Mining area self-reserved roadway non-pillar mining method suitable for gently inclined coal seam

A mining method and technology without coal pillars, which can be used in surface mining, earthwork drilling, underground mining, etc., can solve the problems of tight excavation replacement, long moving time, and high work intensity, so as to reduce excavation costs, simplify mobilization, and save money. The effect of coal resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

[0024] The present invention is applicable to the mining area self-retained roadway without coal pillar mining method in the mining area of gently inclined coal seam, comprises the following steps:

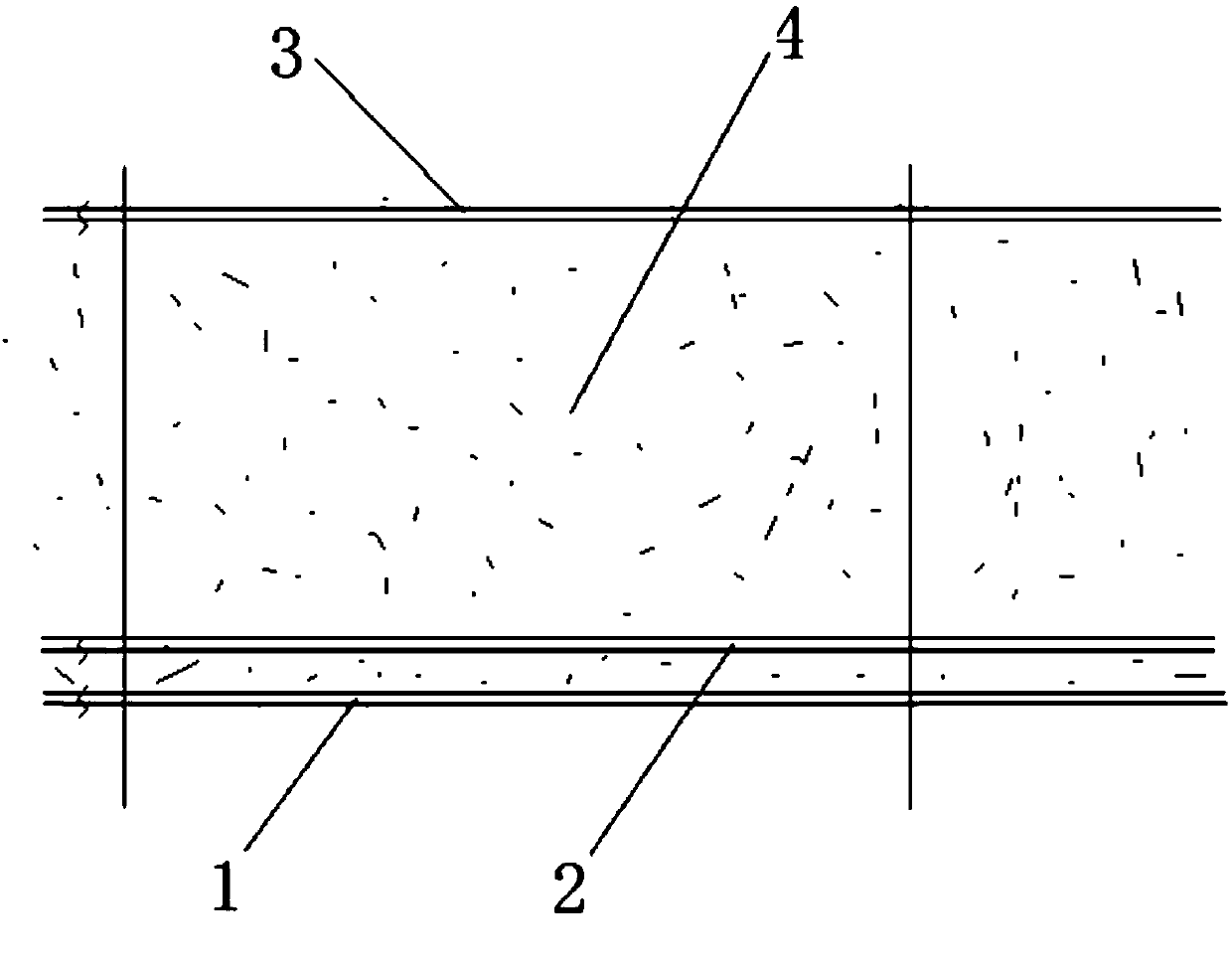

[0025] The first step is to divide the coal seam into several mining areas 4 within the horizontal range after excavating the transportation roadway 1, the track roadway 2 and the air return roadway 3 at a certain level of the coal mine according to the coal seam occurrence conditions, such as figure 1 shown;

