Patents

Literature

35results about How to "Thermal efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

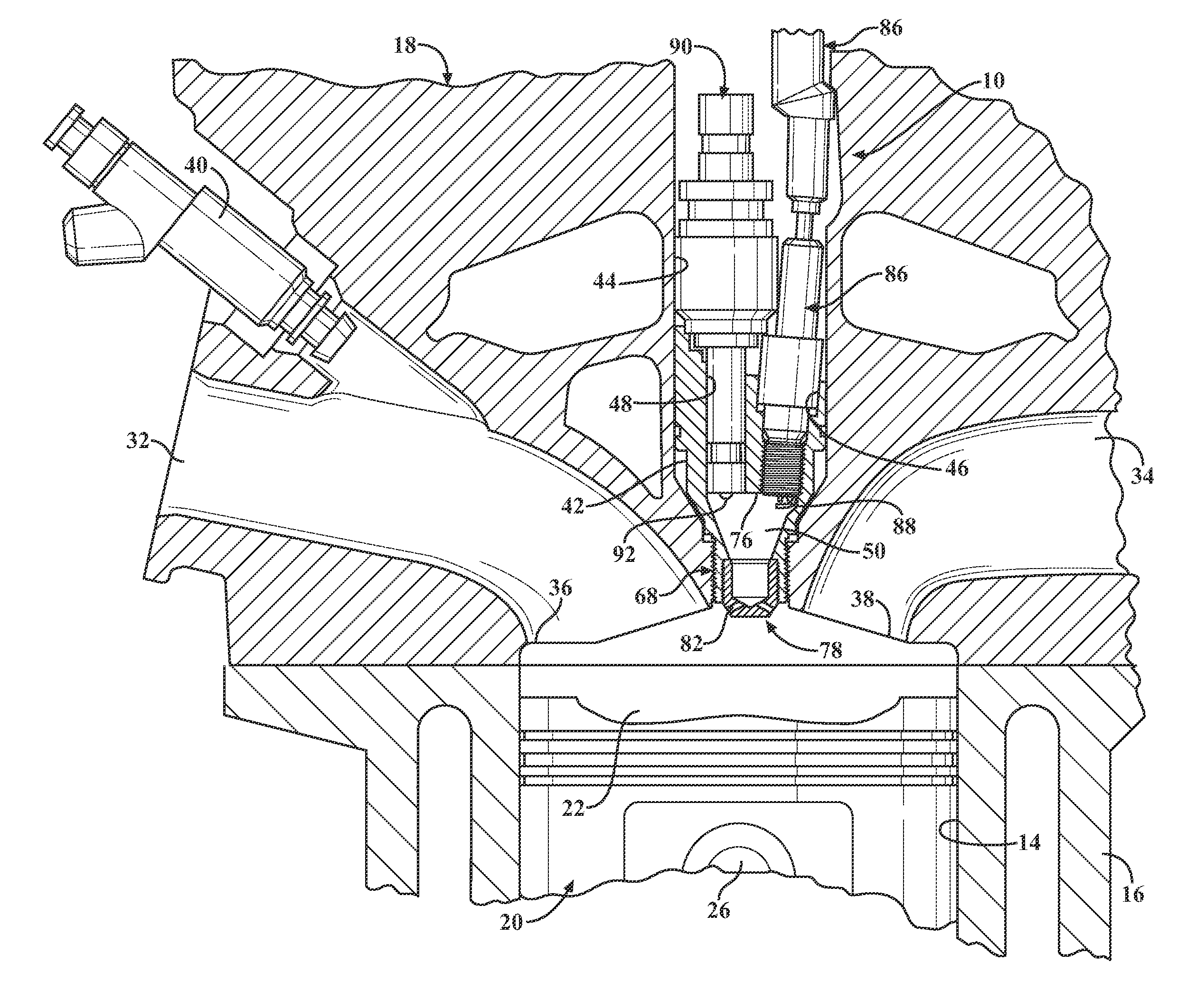

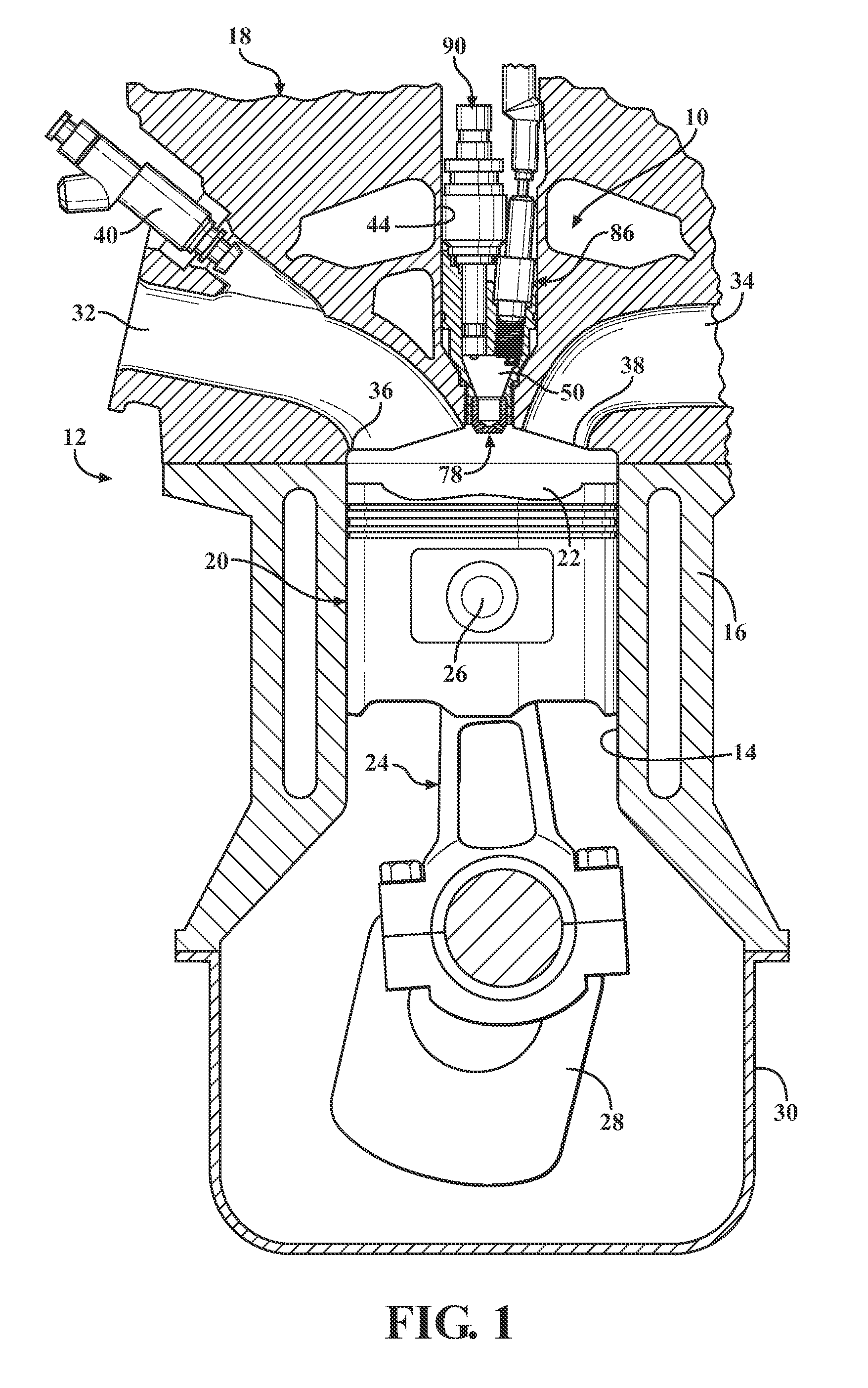

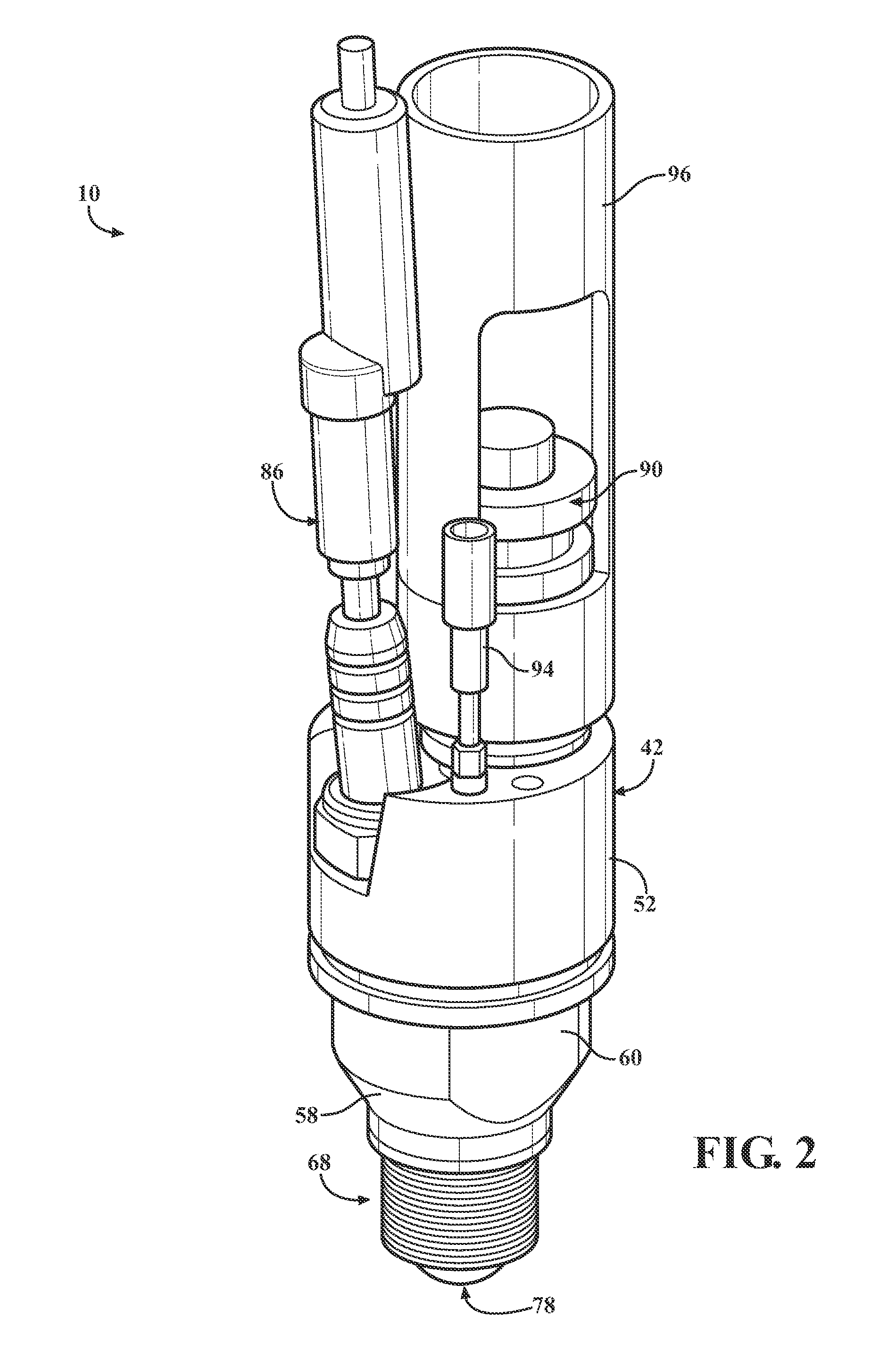

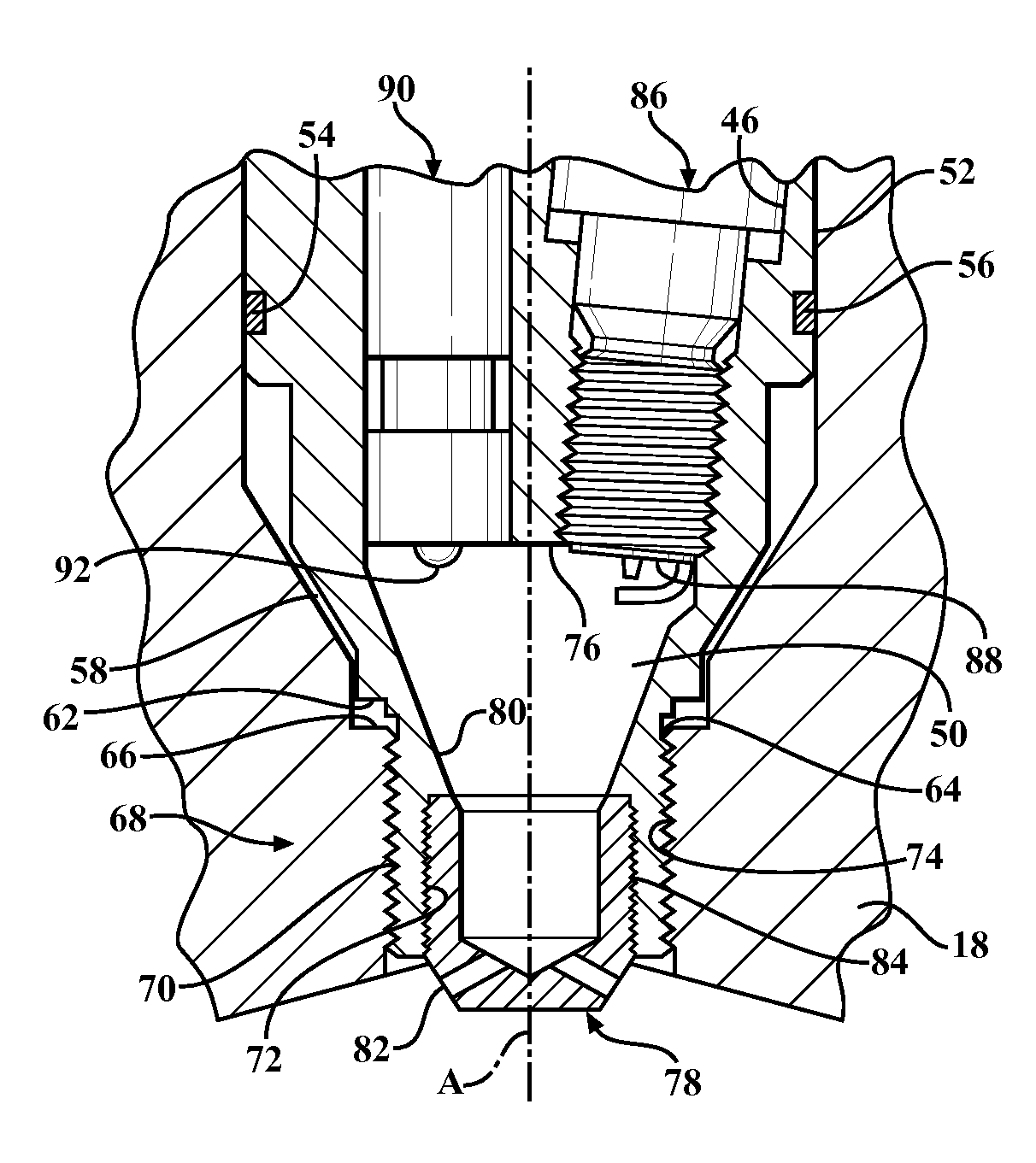

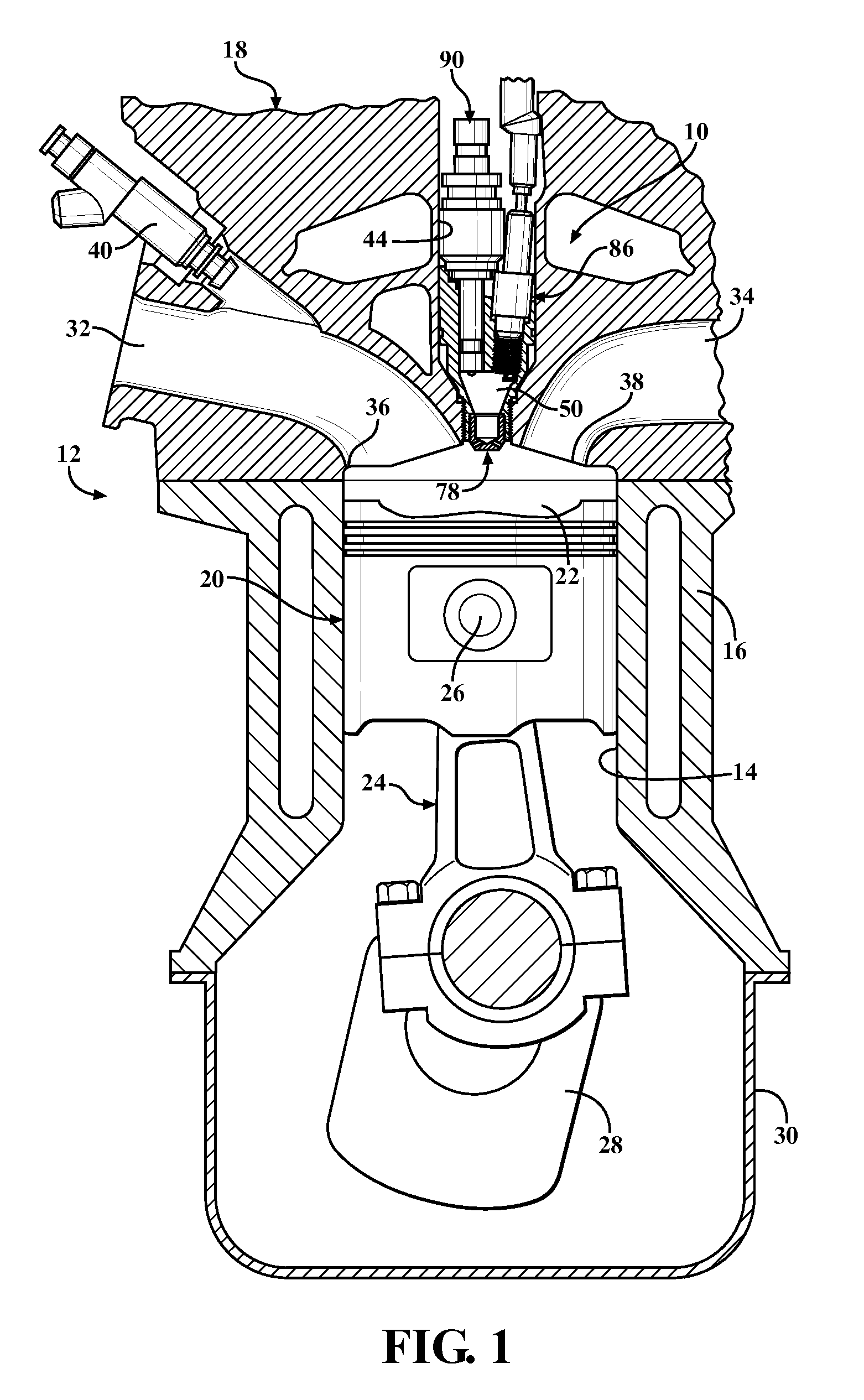

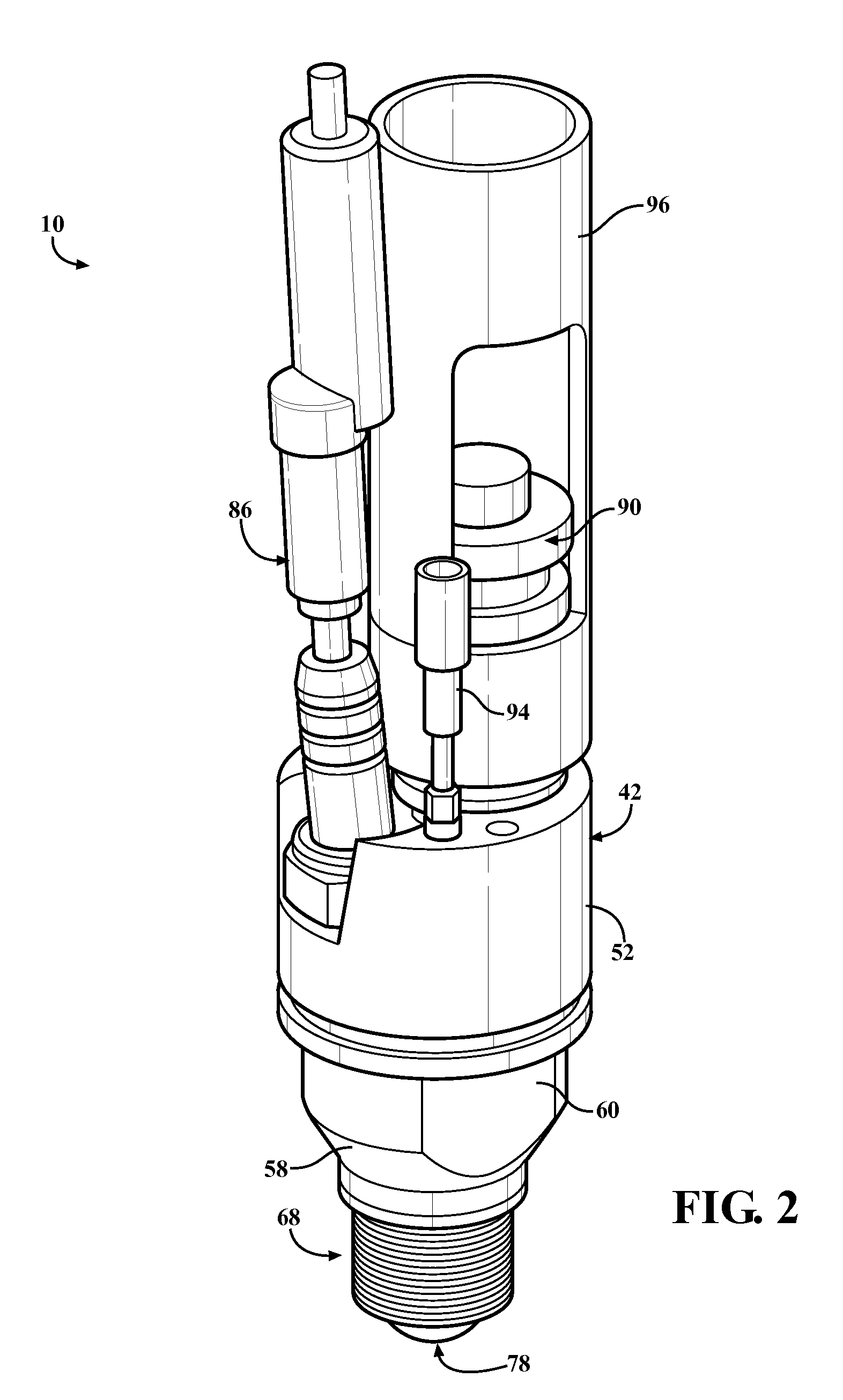

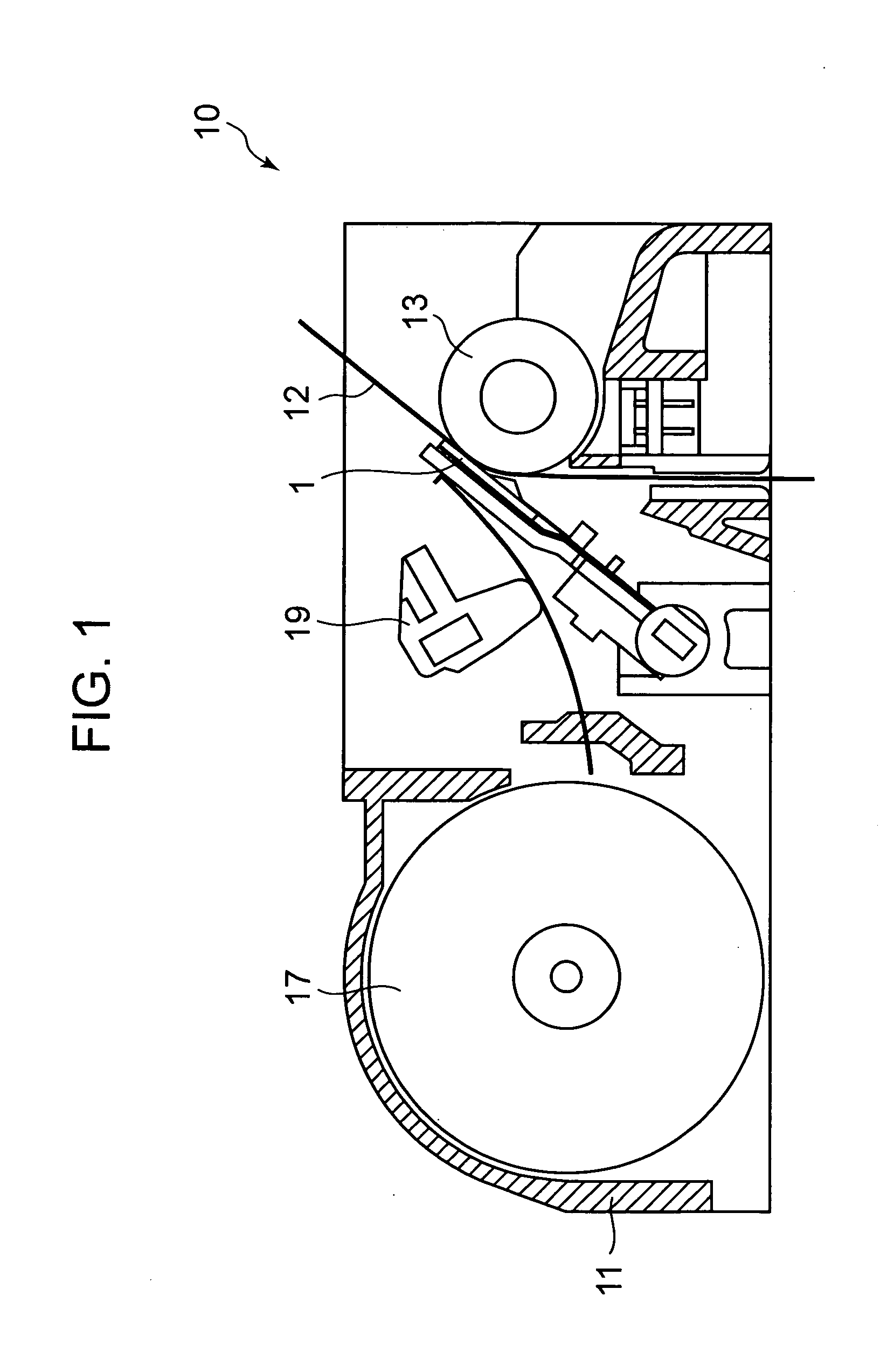

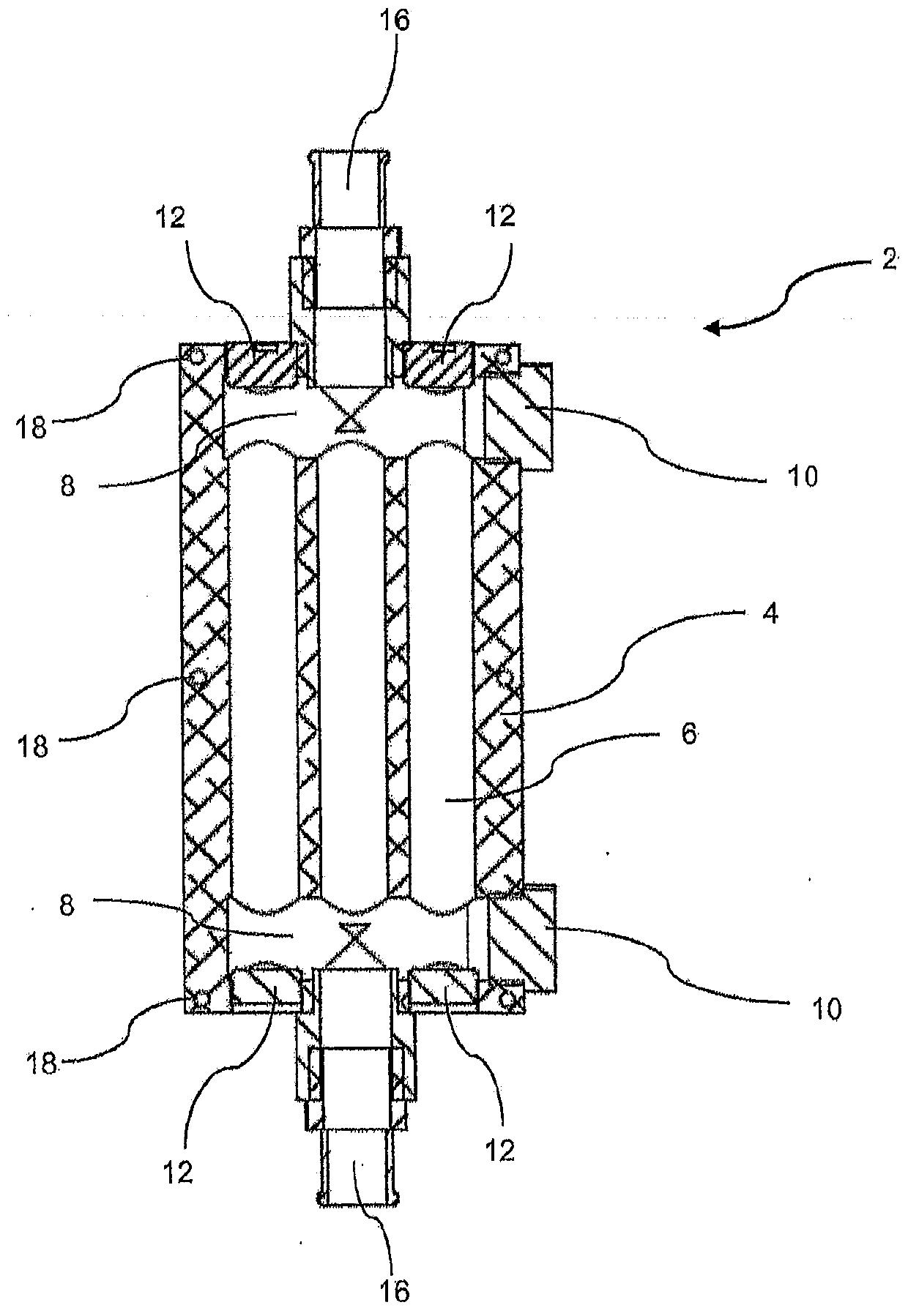

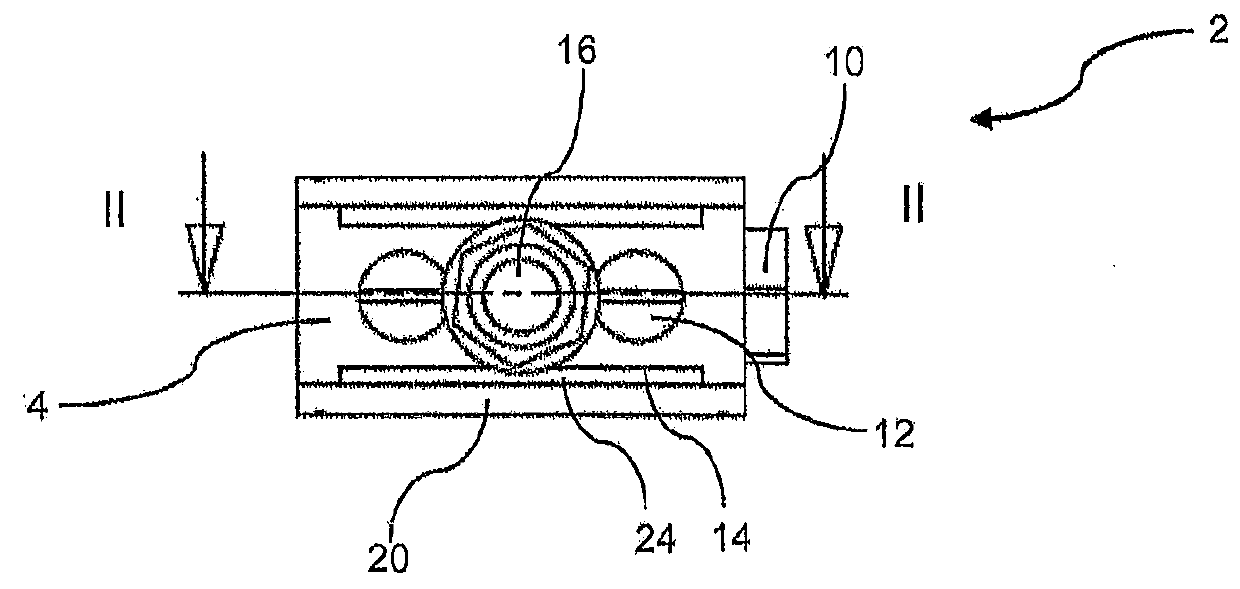

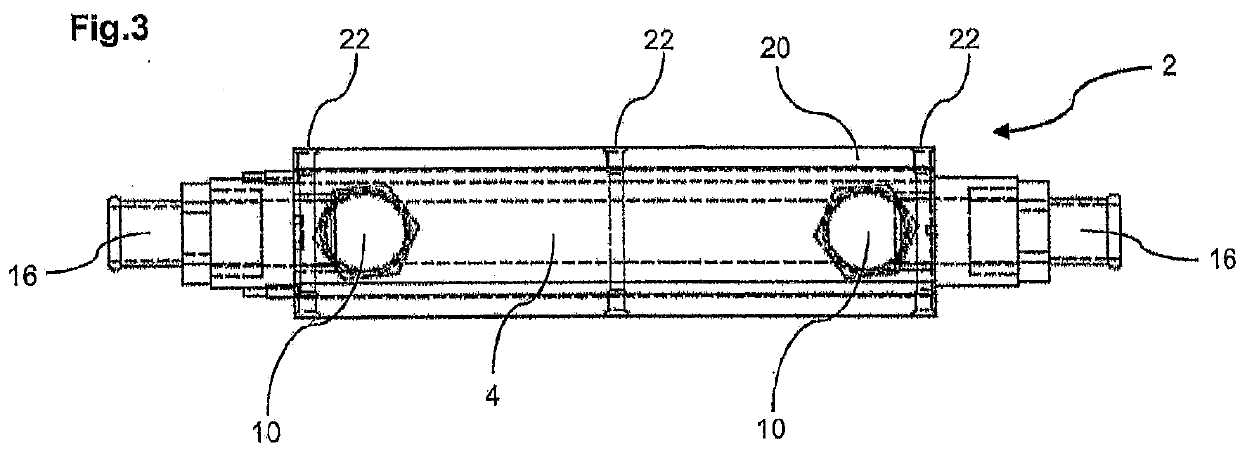

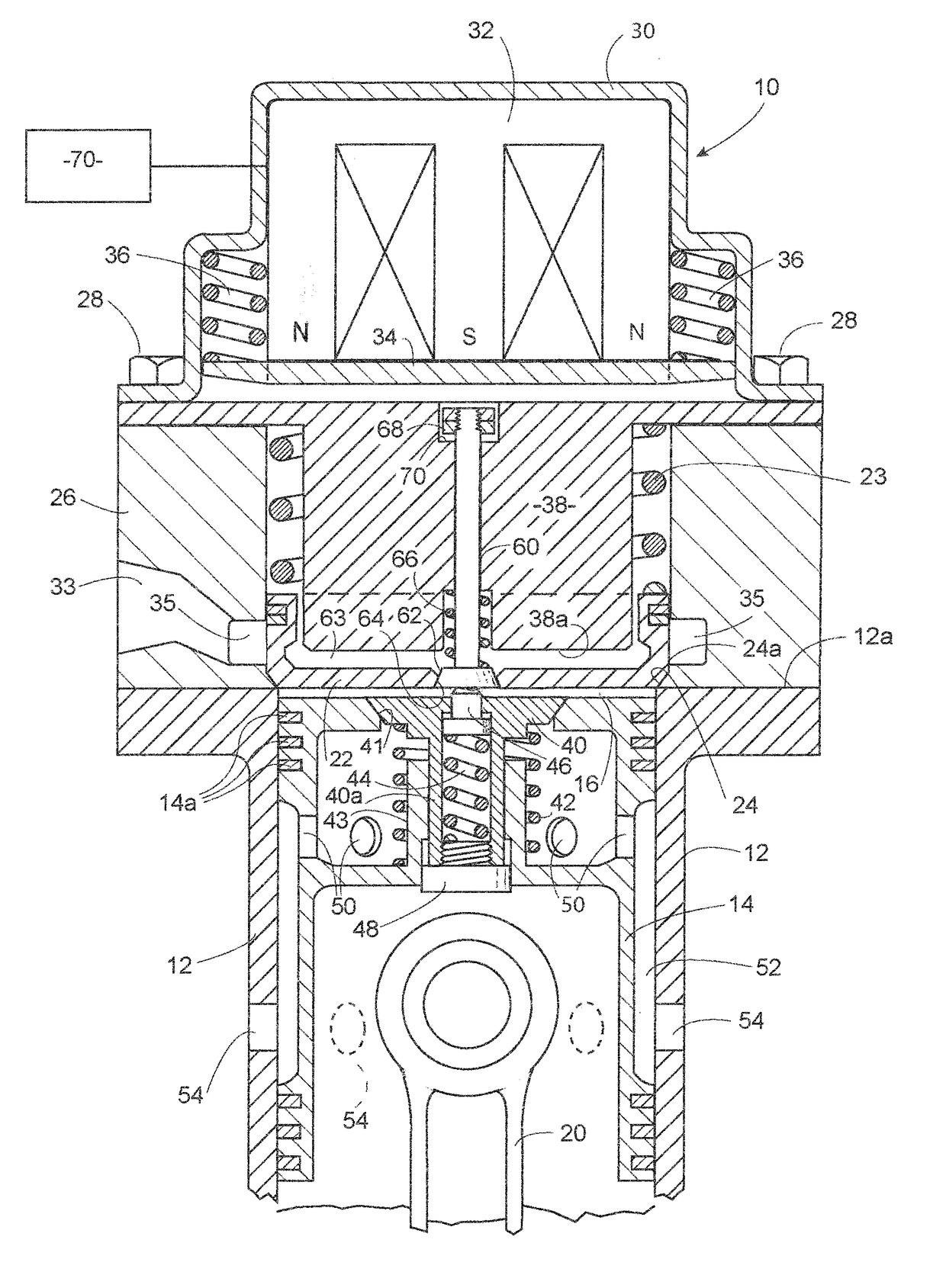

Turbulent jet ignition pre-chamber combustion system for spark ignition engines

ActiveUS8857405B2High-drive cycle (part load) fuel economyThermal efficiencyElectrical controlInternal combustion piston enginesCombustion systemCombustion chamber

An ignition system for an internal combustion engine having at least one combustion chamber where the ignition system includes a housing, an ignition device, an injector, and a pre-chamber having a nozzle disposed spaced from the proximal portion of the pre-chamber. The igniter portion of the ignition device and the nozzle of the injector are operatively supported in the proximal portion of the pre-chamber and disposed flush therewith. The igniter portion ignites the fuel in pre-chamber such that partially combusted pre-chamber products are forced through orifices in the pre-chamber nozzle and extinguish, but dispersed through the combustion chamber so as to ignite the main fuel charge therein.

Owner:MAHLE POWERTRAIN

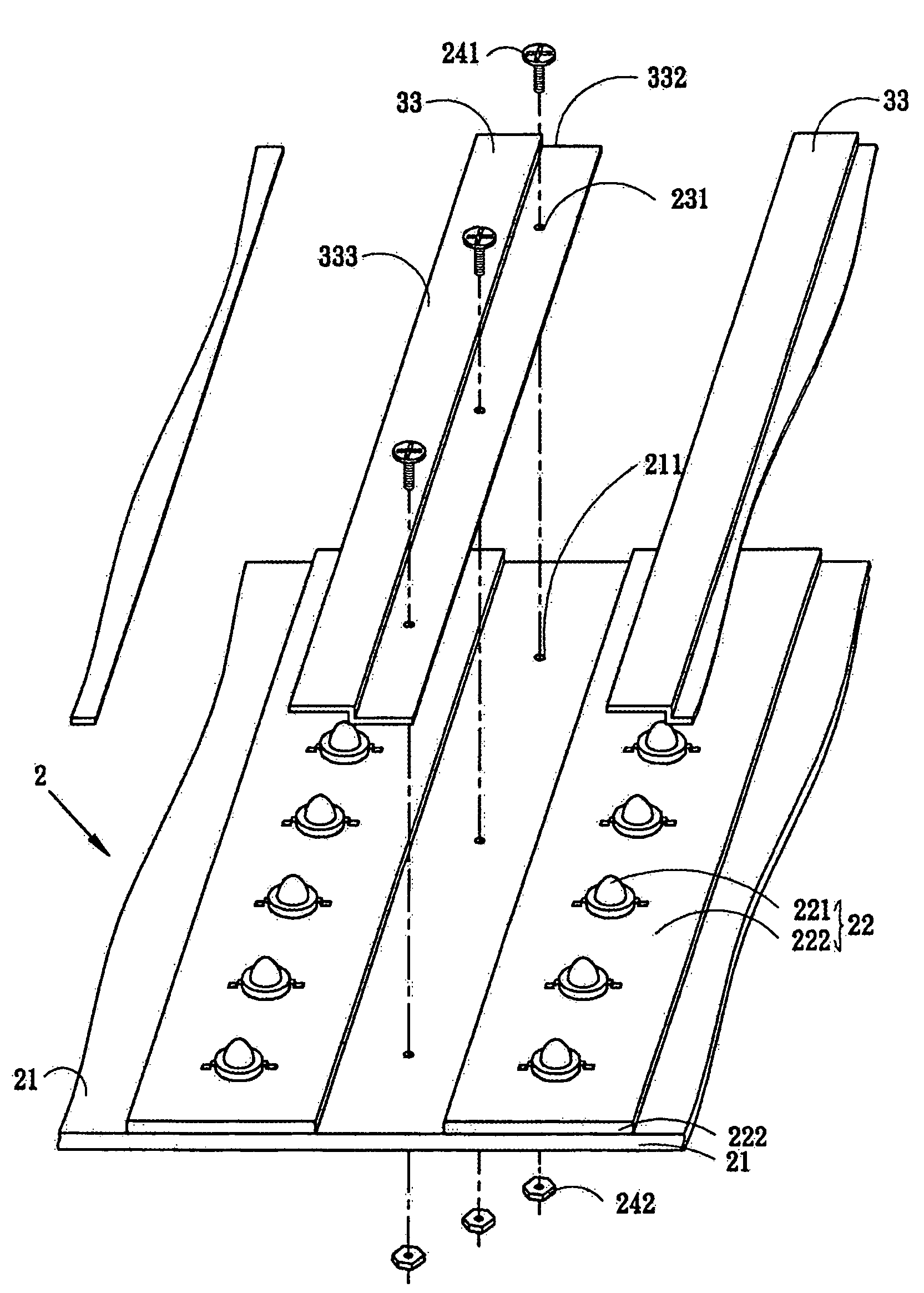

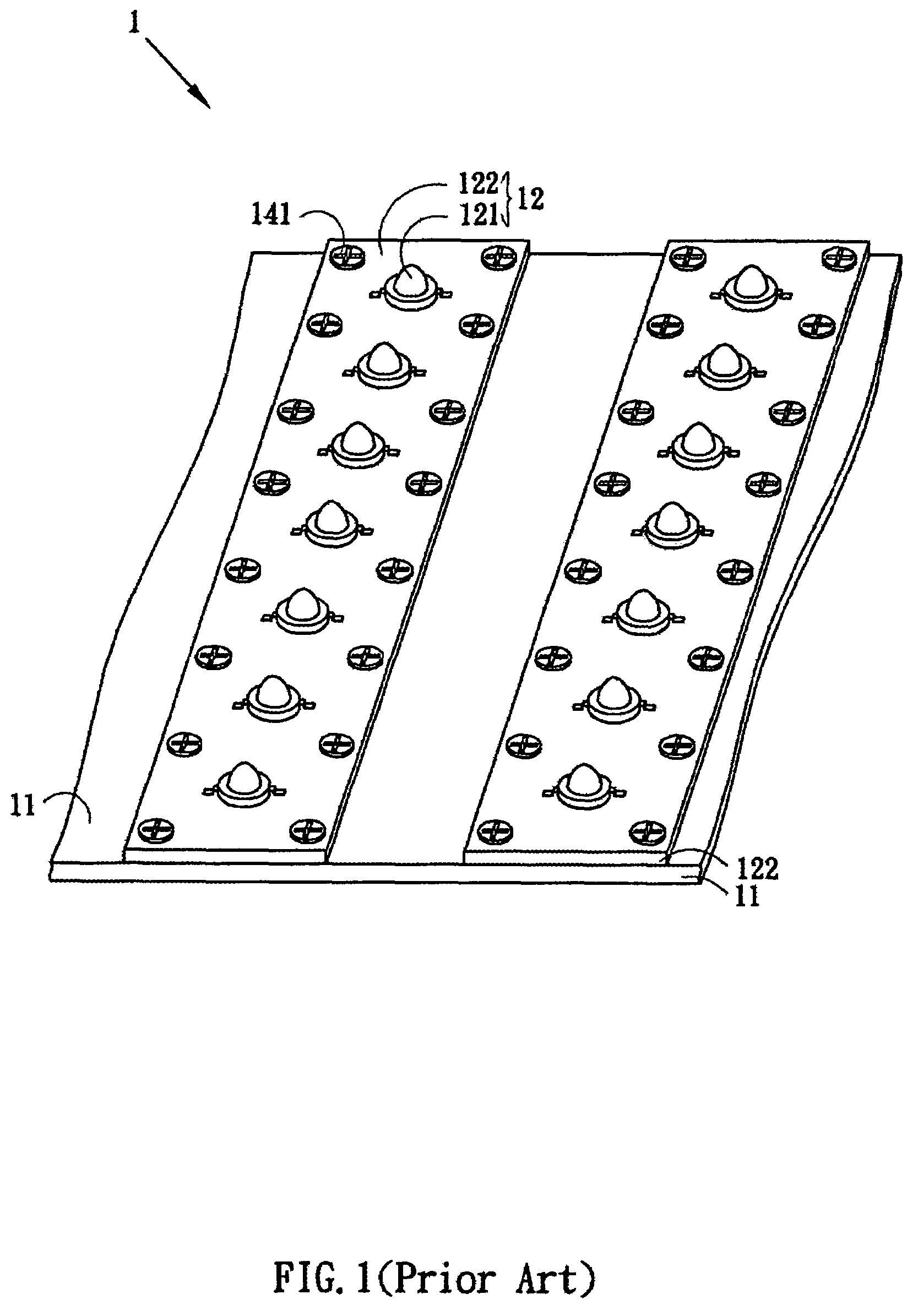

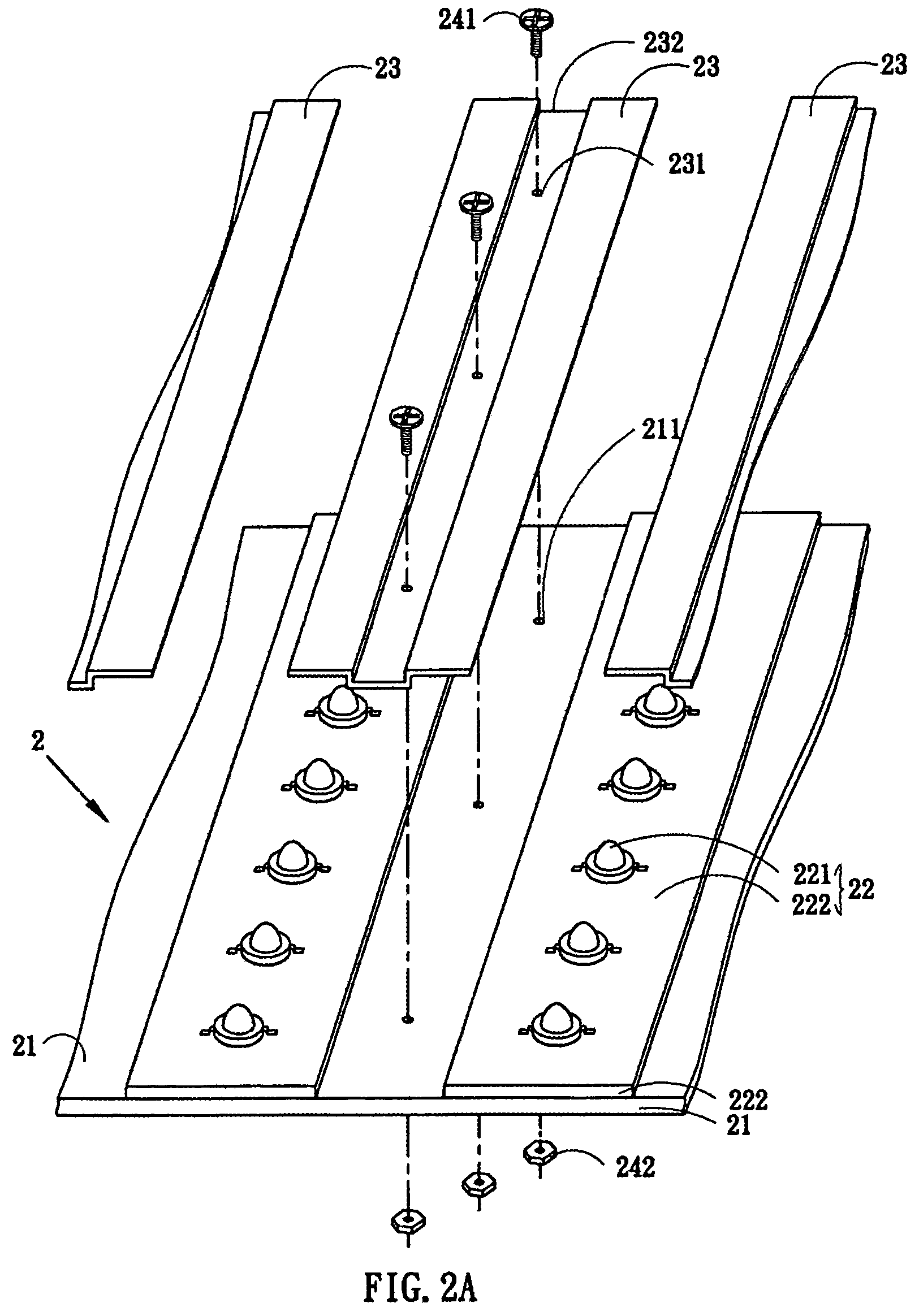

Backlight module having device for fastening lighting units

ActiveUS7374306B2Easy to assembleReduce the amount requiredPoint-like light sourceMeasurement apparatus componentsEngineeringMechanical engineering

Owner:OPTRONIC SCI LLC

Turbulent jet ignition pre-chamber combustion system for spark ignition engines

ActiveUS9353674B2High-drive cycle (part load) fuel economyThermal efficiencyElectrical controlInternal combustion piston enginesCombustion systemCombustion chamber

