A kind of room temperature transparent ferromagnetic semiconductor material and its preparation method

A semiconductor and transparent technology, applied in the direction of material selection, inorganic material magnetism, and manufacturing/processing of electromagnetic devices, etc., can solve the problems of electronic spin devices, elevation, etc., and achieve excellent magnetic soft magnetic properties and preparation technology Simple, Environmentally Friendly Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Preparation of room temperature transparent ferromagnetic semiconductor Co by powder target 20.3 (B 0.62 Fe 0.26 Ta 0.12 ) 40.7 o 39.0 Material. The specific operation steps are as follows: select Co, Fe, Ta and B raw materials with a powder particle size of less than 100 microns; fully mix the weighed powder materials; prepare Al target materials by wire cutting according to the target size of the magnetron sputtering equipment container; put the fully mixed powder raw material into the target container, and flatten the surface to be used for magnetron sputtering coating; the magnetron sputtering equipment is pre-vacuumized to ~10 -4 Pa, into the high-purity inert gas Ar, the working pressure is 0.5-10Pa.

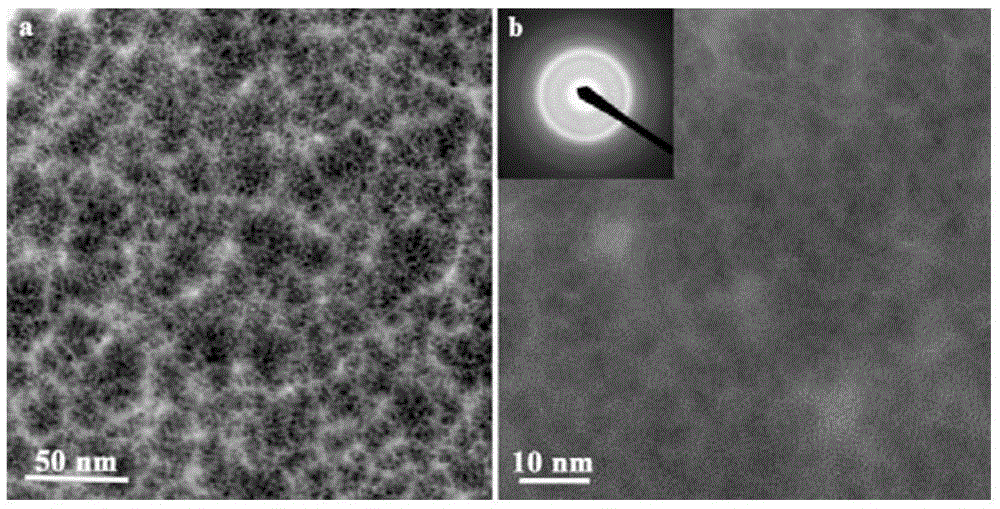

[0031] The as-prepared room temperature transparent ferromagnetic semiconductor Co 20.3 (B 0.62 Fe 0.26 Ta 0.12 ) 40.7 o 39.0 Materials are structurally characterized by TEM and STEM, such as figure 1 The film structure shown is an amorphous structure; ...

Embodiment 2

[0033]Fabrication of room temperature transparent ferromagnetic semiconductor Co using oxide targets 31.9 (B 0.47 Fe 0.36 Ta 0.17 ) 40.2 o 27.9 Material. The specific operation steps are as follows: the oxide target is prepared by powder sintering method; the magnetron sputtering equipment is pre-vacuumized to ~10 -4 Pa, into the high-purity inert gas Ar, the working pressure is 0.5-10Pa.