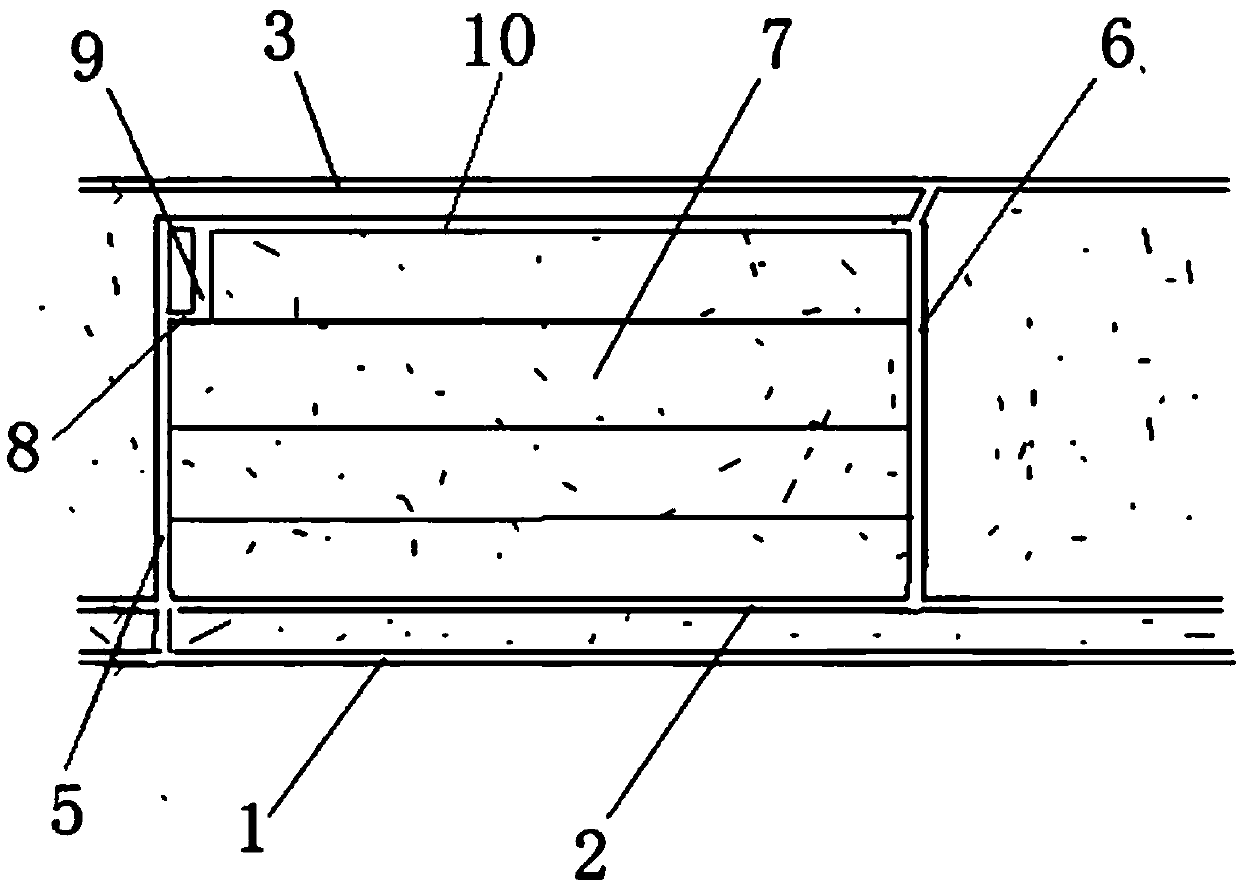

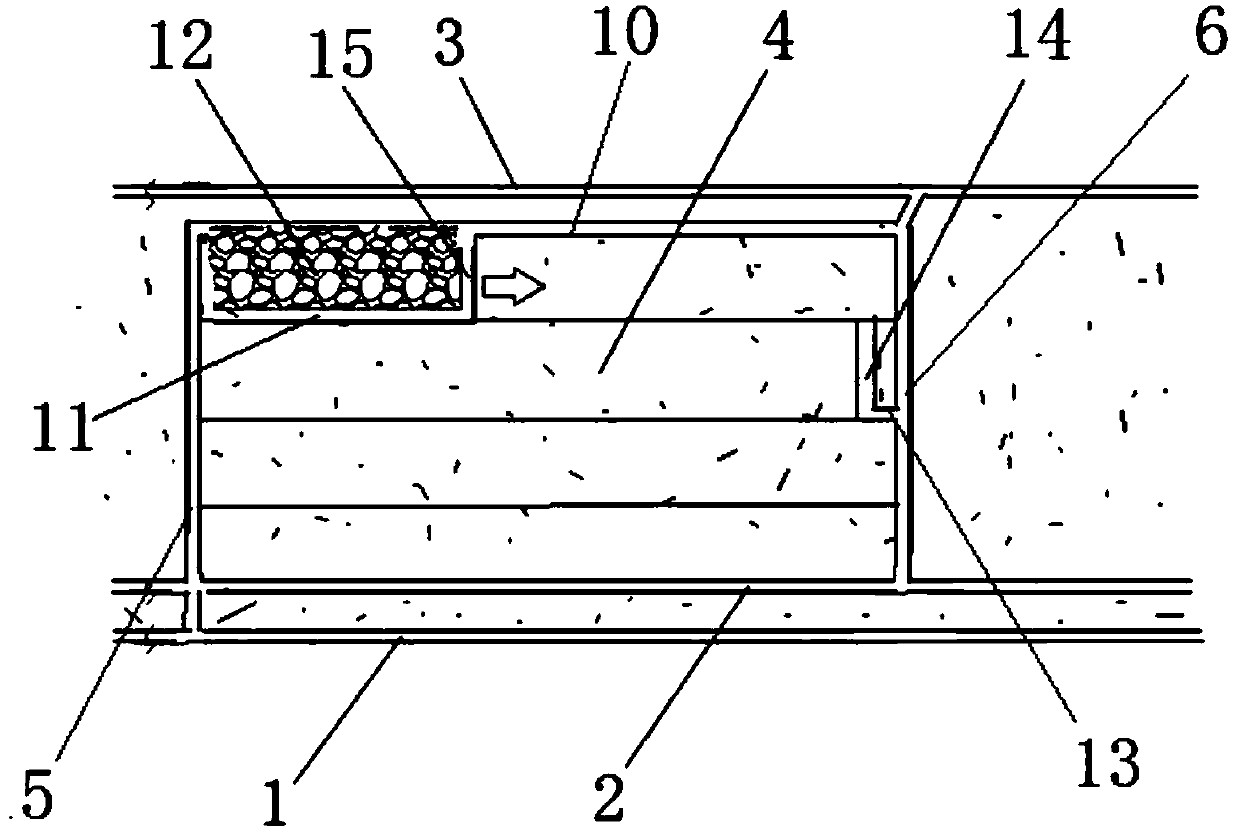

[0026] In the second step, for a certain mining area 4, open from the transportation roadway 1 to one side of the mining area 4, excavate a belt along the coal seam to transport up the mountain 5, and open from the track roadway 2 to the other side of the mining area 4, along the coal seam Incline to excavate a track to transport up the mountain 6, and then divi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com