Owner:MAHLE POWERTRAIN

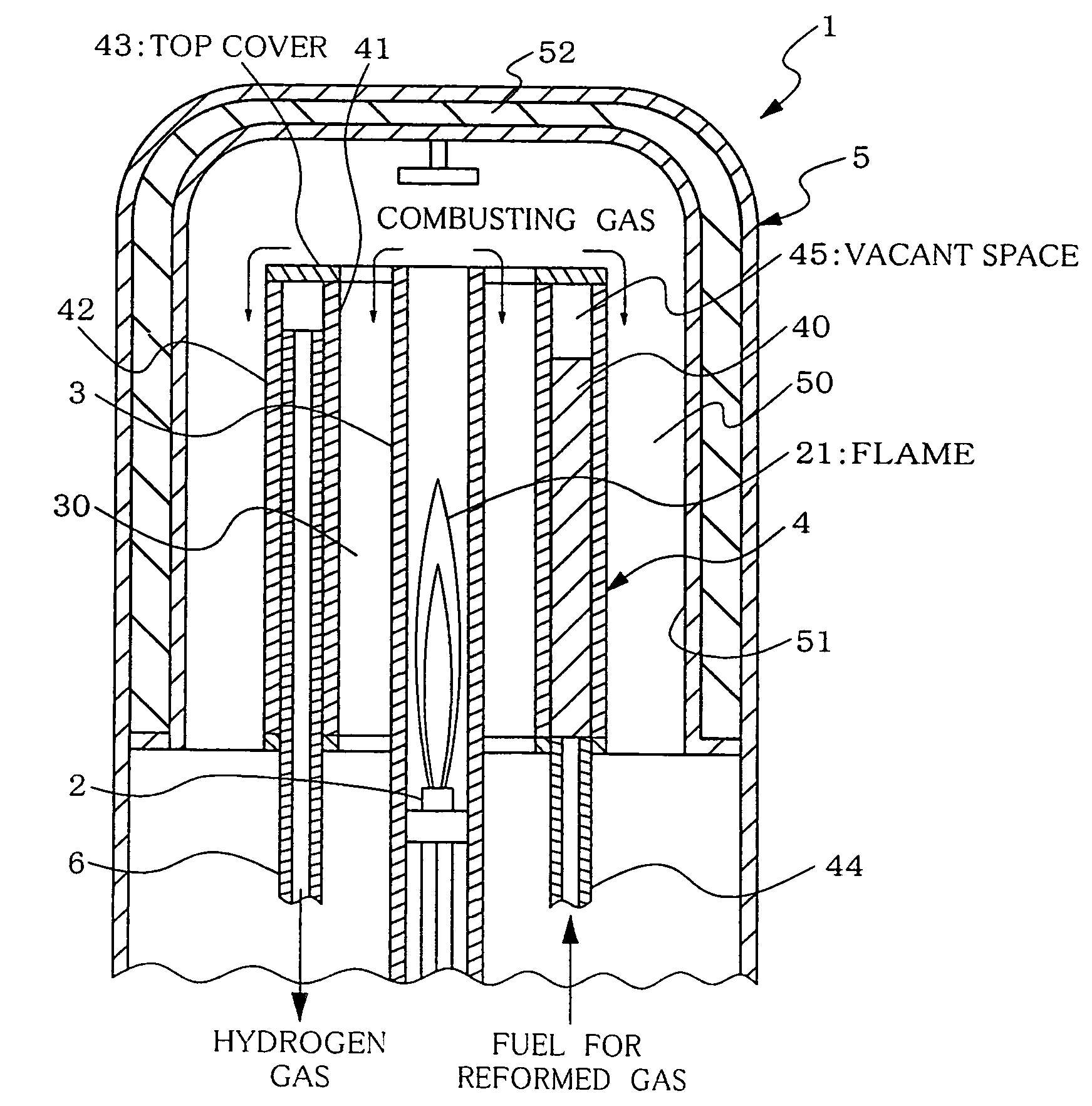

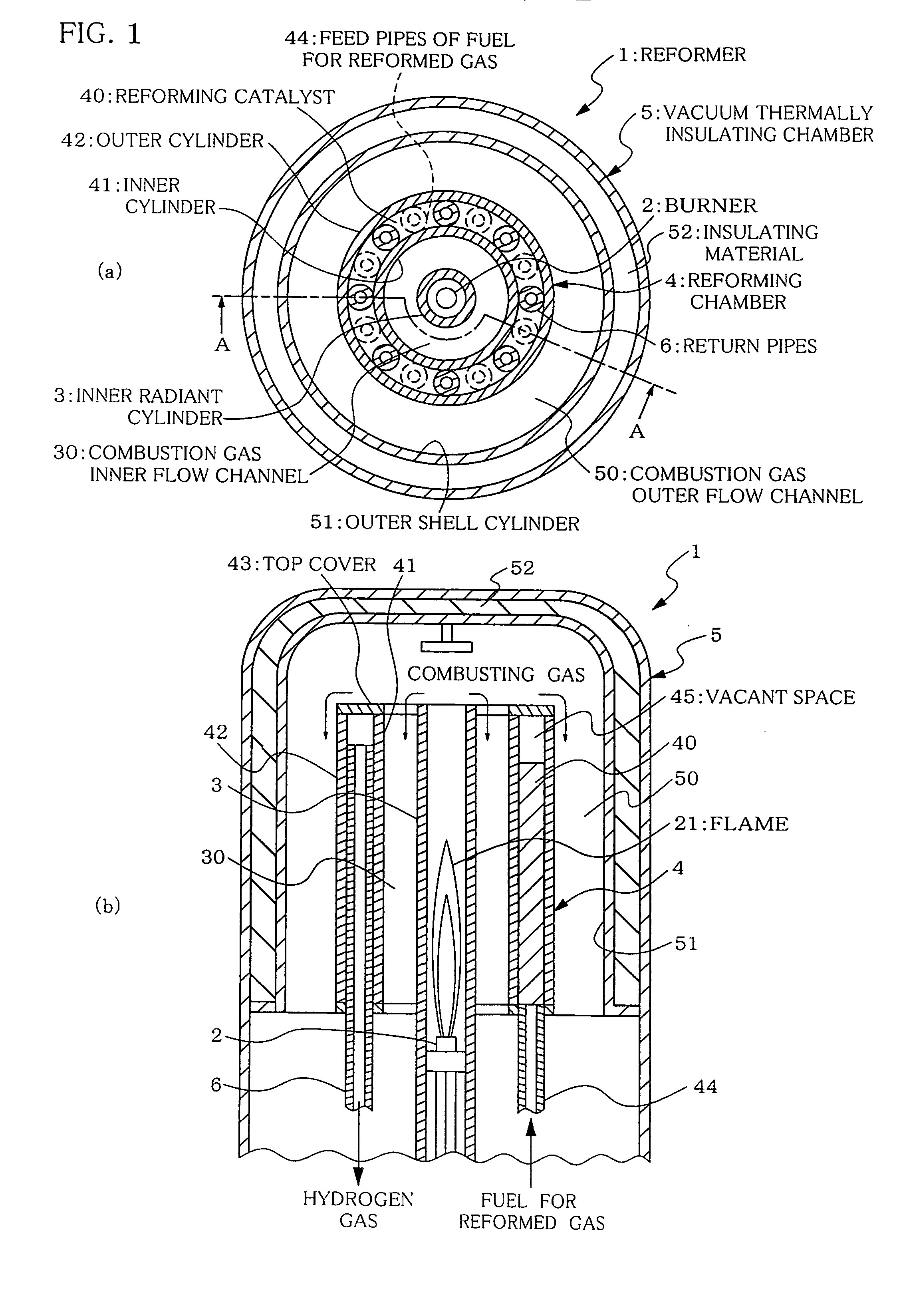

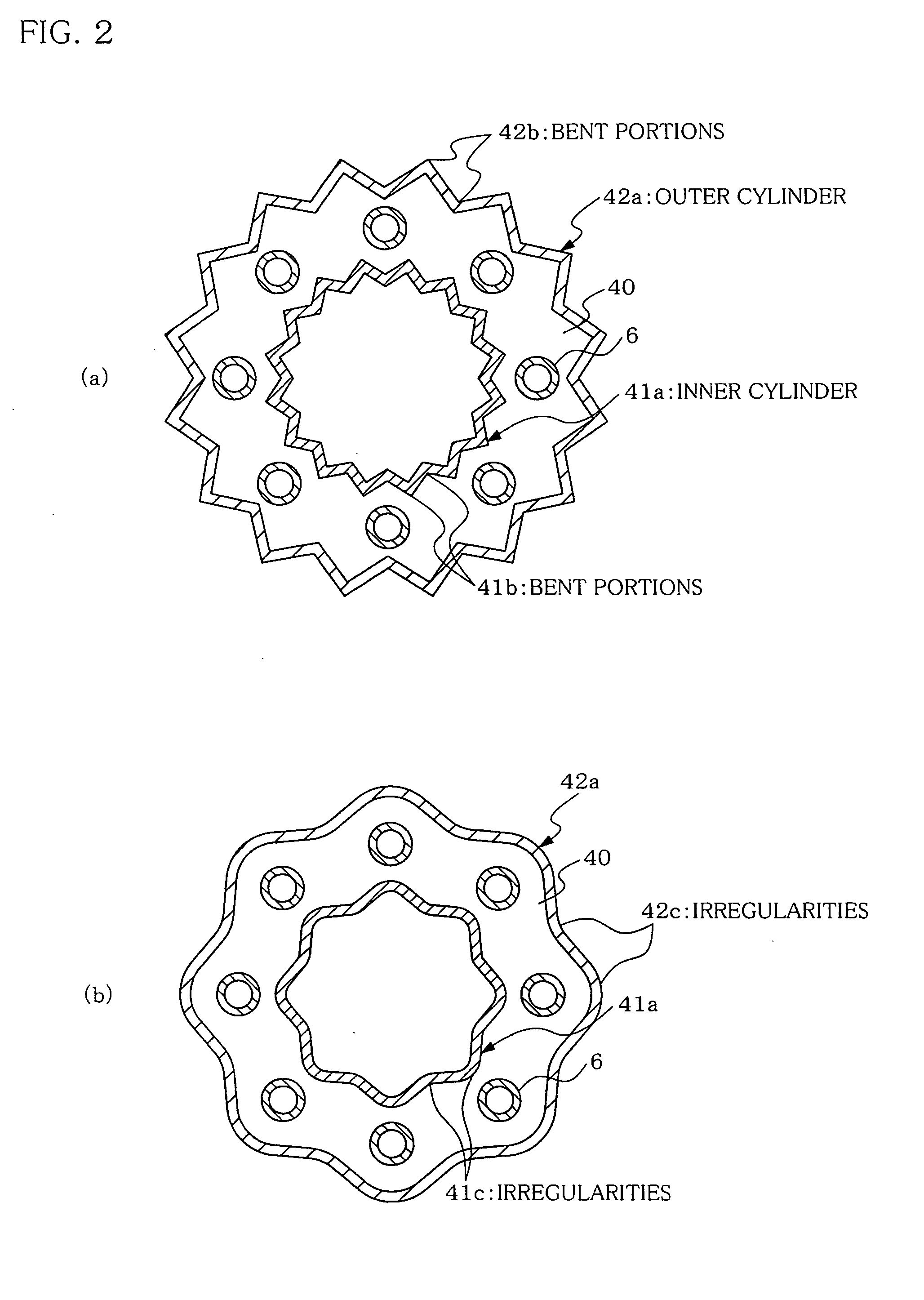

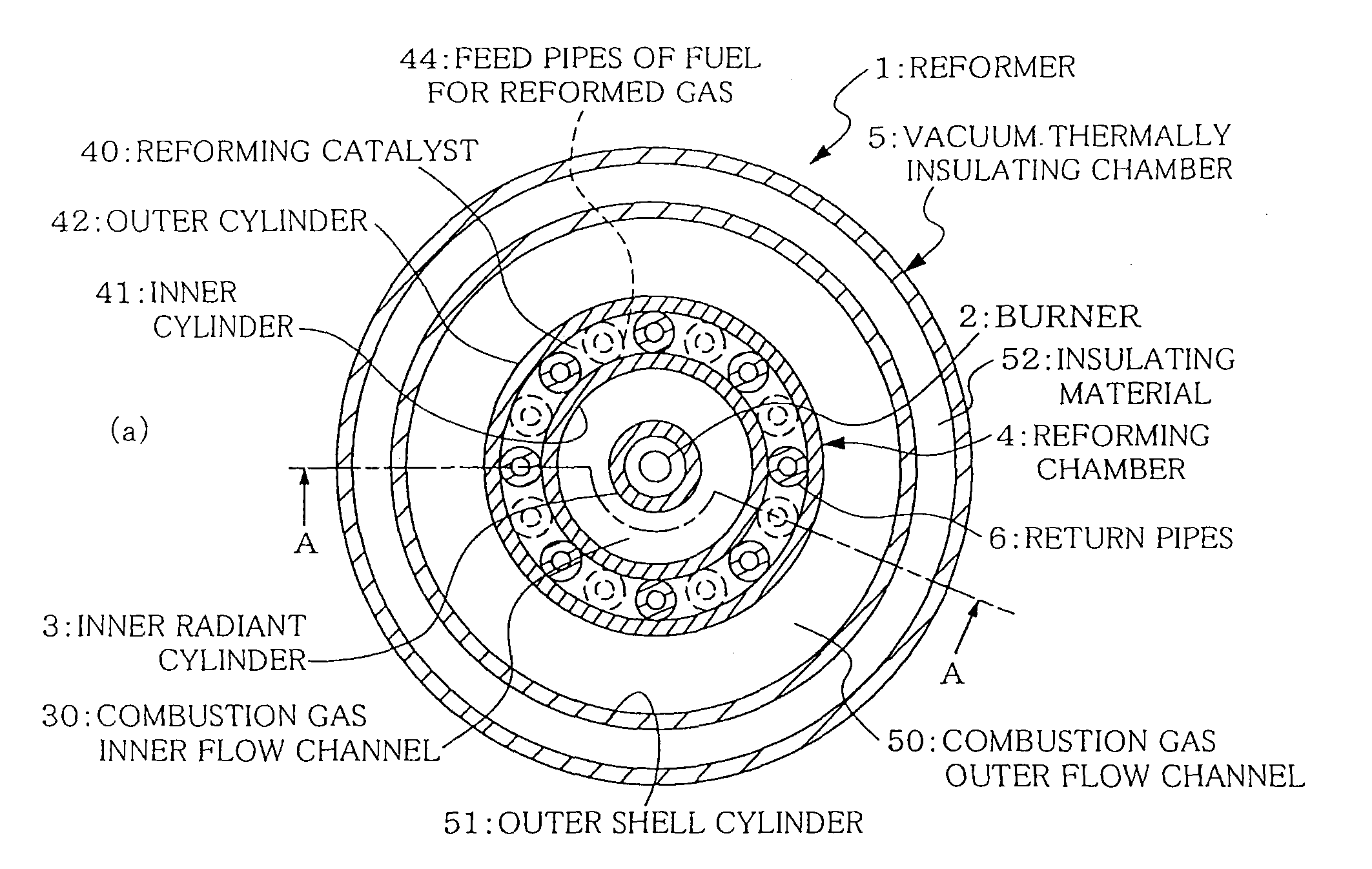

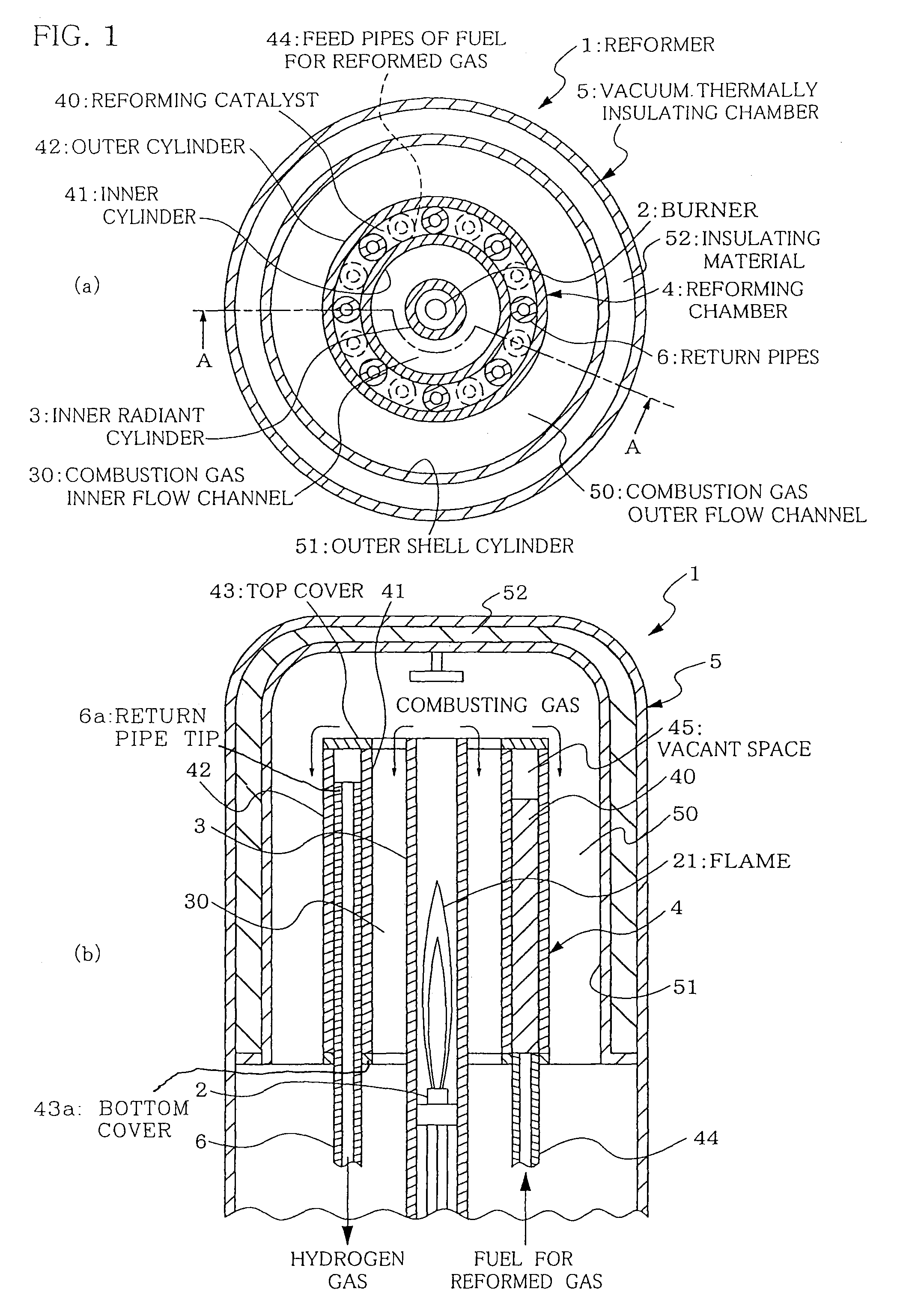

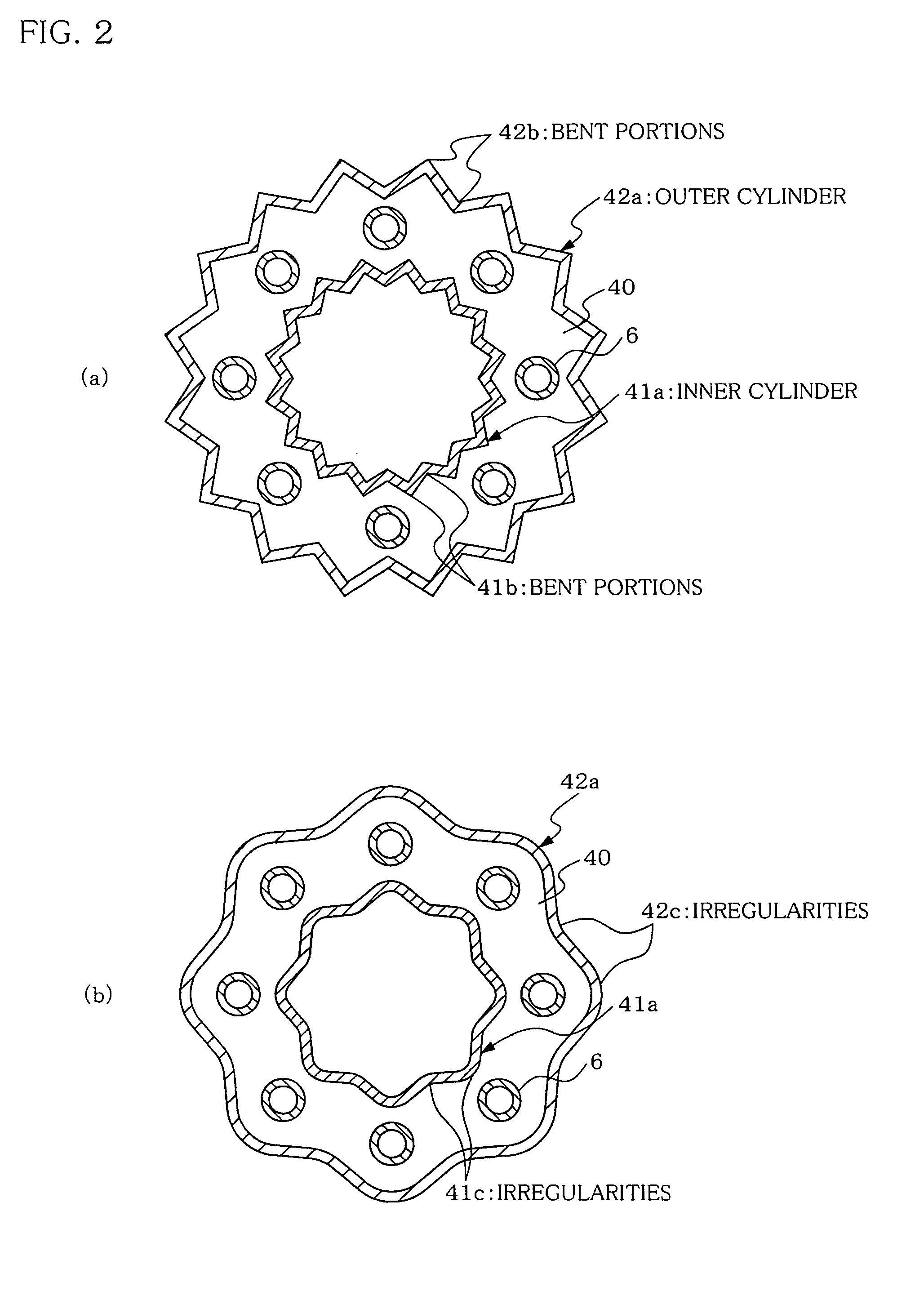

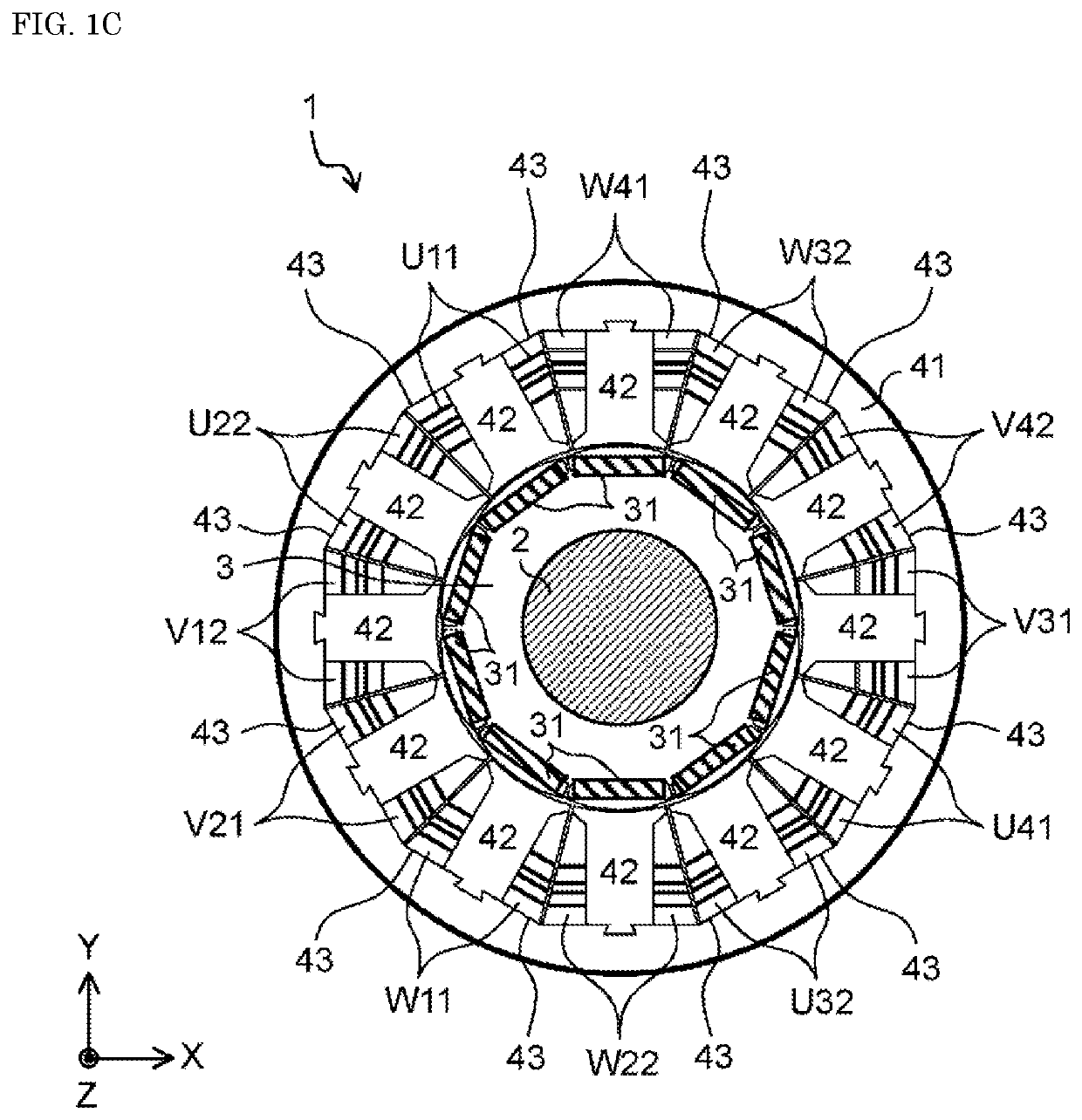

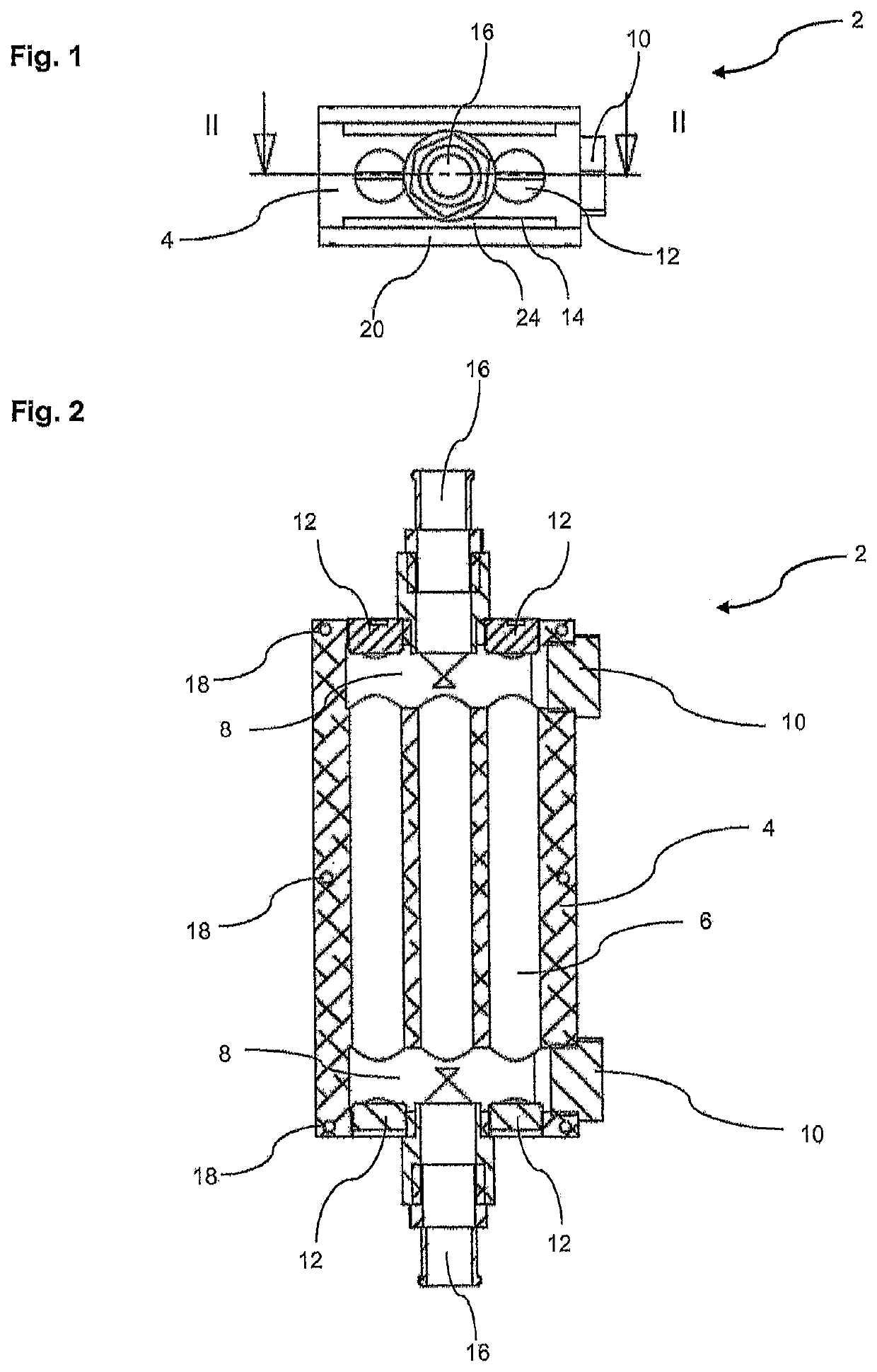

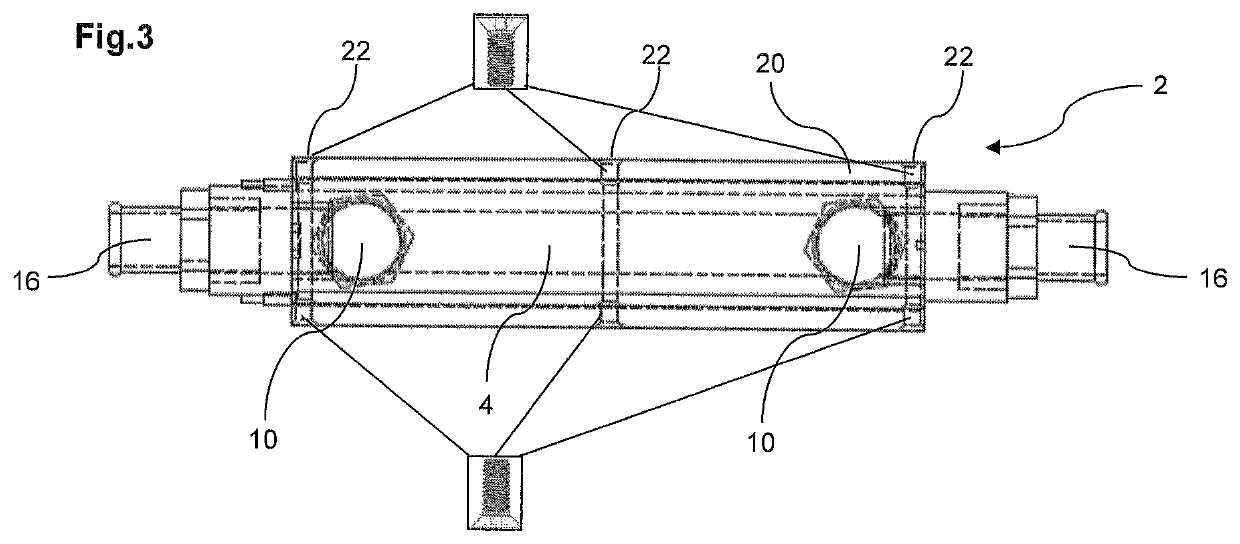

Reformer

InactiveUS20080244973A1Improve thermal efficiencyReduce radiation doseCombustible gas chemical modificationHydrogenCombustorProcess engineering

A reformer that produces reformed gas from a hydrocarbon material includes a reforming chamber having an inner cylinder and an outer cylinder; a reforming catalyst filled in the reforming chamber; a burner that heats the reforming catalyst and fuel of reformed gas; a combustion gas outer flow channel through which combustion gas of the burner flows along an outer side surface of the reforming chamber; a combustion gas inner flow channel through which the combustion gas of the burner flows along an inner side surface of the reforming chamber; and a plurality of return pipes as a reformed gas flow channel.

Owner:IDEMITSU KOSAN CO LTD

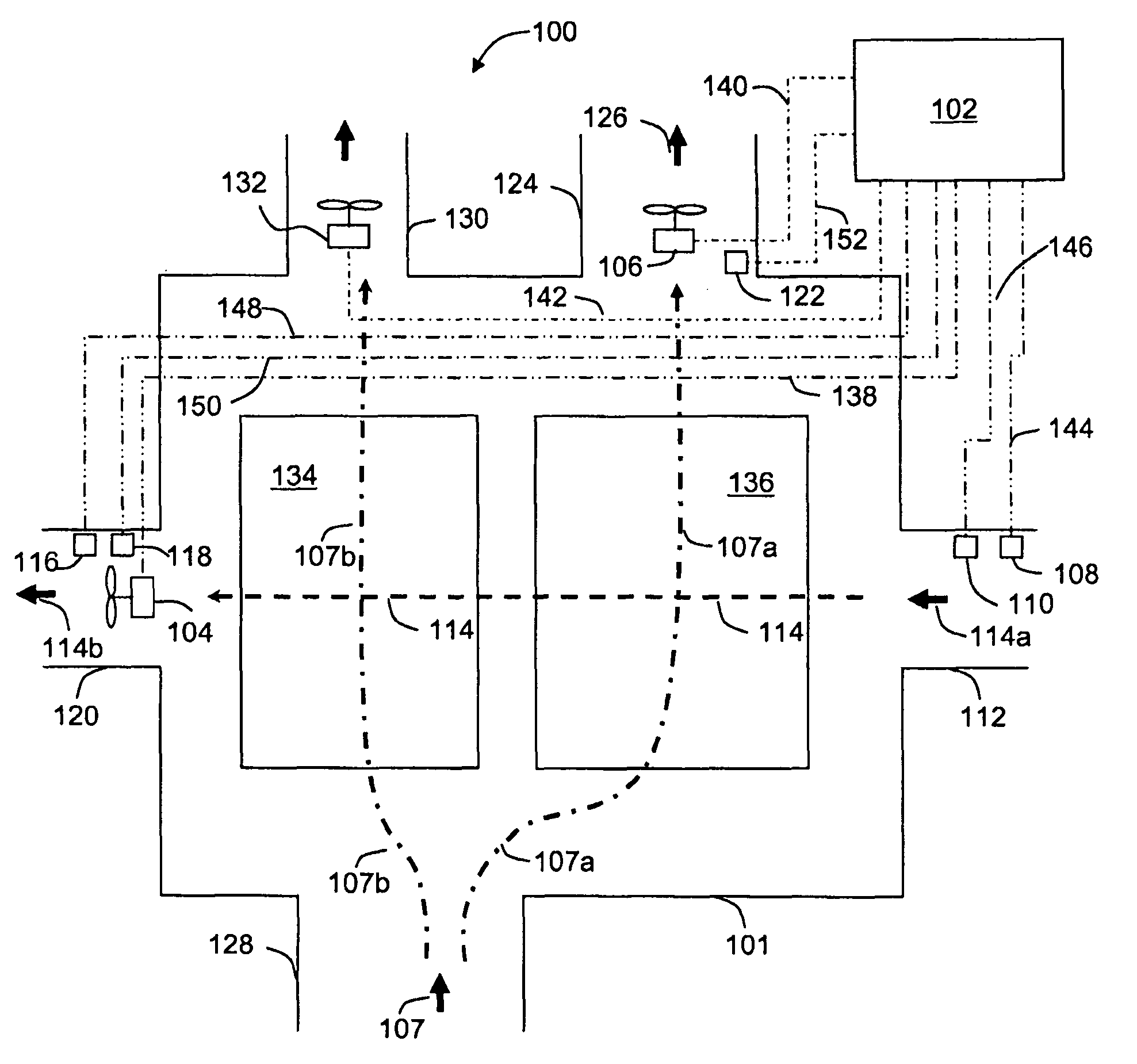

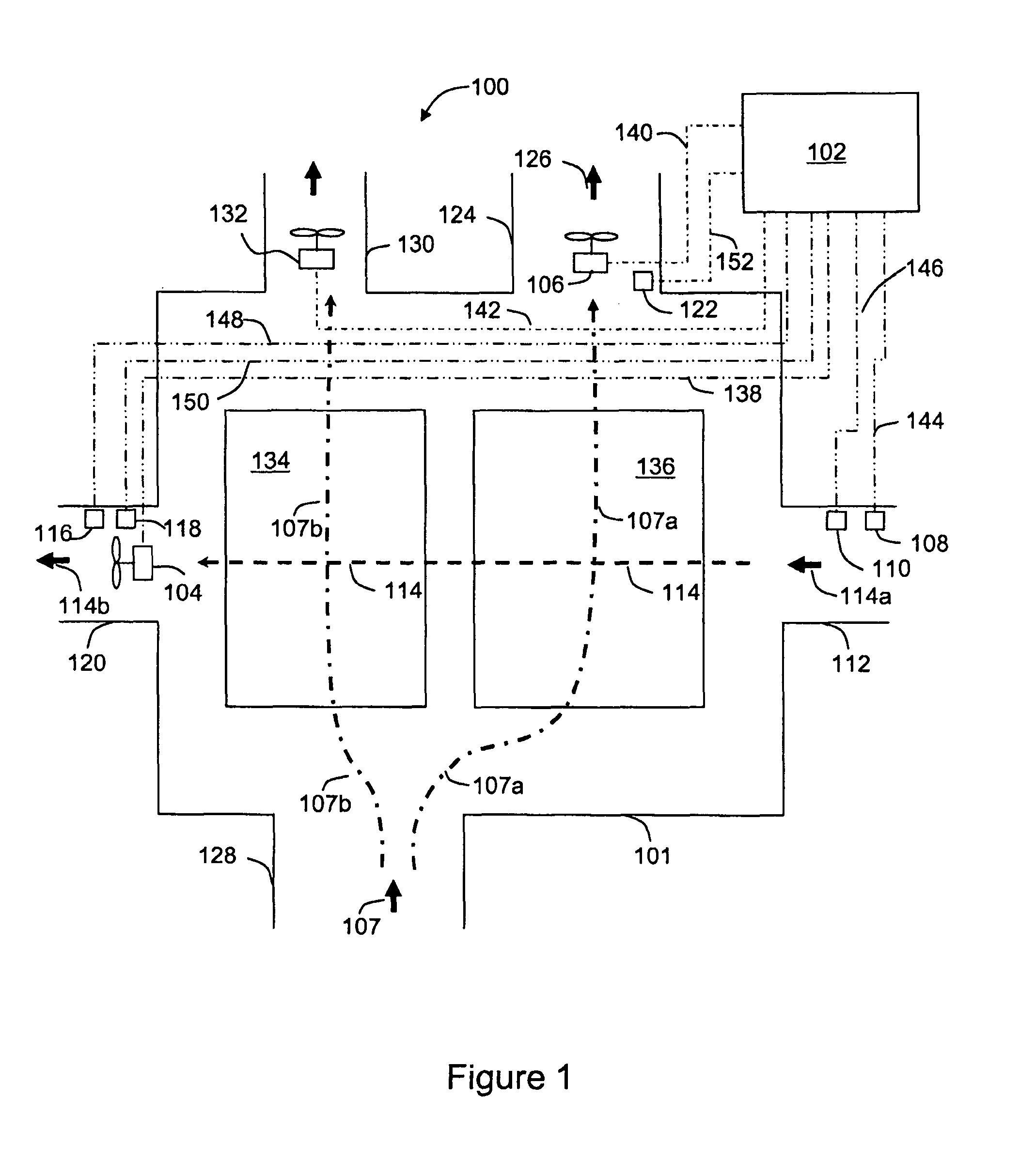

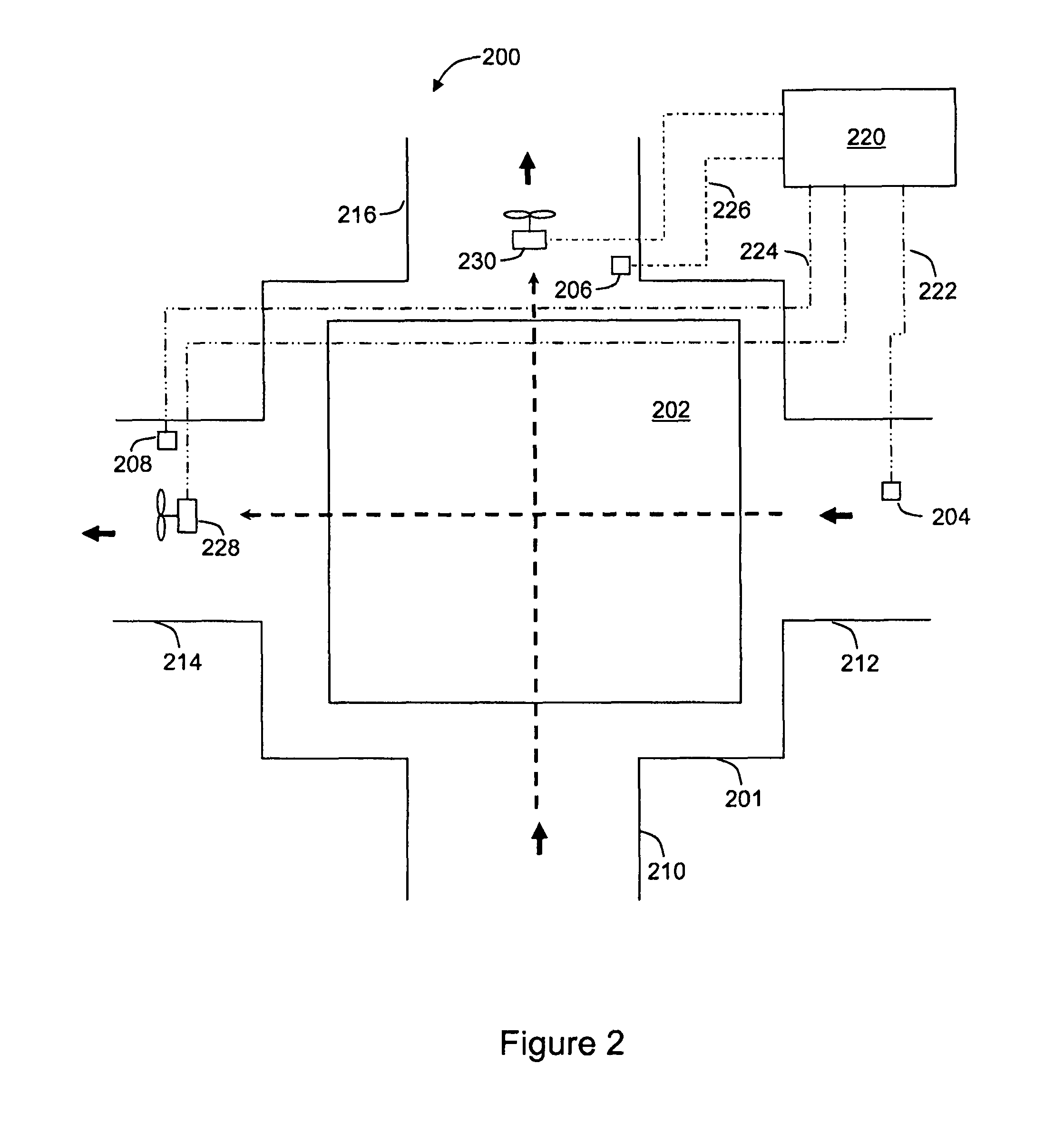

Method and apparatus for controlling ventilation systems

ActiveUS8939827B2Increase speedShorten speedMechanical apparatusLighting and heating apparatusMotor speedEnergy recovery ventilation

An energy recovery ventilation system is described which allows for continuous fan speed control through pulse width modulation of direct current fans. The energy recovery ventilation described is capable of fine motor speed control without the disadvantages of high noise, low efficiency and a fixed number of speeds present in commonly-used speed-varying techniques used with alternating current (AC) fans. This may be accomplished through the use of direct current (DC) fans and pulse width modulation. A controller is used to optimize the ventilation and energy efficiency of the system through the use of several temperature sensors. The energy recovery ventilation also provides a control process for self-optimization of the energy recovery ventilation, in case the supply and exhaust airflows are unequal. An unbalance may be detected by calculating the thermal efficiencies of the exhaust and supply airflows.

