Automatic multi-crucible combined amorphous ribbon making machine

An amorphous belt making machine and combined technology, applied in the direction of manufacturing tools, casting molten material containers, metal processing equipment, etc., can solve the problems of low degree of automation control, unfavorable continuous and stable production, and inability to spray molten steel, etc., to achieve Improve product quality, promote large-scale production, and achieve good quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

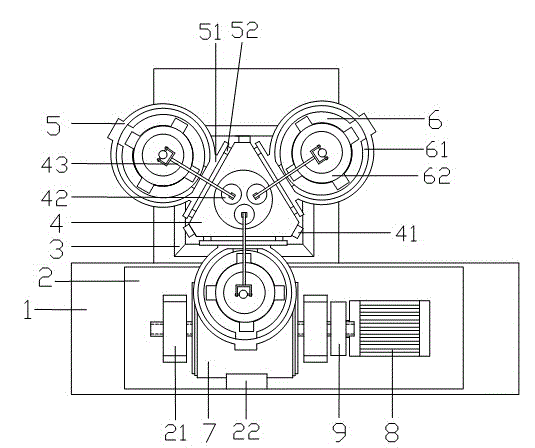

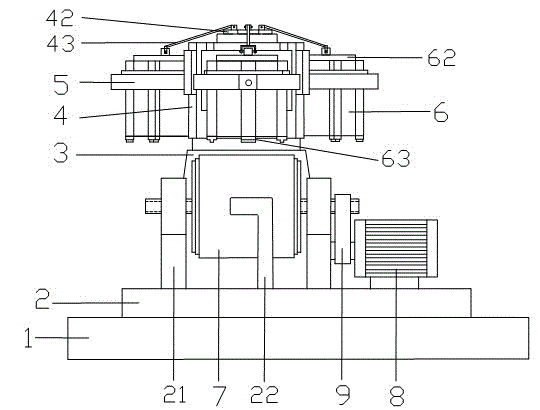

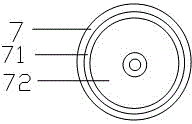

[0019] Such as figure 1 and figure 2 As shown, an automatic multi-crucible 6 combined amorphous tape making machine includes a frame 1, on which a base 2 capable of sliding left and right through a cylinder drive is provided, and a processing mechanism and a rotating shaft drive are provided on the base 2. Device and stripper 22, processing mechanism comprises support frame 21, rotating shaft, guide seat 72, moving seat 71 and cooling roller 7, support frame 21, rotating shaft, guide seat 72 and moving seat 71 are two, and rotating shaft is installed on support frame 21, the rotating shaft is hollow and one end is provided with a rotary joint (not shown in the figure), and the rotary joint (not shown in the figure) is used to connect with the water pipe and pass through the cooling water, such as image 3 As shown, the other end of the rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com