Room-temperature transparent ferromagnetic semiconductor material and preparation method thereof

A semiconductor and transparent technology, which is applied in the selection of materials, the magnetism of inorganic materials, the manufacture/processing of electromagnetic devices, etc., can solve the problems of high rise and cannot meet the requirements of electronic spin devices, and achieves simple preparation process and excellent magnetic softness. Magnetic properties, environmentally friendly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Preparation of room temperature transparent ferromagnetic semiconductor Co by powder target 20.3 (B 0.62 Fe 0.26 Ta 0.12 ) 40.7 o 39.0 Material. The specific operation steps are as follows: select Co, Fe, Ta and B raw materials with a powder particle size of less than 100 microns; fully mix the weighed powder materials; prepare Al target materials by wire cutting according to the target size of the magnetron sputtering equipment container; put the fully mixed powder raw material into the target container, and flatten the surface to be used for magnetron sputtering coating; the magnetron sputtering equipment is pre-vacuumized to ~10 -4 Pa, into the high-purity inert gas Ar, the working pressure is 0.5-10Pa.

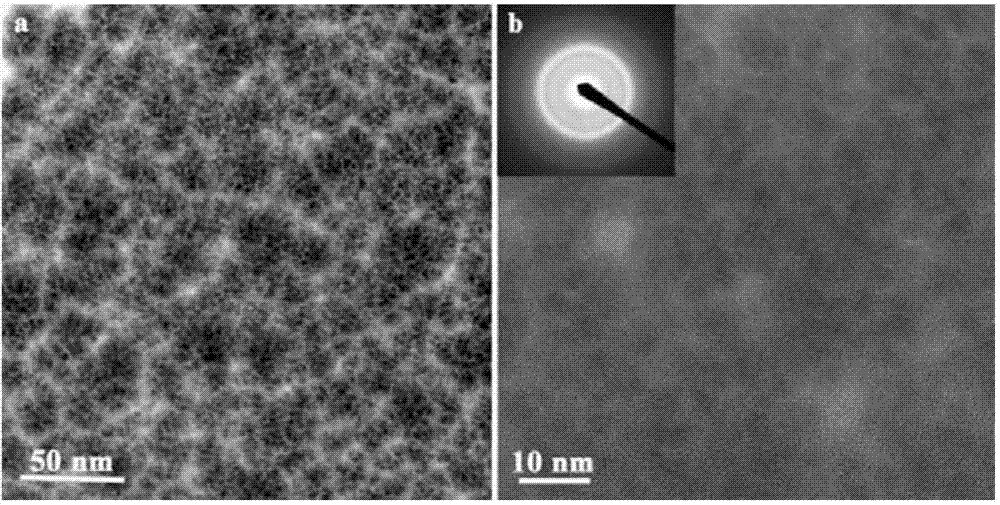

[0031] The as-prepared room temperature transparent ferromagnetic semiconductor Co 20.3 (B 0.62 Fe 0.26 Ta 0.12 ) 40.7 o 39.0 Materials are structurally characterized by TEM and STEM, such as figure 1 The film structure shown is an amorphous structure; ...

Embodiment 2

[0033]Fabrication of room temperature transparent ferromagnetic semiconductor Co using oxide targets 31.9 (B 0.47 Fe 0.36 Ta 0.17 ) 40.2 o 27.9 Material. The specific operation steps are as follows: the oxide target is prepared by powder sintering method; the magnetron sputtering equipment is pre-vacuumized to ~10 -4 Pa, into the high-purity inert gas Ar, the working pressure is 0.5-10Pa.