Owner:AIR TECH EQUIP

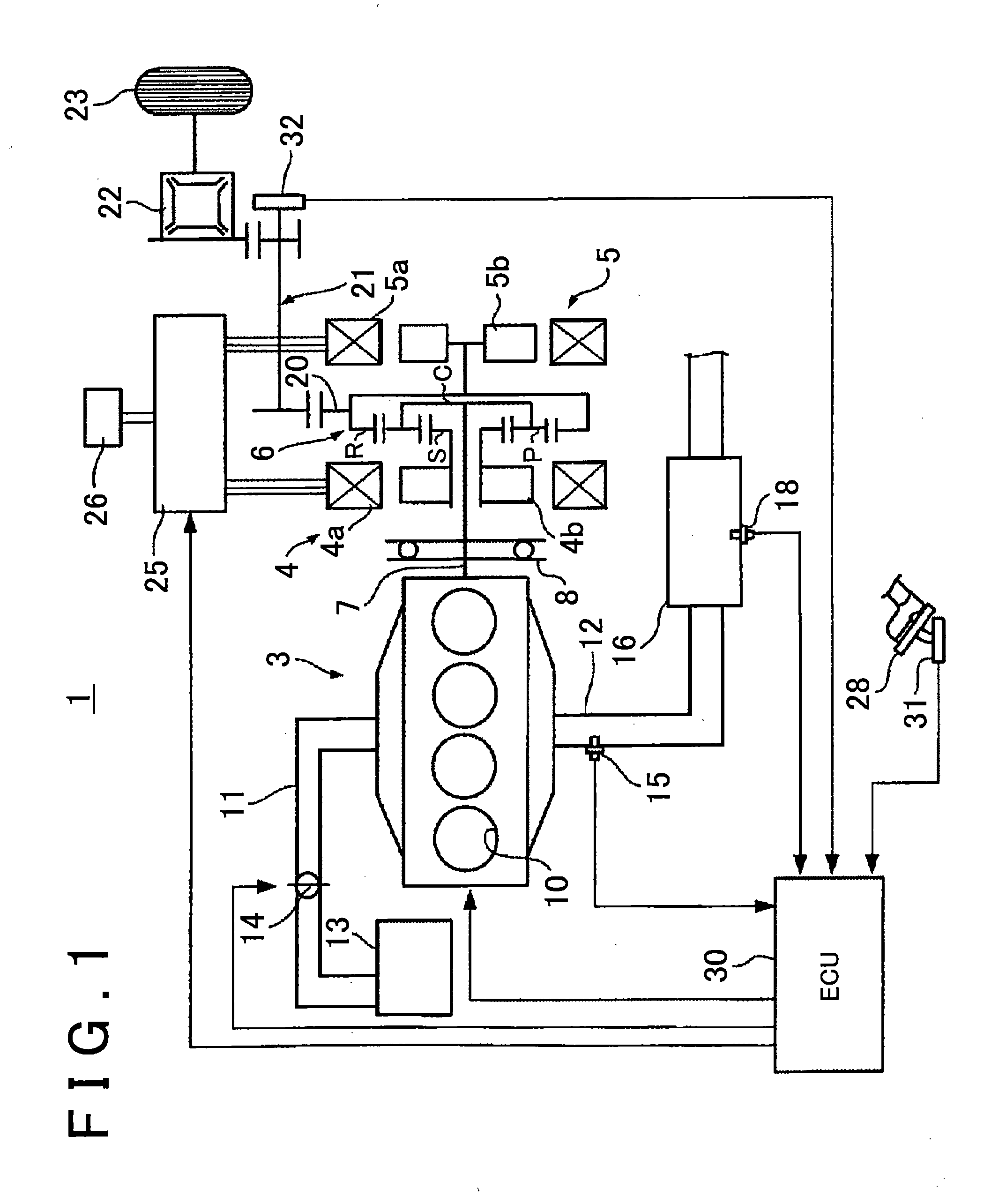

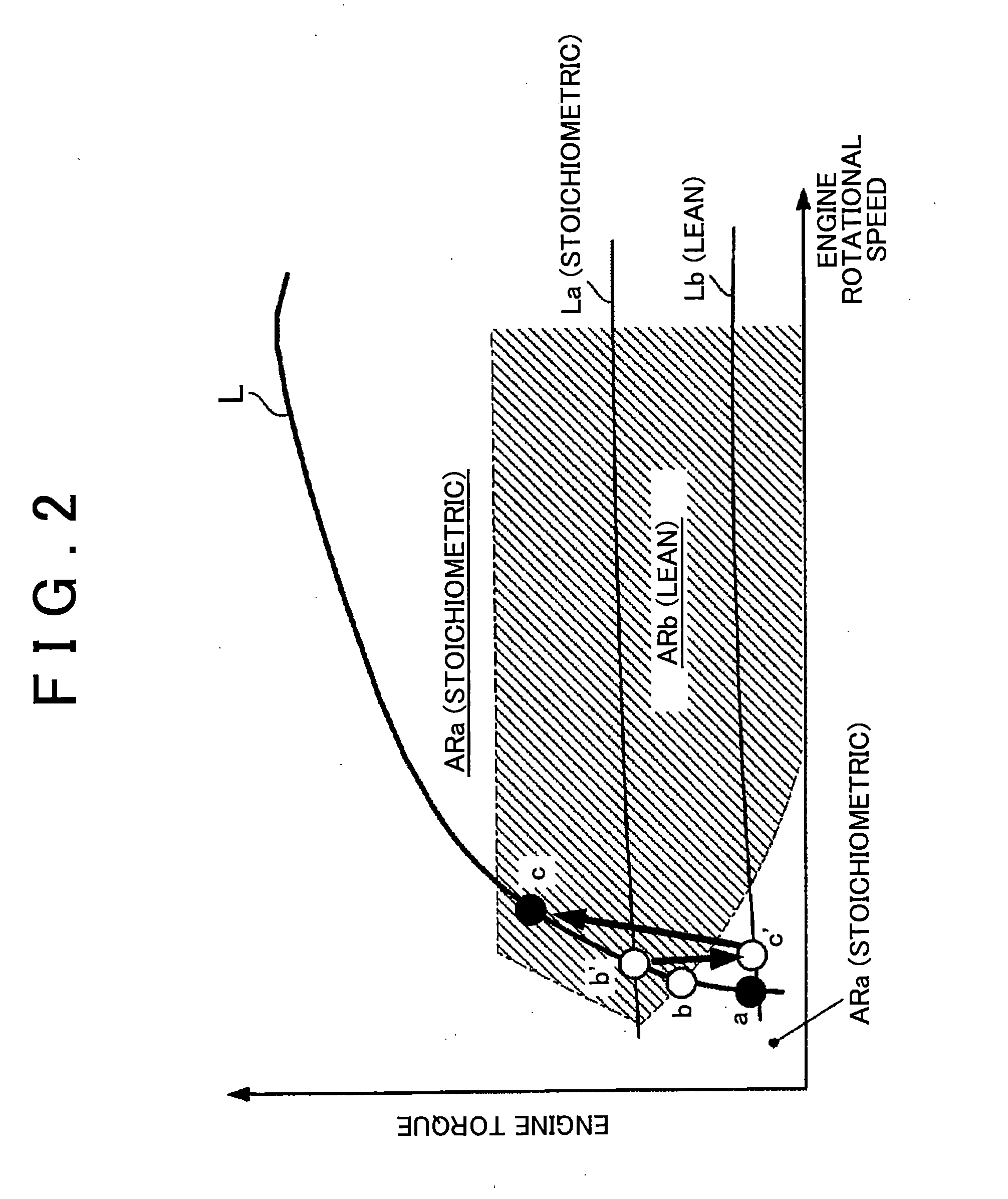

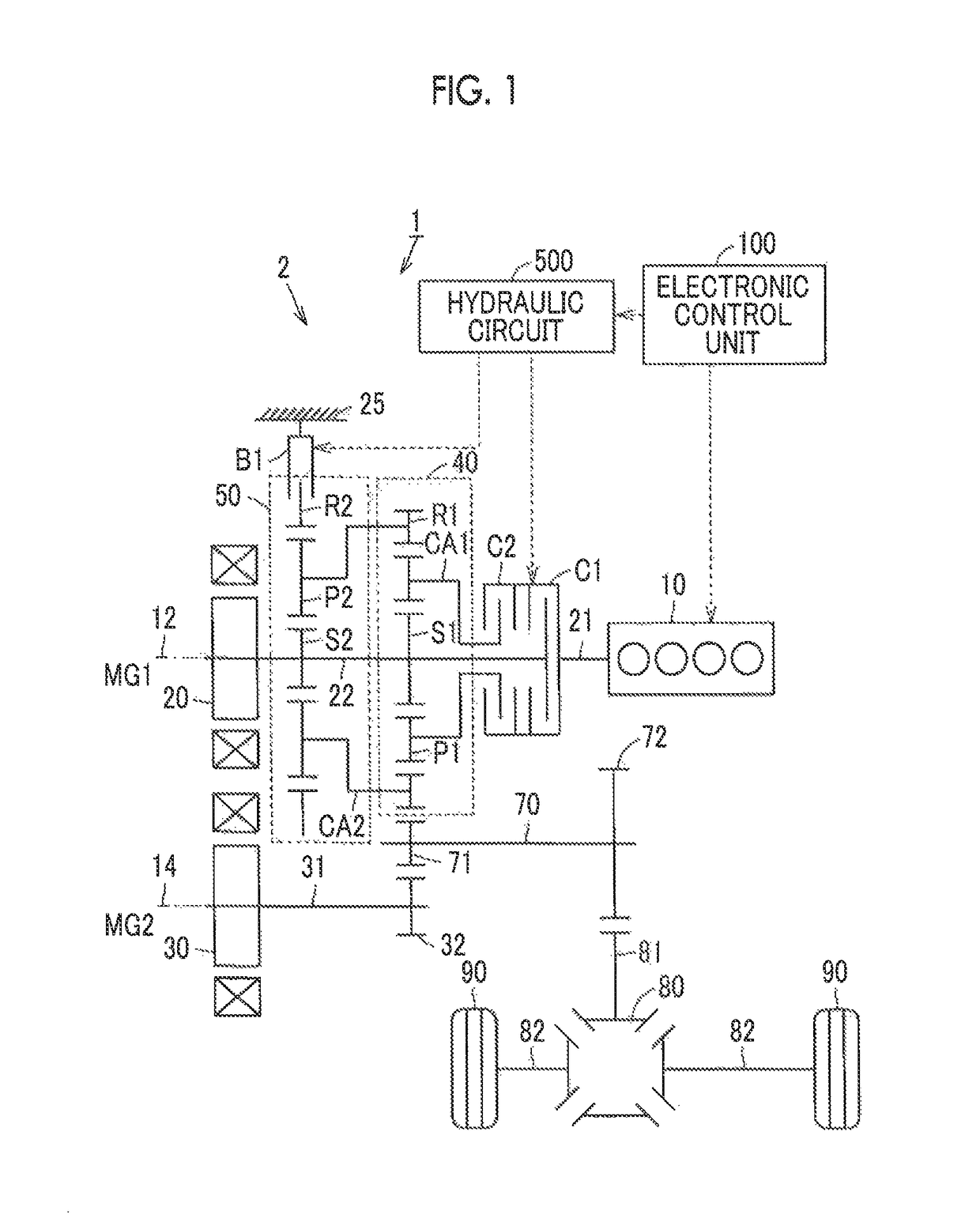

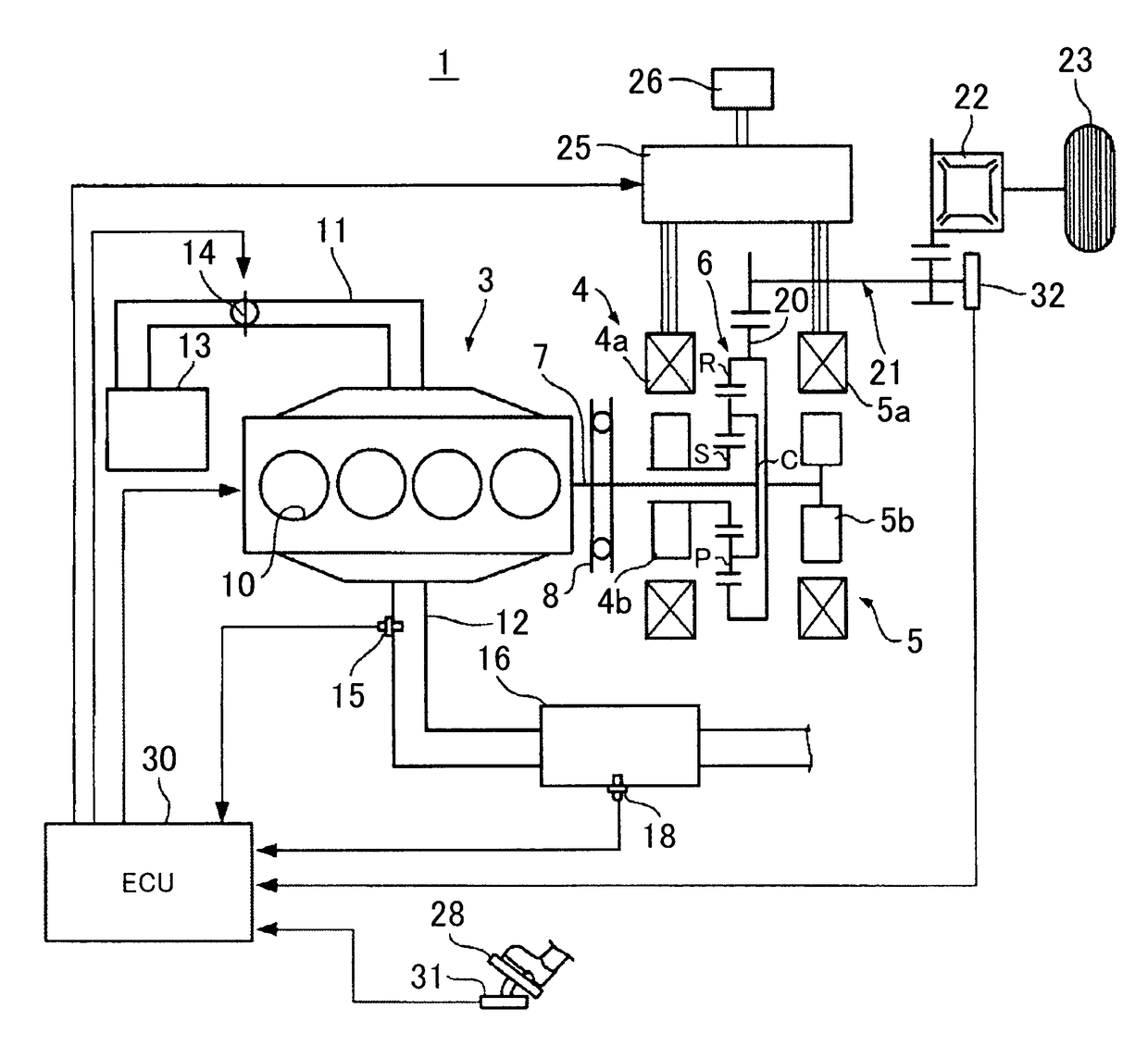

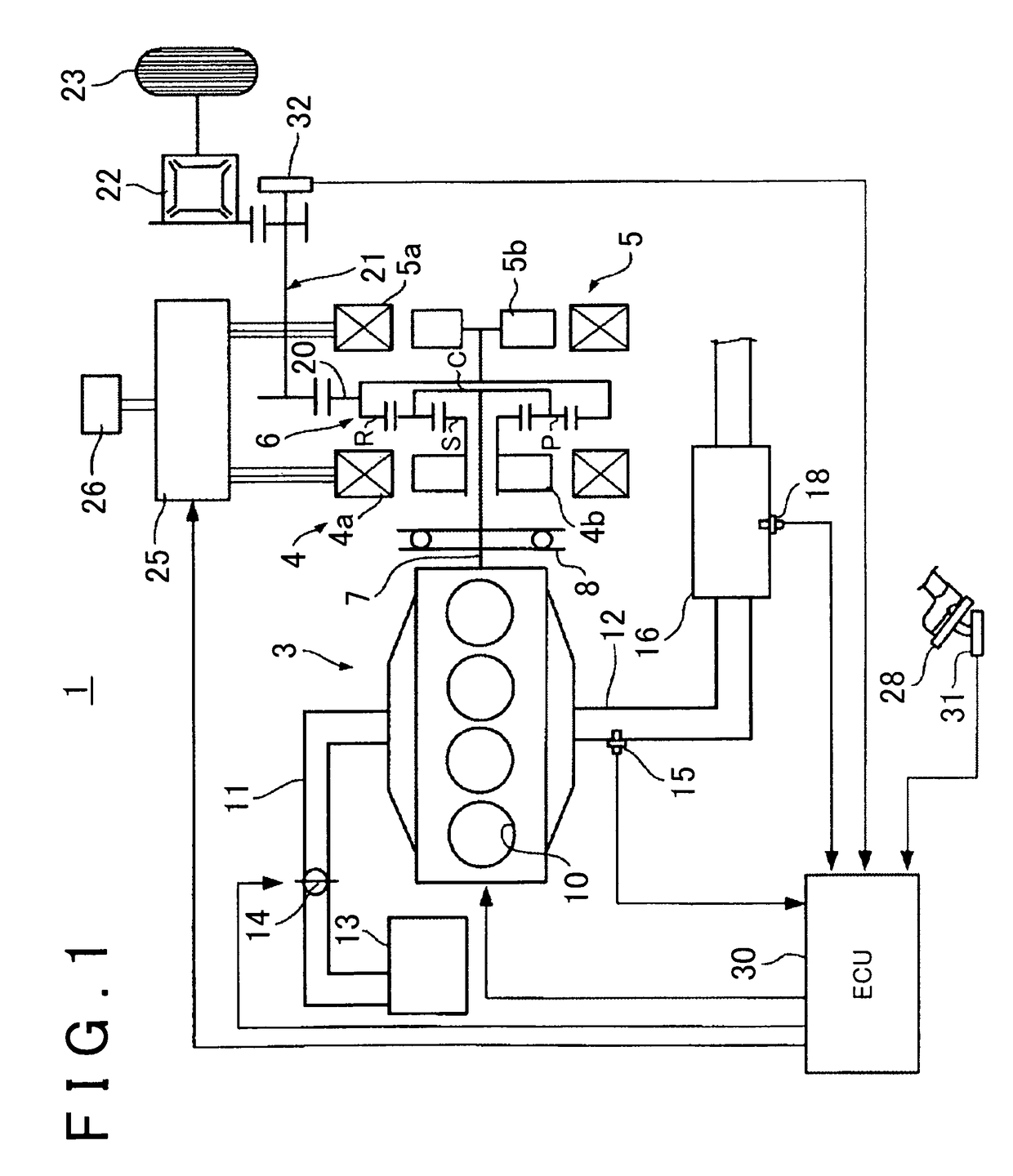

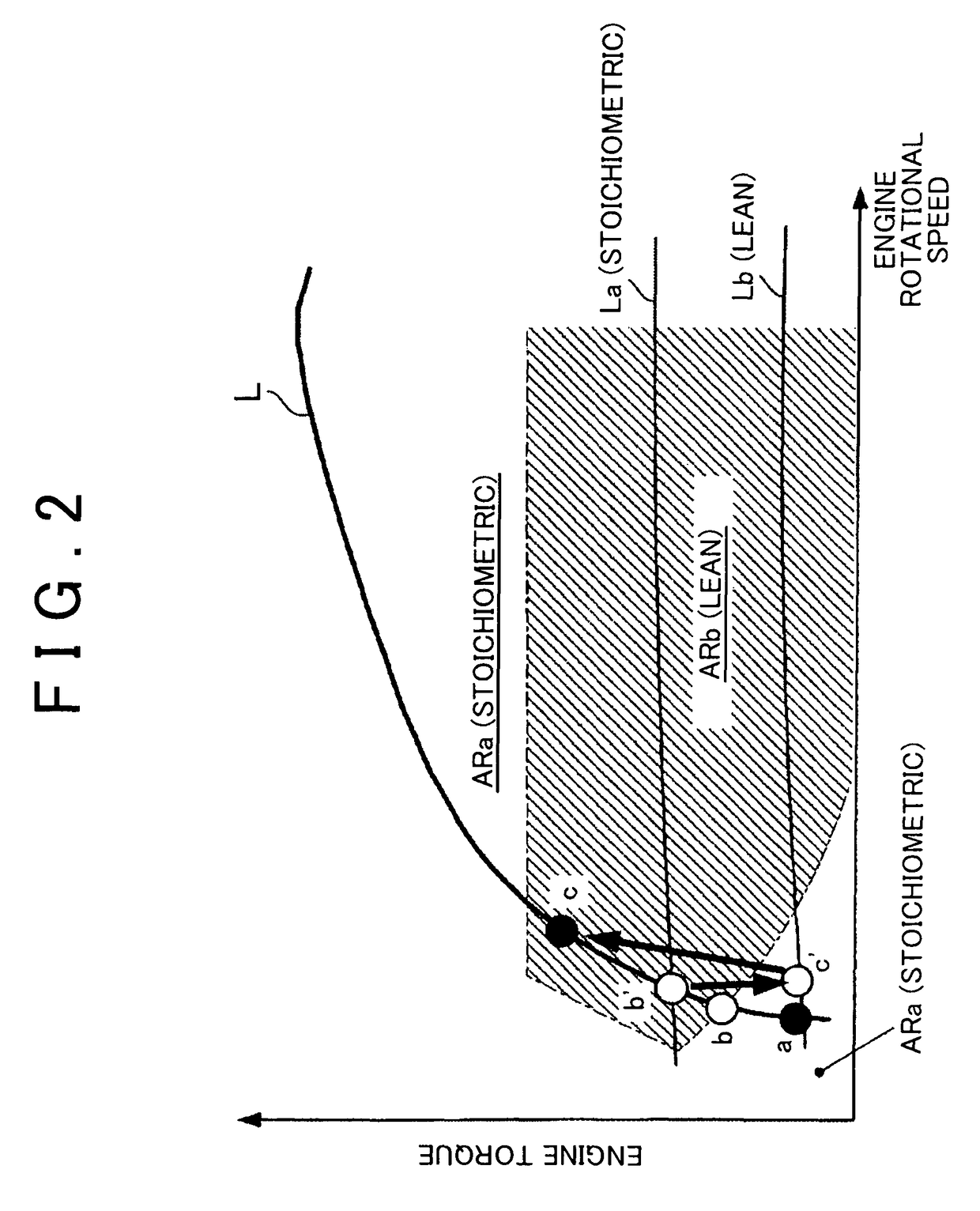

Control apparatus for internal combustion engine

ActiveUS20150377164A1Efficiency of internal can be restrained deterioratingMaintain thermal efficiencyHybrid vehiclesElectrical controlOperating pointExternal combustion engine

A control apparatus for an internal combustion engine is provided. The control apparatus includes an ECU. The ECU is configured to change, in a stepped manner, an air-fuel ratio of the internal combustion engine so as to change over a combustion mode of the internal combustion engine between lean combustion and stoichiometric combustion, when an operating point of the internal combustion engine satisfies a first changeover condition that is defined by a rotational speed and a torque of the internal combustion engine. The first changeover condition is defined by the rotational speed and the torque that correspond to a predetermined intake air amount at which a thermal efficiency of the internal combustion engine is maintained before and after changeover of the combustion mode.

Owner:TOYOTA JIDOSHA KK

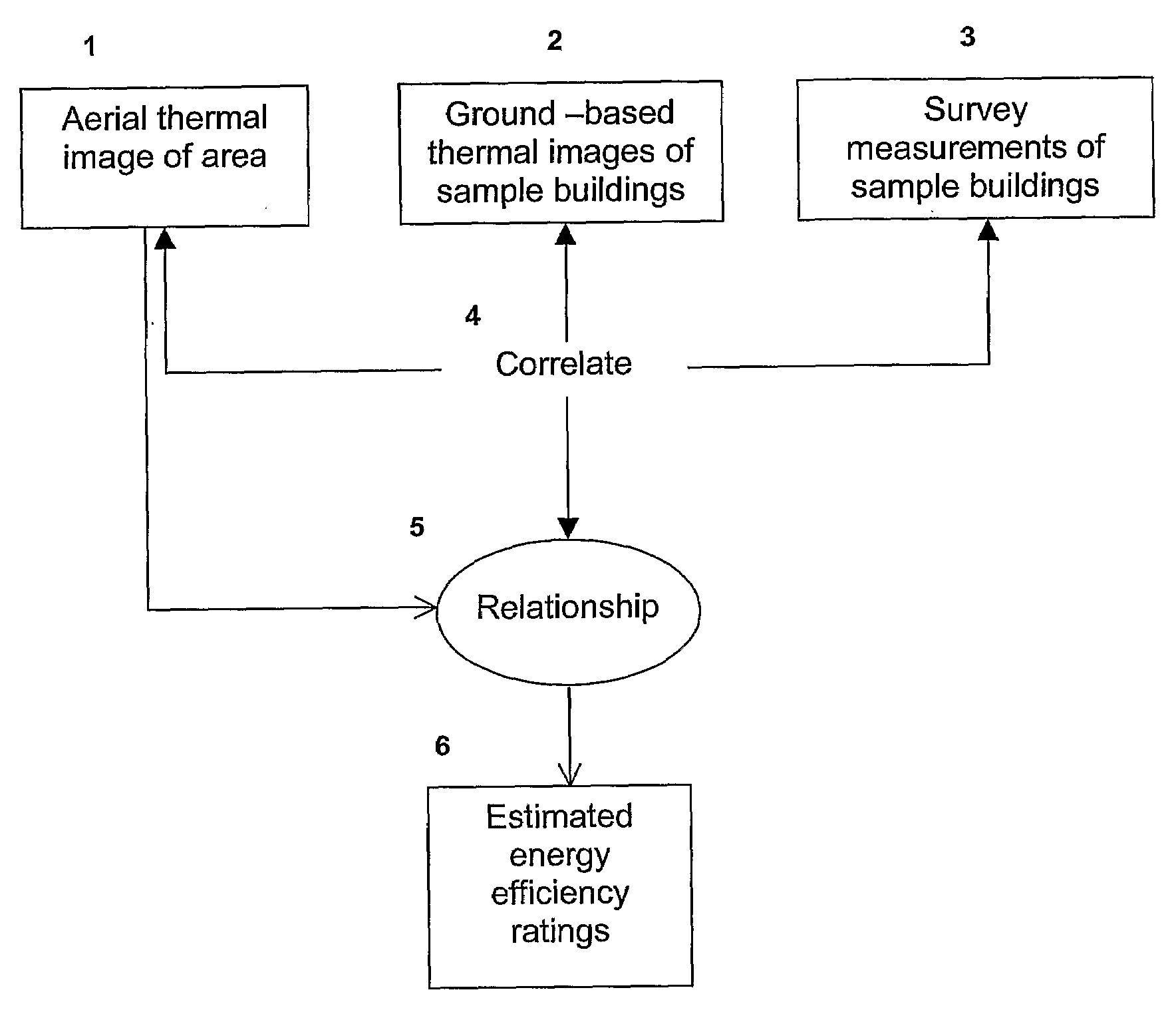

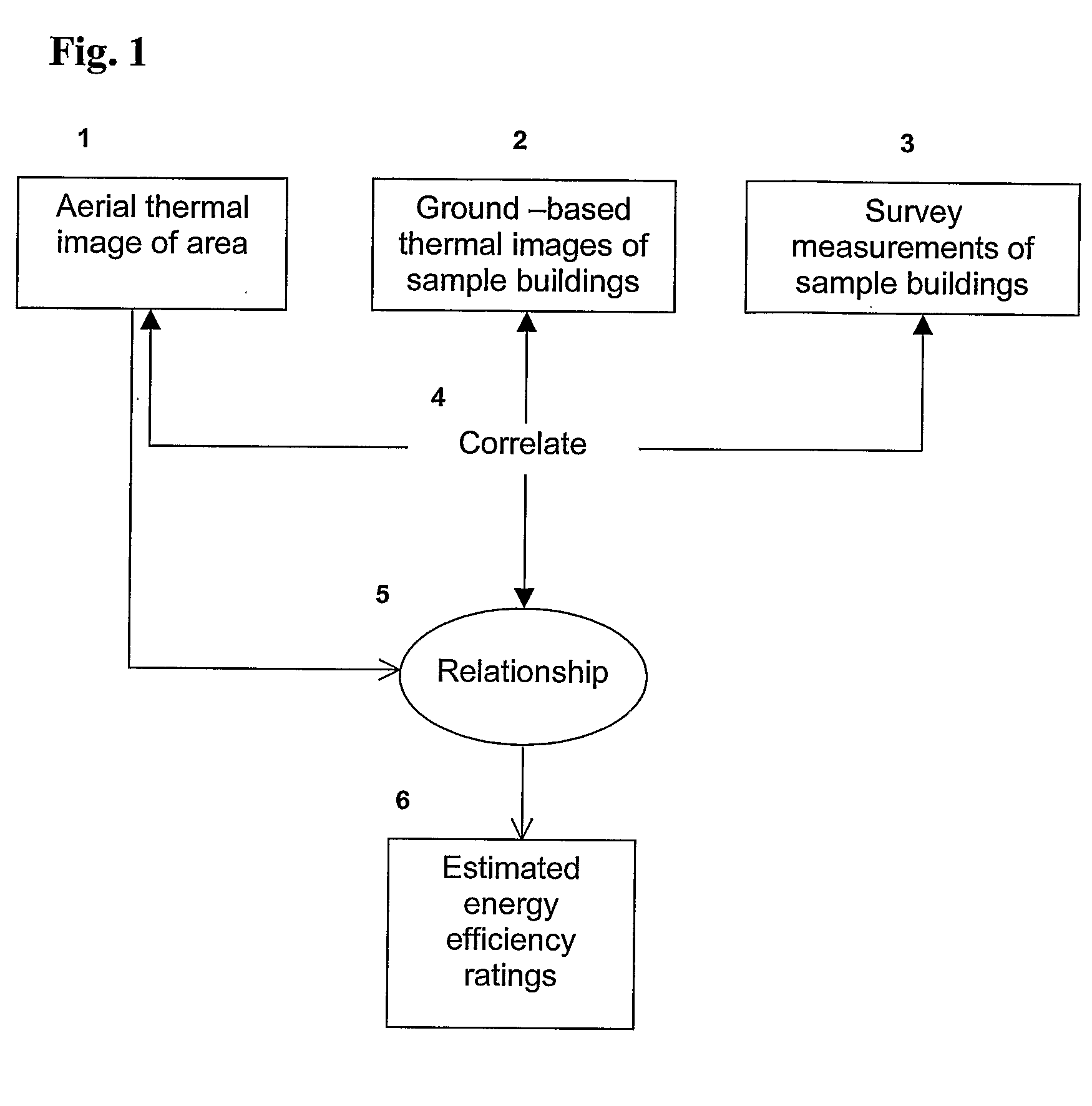

Method of Assessing Energy Efficiency of Buildings

InactiveUS20090210192A1Thermal efficiencyReduce thermal efficiencyTelevision system detailsRadiation pyrometryEngineeringThermal efficiency

A method of identifying, from an aerial thermal image (1) of a plurality of buildings within a predetermined area, those buildings having relatively low thermal efficiency, comprises performing ground-based measurements (2, 3) indicative of the thermal efficiency of a sample of the buildings; correlating (4) the ground-based measurements (2, 3) with the aerial thermal image (1) and estimating (6), on the basis of the correlation (5), which ones of the buildings, other than those of the sample, have relatively low thermal efficiency.

