One-step heat treatment preparation process method for soft nanocrystalline magnetic powder core

A preparation process and magnetic powder core technology, which is applied in the field of preparation of soft magnetic nanocrystalline magnetic powder cores, can solve the problems of difficult control of product performance stability, low magnetic performance of nanocrystalline magnetic powder cores, and many steps in the preparation process, and achieve improved magnetic performance , high bonding strength, and the effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

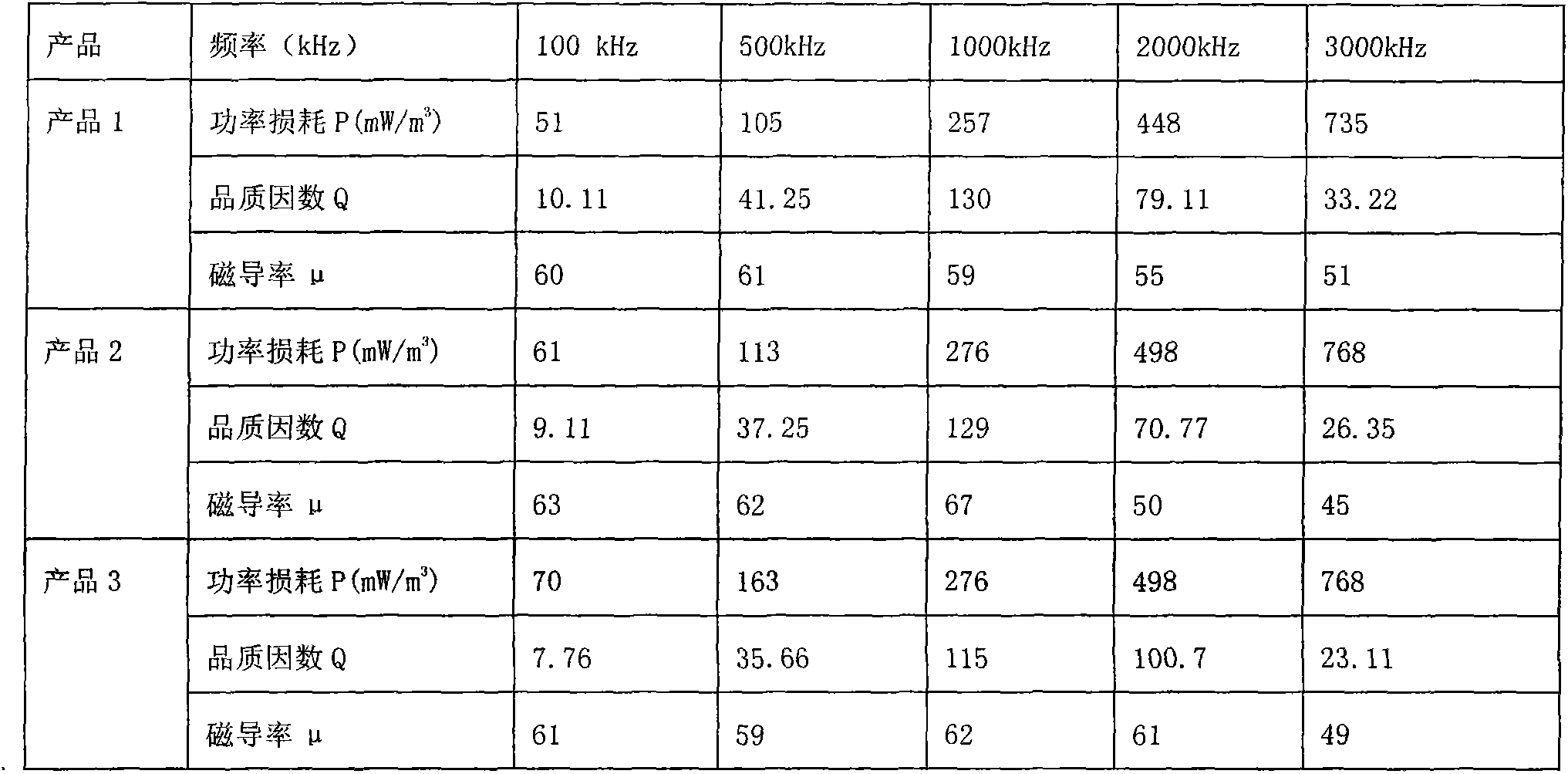

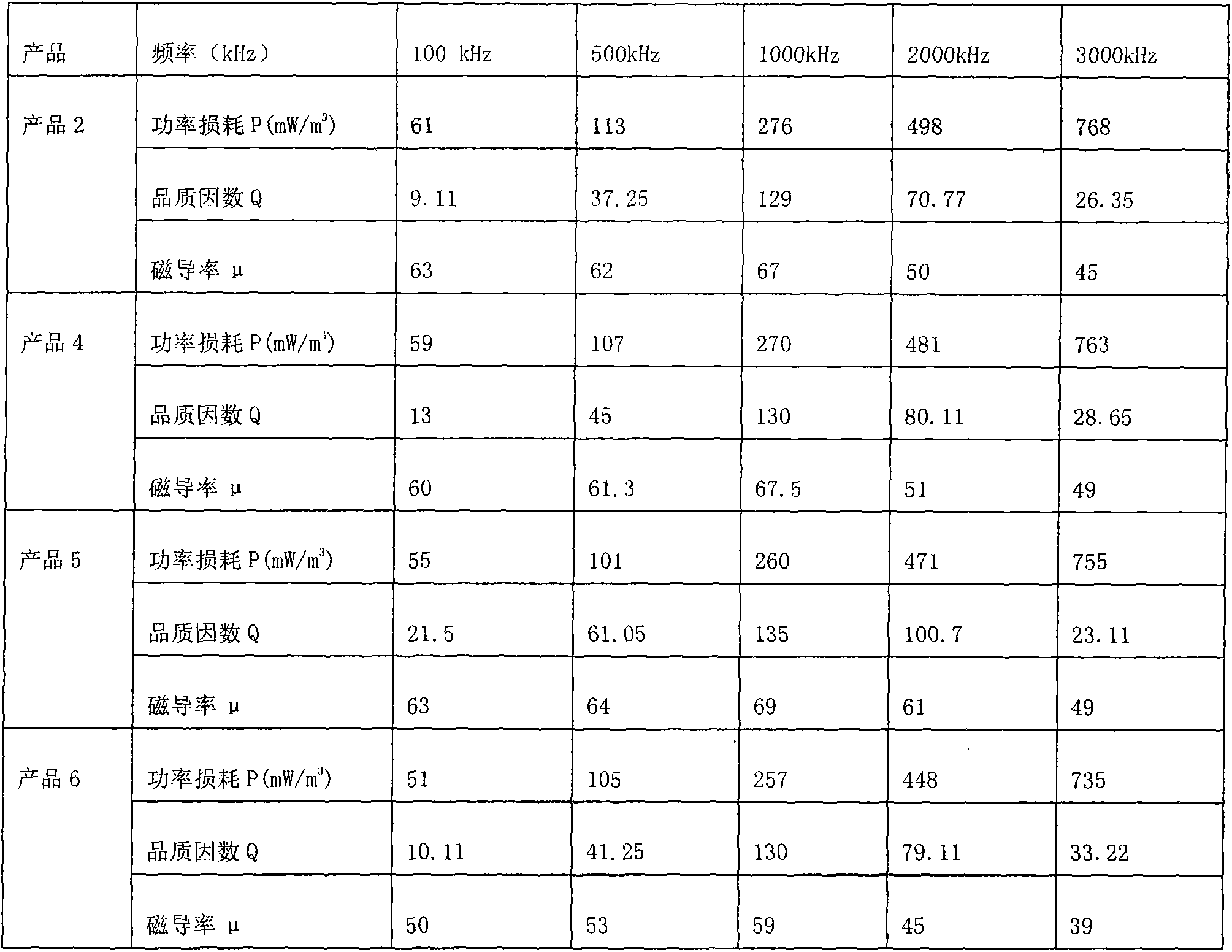

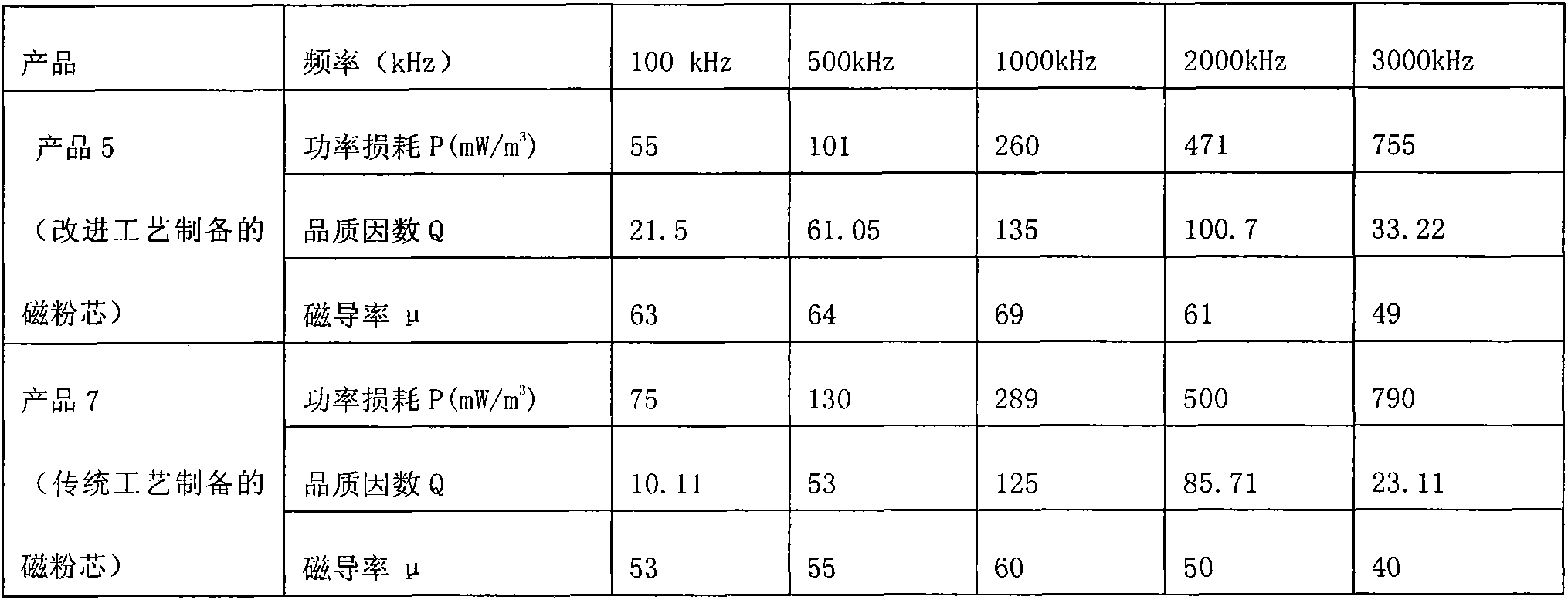

example 1

[0021] Example 1: Change the composition to Fe 73.5 Cu 1 Nb 3 Si 13.5 B 9 The fragmented amorphous strips were crushed by ball milling in a high-energy omnidirectional planetary ball mill with a ball-to-material ratio of 1:30, a rotating speed of the large plate at 240 rpm, and a ball milling time of 8 hours. The amorphous metal powder is sieved, and then mixed into a powder consisting of 10% of the first powder passing through -120~+200 mesh, 80% of the second powder passing through -200~+250 mesh and 10% of the third powder