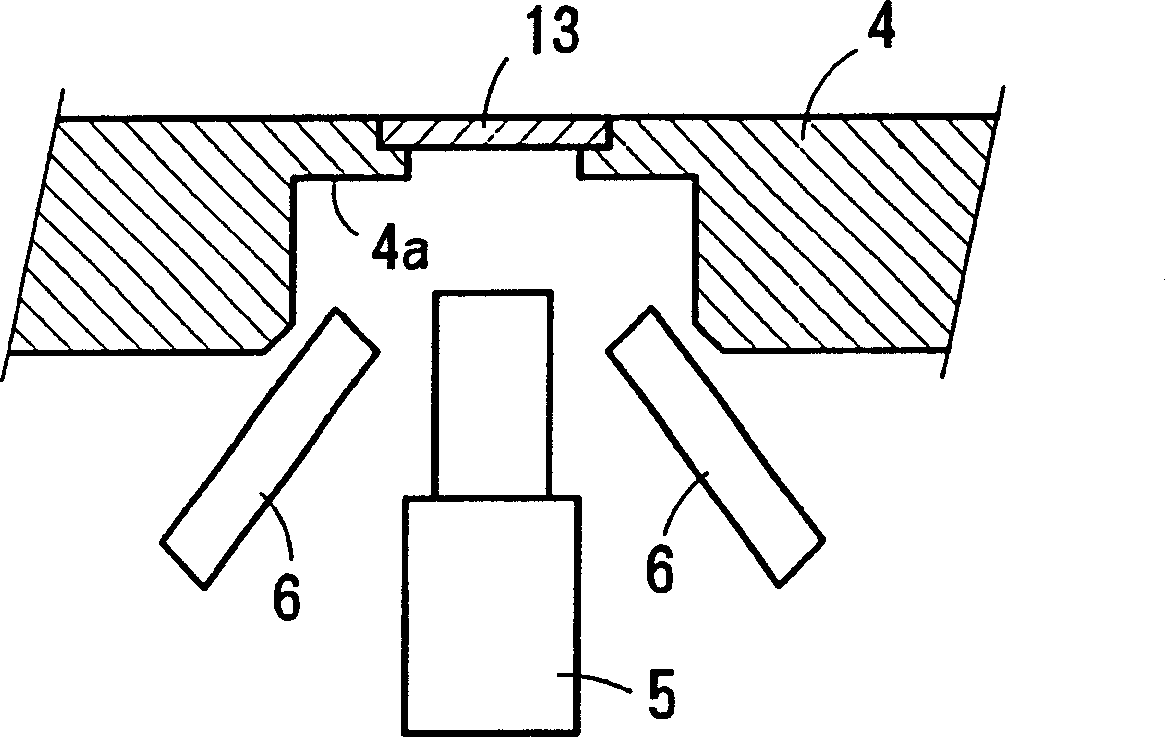

[0061] figure 1 An example of a continuous sheet printing device related to the present invention is shown.