Owner:SPELTHORNE BOROUGH COUNCIL

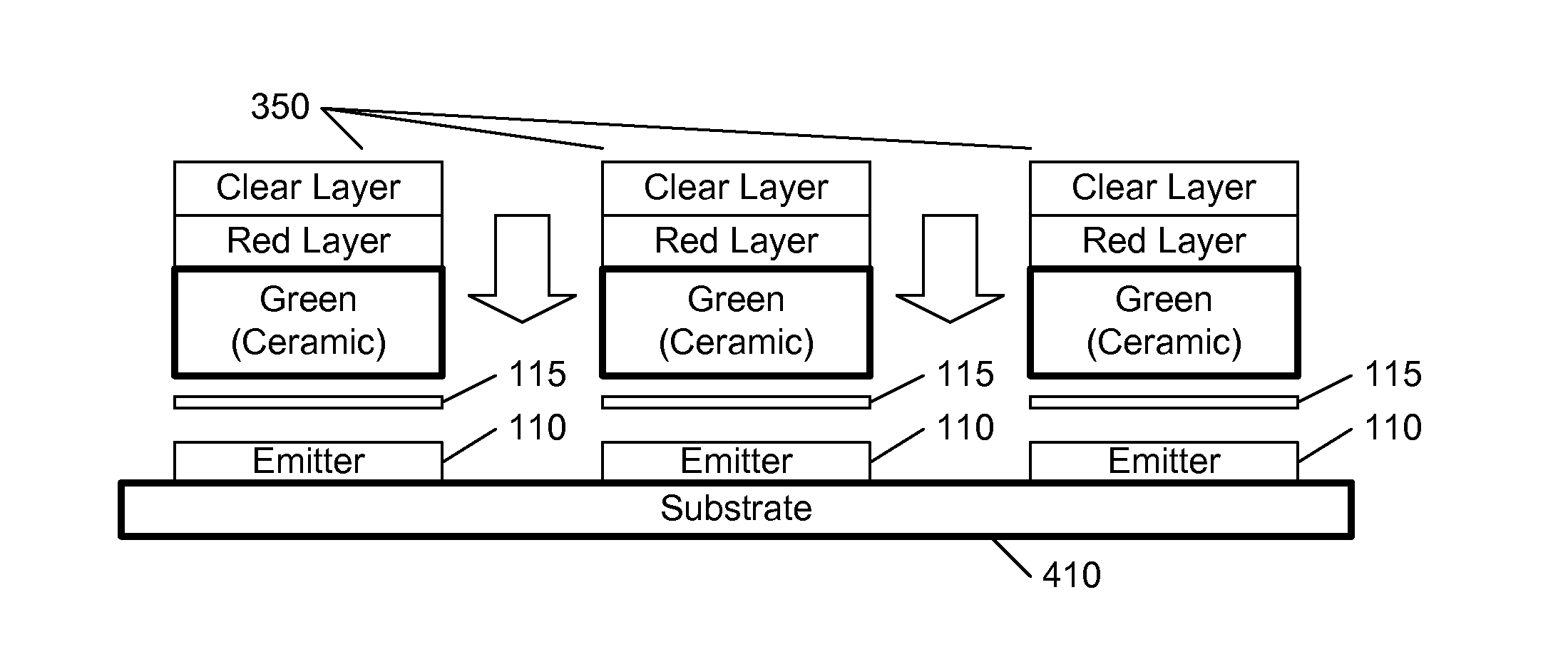

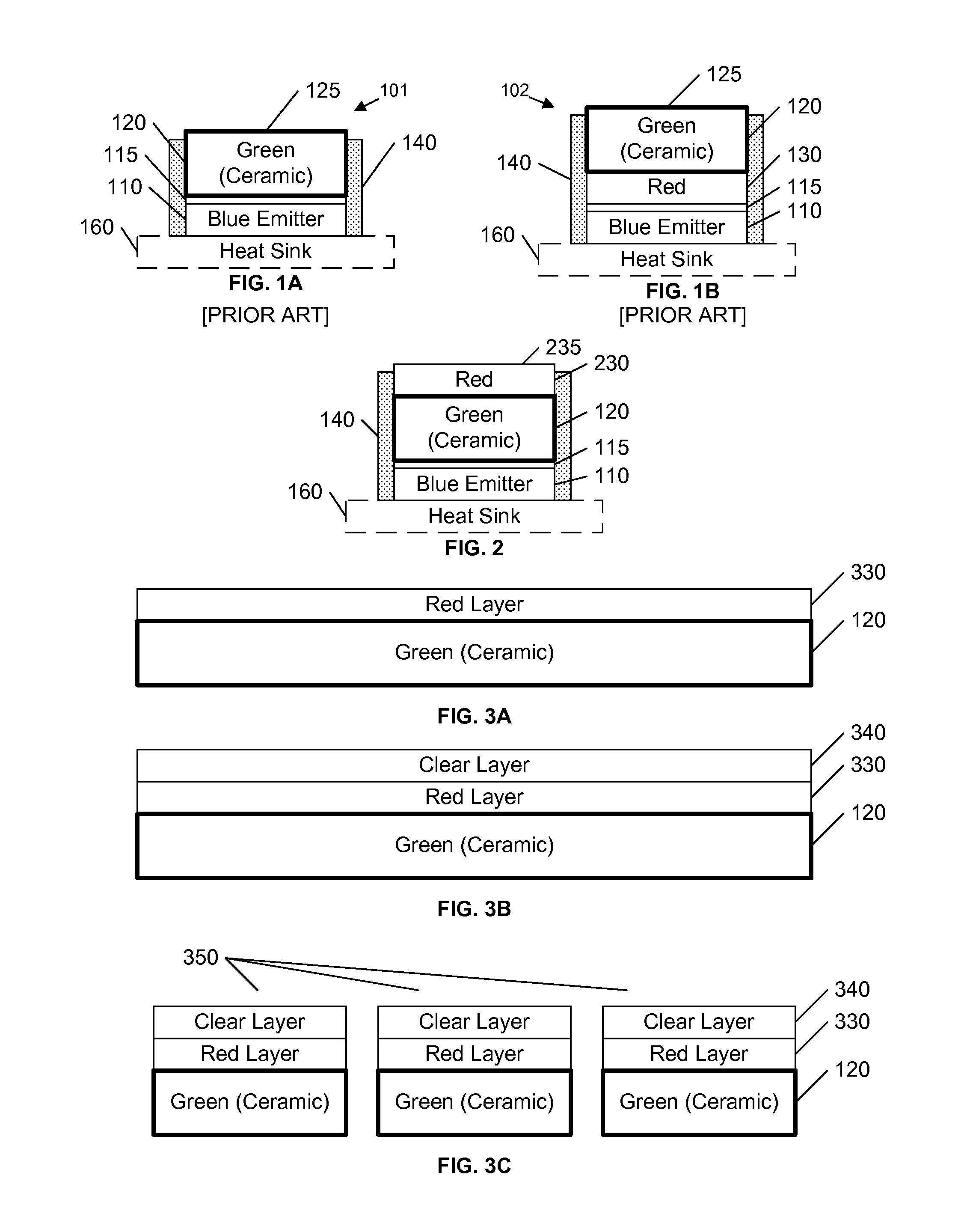

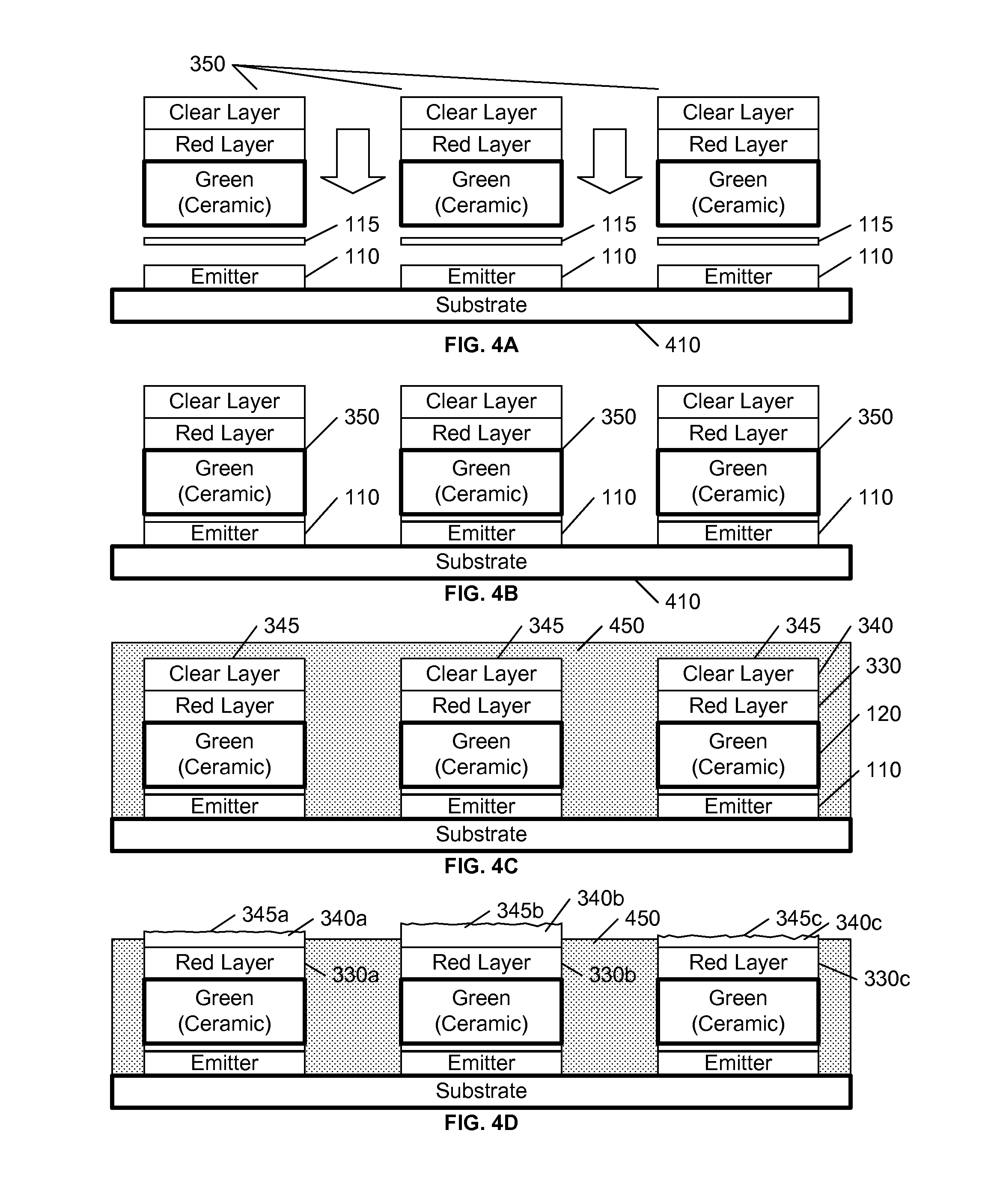

LED with ceramic green phosphor and protected red phosphor layer

ActiveUS20150188001A1Thermal efficiencyConsistent color temperatureSolid-state devicesSemiconductor/solid-state device manufacturingPhosphorWavelength conversion

A ceramic green wavelength conversion element (120) is coated with a red wavelength conversion material (330) and placed above a blue light emitting element (110) such that the ceramic element (120) is attached to the light emitting element (110), thereby providing an efficient thermal coupling from the red and green converters (330, 120) to the light emitting element (110) and its associated heat sink. To protect the red converter coating (330) from the effects of subsequent processes, a sacrificial clear coating (340) is created above the red converter element (330). This clear coating (340) may be provided as a discrete layer of clear material, or it may be produced by allowing the red converters to settle to the bottom of its suspension material, thereby forming a converter-free upper layer that can be subjected to the subsequent fabrication processes.

Owner:LUMILEDS

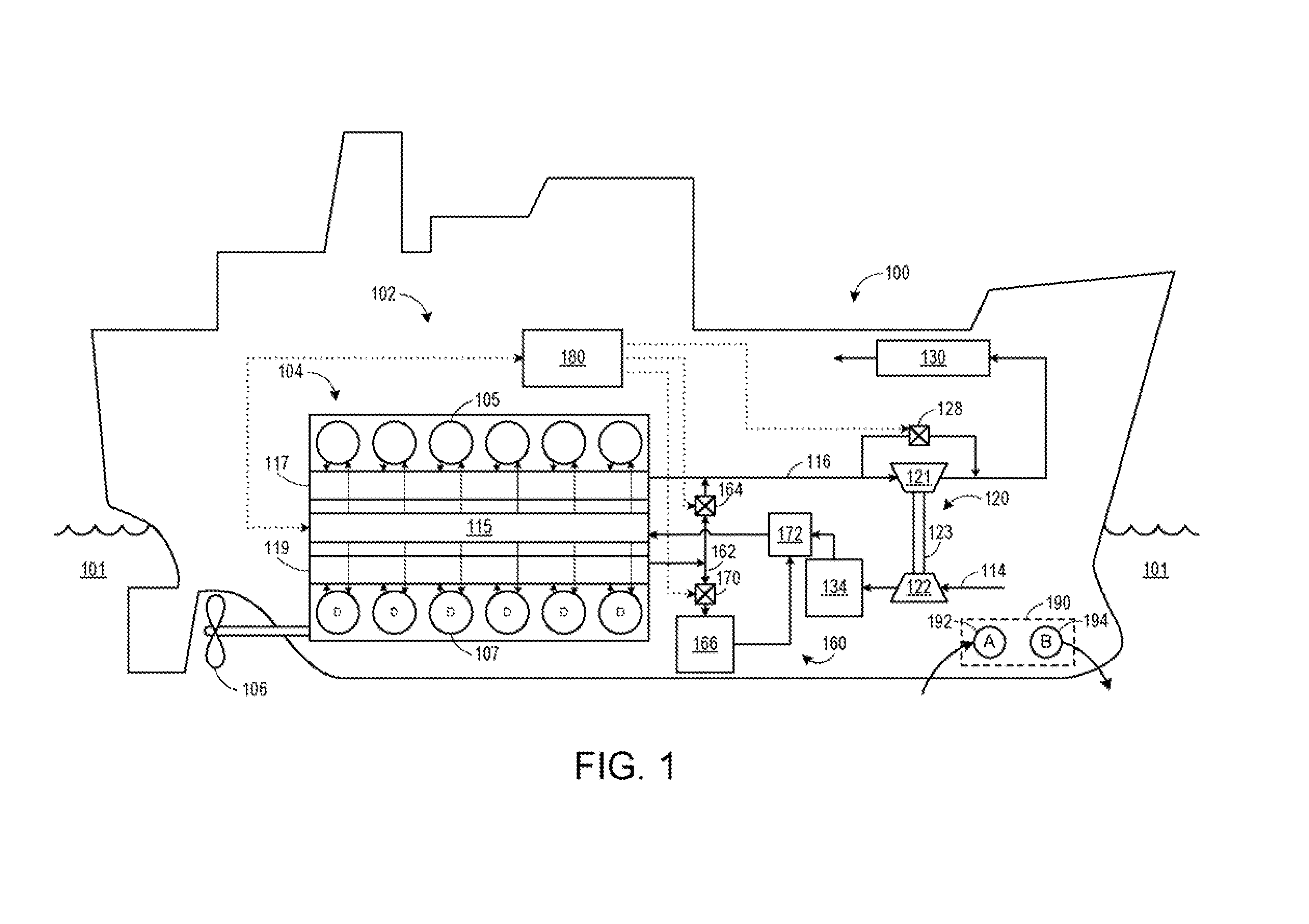

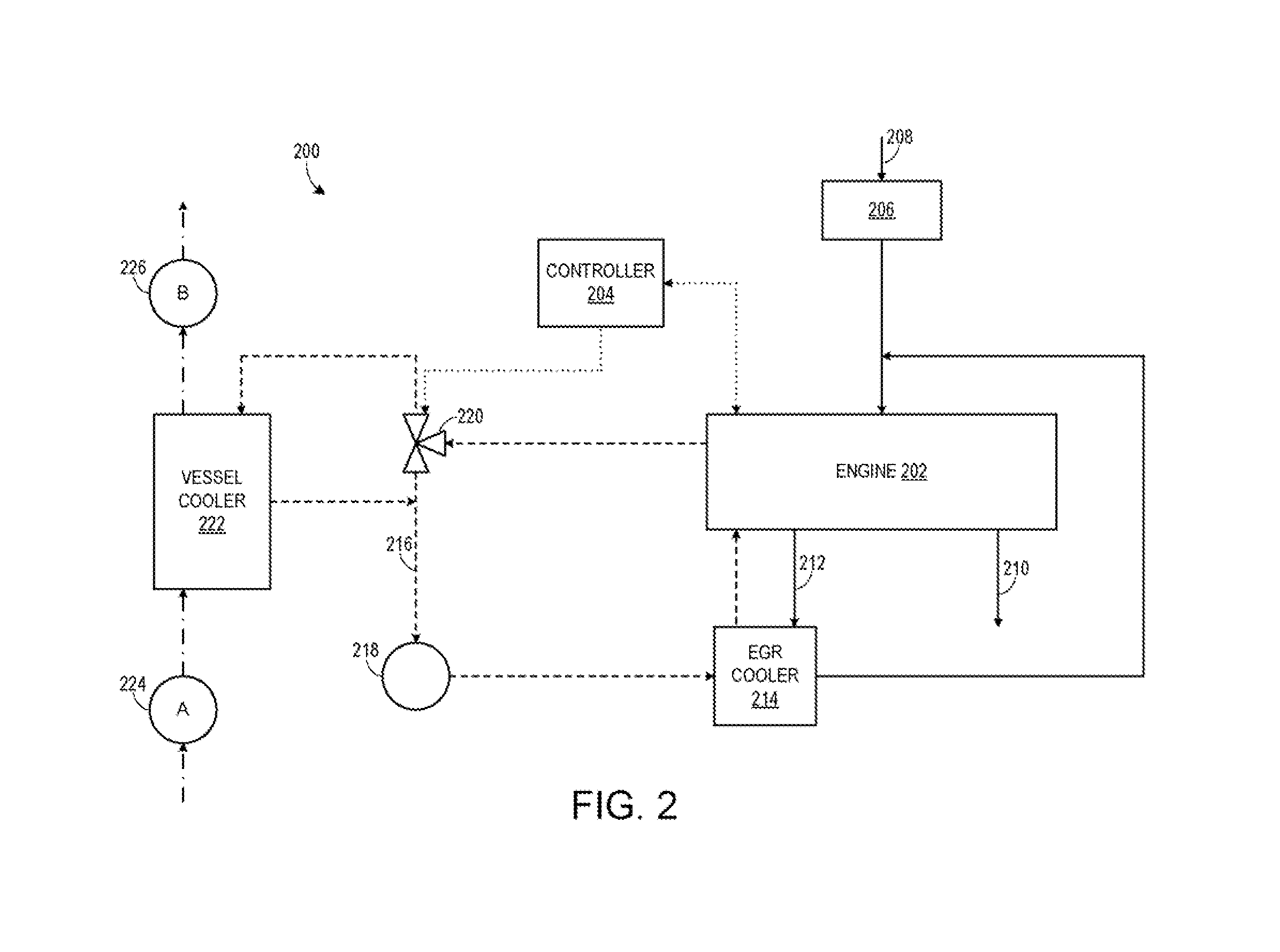

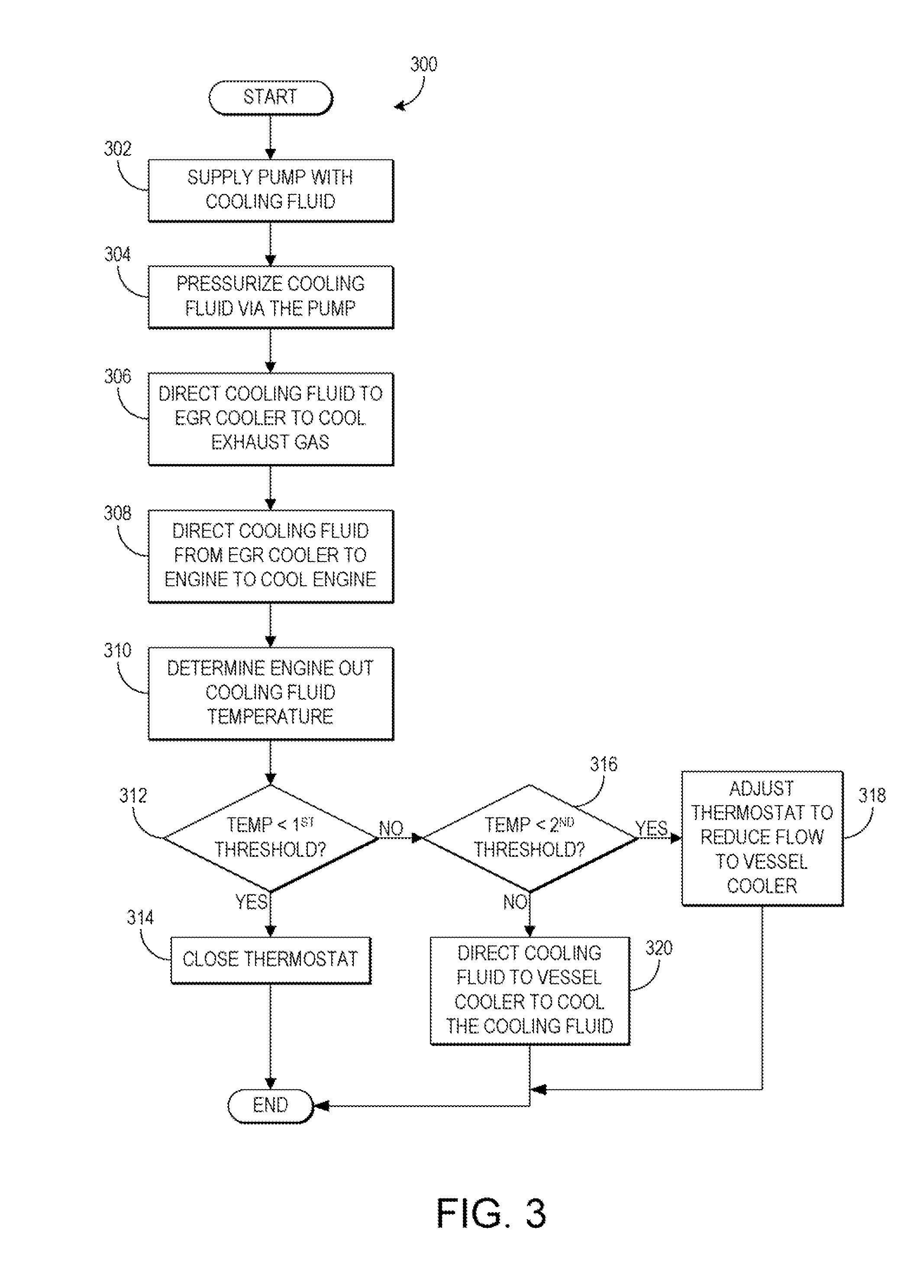

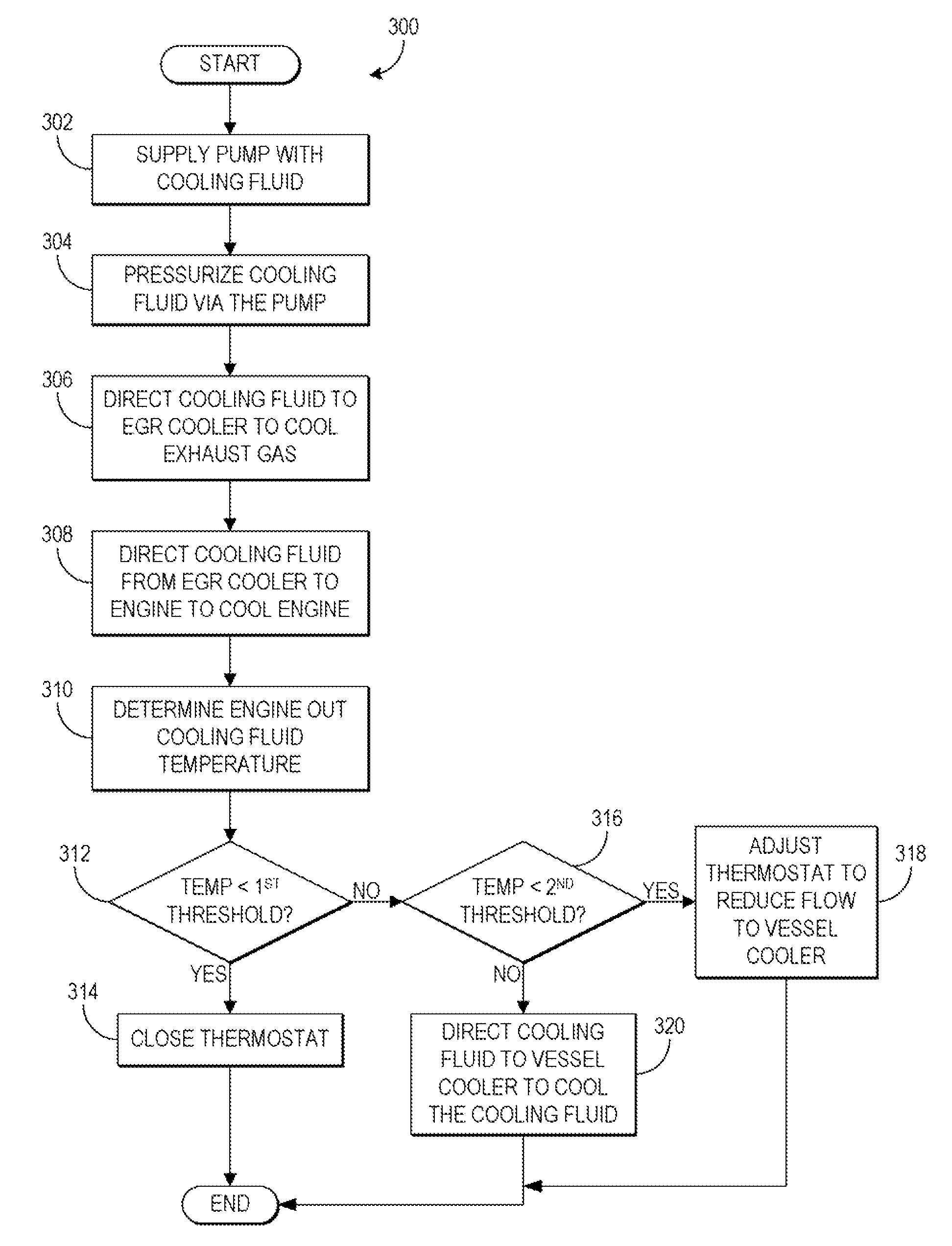

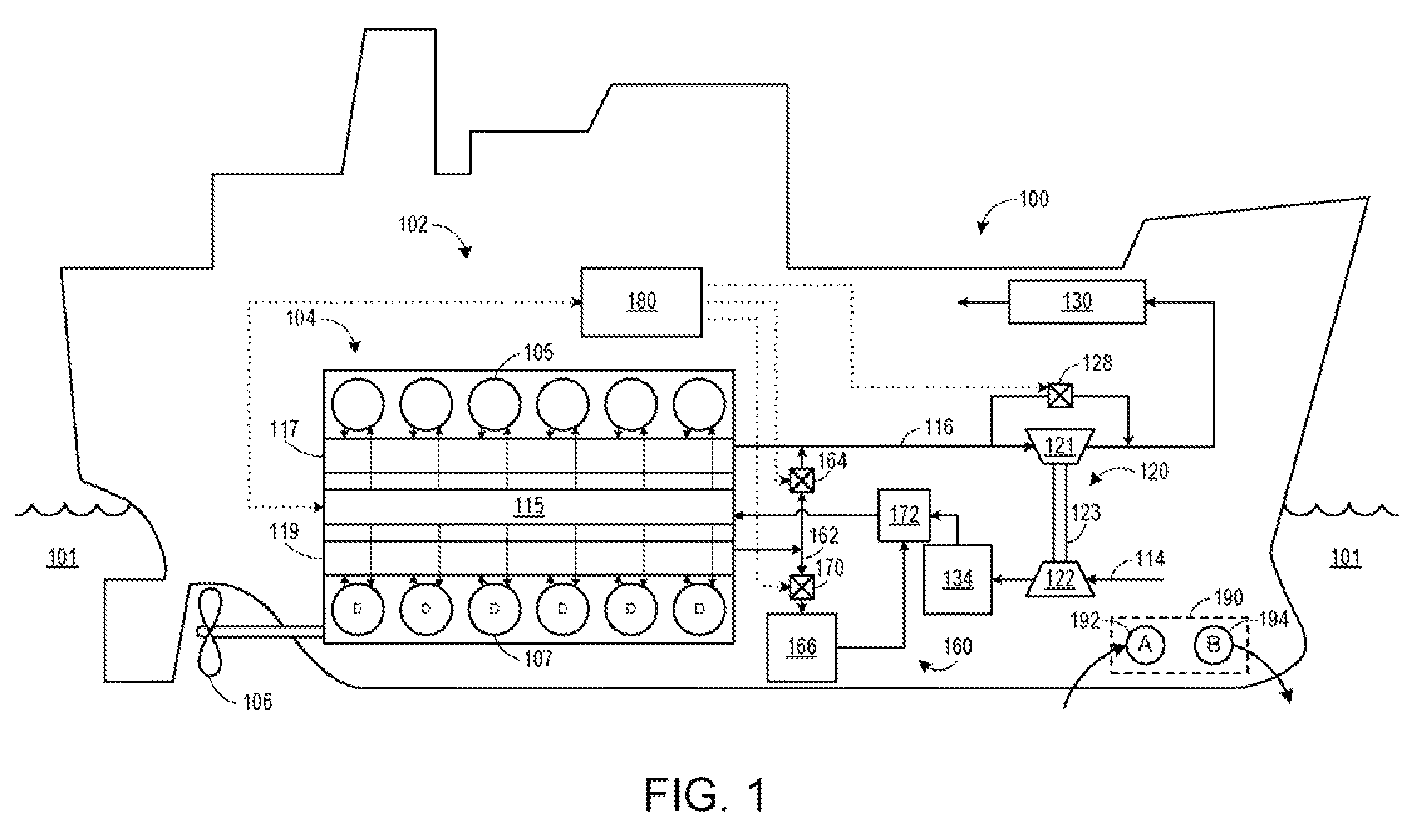

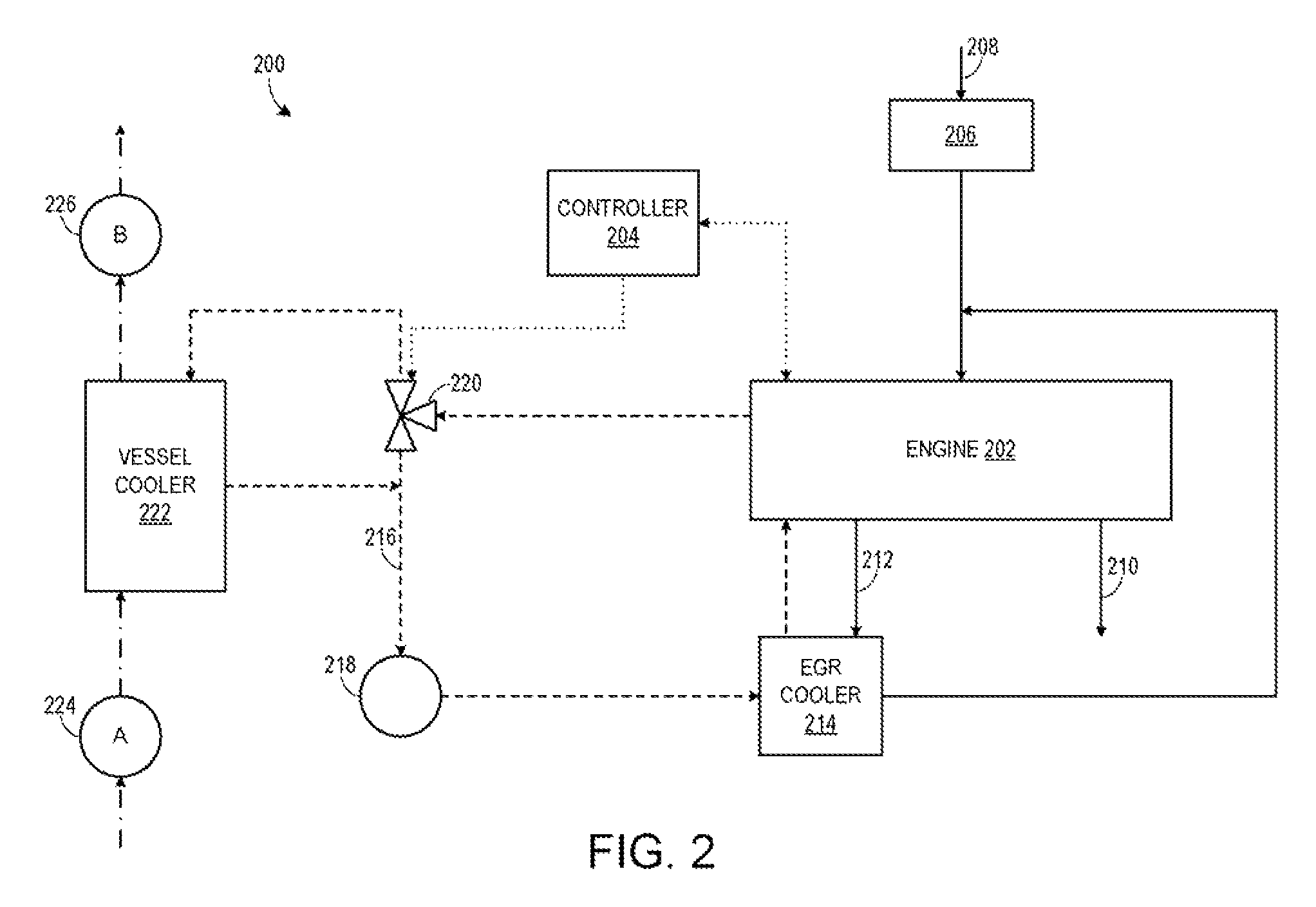

Systems and methods for a cooling fluid circuit

ActiveUS20140014076A1Increase temperatureThermal efficiencyCoolant flow controlNon-fuel substance addition to fuelExhaust fumesExhaust gas recirculation

Various methods and systems are provided for cooling an engine system. In one example, a system includes an exhaust gas recirculation cooler and an engine. The system further includes a cooling fluid circuit in which the exhaust gas recirculation cooler and the engine are positionable in series with the exhaust gas recirculation cooler disposed upstream of the engine.

