Heat conducting oil circular cooling system for amorphous magnetic materials

A circulating cooling system and magnetic material technology, applied in the field of non-gold alloy magnetic strip processing equipment, can solve the problems of limited cooling efficiency and difficulty in further improving the production efficiency of amorphous alloy magnetic strip, so as to improve cooling efficiency and ensure high speed Effect of recycling and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

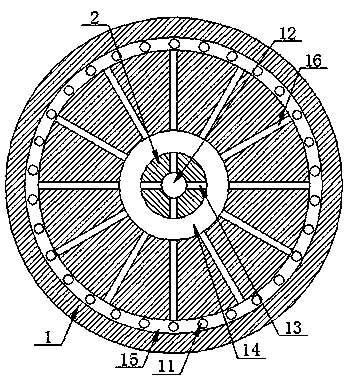

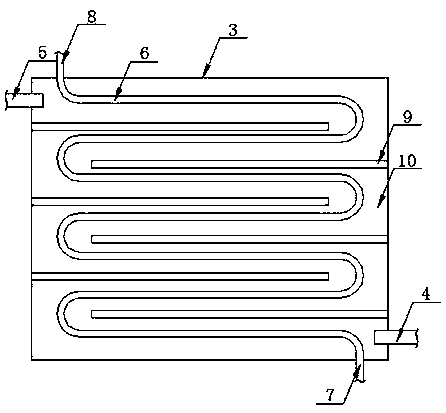

[0016] refer to Figure 1 to Figure 2 , Figure 1 to Figure 2 It is a structural schematic diagram of a specific embodiment of the present invention.

[0017] Such as Figure 1 to Figure 2 As shown, a heat transfer oil circulating cooling system for amorphous magnetic materials includes a heat transfer oil cooling roller 1, a cooling roller shaft 2 and a heat transfer oil cooling box 3, and the two ends of the shaft center of the cooling roller shaft 2 are coaxially connected to the heat transfer oil An input pipe 4 and a heat transfer oil output pipe 5, the heat transfer oil cooling roller 1 is provided with a heat conduction oil cooling channel communicating with the heat transfer oil input pipe 4 and the heat transfer oil output pipe 5, the heat transfer oil input pipe 4 and the heat transfer oil output pipe 5 The heat transfer oil output pipes 5 are all connected to the heat transfer oil cooling box 3, and the heat transfer oil cooling box 3 is also provided with a liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com