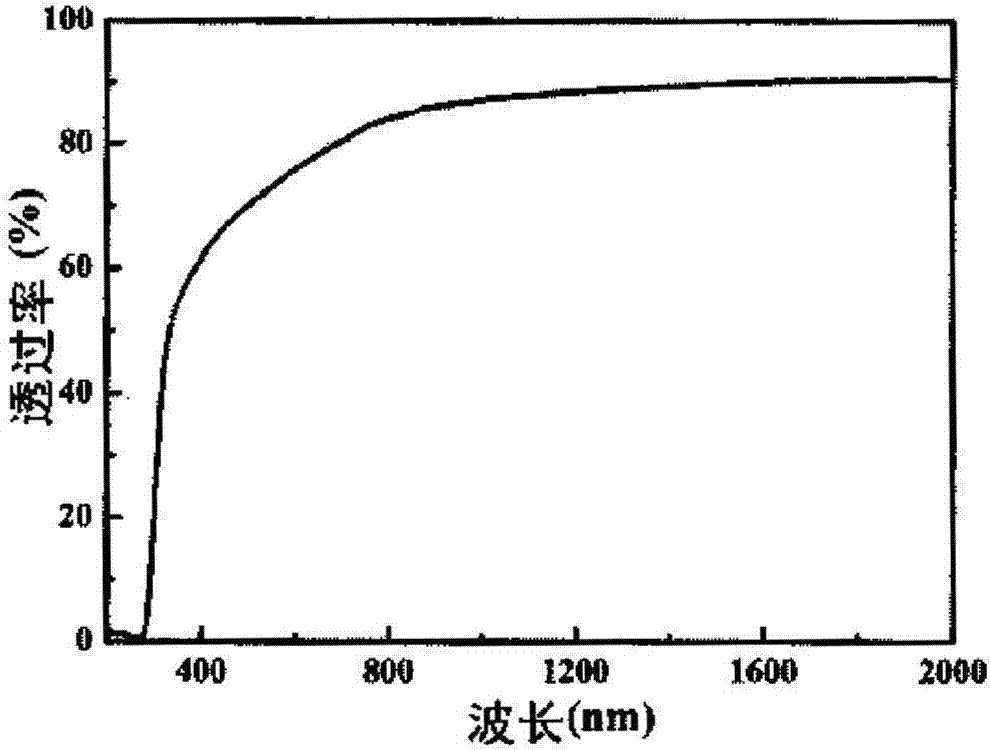

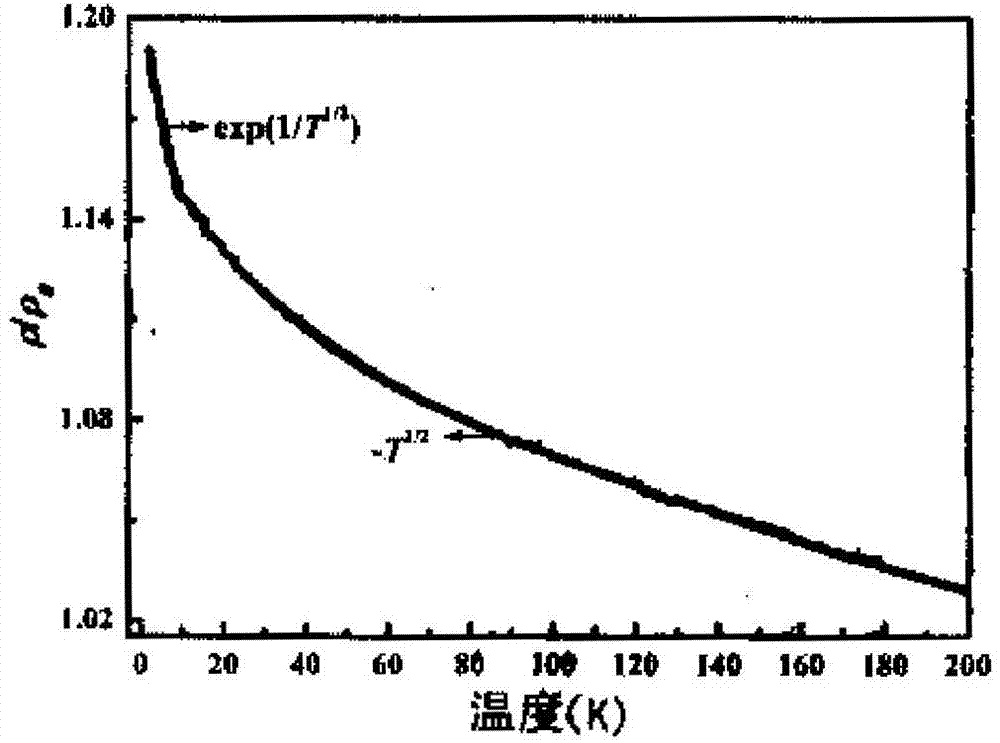

[0034] The as-prepared room temperature transparent ferromagnetic semiconductor Co 31.9 (B 0.47 Fe 0.36 Ta 0.17 ) 40.2 o 27.9 The structure of the material is characterized by TEM and STEM; electrical measurement: the instrument used is PPMS-9 from Quantum Design Company, such as image 3 As shown, the resistivity versus temperature curve presents the negative temperature-dependent characteristics of the resistivity of typical semiconductor materials, the low-temperature region (below 10K) presents an electron hopping conduction mechanism, and the relatively high-temperature reg...

Embodiment 3

[0036] Fabrication of room temperature transparent ferromagnetic semiconductor Co by using metal alloy targets 32.4 (B 0.66 Fe 0.44 Ta 0.09 ) 35.2 o 32.4 Material. The specific operation steps are as follows: the raw materials are bulk Co, Fe, Ta and B, and the target is prepared by melting and casting after mixing the raw materials; the magnetron sputtering equipment is pre-evacuated to ~10 -4 Pa, high-purity inert gas Ar and oxygen are introduced, the partial pressure ratio of the two is 9:1, and the working pressure is 0.5-10Pa.

[0037] The as-prepared room temperature transparent ferromagnetic semiconductor Co 32.4 (B 0.66 Fe 0.44 Ta 0.09 ) 35.2 o 32.4 The structure of the material is characterized by TEM and STEM; electrical measurement: the instrument used is PPMS-9 from Quantum Design Company, such as Figure 8 Typical anomalous Hall effect occurring in ferromagnetic materials shown, Figure 9 The abnormal magnetoresistance phenomenon shown; the transmitta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical band gap | aaaaa | aaaaa |

| saturation magnetization | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com