Owner:GE GLOBAL SOURCING LLC

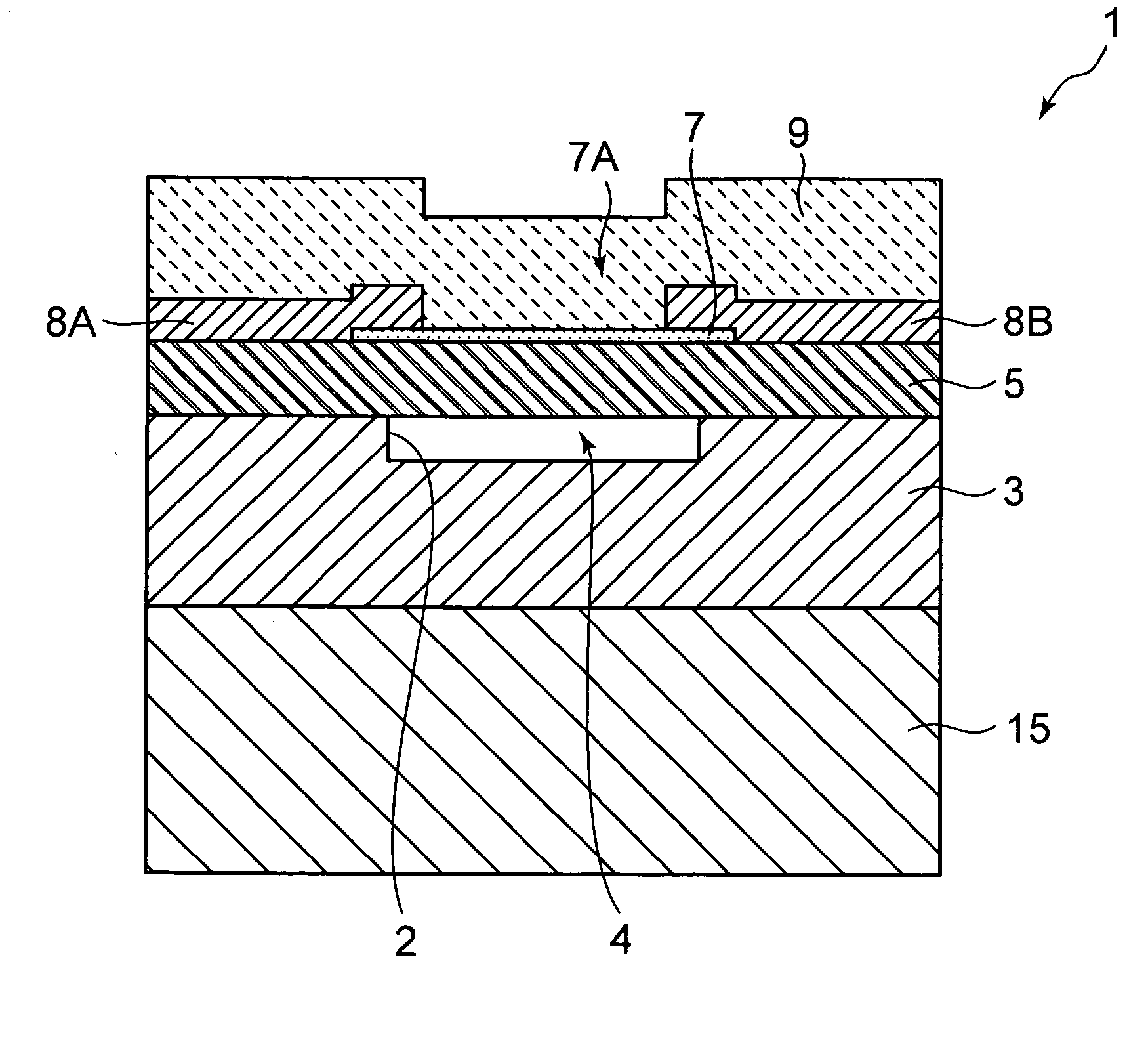

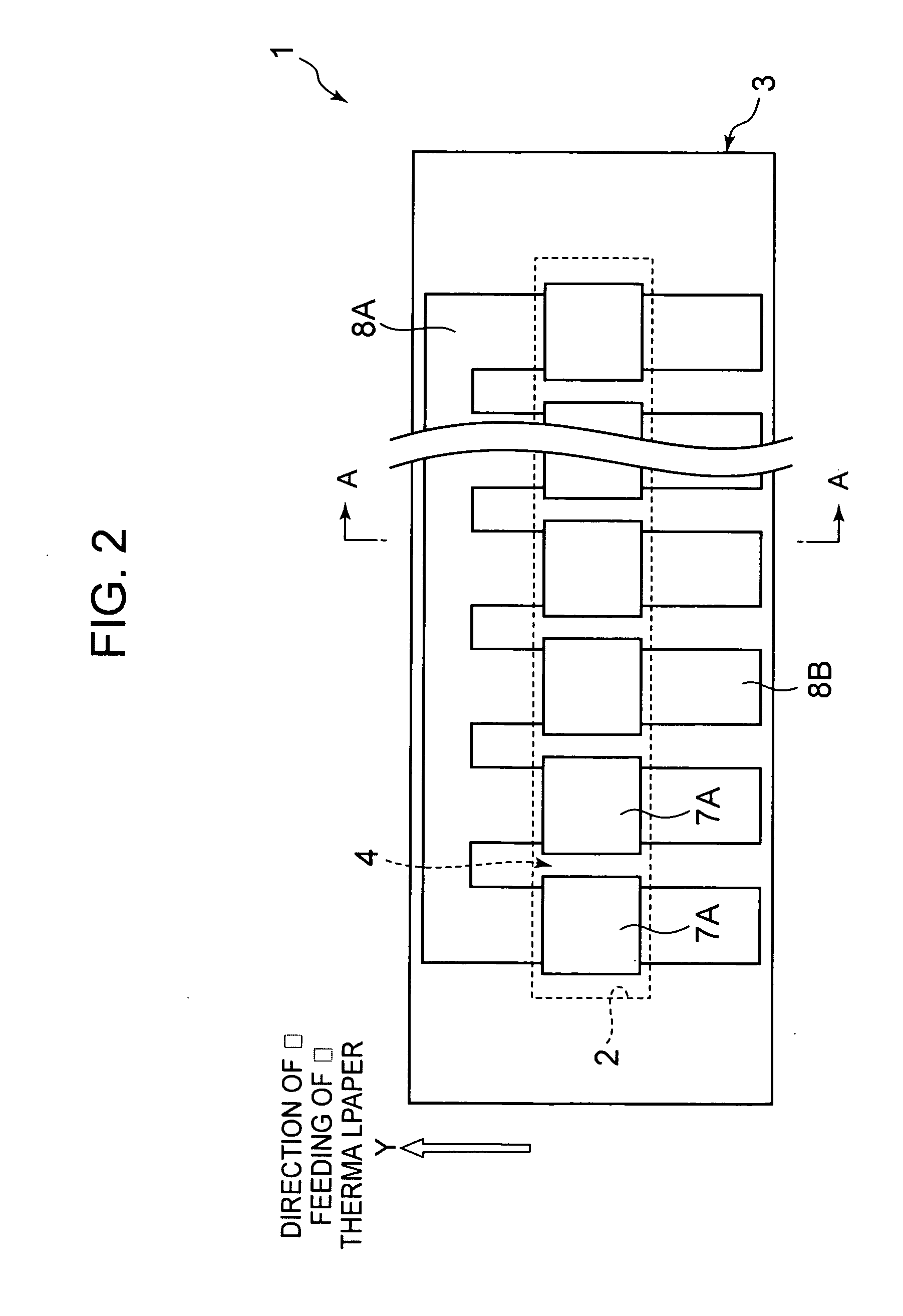

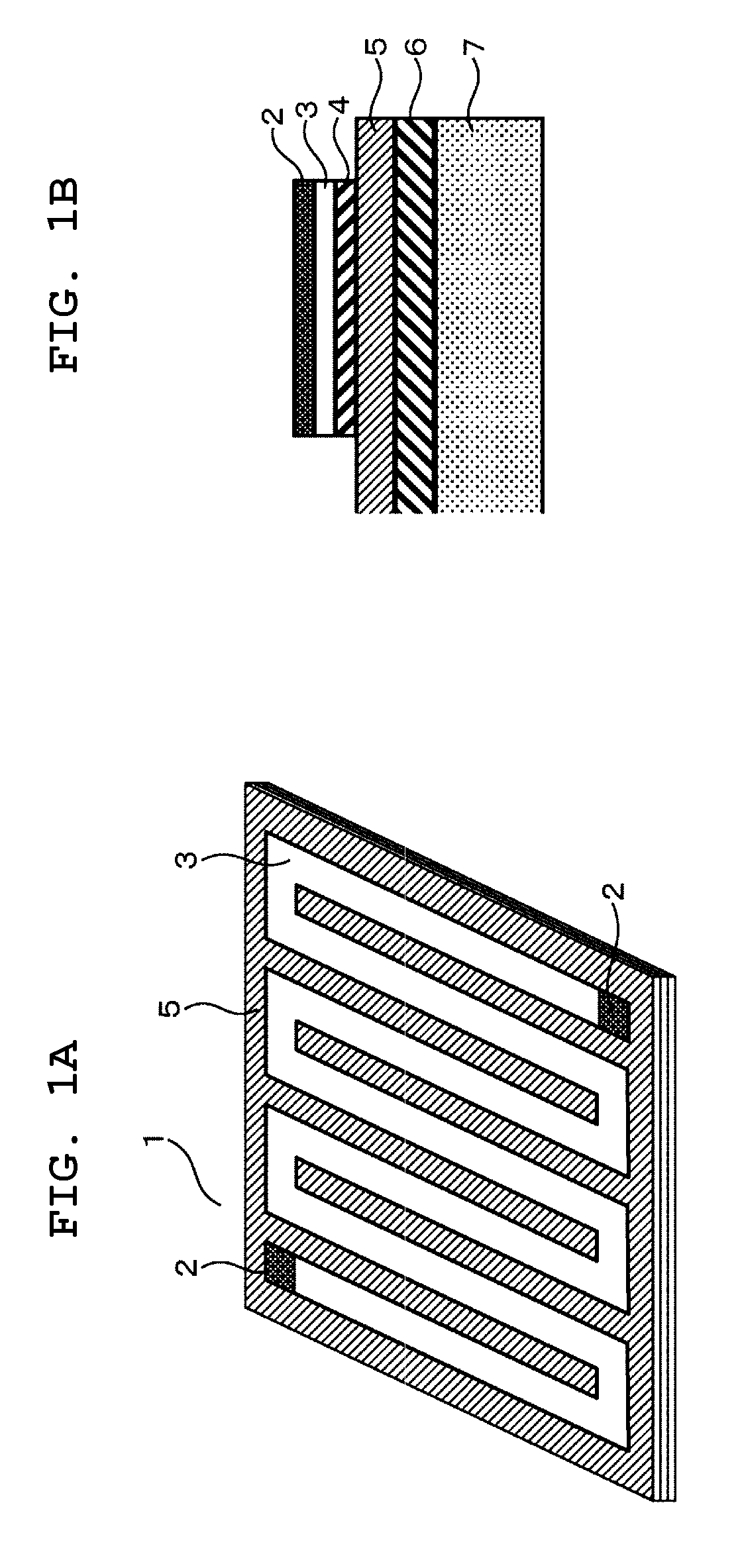

Thermal head and printer

InactiveUS20110025808A1Reduce the amount requiredImprove thermal efficiencyPrintingHeat sensitiveEngineering

Provided is a thermal head in which, even when an upper plate substrate and a lower plate substrate are in a bonded state, a thickness of the upper plate substrate is adjusted to an appropriate value to allow an improvement in thermal efficiency. Adopted is a thermal head including: a support substrate; an upper plate substrate having a back surface thereof bonded to a top surface of the support substrate; a heating resistor provided on the upper plate substrate; a concave portion formed in a region of at least one of the top surface of the support substrate and the back surface of the upper plate substrate, which opposes the heating resistor; and a through portion formed in the upper plate substrate, which passes through the upper plate substrate from a top surface of the upper plate substrate to the top surface of the support substrate in a plate thickness direction.

Owner:SEIKO INSTR INC

Reformer

InactiveUS8038960B2Improve thermal efficiencyReduce radiation doseCombustible gas chemical modificationHydrogenCombustorProcess engineering

A reformer that produces reformed gas from a hydrocarbon material includes a reforming chamber having an inner cylinder and an outer cylinder; a reforming catalyst filled in the reforming chamber; a burner that heats the reforming catalyst and fuel of reformed gas; a combustion gas outer flow channel through which combustion gas of the burner flows along an outer side surface of the reforming chamber; a combustion gas inner flow channel through which the combustion gas of the burner flows along an inner side surface of the reforming chamber; and a plurality of return pipes as a reformed gas flow channel.

Owner:IDEMITSU KOSAN CO LTD

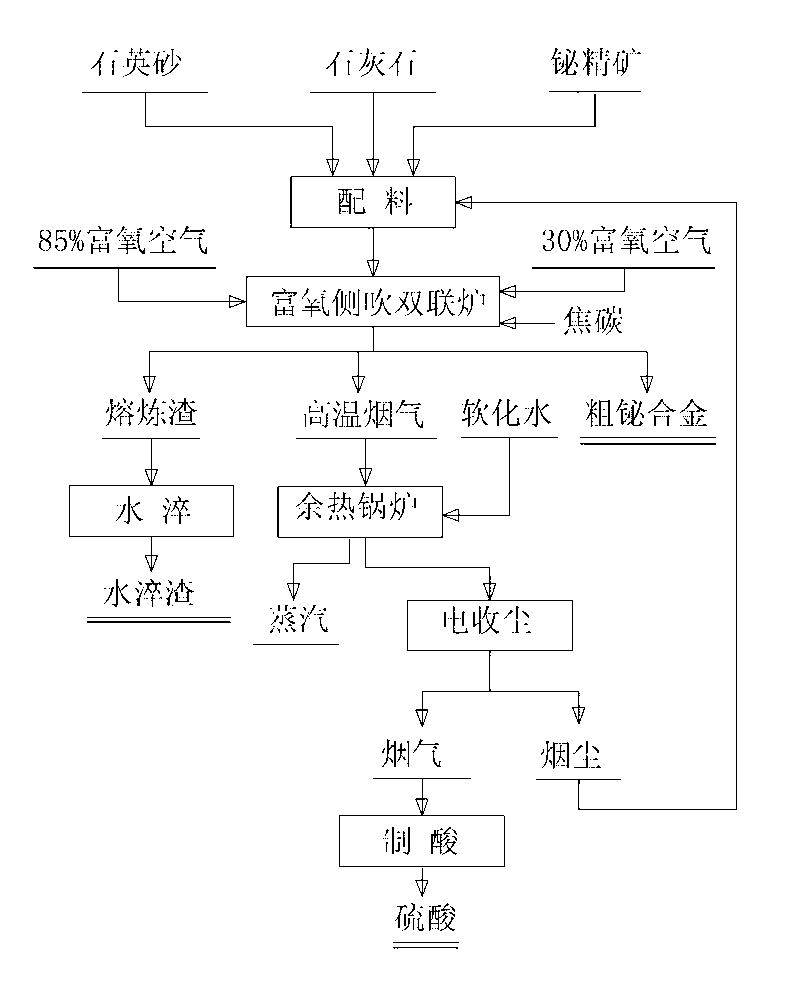

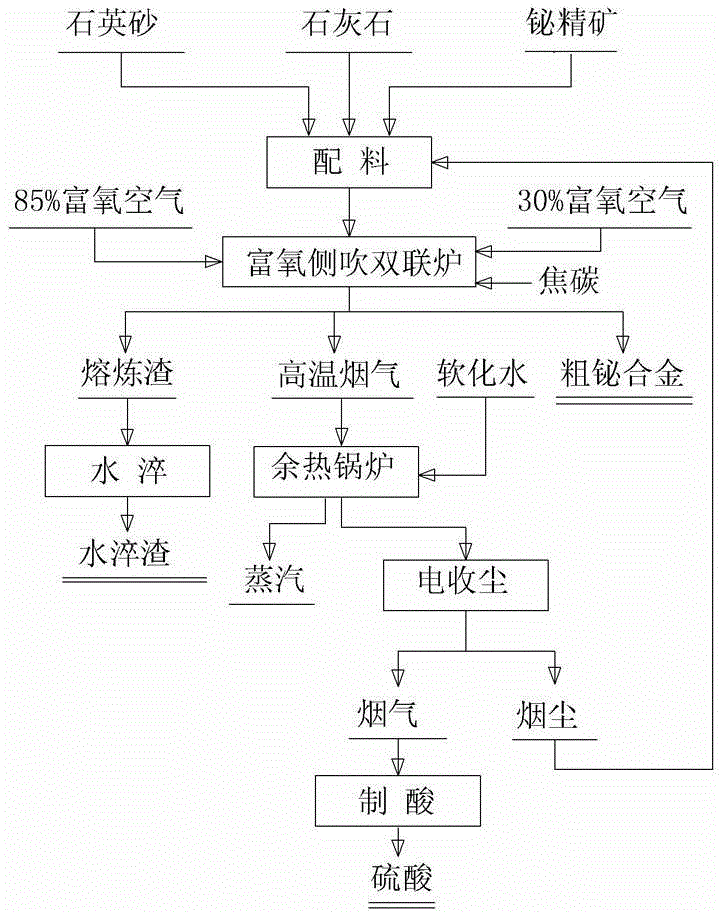

Method for smelting lead-bismuth concentrate in oxygen-rich side-blown duplex furnace

InactiveCN103060578AImprove direct yieldThe melting process is simpleProcess efficiency improvementLead bismuthFlue gas

The invention discloses a method for smelting a lead-bismuth concentrate in an oxygen-rich side-blown duplex furnace, belonging to the technical field of smelting bismuth concentrates. The method comprises the steps of preparing raw materials, and smelting in the oxygen-rich side-blown oxidation-reduction duplex furnace to directly produce a crude bismuth alloy. According to the method, scrap iron is not required to be added, so that the production cost is low; the concentration of SO2 in flue gases generated from oxidizing smelting reaches 10 to 25 percent, and the SO2 can be recycled to prepare acid, so that the problem of environmental pollution caused by the flue gases is solved; and the oxidation-reduction duplex smelting ensures that the direct yield of bismuth is greatly promoted.

