Block-shaped nanocrystalline magnetically soft alloy material and preparation method thereof

A nanocrystalline soft magnetic and alloy material technology, which is applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problems of alloy soft magnetic properties deterioration, high sintering temperature, and long sintering time, and achieve fine grain size and high Effects of operating temperature range, ease of miniaturization and integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

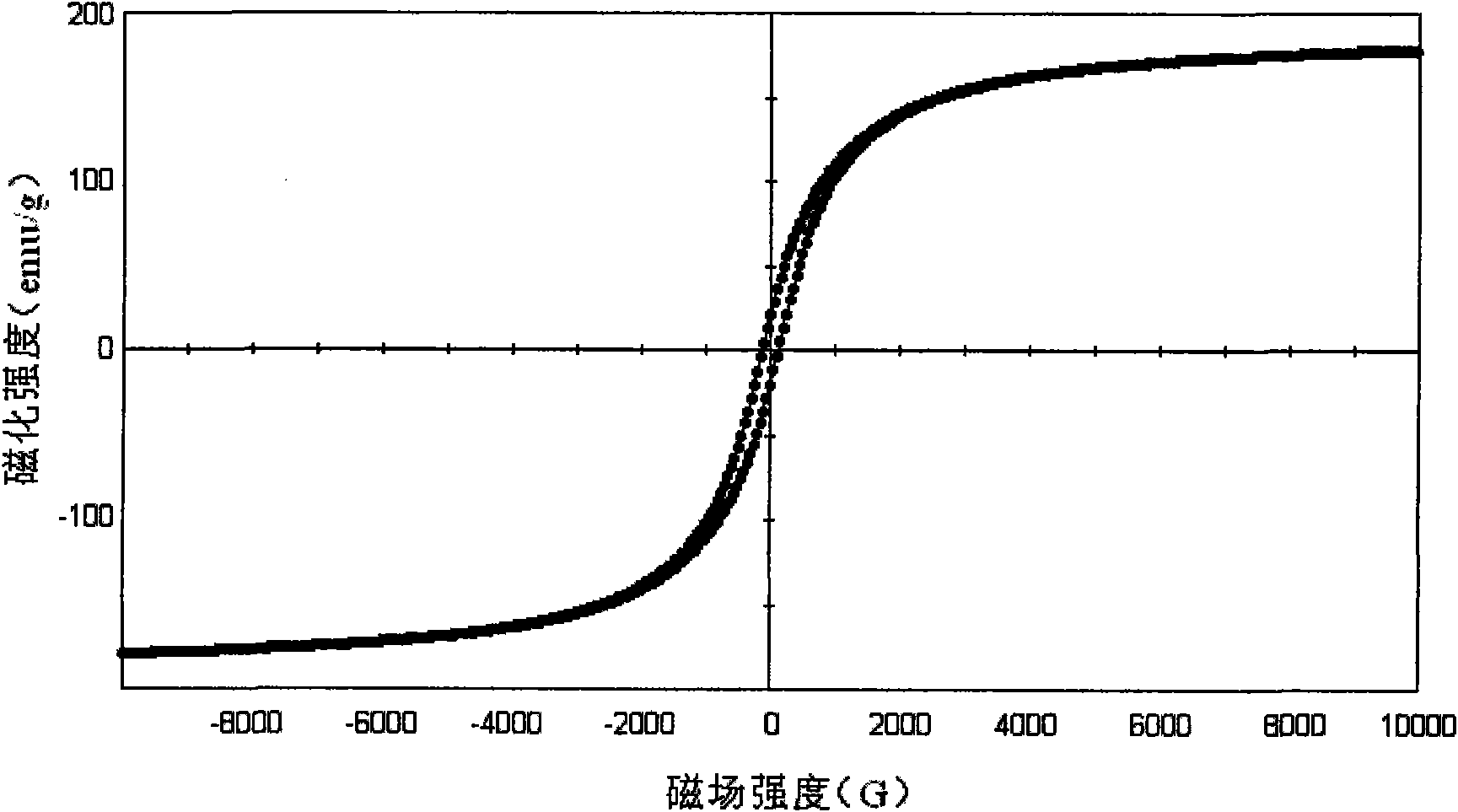

[0055] Select bulk Fe, Co, Cu and powdered Nb, B elements with a purity greater than 99.5%, and distribute Fe according to the atomic percentage of each element in the alloy composition 42.5 co 42.5 Nb 6 Cu 1 B8 Ingredients and mixtures are smelted in an electric arc furnace at a melting temperature of 1100°C. The smelted samples are cut into small pieces and made into amorphous thin strips using a single-roller stripping device. Keep warm at ℃ for 2 hours, then pulverize into 100μm powder, shape and sinter in SPS sintering device, sintering temperature 720℃, holding time 10 minutes, keep pressure 60MPa, and finally get a bulk nanocrystalline soft magnetic with a size of φ10×5mm The alloy material has a saturation magnetization Ms of 1.75T, a Curie temperature Tc of 560°C and a coercive force of 1177.8A / m. The hysteresis loop diagram of the soft magnetic bulk alloy prepared in this embodiment can be found in figure 1 .

