Crawling torque output control method and device, and automobile

A technology of torque output and control method, which is applied in the direction of control devices, electric vehicles, control drives, etc. It can solve the problems of long time for manual control to release the brake pedal, lagging response of creeping torque, and vehicle slippage, etc., so as to avoid adverse effects , speed up response and save cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

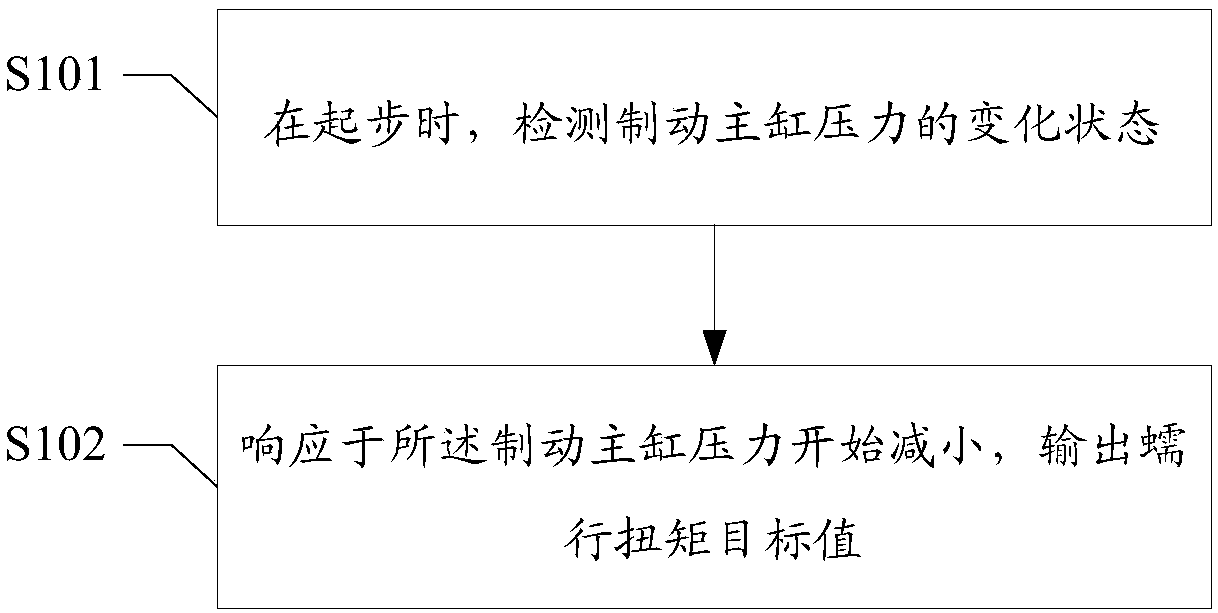

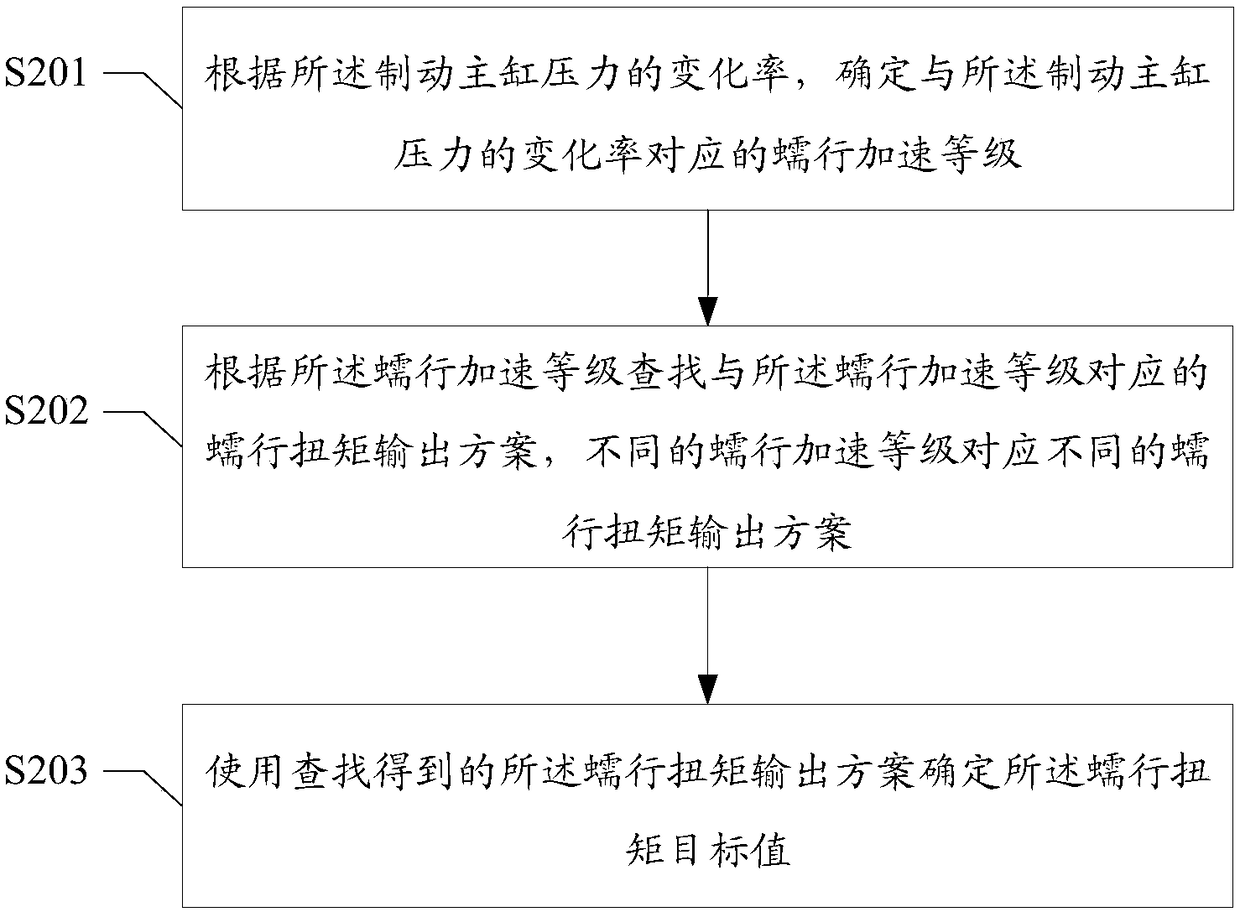

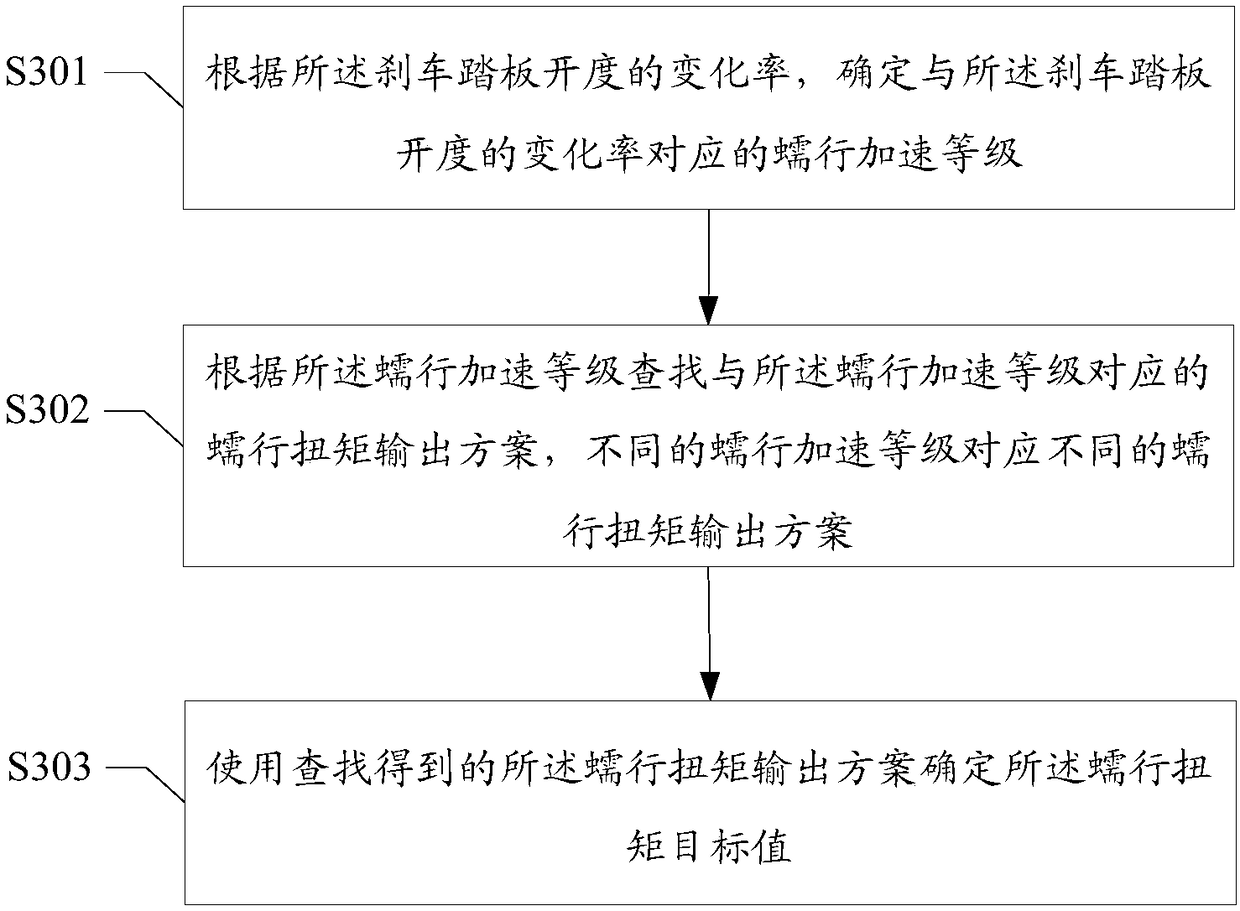

[0039] As mentioned above, in the starting stage of the vehicle, new energy vehicles are mostly driven by motors. When the motor-driven vehicle is running in creep mode, the torque output method is as follows: after the brake pedal is released, the motor outputs a preset value according to the current vehicle speed. Set the creep torque to drive the vehicle into creep. Wherein, for the same vehicle speed, the motor outputs the same creep torque. However, the above-mentioned creep torque output method will cause the creep torque response to lag, and if the vehicle creeps and starts on a slope with a certain slope, the vehicle is prone to slide downhill.

[0040] The inventor of the present invention has found through research that the key to the above problem is that in the prior art, the motor does not output creep torque during the period from when the driver releases the brake pedal to when it is fully released, resulting in no forward power of the vehicle.

[0041] In the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com