Owner:HUNAN JINWANG BISMUTH

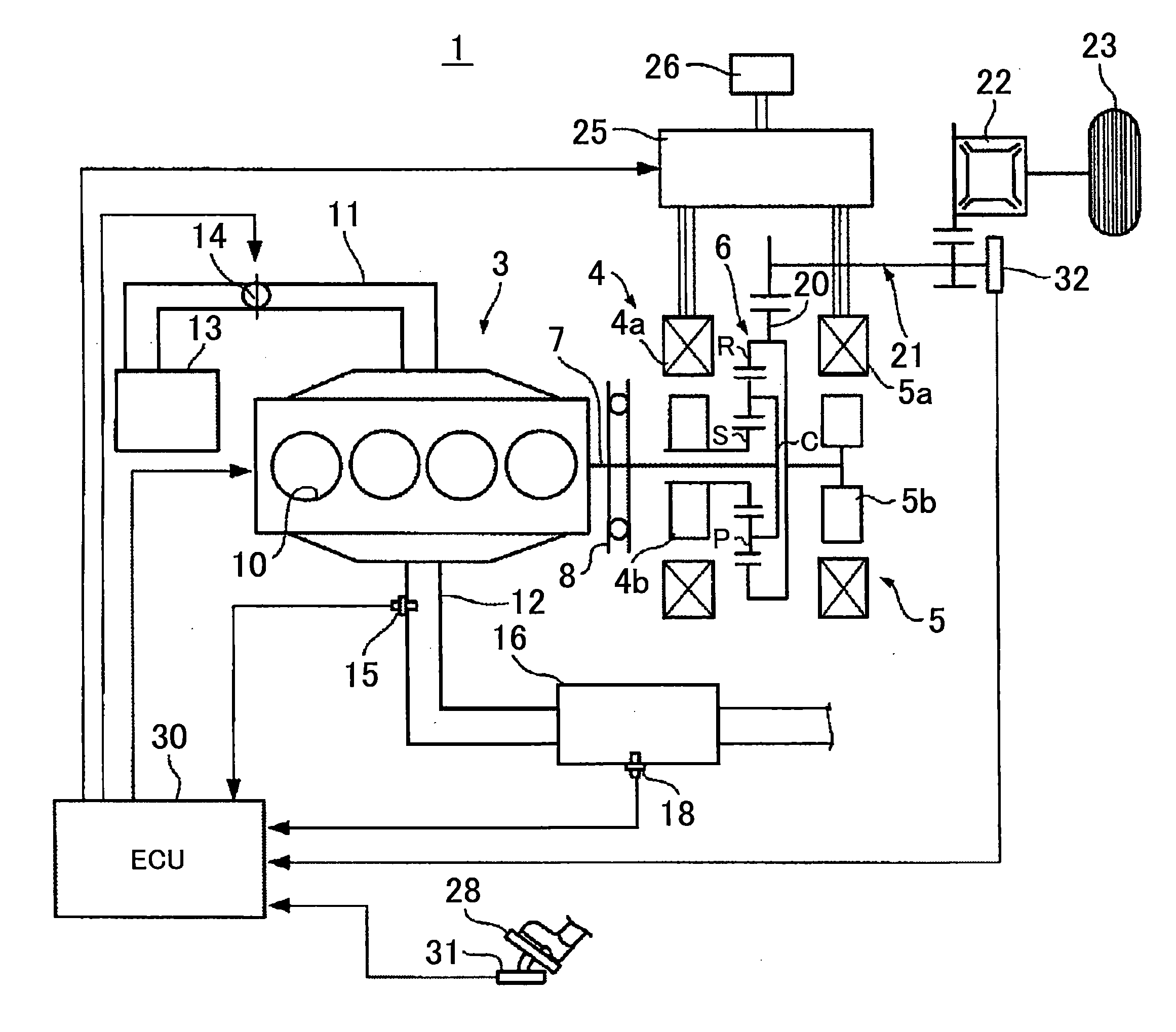

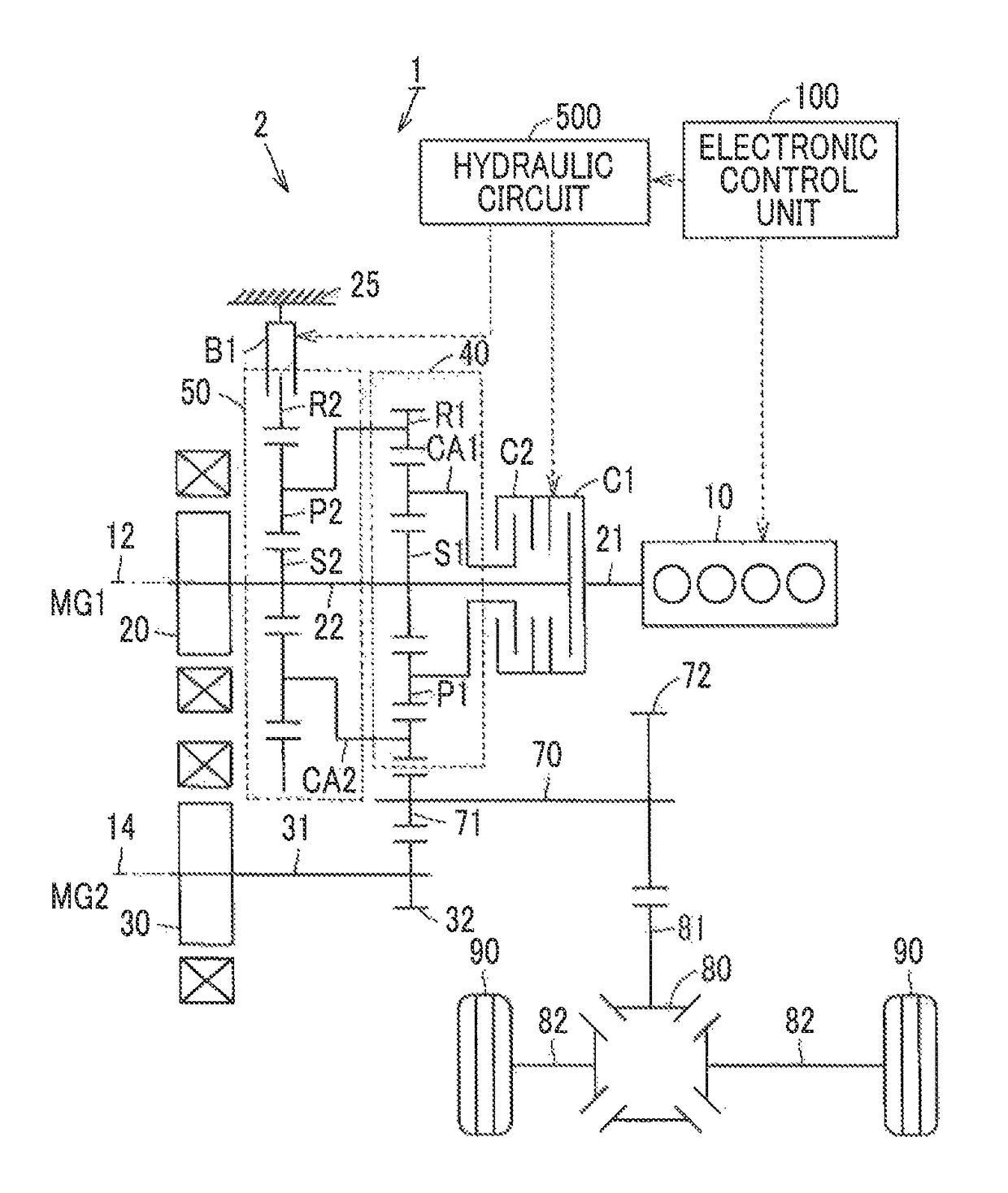

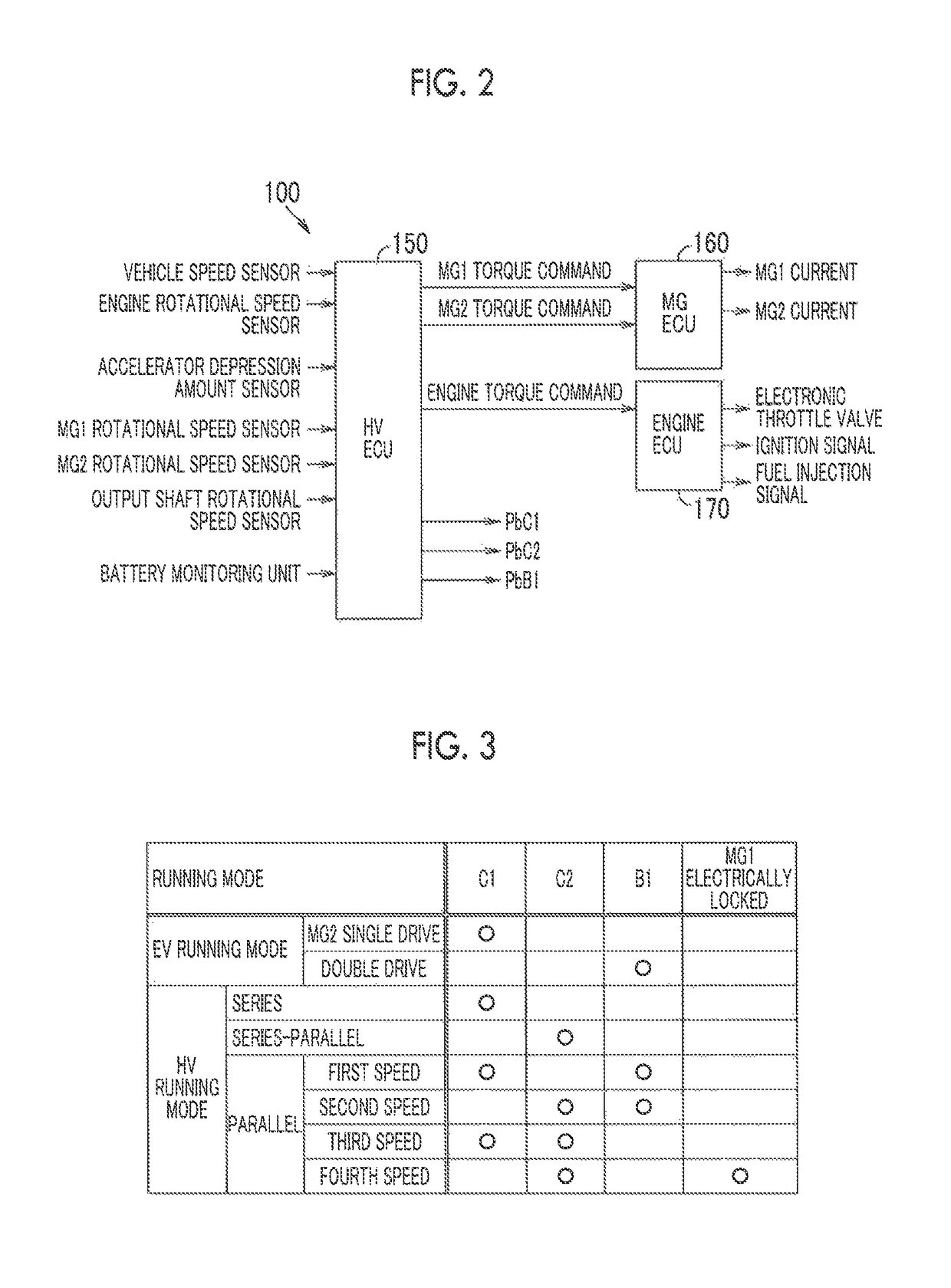

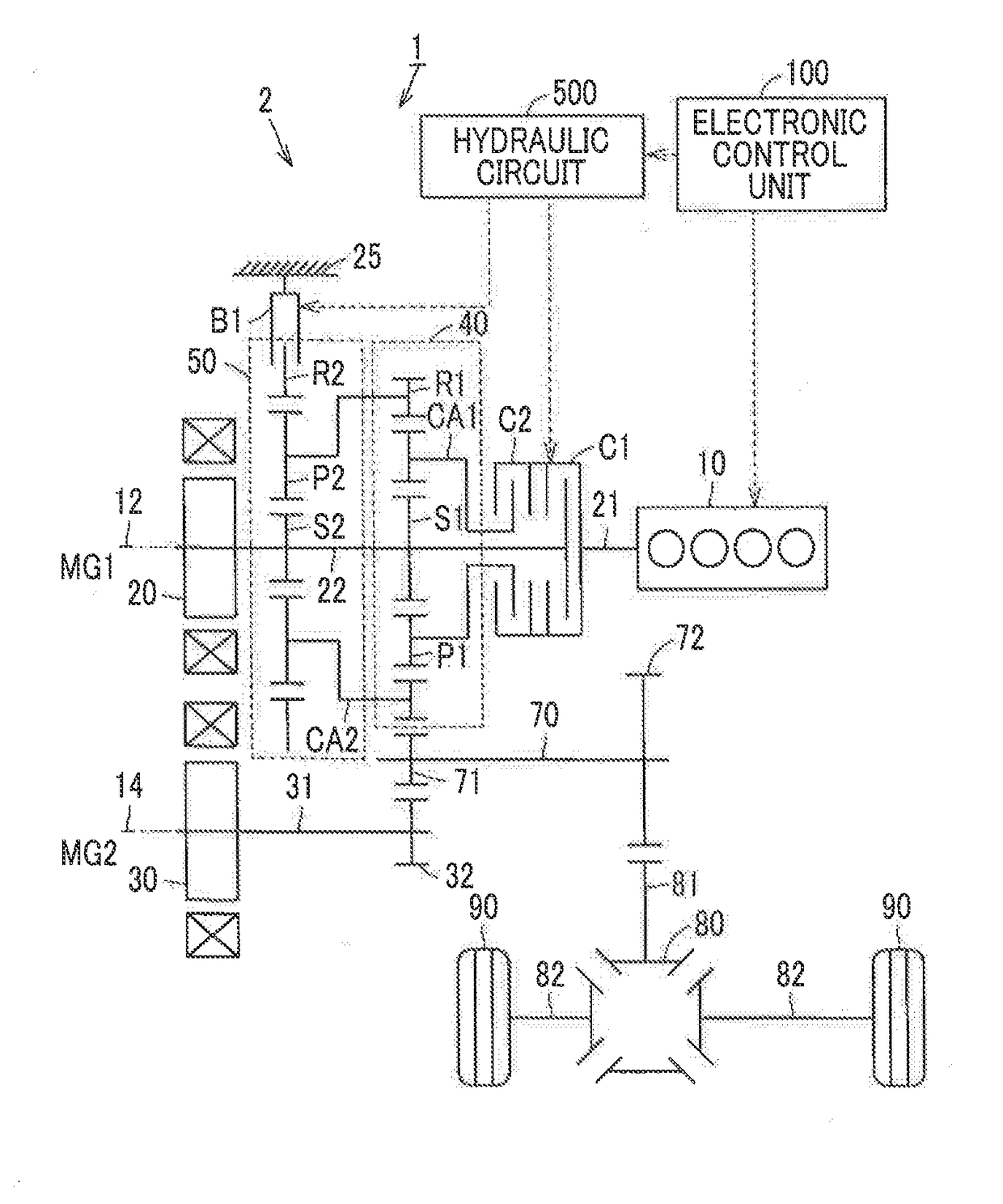

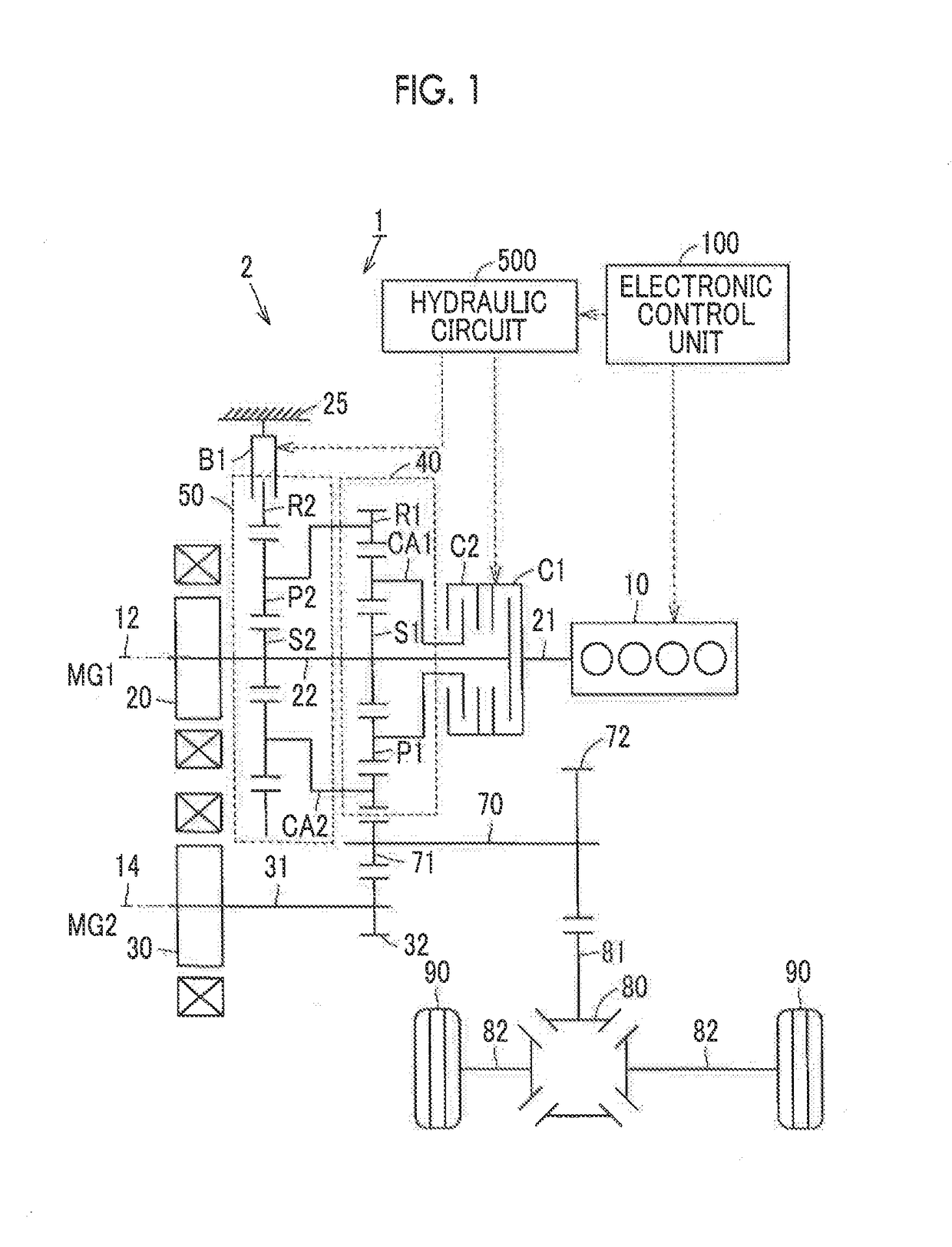

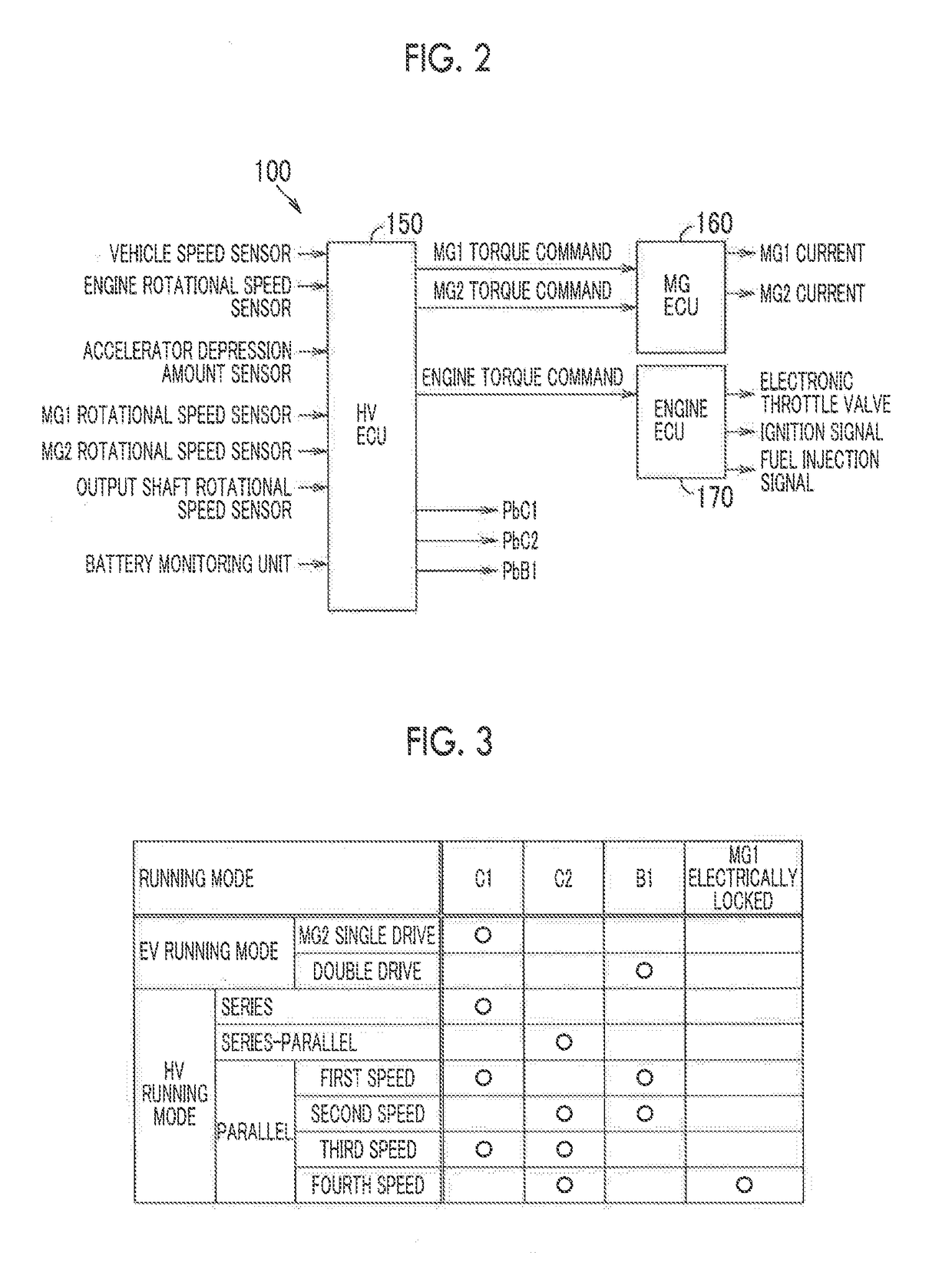

Control apparatus for hybrid vehicle and control method for hybrid vehicle

InactiveUS9987917B2Excellent in engine thermal efficiency and motive power transmission efficiencyAvoid efficiencyHybrid vehiclesSpeed controllerEngineeringHigh load

An electronic control unit is configured to select one of a series mode, a series-parallel mode and a parallel mode as a running mode. A load level of a hybrid vehicle is set to a value that is high in the order of a load level at which the parallel mode is selected, a load level at which the series-parallel mode is selected, and a load level at which the series mode is selected. That is, the electronic control unit selects the series-parallel mode in an intermediate load region, selects the series mode in a low load region, and selects the parallel mode in a high load region.

