Preparation and application of palladium/copper oxide nano porous structure composite material loaded with titanium dioxide nanoparticles

A nanoparticle and nanoporous technology is applied in the field of preparation of oxide composite materials to achieve the effects of simple and easy operation, low implementation cost and easy control of operation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1, the preparation of a palladium / copper oxide nanoporous structure composite material loaded with titanium dioxide nanoparticles, mainly uses simple deposition method to load TiO on the Pd / CuO nanoporous structure 2 Nanoparticles to obtain uniform distribution of TiO on the surface and inside 2 Composite nanoporous structure of particles. Proceed as follows:

[0021] Step 1. Prepare Ti-Cu-Pd amorphous alloy strips according to the following components and atomic percentages: the content of Ti is 30%, the content of Cu is 60%, and the content of Pd is 10%. Put the strips into 5M Hydrochloric acid solution, at a temperature of 90 ° C, hydrothermal reaction was carried out in a reactor for 5 hours. After the reaction was completed, the Pd / CuO nanoporous structure to be composited was obtained by washing in deionized water and absolute ethanol respectively.

[0022] Step 2: Add 3mL of oleic acid, 0.1mL of tetrabutyl titanate and 3mL of oleylamine into a beaker...

Embodiment 2

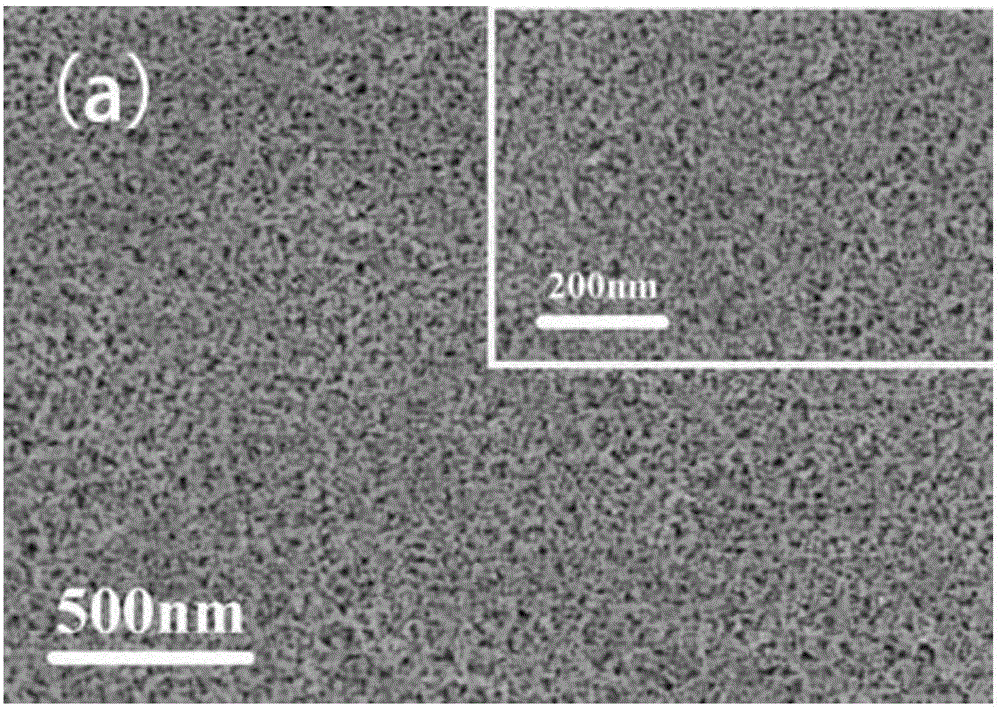

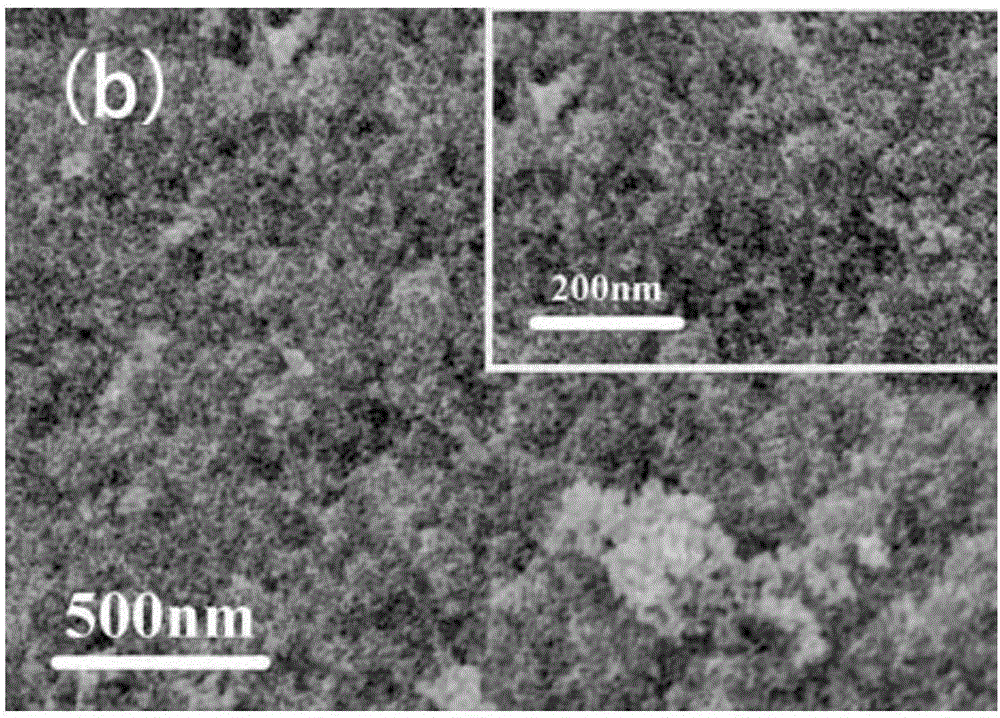