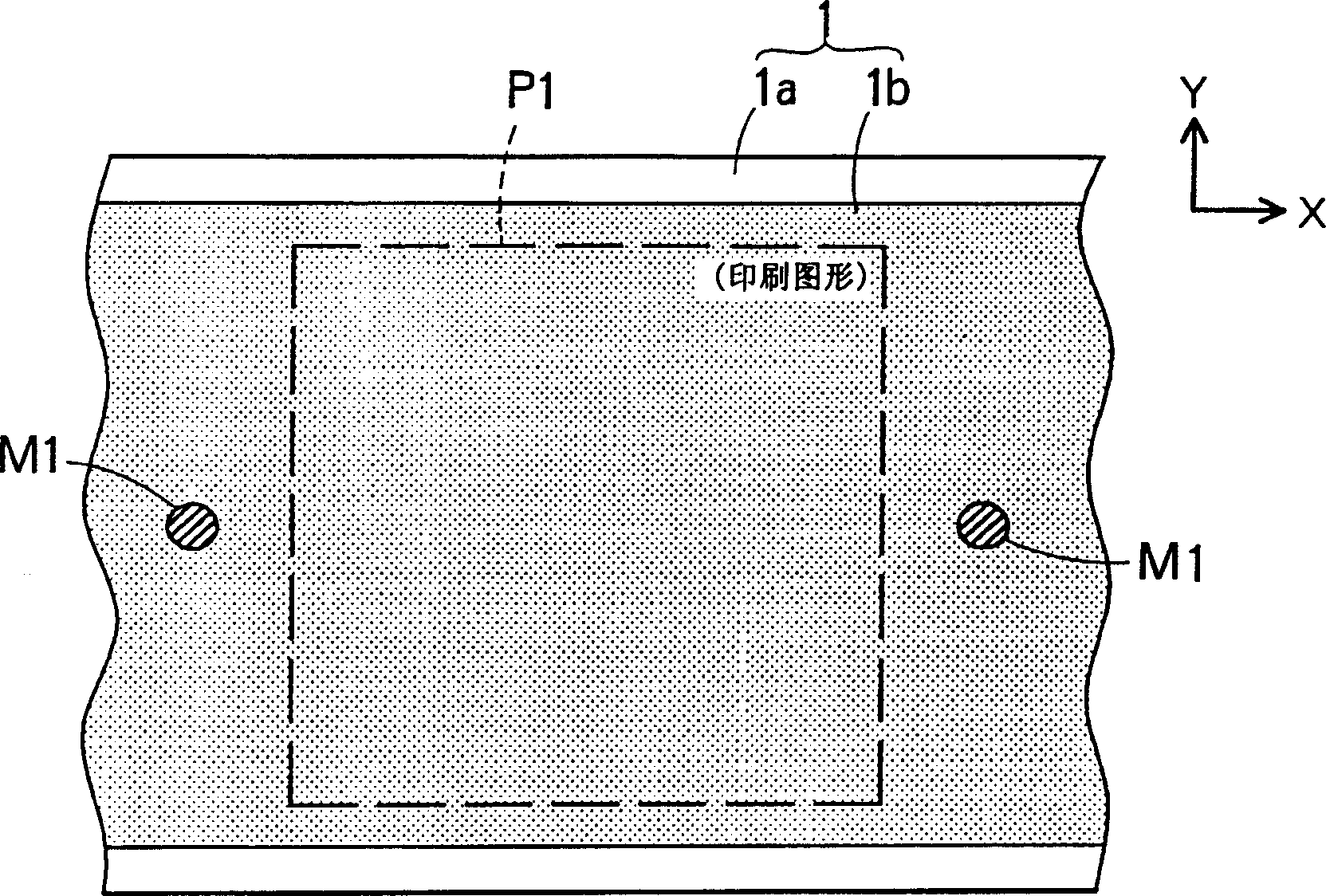

[0062] The continuum sheets used here 11 and figure 2 The raw material ceramic layer 1b is formed in a continuous film form on a flexible support body 1a such as a relatively long carrier film as shown, and the first pattern P1 and the pattern corresponding to the P1 are formed in advance by printing or the like at certain intervals in the longitudinal direction on the upper surface thereof. Multiple alignment marks M1. In this example, the pattern P1 and the mark M1 are printed to a predetermined thickness using an electrode material such as Ni paste. When the thickness of the ceramic layer 1b is 5 μm-0.2 μm, because the continuum sheet 1 itself is almost transparent, so the back side of the continuum sheet 1 can be seen through, and the pattern P1 and the mark M1 can be recognized, as will be described later. Logo M2 for printing plate 7. The alignment mark M1 ...

no. 2 Embodiment

[0080] The amount of printing deformation in screen printing can be known from the large deviation of each pattern. Such as Figure 10 Shown: When the marks M1 and M2 for position deviation detection are arranged outside the surroundings of the patterns P1 and P2', the marks M1 and M2 can be aligned, but the patterns P1 and P2' do not have to be aligned.

[0081] Figure 10 (a) is when the mutual positional relationship between the sign M1 and the pattern P1, the sign M2 and the pattern P2' is equal, Figure 10 (b) is when the mutual positional relationship is different.

[0082] However, by using the feedback correction value (B'-A) obtained by image processing and the correction value of both sides of the offset (offset) value calculated by measuring the mutual position of the printed coating film in advance, so that the original desired pattern P1, The position offset correction of P2' is corrected together with other offsets due to long-term differences. In order to ...

no. 3 Embodiment

[0087] In the first and second embodiments, after printing at the printing station 4, the printing offset at the feedback station 9 is obtained and fed back, but in the third embodiment, the feedback station is omitted, and the printing offset is obtained at the printing station 4 Feedback for the next printing.

[0088] Although the system diagram of the printing device of the third embodiment is omitted, it is from figure 1 In the printing unit shown, the system of feedback table 9, lighting 10, camera 11, etc. has been omitted. In addition, the amount of displacement between the printed position identification mark M2 and the alignment mark M1 is measured by image processing with the camera 5 provided on the printing table 4 .

[0089] Figure 13 , Figure 14 It is a flowchart of the printing method of the third embodiment.

[0090] exist Figure 13 In the initial printing shown, the processing of steps S1 to S7 is the same as Figure 7 . After printing, the continu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com