Substrate processing device, method and program

A technology of a substrate processing device and a substrate processing method, which is applied to the device for coating liquid on the surface, physical therapy, transportation and packaging, etc., can solve problems such as difficulty in shortening the intermittent time, and achieve the effect of shortening the intermittent time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

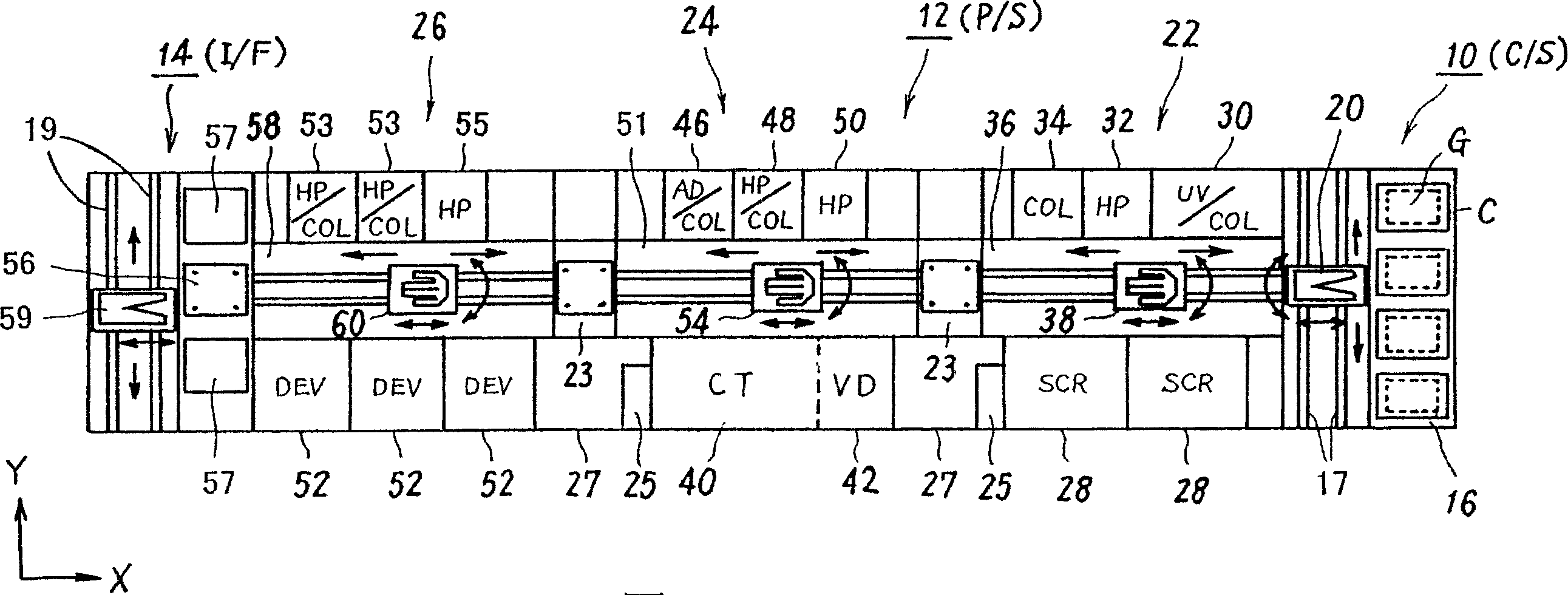

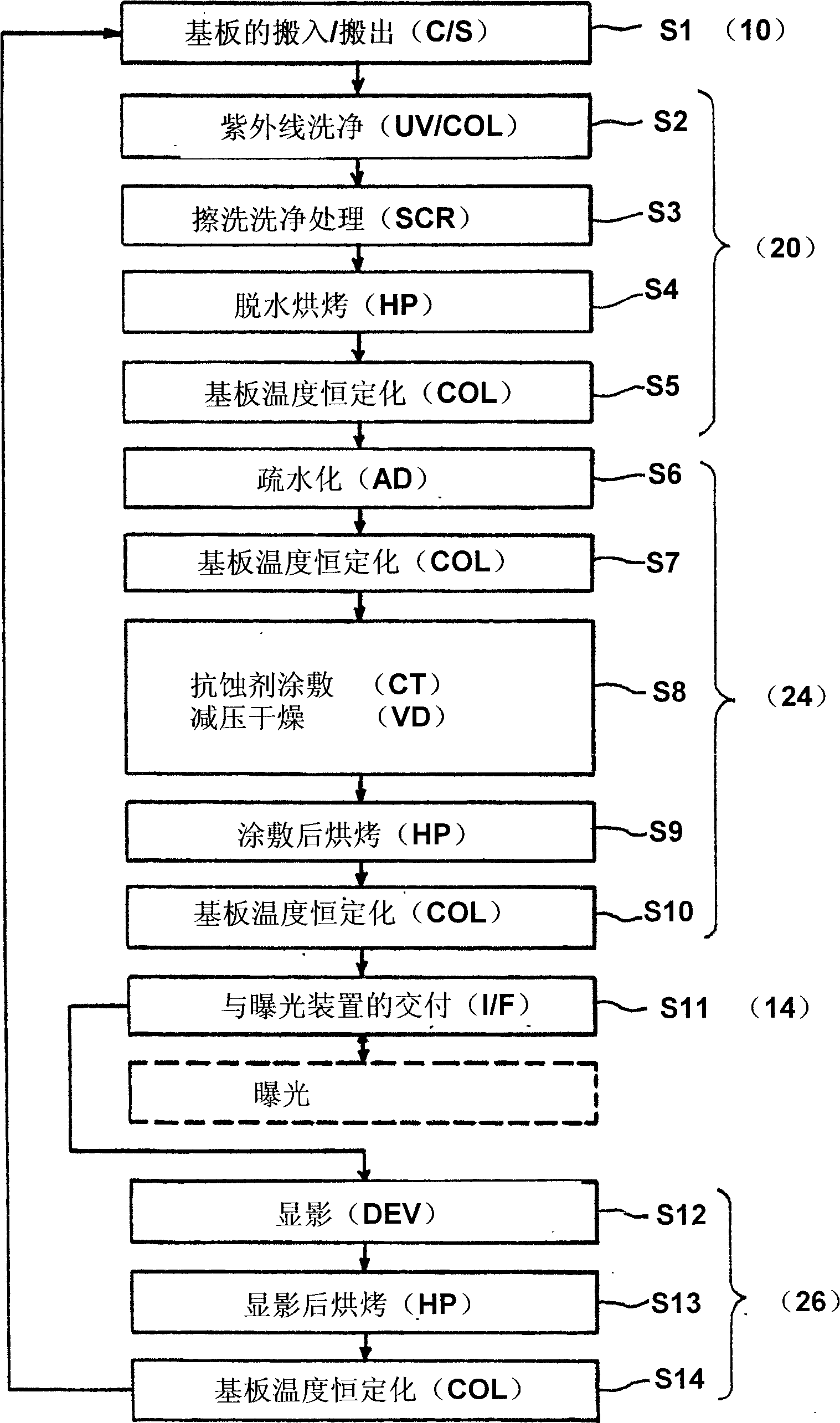