[0024] Embodiment 2: Preparation of a palladium / copper oxide nanoporous structure composite material loaded with titanium dioxide nanoparticles, the steps are basically the same as in Example 1, the only difference being that the titanium dioxide nanoparticles added in step 3 were changed from 80 μL to 160 μL, The final loaded TiO 2 The morphology of the Pd / CuO nanoporous structure of nanoparticles is shown in Figure 1(b), and Figure 2(a) and Figure 2(b) are TEM images of the structure obtained in Example 2.

Embodiment 3

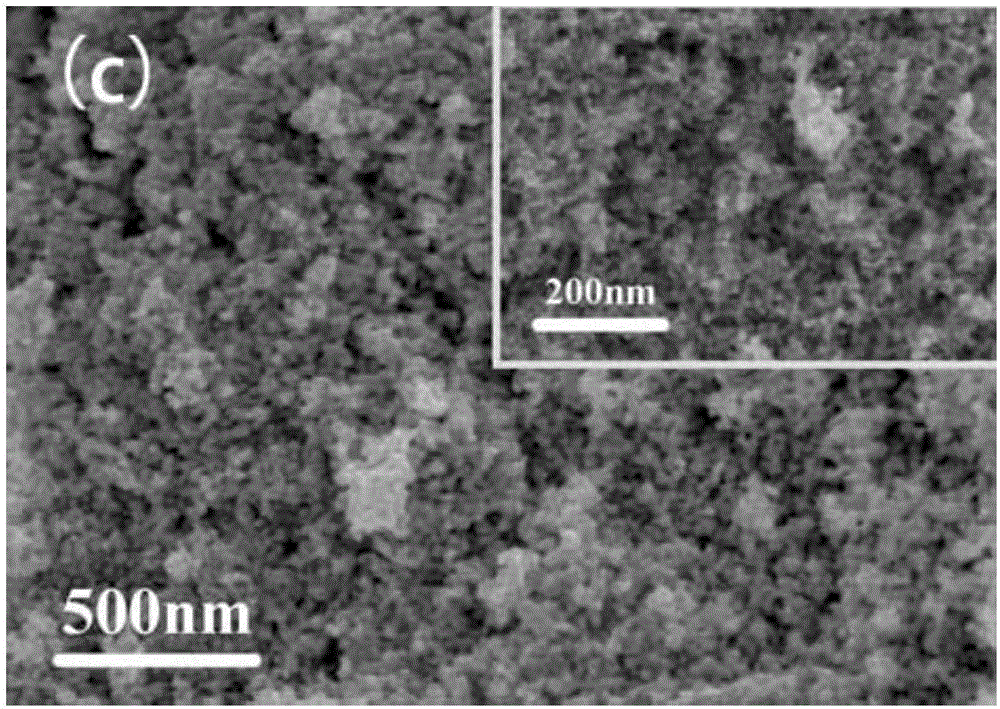

[0025] Embodiment 3: Preparation of a palladium / copper oxide nanoporous structure composite material loaded with titanium dioxide nanoparticles. The steps are basically the same as in Example 1, except that the titanium dioxide nanoparticles added in step 3 are changed from 80 μL to 240 μL. The final loaded TiO 2 The morphology of the Pd / CuO nanoporous structure of nanoparticles is shown in Fig. 1(c).

[0026] It can be concluded from the above examples that when prepared according to the process shown in the claims, the Pd / CuO nanoporous surface and TiO uniformly distributed inside can be obtained 2 Particle-based composite nanoporous materials.

[0027] Figure 1(a), Figure 1(b) and Figure 1(c) show that when there is a small amount of TiO 2 The sample still maintains its basic bicontinuous structure when the loading of nanoparticles is large. With TiO 2 Increased loading of nanoparticles, more nanosized TiO 2 The particles were loaded onto the surface and pore walls of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com