Embodiment 2

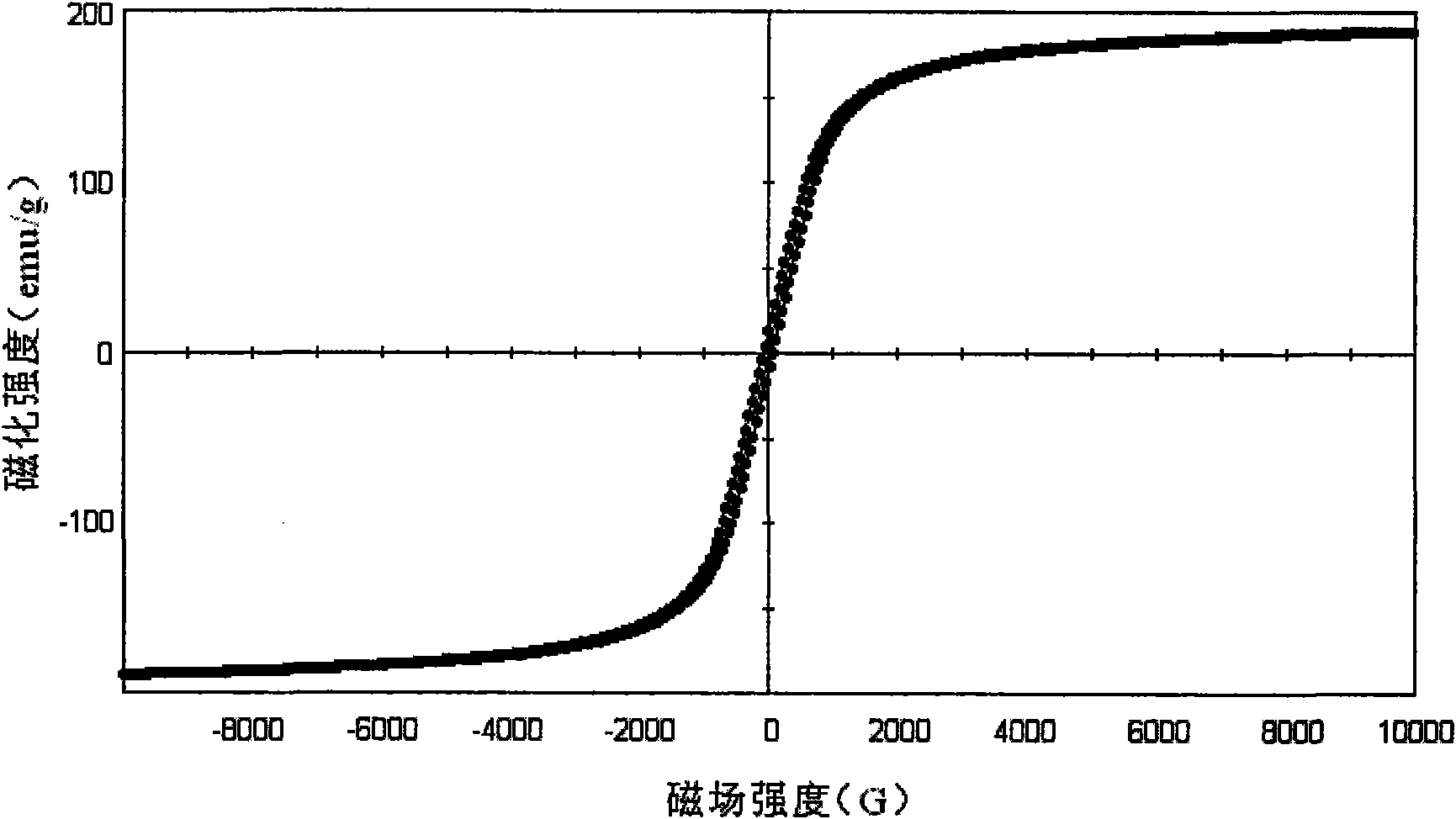

[0057] Select bulk Fe, Co, Cu, Sm and powdered Nb, B elements with a purity greater than 99.5%, according to the atomic percentage distribution of each element in the alloy composition Fe 42.5 co 42.5 Nb 4.5 Cu 1 B 8 SM 1.5 Ingredients and mixtures are smelted in an electric arc furnace at a melting temperature of 1100°C. The smelted samples are cut into small pieces and made into amorphous thin strips using a single-roller stripping device. Keep warm at ℃ for 1 hour, then pulverize into 50μm powder, shape and sinter in SPS sintering device, sintering temperature 800℃, holding time 5 minutes, keep pressure 60MPa, and finally get a bulk nanocrystalline soft magnetic with a size of φ10×5mm The alloy material has a saturation magnetization Ms of 1.85T, a Curie temperature Tc of 645°C and a coercive force of 715.4A / m. The hysteresis loop diagram of the soft magnetic bulk alloy prepared in this embodiment can be found in figure 2 .