passing through -250 mesh particle distribution. Passivate the proportioned amorphous powder for 2 hours, and then dry the powder. Add 3wt% mica powder, 2.5wt% silicone resin, 1wt% zinc stearate, and 15wt% absolute ethanol to the passivated amorphous powder, heat and wet mix and stir to evenly volatilize. Evenly put the insulating coated amorphous powder into the mold, apply pressure to 1700MPa within 3 minutes, hold the pressure for 3 minutes, and ...

example 2

[0022] Example 2: Change the composition to Fe 73.5 Cu 1 Nb 3 Si 13.5 B 9 The fragmented amorphous strips were crushed by ball milling in a high-energy omnidirectional planetary ball mill with a ball-to-material ratio of 1:30, a rotating speed of the large plate at 240 rpm, and a ball milling time of 8 hours. The amorphous metal powder is sieved and then mixed into a powder consisting of 15% of the first powder passing through -120~+200 mesh, 70% of the second powder passing through -200~+250 mesh and 15% of the third powder passing through -250 mesh particle distribution. Passivate the proportioned amorphous powder for 2 hours, and then dry the powder. Add 3wt% mica powder, 2.5wt% silicone resin, 1wt% zinc stearate, and 15wt% absolute ethanol to the passivated amorphous powder, heat and wet mix and stir to evenly volatilize. Evenly put the insulating coated amorphous powder into the mold, apply pressure to 1700MPa within 3 minutes, hold the pressure for 3 minutes, and o...

example 3

[0023] Example 3: Change the composition to Fe 73.5 Cu 1 Nb 3 Si 13.5 B 9 The fragmented amorphous strips were crushed by ball milling in a high-energy omnidirectional planetary ball mill with a ball-to-material ratio of 1:30, a rotating speed of the large plate at 240 rpm, and a ball milling time of 8 hours. The amorphous metal powder is sieved, and then mixed into a powder consisting of 20% of the first powder passing through -120~+200 mesh, 60% of the second powder passing through -200~+250 mesh and 20% of the third powder passing through -250 mesh particle distribution. Passivate the proportioned amorphous powder for 2 hours, and then dry the powder. Add 3wt% mica powder, 2.5wt% silicone resin, 1wt% zinc stearate, and 15wt% absolute ethanol to the passivated amorphous powder, heat and wet mix and stir to evenly volatilize. Evenly put the insulating coated amorphous powder into the mold, apply pressure to 1700MPa within 3 minutes, hold the pressure for 3 minutes, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com