Photochromic-based optical storage material and preparation method thereof

An optical storage material and photochromic technology, applied in the field of optical storage materials, can solve the problems of limited types of ferroelectric materials, limited color changes, and restrictions on the application of ferroelectric materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

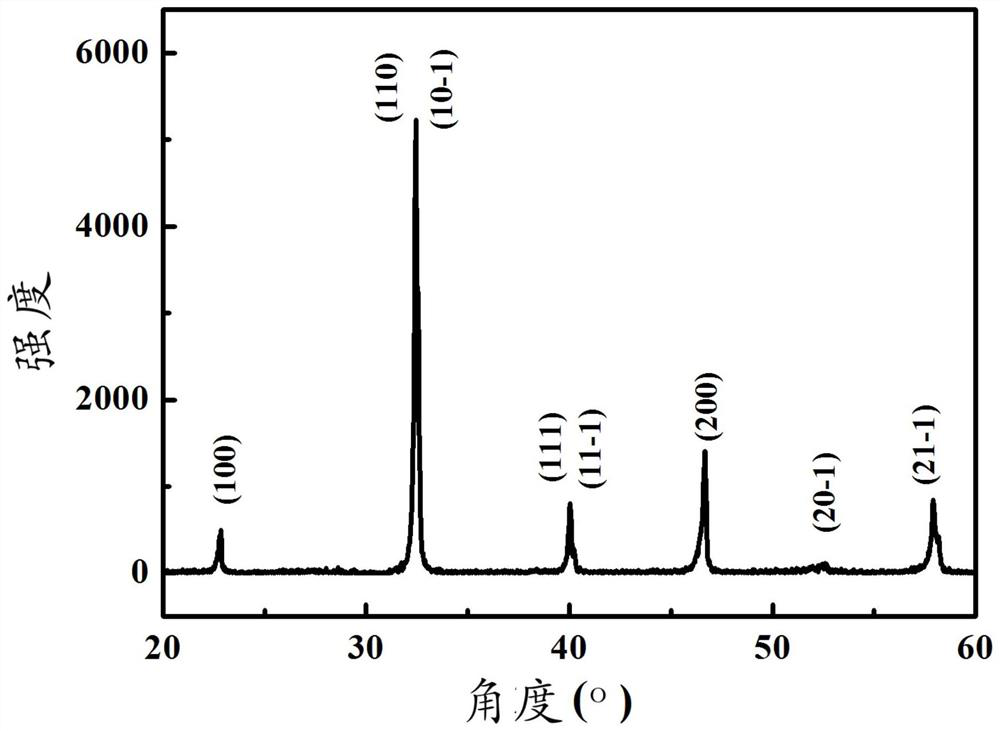

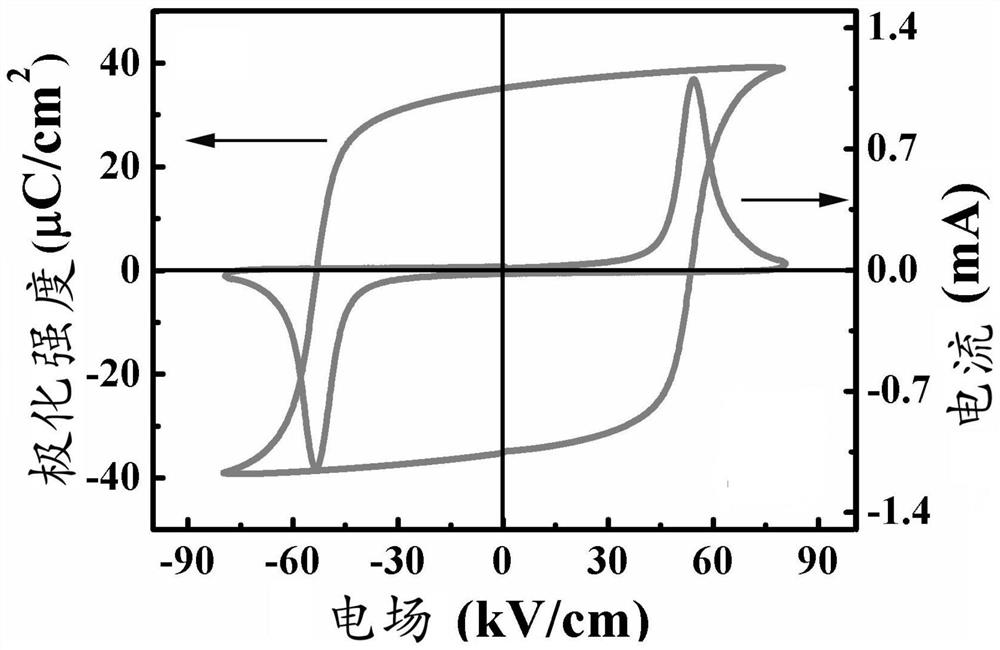

[0035] Using Bi with a purity of 99.5% 2 o 3 , 99.8% Na 2 CO 3 , 99.0% TiO 2 , 99.5% of K 2 CO 3 , 99.5% Nb 2 o 5 , 99.9% Er 2 o 3 As raw material, according to 0.98Na 0.5 Bi 0.5 TiO 3 -0.02Na 0.5 K 0.5 NbO 3: 0.002Er metering ratio and weighing, put it into a ball mill tank and mix ball milling, ball milling conditions: the volume ratio of raw materials, agate ball volume, and ball milling medium anhydrous ethanol is equal to 1:1:1.5, ball mill it for 12 hours, after ball milling The raw materials were put into an oven and baked at 80° C. for 4 hours. Afterwards, use a tablet machine to press the dried raw materials into raw material green embryos with a diameter of 40 mm, and then put the pressed green embryos into a KBF1400 box furnace for pre-calcination. The pre-calcination condition is 800 ° C for 2 hours. , and then crush the pre-fired block sample, grind it into a powder, sieve it, ball mill it for 8 hours, and put it into an oven at 80° C. for 4 hours ...