Owner:TOYOTA JIDOSHA KK

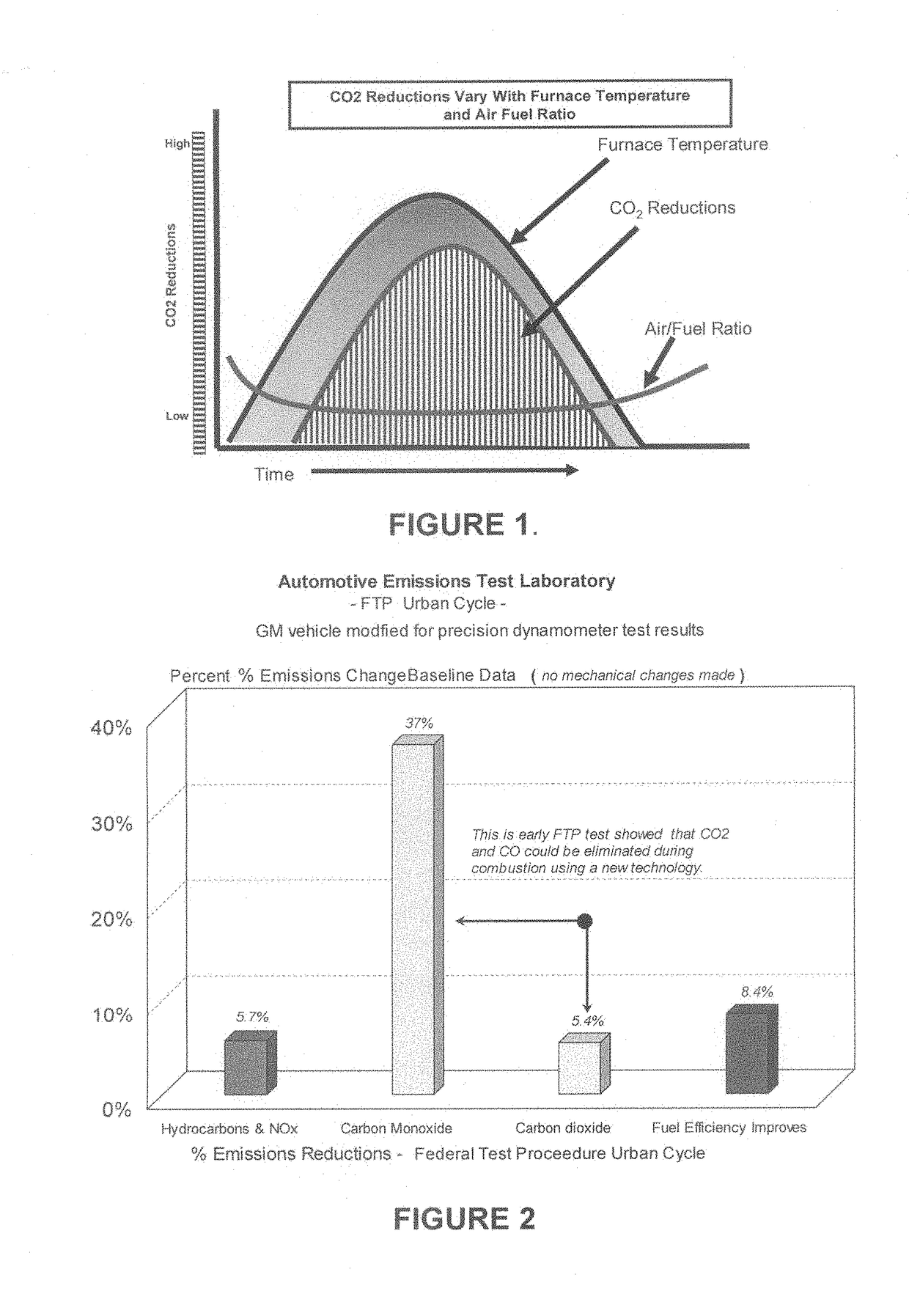

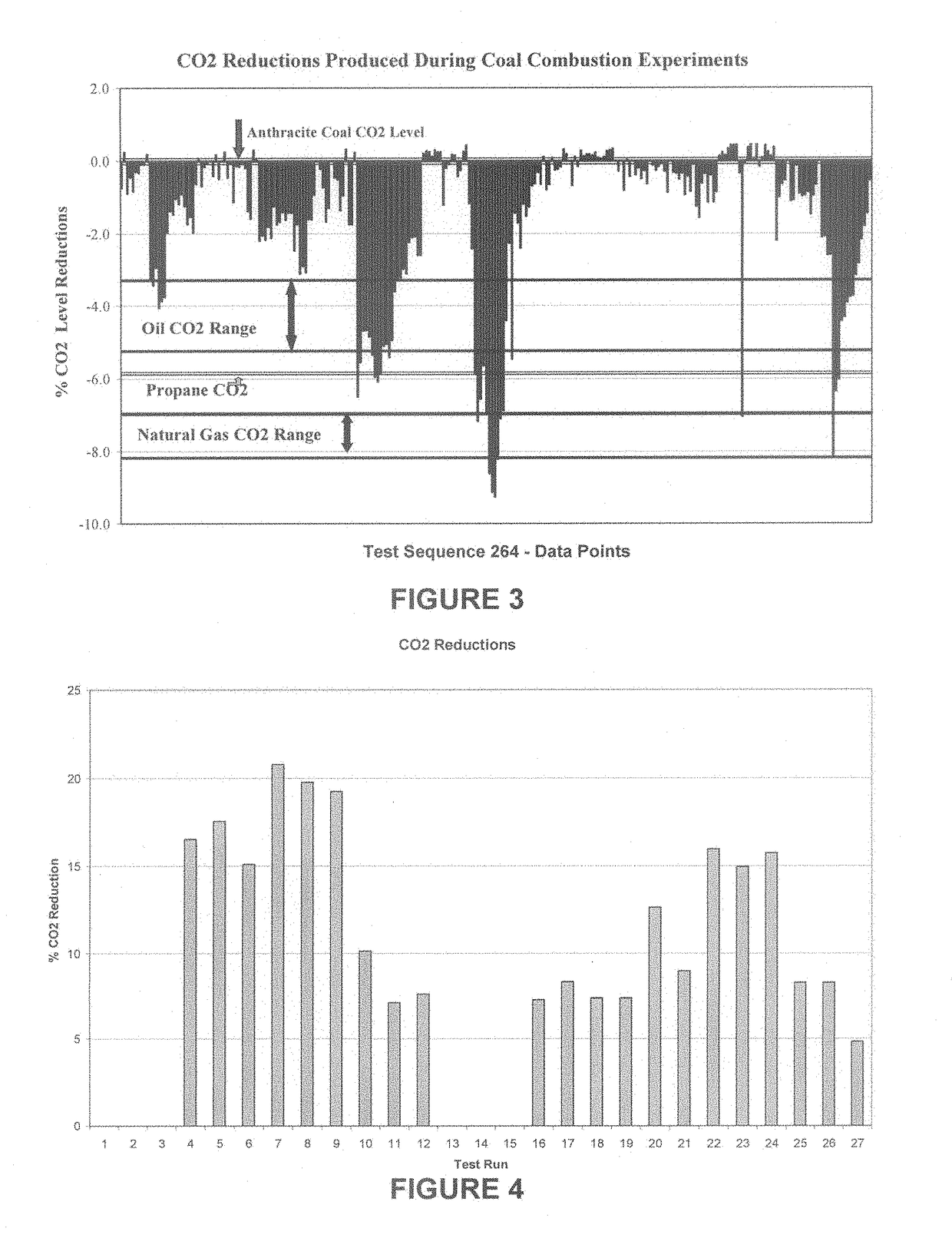

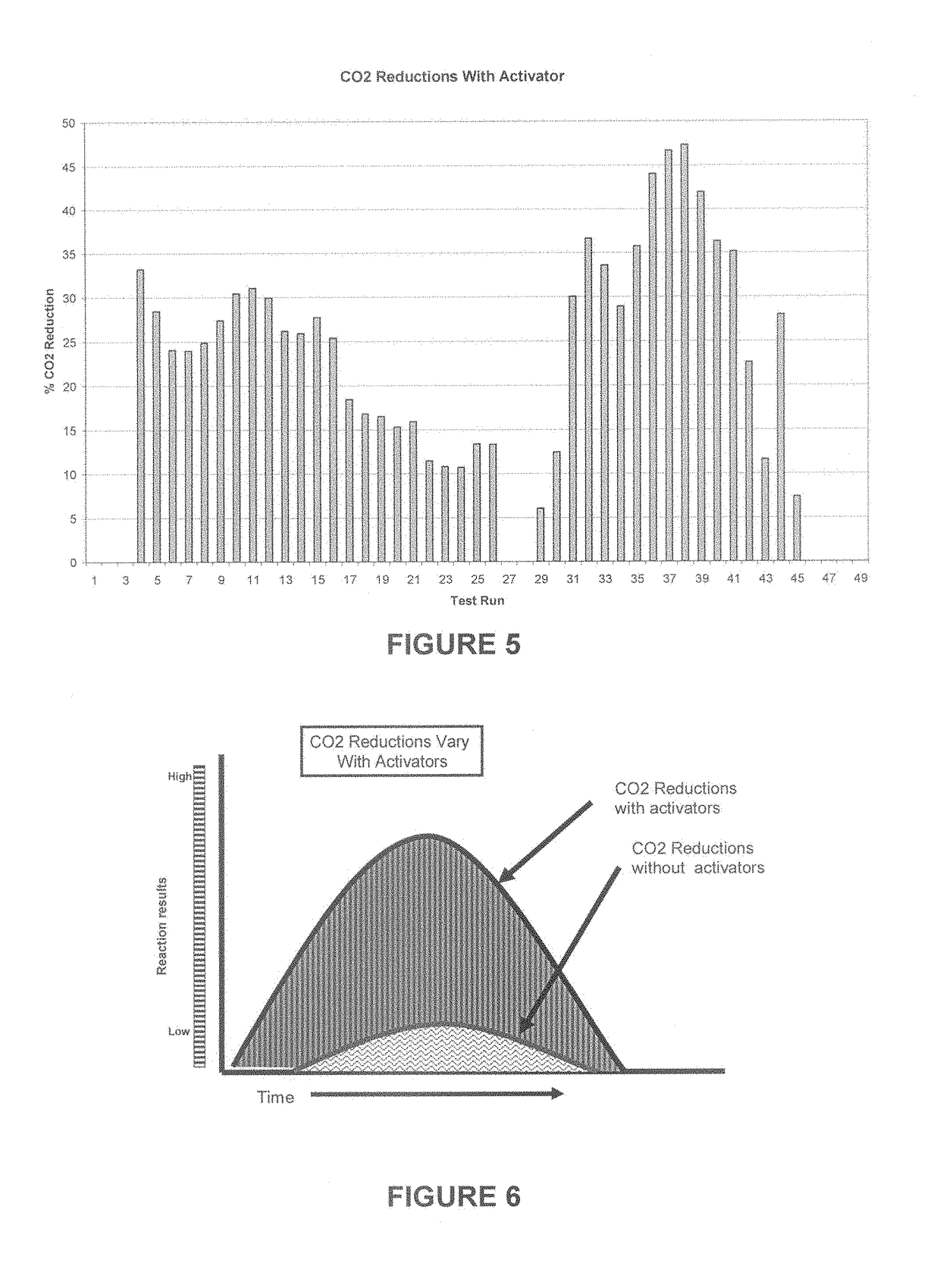

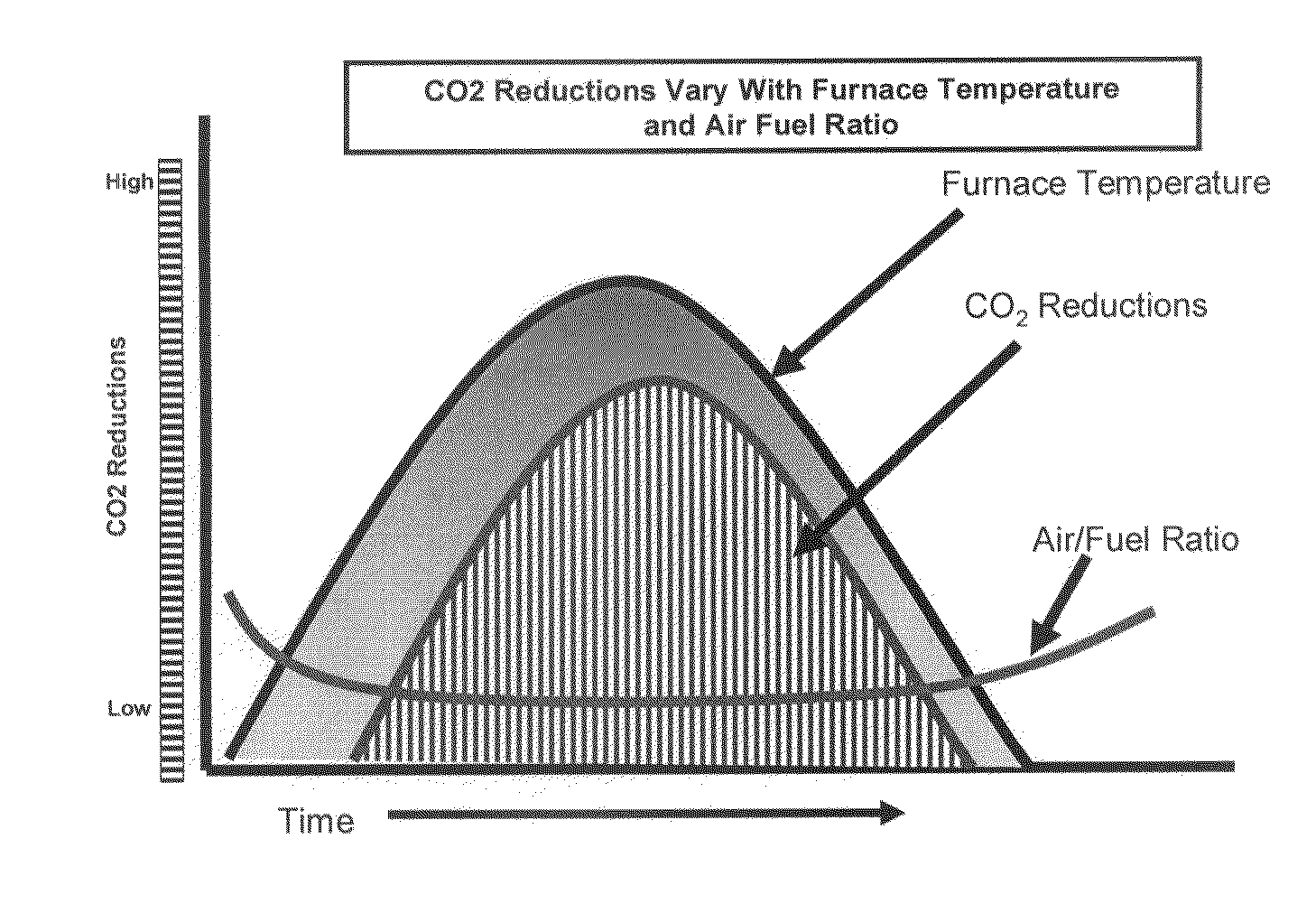

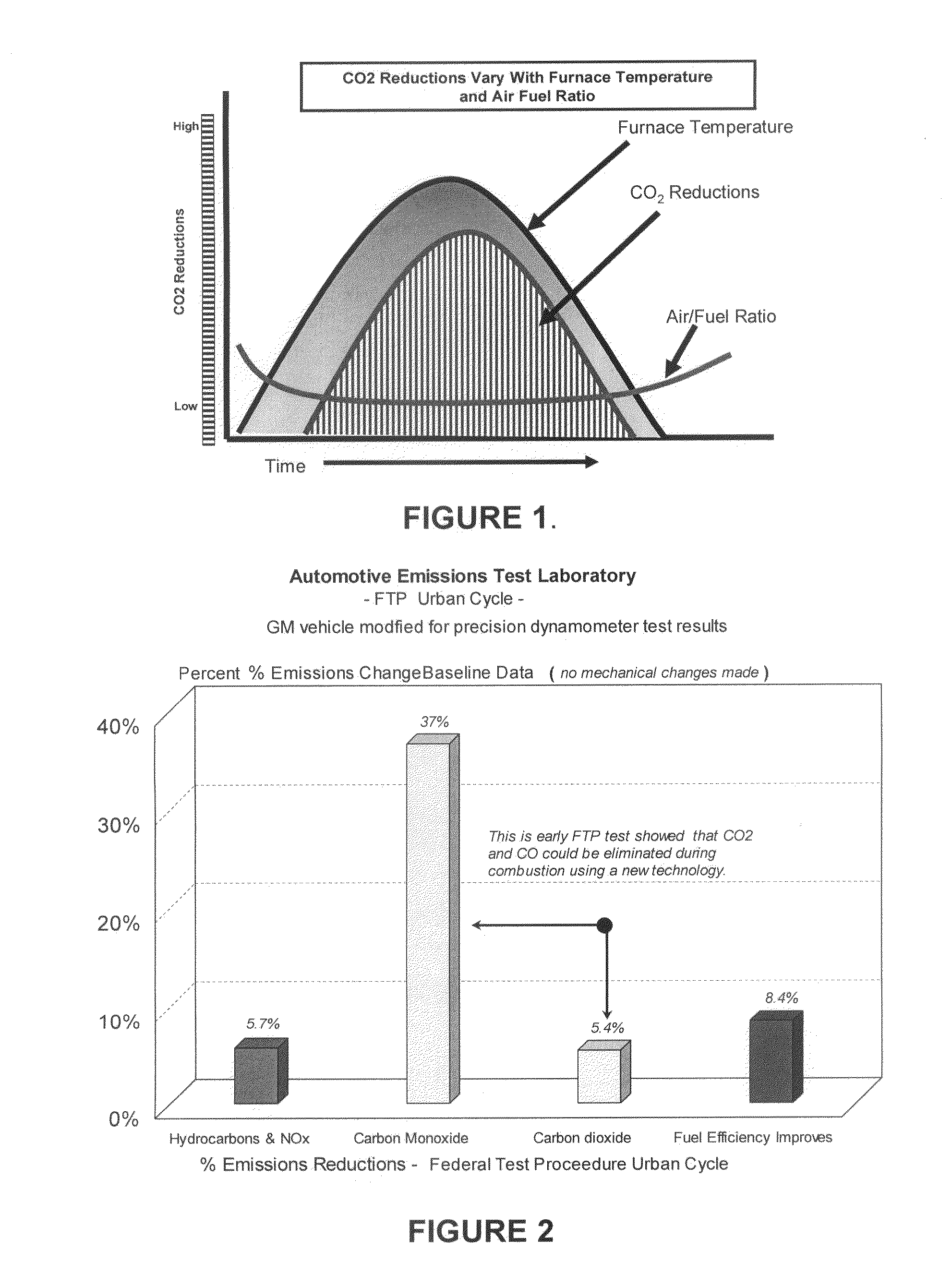

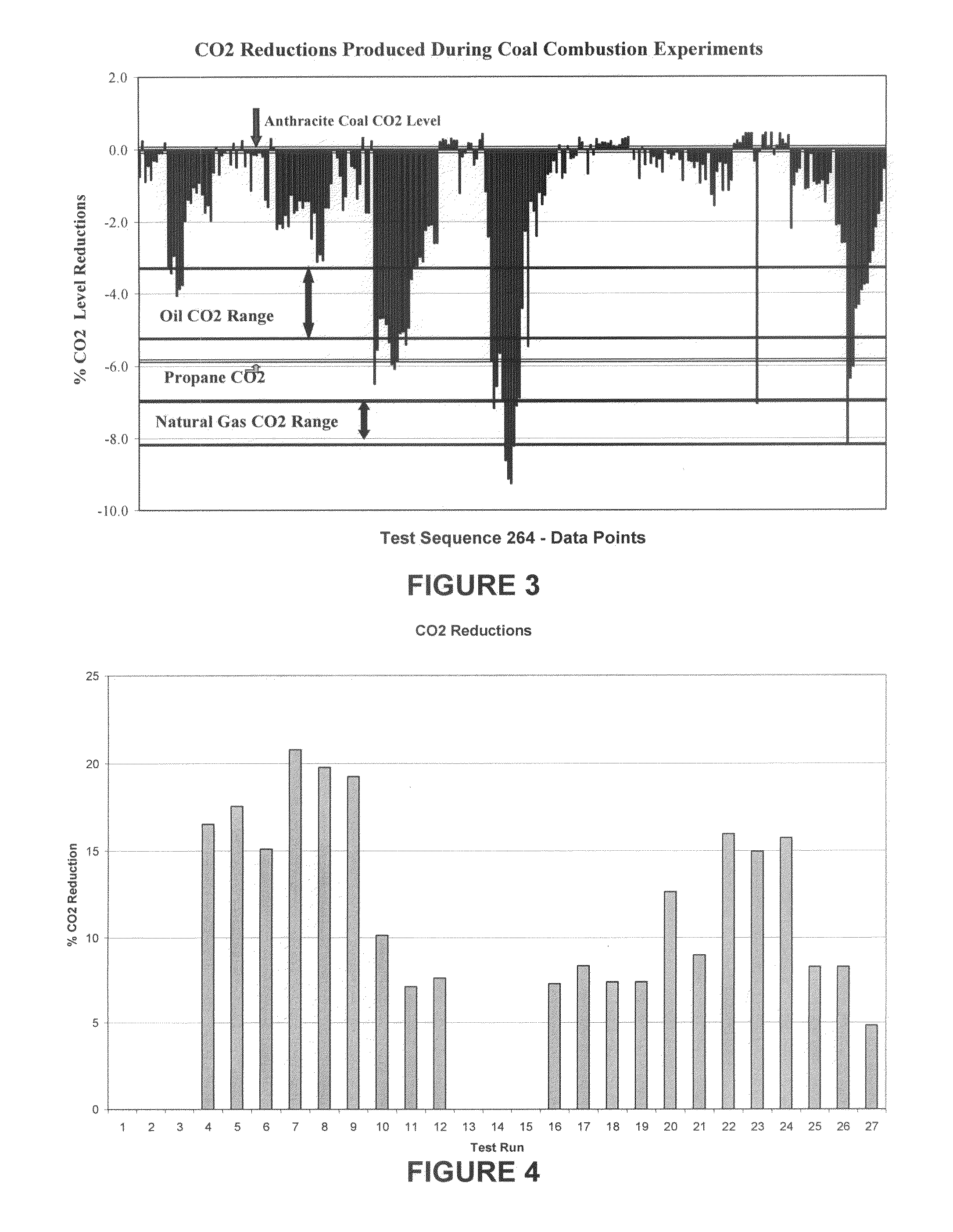

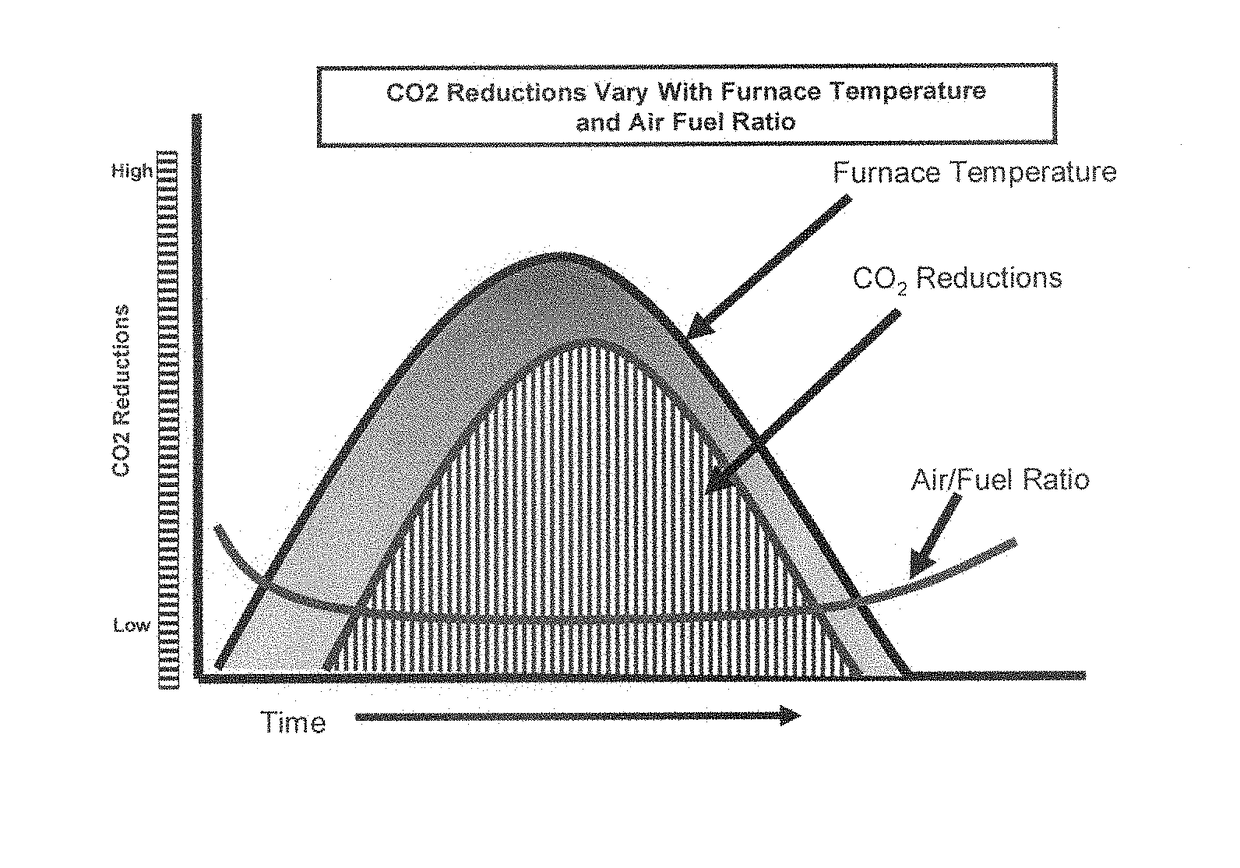

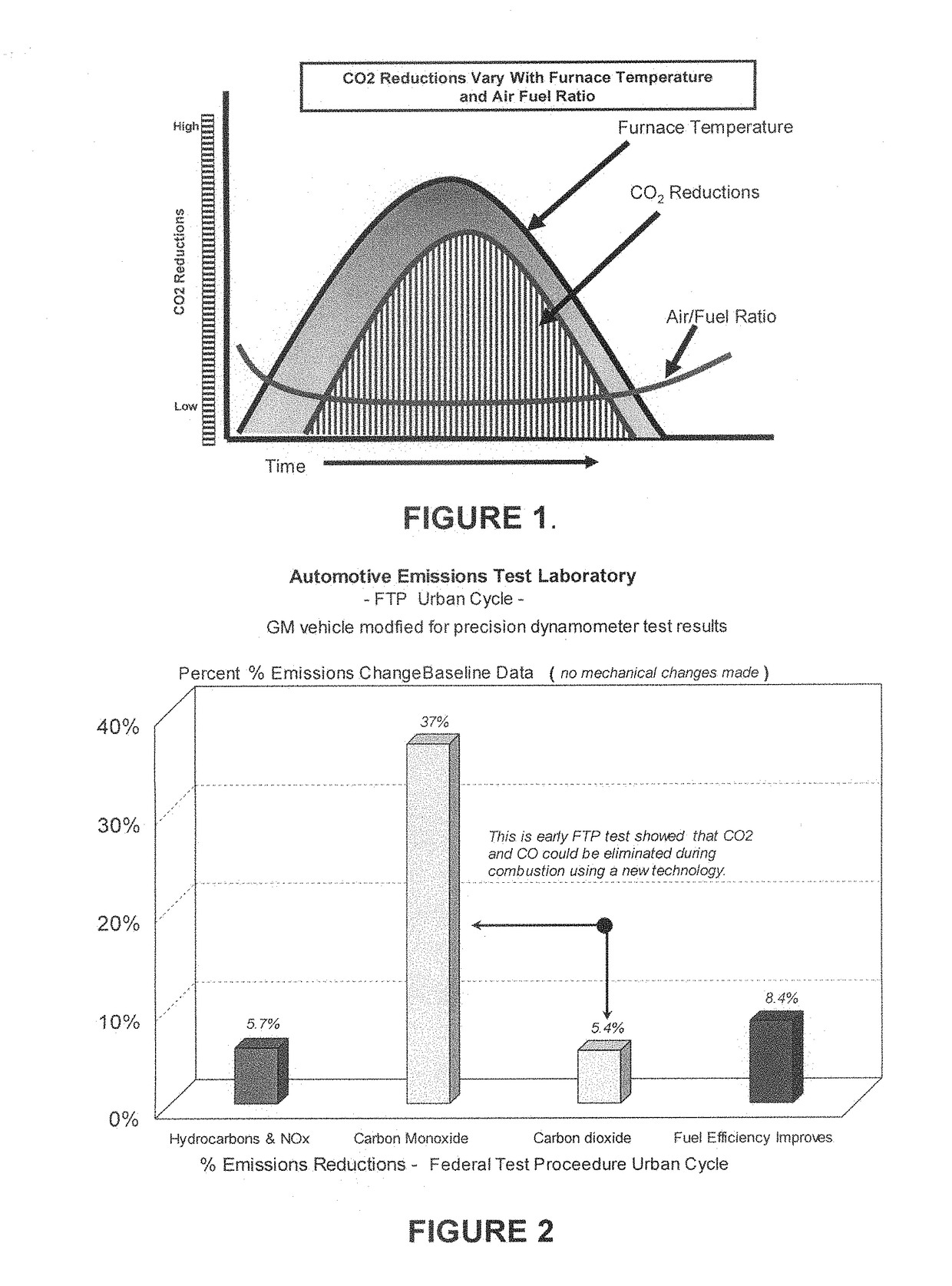

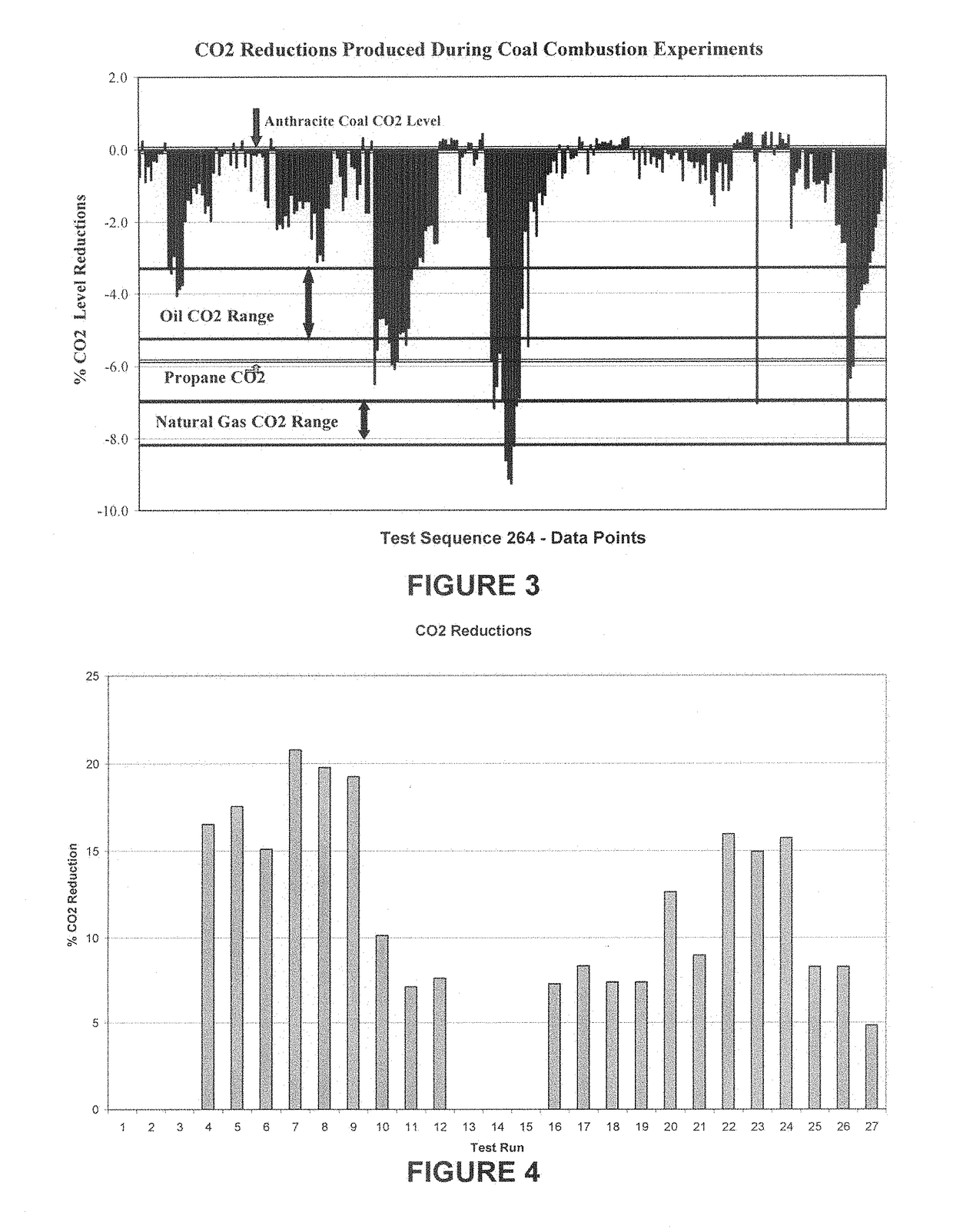

System for combustion of fuel to provide high efficiency, low pollution energy

ActiveUS20190024884A1Reduce carbon dioxideReduce CO2Fuel supply regulationEmission preventionCombustion systemLithium

An afterburner system and method for reducing the CO2 and other pollutants produced by the combustion of a fuel in a combustion chamber while maintaining or increasing the efficiency of said combustion includes feeding a catalyst, preferably lithium and / or boron to the afterburner, or a preconditioning afterburner, along with the exhaust from the combustion chamber. The presence of the catalyst in the after burner results in further reduction of pollutants generated by the combustion in the combustion chamber.

Owner:TAPLIN JR HARRY R

Control apparatus for hybrid vehicle and control method for hybrid vehicle