Embodiment 3

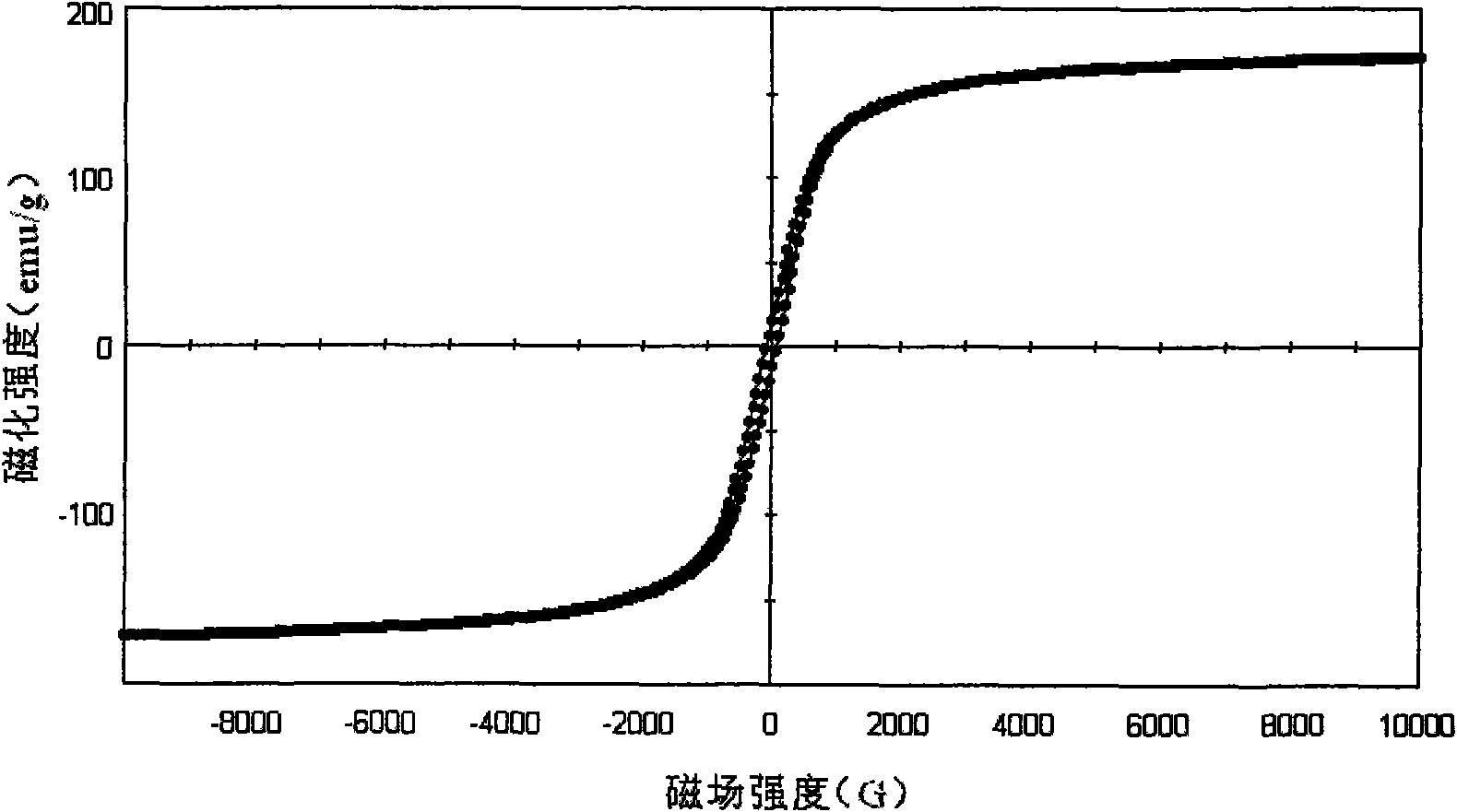

[0059] Select bulk Fe, Co, Cu, Sm and powdered Nb, B elements with a purity greater than 99.5%, according to the atomic percentage distribution of each element in the alloy composition Fe 42.5 co 42.5 Nb 3 Cu 1 B 8 SM 3 Ingredients and mixtures are smelted in an electric arc furnace at a melting temperature of 1100°C. The smelted samples are cut into small pieces and made into amorphous thin strips using a single-roller stripping device. Keep warm at ℃ for 2 hours, then pulverize into 100μm powder, shape and sinter in SPS sintering device, sintering temperature 800℃, holding time 8 minutes, keep pressure 65MPa, and finally get a bulk nanocrystalline soft magnetic with a size of φ10×5mm The alloy material has a saturation magnetization Ms of 1.68T, a Curie temperature Tc of 660°C and a coercive force of 791.8A / m. The hysteresis loop diagram of the soft magnetic bulk alloy prepared in this embodiment can be found in image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com