Mine gallery driving cut blasting method

A technology for level entry and mines, which is applied in the field of excavation and blasting of mine entry and entry, which can solve the problems of affecting the efficiency of excavation, small space, and many charges in charging holes, and achieve the effect of saving explosives and production excavation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

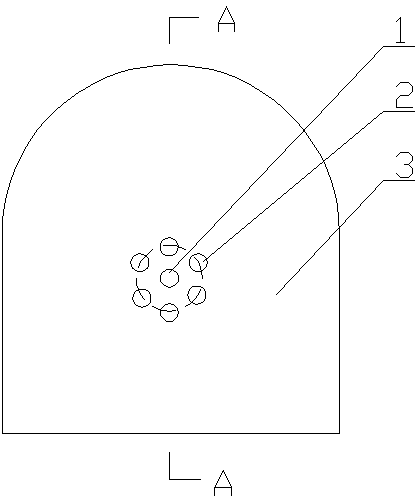

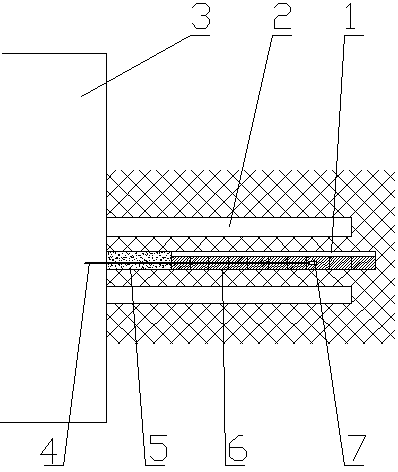

[0017] Example 1 figure 1 , 2 Shown: A method of cutting and blasting for tunnel excavation in mines, which includes drilling a cutting blast hole perpendicular to the work surface 3 in the center of the tunnel excavation work surface. Its characteristics are:

[0018] ① Drill a central blast hole 1 perpendicular to the working surface 3 in the center of the tunnel driving working surface 3, drill 6 evenly distributed perimeters on a circle with the central blast hole 1 of the working surface 3 as the center and a radius of 10 cm Hole 2

[0019] ② The depth of the central blasthole 3 is 30cm greater than the depth of the surrounding peripheral holes 2 and the depths of the surrounding peripheral holes 2 are equal. The central blasthole 1 and the surrounding peripheral holes 2 are parallel to each other;

[0020] ③ The center blast hole 1 is a charge hole, and the surrounding peripheral holes 2 are hollow holes;

[0021] ④ After the central blast hole 1 is filled with the explosive rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com