Method for measuring pressure of hydrodynamic force contact area by using quantum dots

A technology of fluid power and quantum dots, applied in the direction of fluid pressure measurement using optical methods, can solve problems such as engineering application limitations, low signal-to-noise ratio, and easy damage, and achieve high versatility, high practicability, and stability good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0024] The method for measuring the pressure of a hydrodynamic contact zone by using quantum dots comprises the following steps:

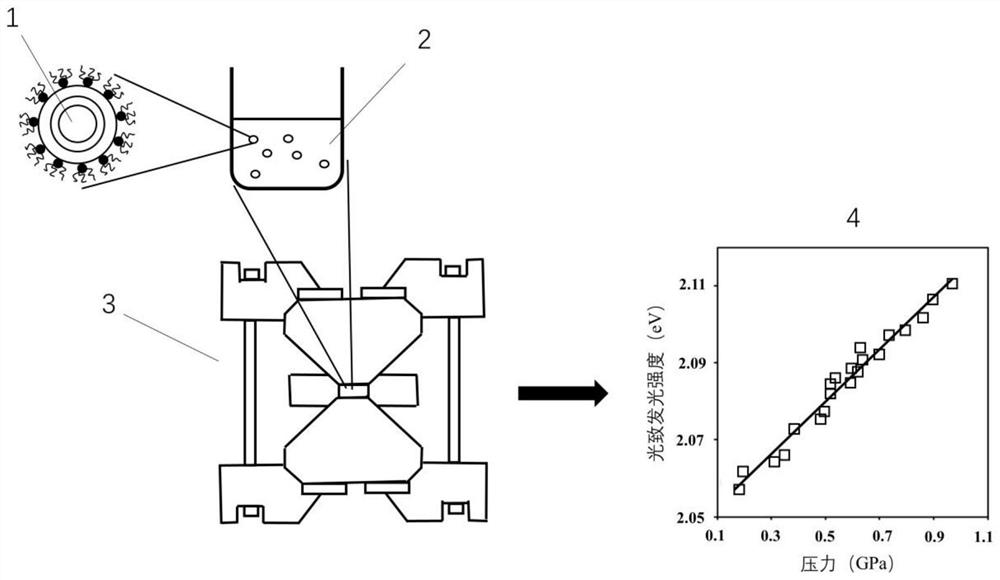

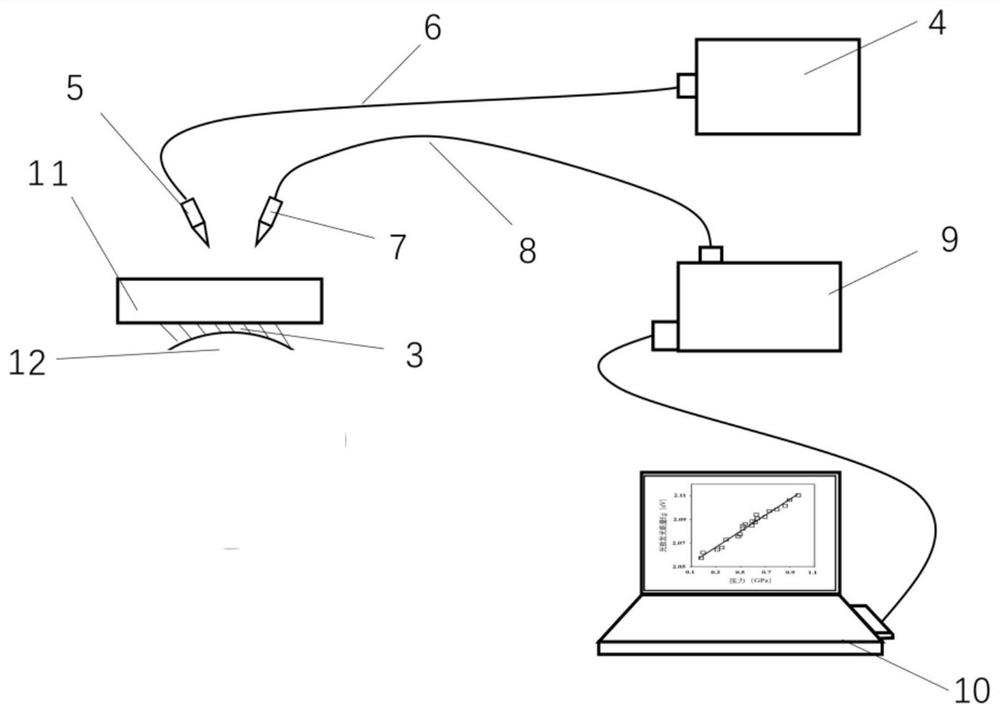

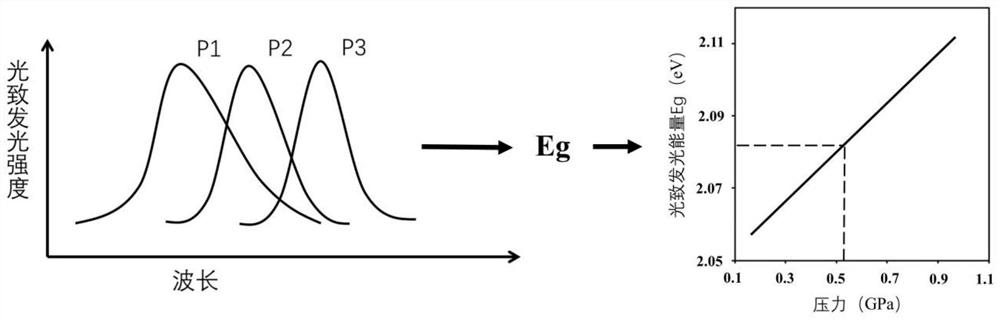

[0025] (1) Selection and calibration of pressure-sensitive quantum dots: refer to figure 1 , according to the sensitivity of different types of quantum dots to pressure, select suitable pressure-sensitive quantum dots 1 as sensors, mix them in lubricating fluid 2, and use them as quantum dot calibration solutions for pressure calibration. Use the pressure calibration device 3 to apply different loading pressures, and select four different positions in the calibration solution inside the calibration device as measurement points, collect the emission spectrum of each measurement point, and when the photoluminescence intensity of the quantum dot spectrum reaches the maximum value The recorded average emission energy is used as the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com