Amorphous magnetic shielding board for transformer and processing method thereof

A processing method and magnetic shielding technology, applied in the fields of magnetic field/electric field shielding, preventing/reducing unwanted electric/magnetic effects, electrical components, etc., can solve the problems of heavy weight, large thickness of shielding plate, high production cost, etc., to achieve Reduce eddy current loss and line loss, good magnetic permeability, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: Take the application of the amorphous magnetic shielding plate of the present invention in the SFSZ10-150000 / 220 type oil-immersed transformer as an example.

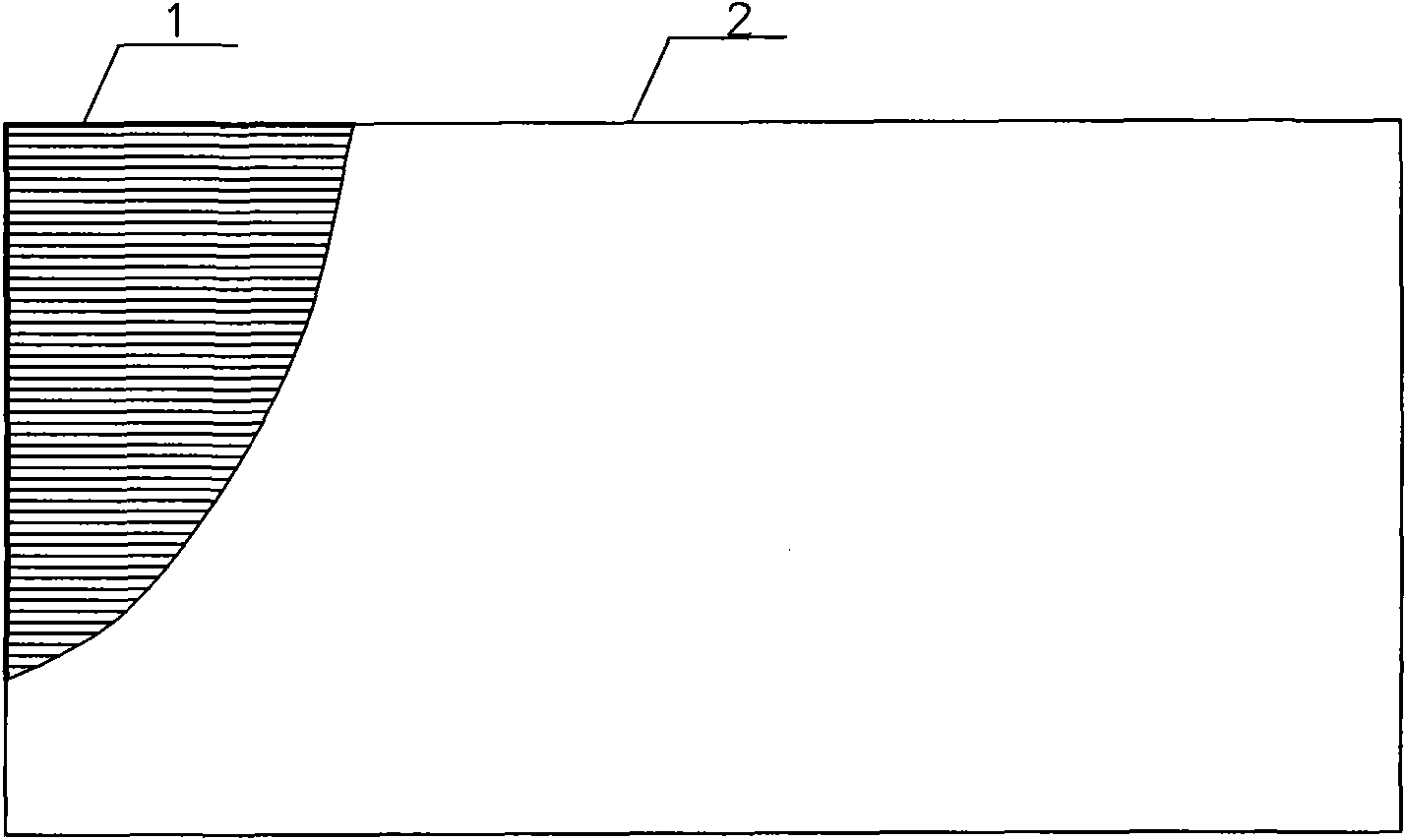

[0023] The amorphous magnetic shielding plate described in this embodiment includes an amorphous magnetic plate 1 and an insulating cardboard 2, and 220 amorphous magnetic plates 1 made of 3605A-1 type amorphous strips are stacked sequentially in front and back It is placed into an amorphous laminate, and after the amorphous laminate is annealed and solidified, the insulating paperboard 2 is wrapped on the above-mentioned amorphous laminate. The insulating cardboard 2 is 1.0110 / 00 type, its thickness is 1mm, and its density is 1.0~1.2g / cm 3 , the tensile strength is 90MPa, and the electric strength is ≥3.5KV / mm. The width x length x thickness of the amorphous magnetic shielding plate = 213 x 2050 x 6 mm.