Embodiment 2

[0039] It is basically the same as Example 1, the difference is that this example is based on 0.88Na 0.5 Bi 0.5 TiO 3 -0.12Na 0.5 K 0.5 NbO 3 : 0.002Er metering ratio weighing, made 0.88Na 0.5 Bi 0.5 TiO 3 -0.12Na 0.5 K 0.5 NbO 3 :0.002Er ceramics, the ceramics have a pure perovskite structure.

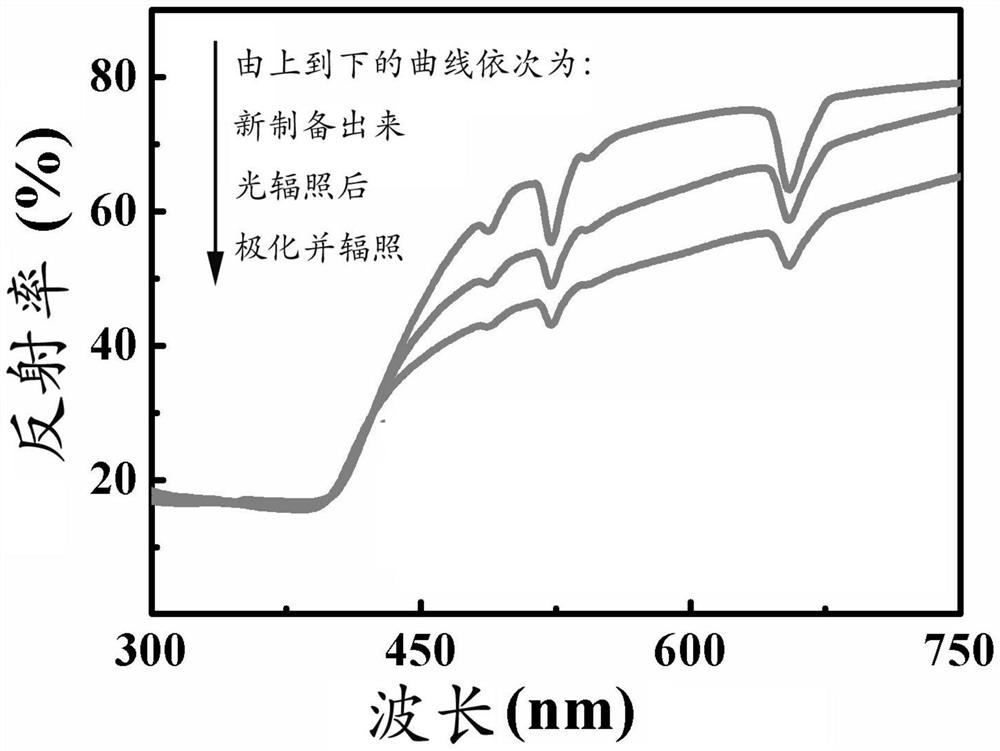

[0040] Similarly, the 0.88Na prepared in this embodiment 0.5 Bi 0.5 TiO 3 -0.12Na 0.5 K 0.5 NbO 3 :0.002Er ceramics for relevant tests, test results please refer to Figure 5-7 . Figure 5 Show 0.88Na 0.5 Bi 0.5 TiO 3 -0.12Na 0.5 K 0.5 NbO 3 : The remnant polarization of 0.002Er material is about 16μC / cm 2 , weaker ferroelectricity; Figure 6 It shows that the reflection coefficient of the ceramics after irradiation is significantly reduced, and the reflection coefficient of the ceramics after polarization and irradiation is not further reduced like that of the ceramics in Example 1, which is mainly due to the 0.88Na 0.5 Bi 0.5 TiO 3 -0.12Na 0.5 K 0.5 NbO...

Embodiment 3

[0043] Using Bi with a purity of 99.5% 2 o 3 , 99.8% Na 2 CO 3 , 99.0% TiO 2 , 99.5% of K 2 CO 3 , 99.5% Nb 2 o 5 , 99.9% Er 2 o 3 As raw material, according to 0.92Na 0.5 Bi 0.5 TiO 3 -0.08Na 0.5 K 0.5 NbO 3 : 0.002Er metering ratio and weighing, put it into a ball mill tank and mix ball milling, ball milling conditions: the volume ratio of raw material, agate ball volume, and ball milling medium anhydrous ethanol is equal to 1:1.2:1, mill it for 2 hours, after ball milling The raw materials were put into an oven and baked at 80° C. for 4 hours. Afterwards, use a tablet machine to press the dried raw materials into raw material green embryos with a diameter of 40 mm, and then put the pressed green embryos into a KBF1400 box furnace for pre-calcination. The pre-calcination condition is 750 ° C for 3 hours. , and then crush the pre-fired block sample, grind it into a powder, sieve it, ball mill it for 5 hours, and put it into an oven at 80°C for 4 hours to dry t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| remanent polarization | aaaaa | aaaaa |

| remanent polarization | aaaaa | aaaaa |

| remanent polarization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com