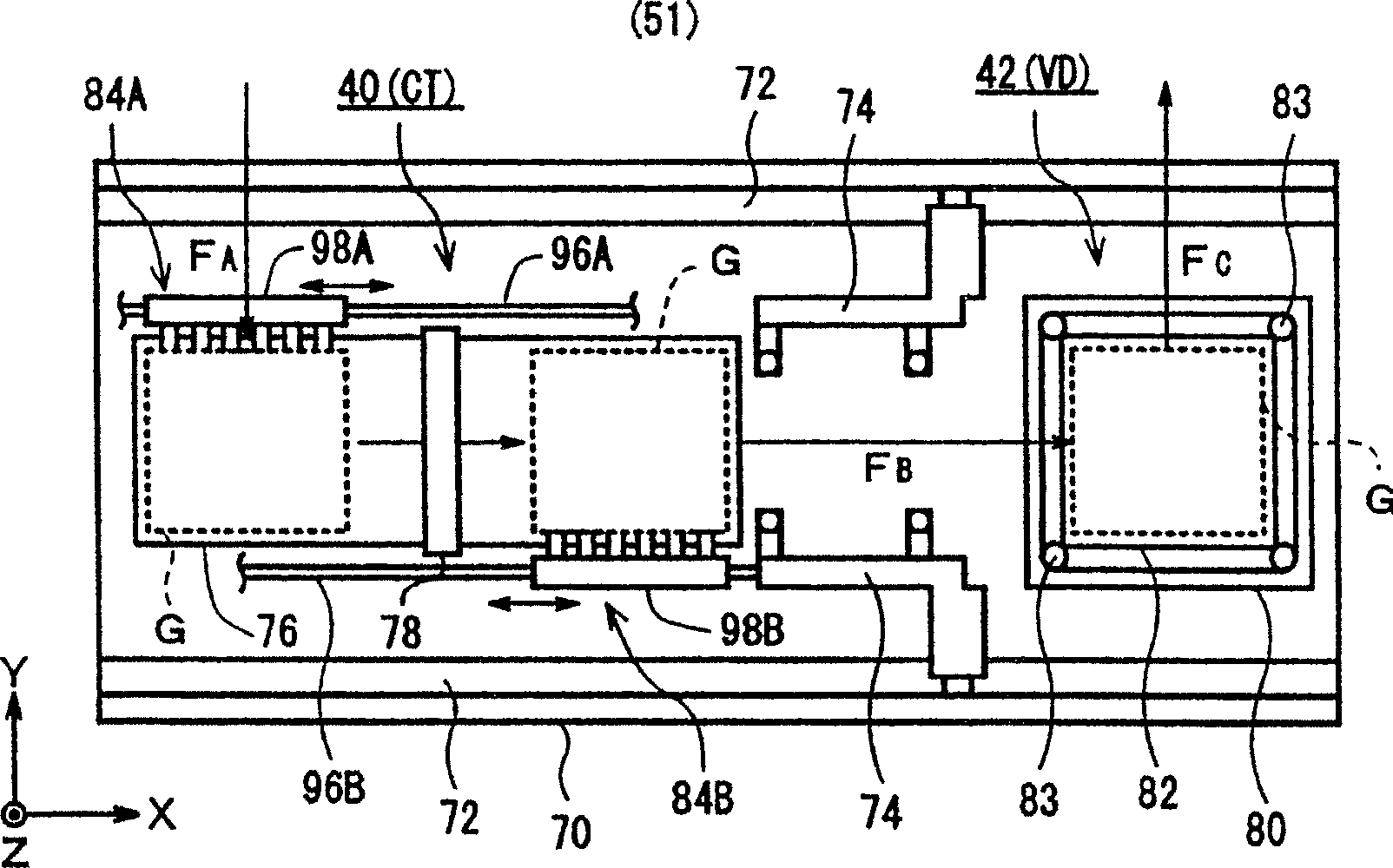

[0072] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings.

[0073] figure 1 It shows an example of a configuration that a coating and development processing system can be applied to as the substrate processing apparatus of the present invention. The coating and development processing system is installed in a clean room, for example, the LCD substrate is used as the substrate to be processed. In the LCD manufacturing process, cleaning, resist coating, pre-baking, developing and post-baking are performed in the photolithography process. each processing.

[0074] Roughly speaking, this coating and development processing system is composed of a cassette station (C / S) 10 , a processing station (P / S) 12 and an interface unit (I / F) 14 .

[0075] The box station (C / S) 10 provided on one end of the system includes: a box loading station 16, which can place a predetermined number (for example, 4) of boxes C containing a plural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com