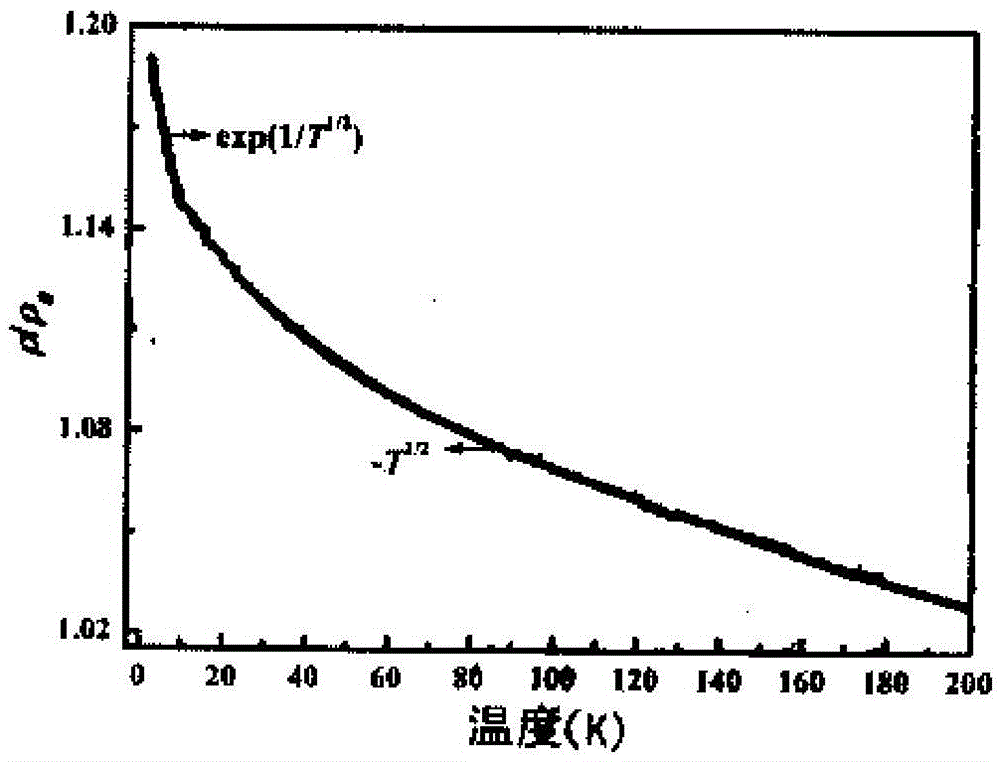

[0034] The as-prepared room temperature transparent ferromagnetic semiconductor Co 31.9 (B 0.47 Fe 0.36 Ta 0.17 ) 40.2 o 27.9 The material is characterized by TEM and STEM; electrical measurement: the instrument used is QuantumDesign's PPMS-9, such as image 3 As shown, the resistivity versus temperature curve presents the negative temperature-dependent characteristics of the resistivity of typical semiconductor materials, the low-temperature region (below 10K) presents an electron hopping conduction mechanism, and the relatively high-temperature region (above 10K) presents a co...

Embodiment 3

[0036] Fabrication of room temperature transparent ferromagnetic semiconductor Co by using metal alloy targets 32.4 (B 0.66 Fe 0.44 Ta 0.09 ) 35.2 o 32.4 Material. The specific operation steps are as follows: the raw materials are bulk Co, Fe, Ta and B, and the raw materials are mixed and the target is prepared by melting and casting; the magnetron sputtering equipment is pre-evacuated to ~10 -4 Pa, high-purity inert gas Ar and oxygen are introduced, the partial pressure ratio of the two is 9:1, and the working pressure is 0.5-10Pa.

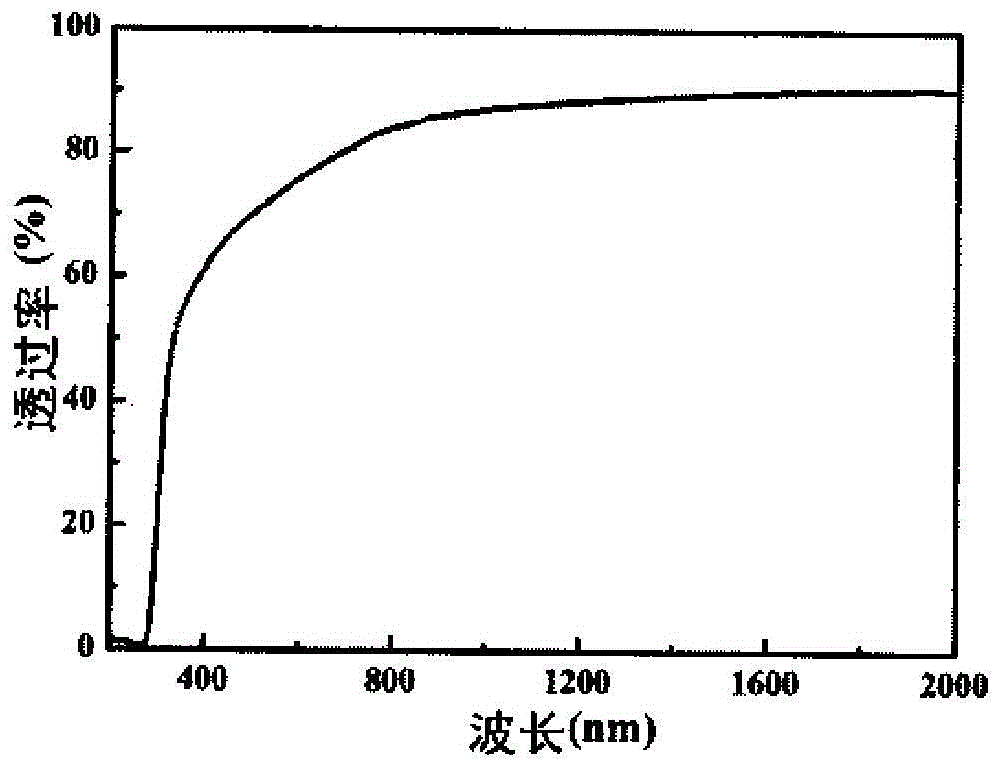

[0037] The as-prepared room temperature transparent ferromagnetic semiconductor Co 32.4 (B 0.66 Fe 0.44 Ta 0.09 ) 35.2 o 32.4 The structure of the material is characterized by TEM and STEM; electrical measurement: the instrument used is PPMS-9 from QuantumDesign Company, such as Figure 8 Typical anomalous Hall effect occurring in ferromagnetic materials shown, Figure 9 The abnormal magnetoresistance phenomenon shown; the transmitta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical band gap | aaaaa | aaaaa |

| saturation magnetization | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com