[0024] The processing method of the amorphous magnetic shielding plate described in the embo...

Embodiment 2

[0031] Embodiment 2: Take the application of the amorphous magnetic shielding plate of the present invention in the SSZ-50000 / 110 type oil-immersed transformer as an example.

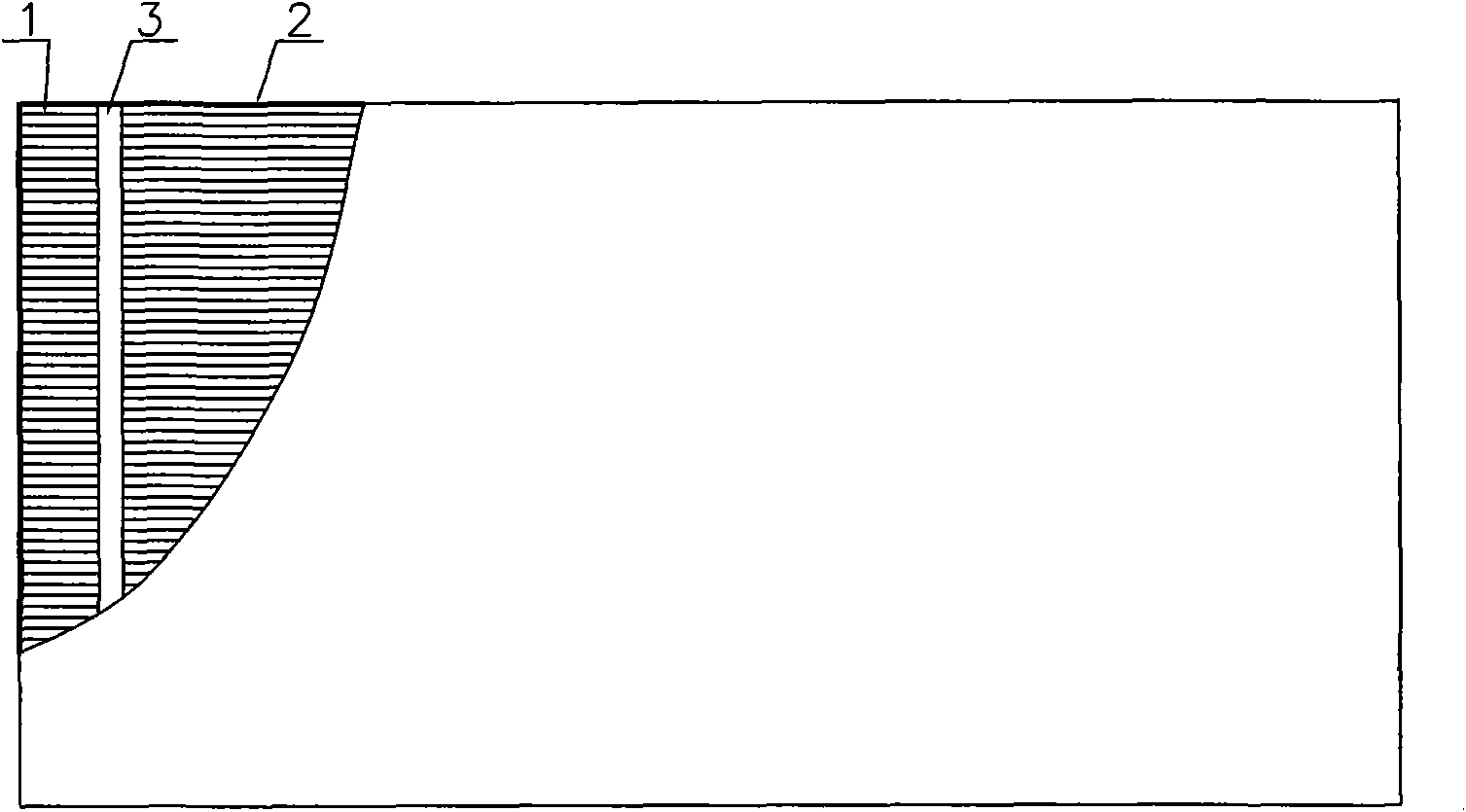

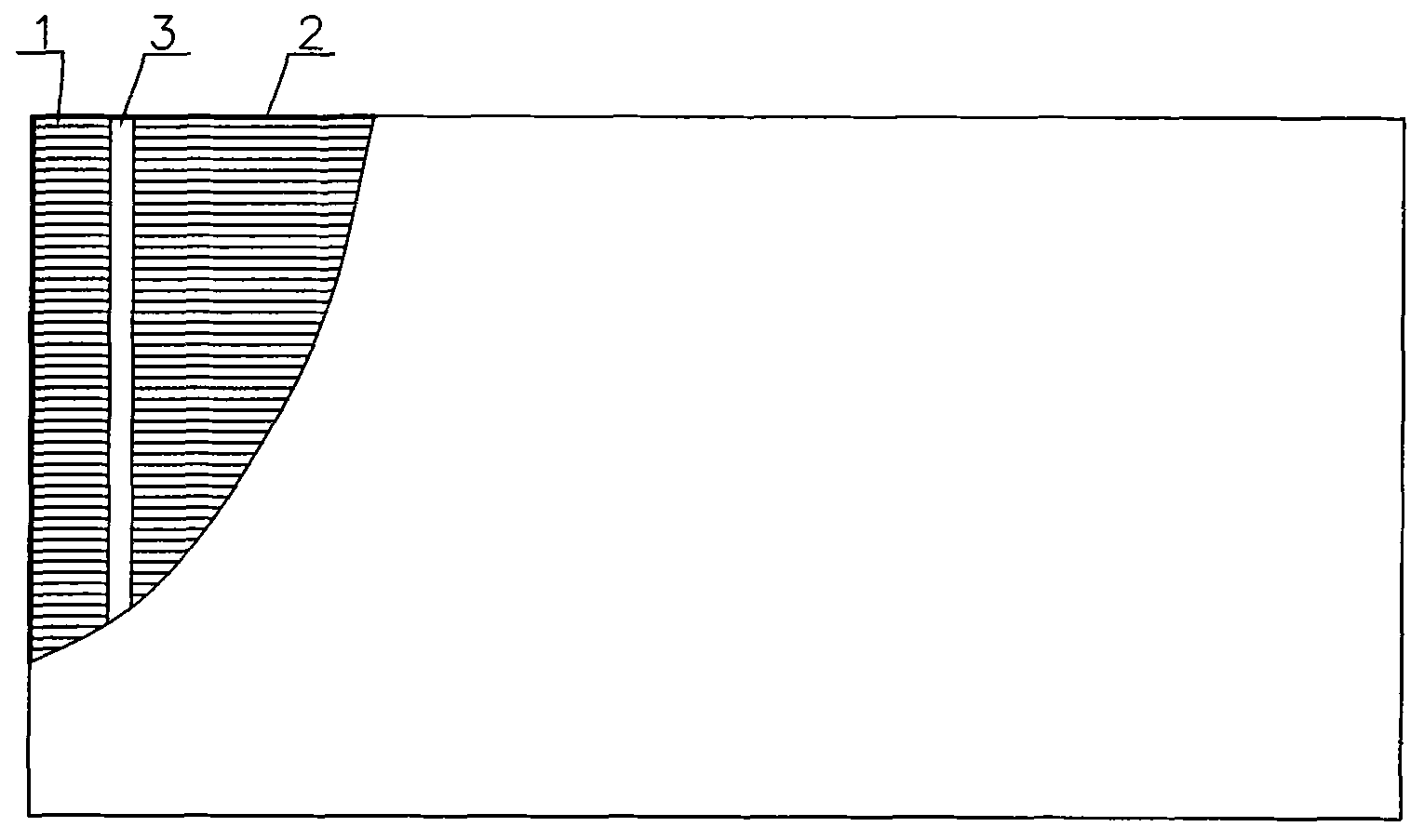

[0032] The amorphous magnetic shielding plate described in this embodiment includes an amorphous magnetic plate 1 and an insulating cardboard 2; the amorphous magnetic plate is cut from a 3605A-1 type amorphous strip, and several An assembly hole 3 corresponding to the transformer; 220 pieces of amorphous magnetic plates 1 are stacked in sequence in front and back to form amorphous laminates. After the amorphous laminates are annealed and cured, insulating cardboard 2 is coated on the above amorphous Outside the crystal stack. The insulating cardboard 1 is 1.0110 / 00 type, its thickness is 1mm, and its density is 1.0~1.2g / cm 3 , the tensile strength is 90MPa, and the electric strength is ≥3.5KV / mm. The width x length x thickness of the amorphous magnetic shielding plate = 213 x 1640 x 6 mm.

[0033] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com