Method for preparing TiO2 coating on surface of iron-based amorphous ribbon through sol-gel method

A sol-gel method, iron-based amorphous technology, applied in metal material coating process, coating, solid-state chemical plating, etc., can solve the problems of low high-frequency characteristics, influence on appearance and performance, and low free surface activity. , to achieve uniform particle size distribution, strong UV resistance, and excellent transparency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

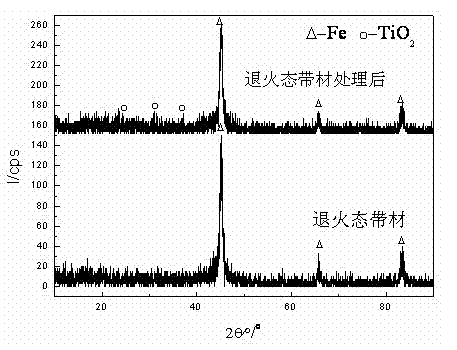

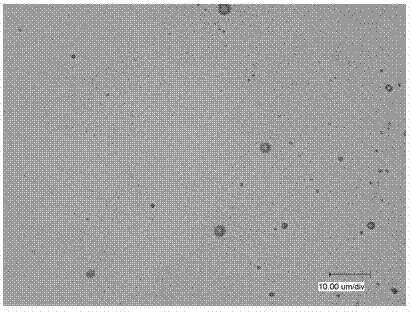

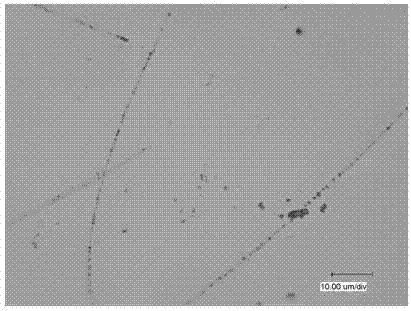

[0012] Fe 73.5 Cu 1 Nb 3 Si 13.5 B 9 Iron-based amorphous and nanocrystalline strips 0.5~5mm wide, 20~30 mu m thick, after being degreased by a degreasing solution at 80-90°C, it is pulled in a sol at 80°C for 5 times, dried in an oven at 55°C, and then annealed at 300°C for 60 minutes. A layer of transparent film mainly composed of titanium dioxide is obtained on the surface of the strip.

Embodiment 2

[0014] Fe 73.5 Cu 1 Nb 3 Si 13.5 B 9 Iron-based amorphous nanocrystalline strip 5~10mm wide, 20~30 mu m thick, after being degreased by a degreasing solution at 80-90°C, it is pulled in a sol at 80°C for 5 times, dried in an oven at 55°C, and then annealed at 300°C for 60 minutes. A layer of transparent film mainly composed of titanium dioxide is obtained on the surface of the strip.

Embodiment 3

[0016] Fe 73.5 Cu 1 Nb 3 Si 13.5 B 9 Iron-based amorphous and nanocrystalline strips 10~50mm wide, 20~30mm mu m thick, after being degreased by a degreasing solution at 80-90°C, it is pulled in a sol at 80°C for 5 times, dried in an oven at 55°C, and then annealed at 300°C for 60 minutes. A layer of transparent film mainly composed of titanium dioxide is obtained on the surface of the strip.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com