InactiveUS20180001757A1Guaranteed uptimeExcellent in engine thermal efficiency and motive power transmission efficiencyHybrid vehiclesSpeed controllerLow loadEngineering

An electronic control unit is configured to select one of a series mode, a series-parallel mode and a parallel mode as a running mode. A load level of a hybrid vehicle is set to a value that is high in the order of a load level at which the parallel mode is selected, a load level at which the series-parallel mode is selected, and a load level at which the series mode is selected. That is, the electronic control unit selects the series-parallel mode in an intermediate load region, selects the series mode in a low load region, and selects the parallel mode in a high load region.

Owner:TOYOTA JIDOSHA KK

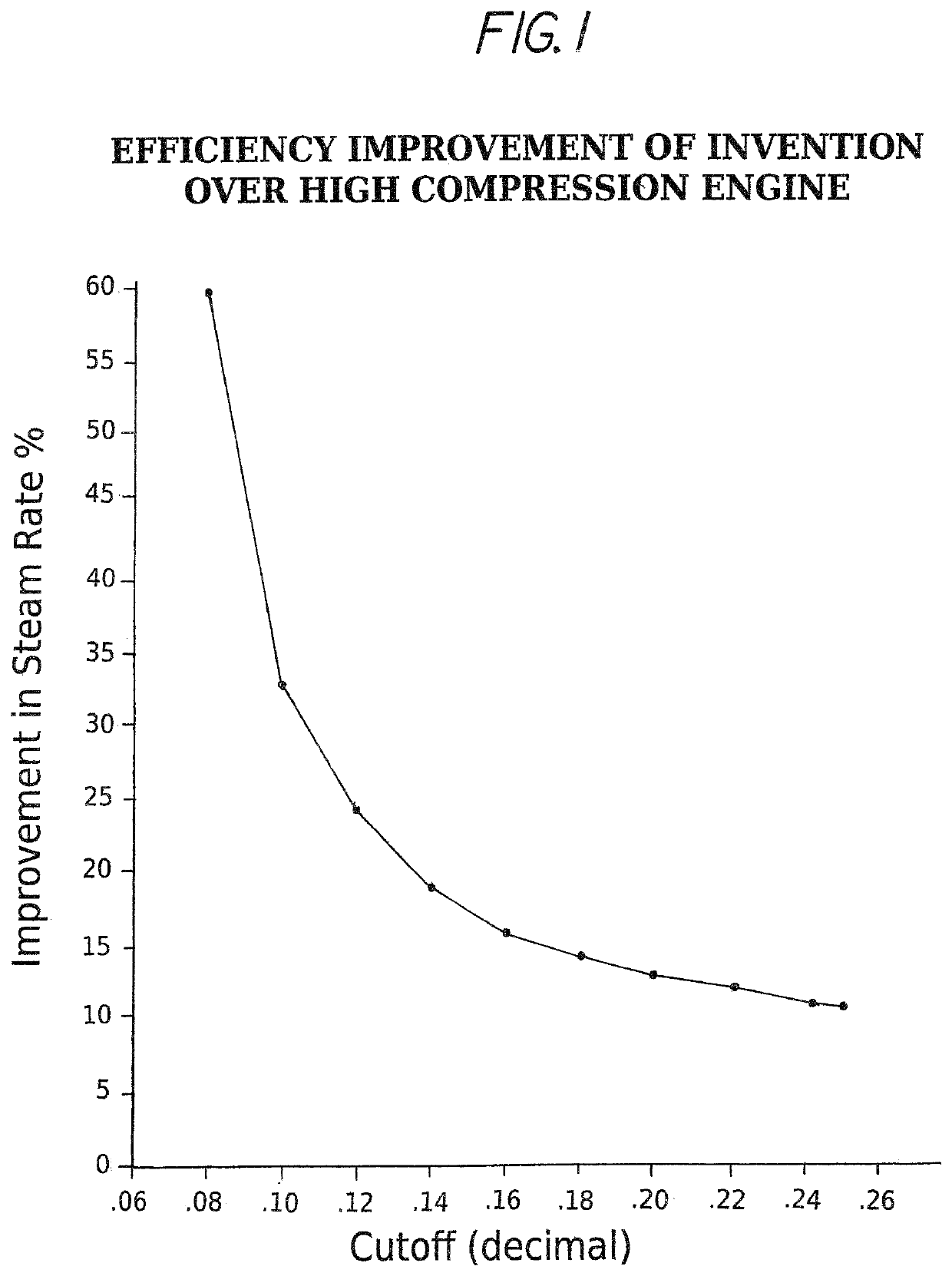

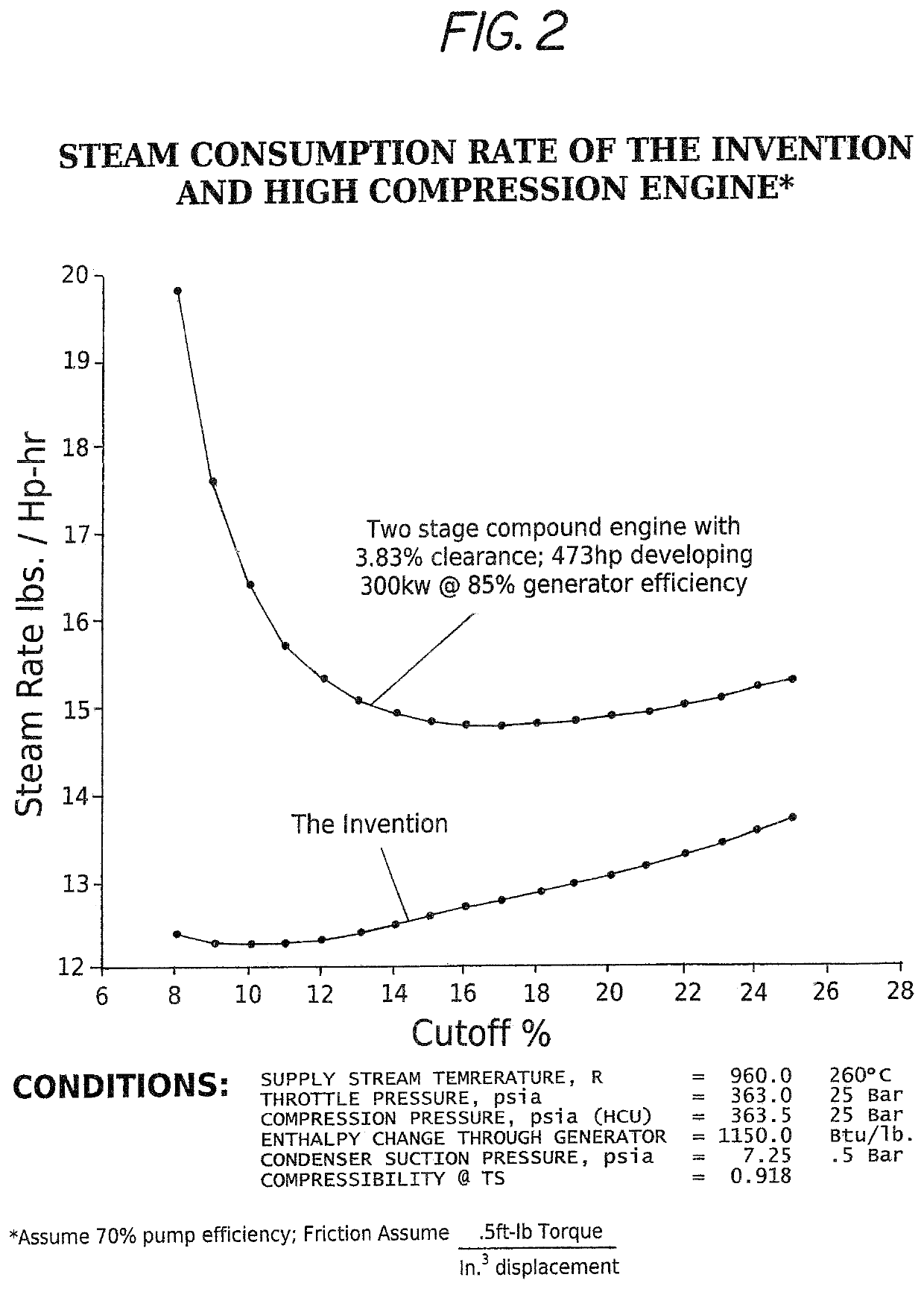

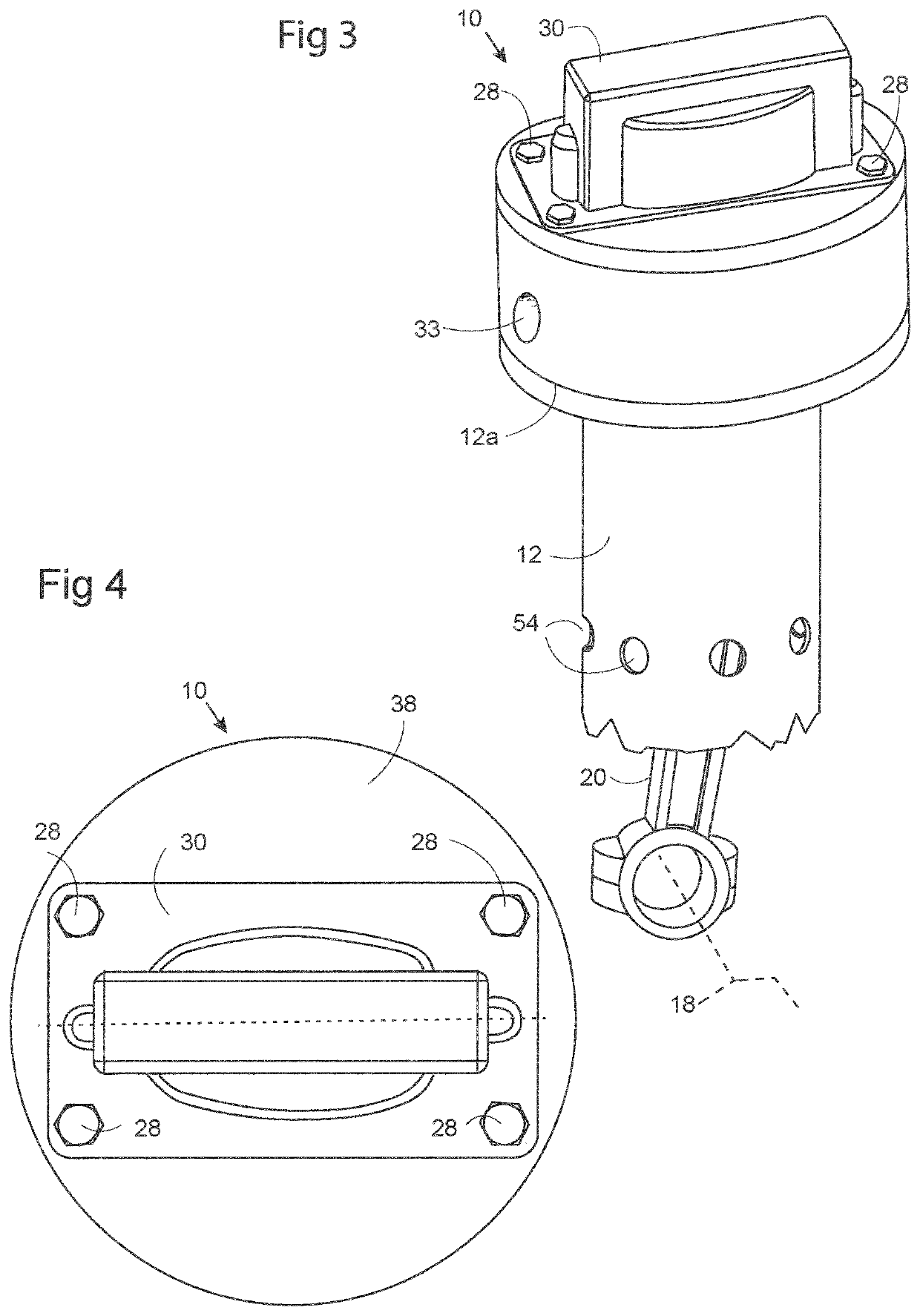

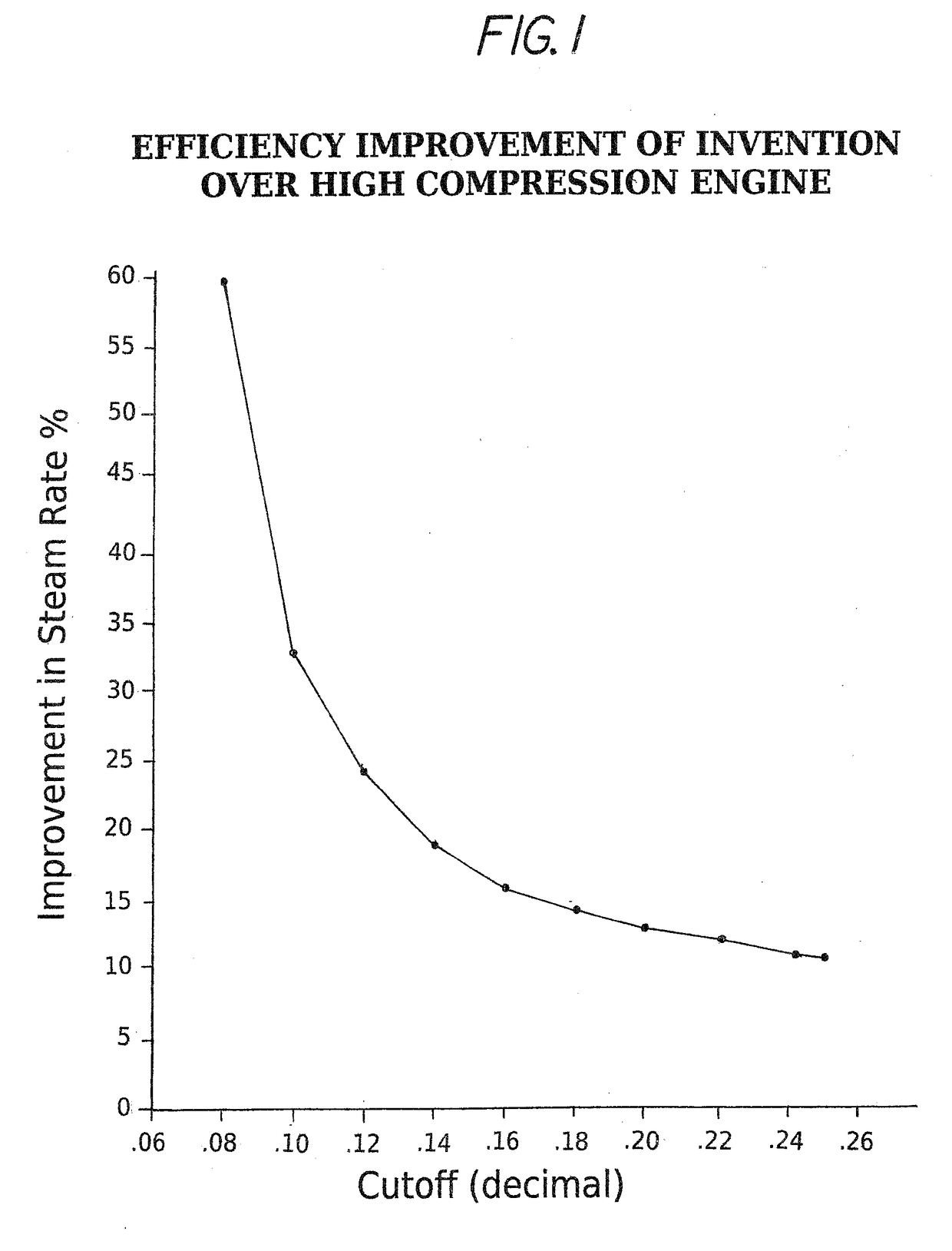

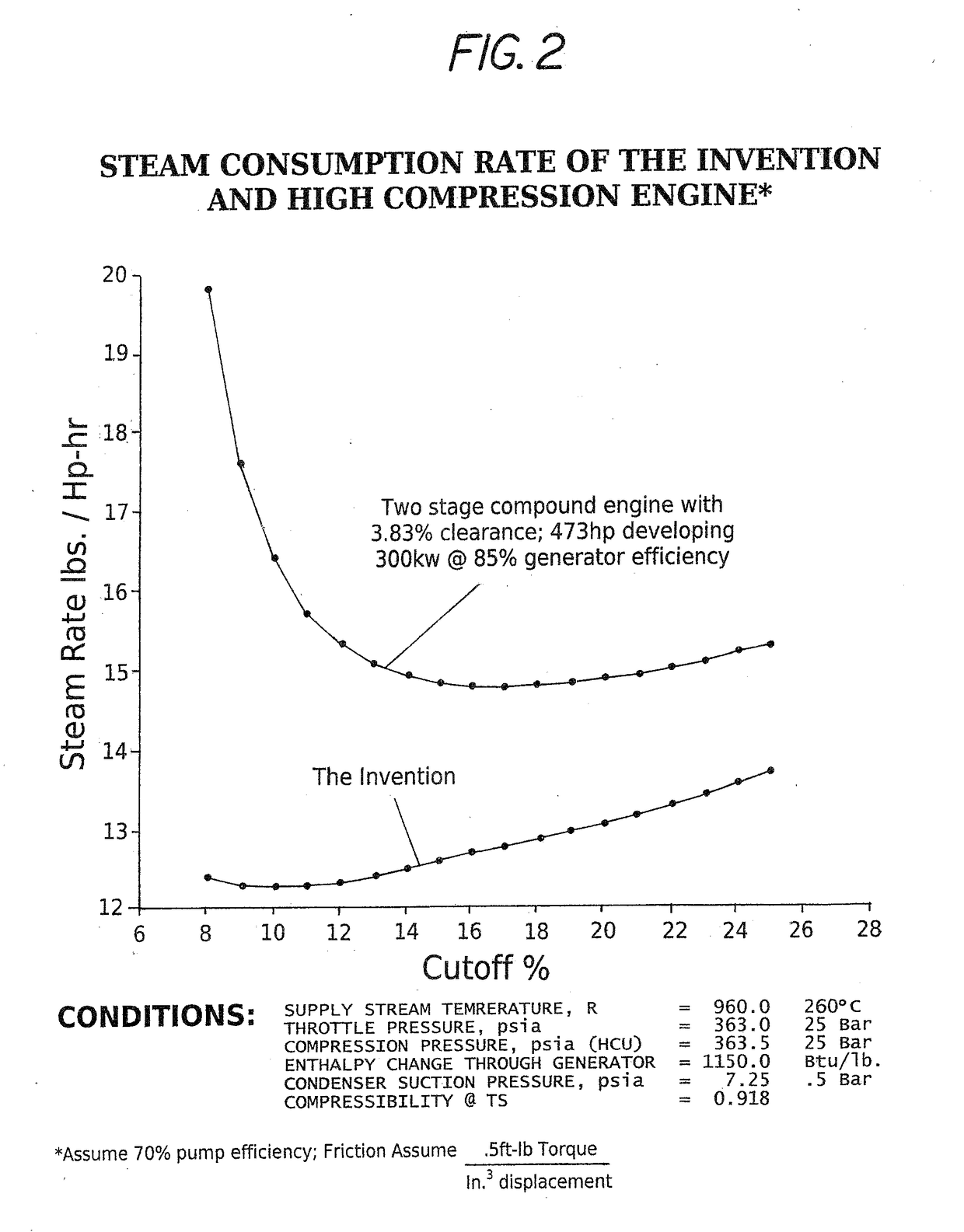

High efficiency steam engine having improved steam cutoff control

ActiveUS10550737B2Improve efficiencyLittle or no valve wearSteam inlet/outlet valvesEngines characterised by uniflow principleExhaust valveSteam pressure

A high efficiency uniflow steam engine with automatic inlet and exhaust valves rather than camshaft operated valves includes an electromagnet and cooperating armature that actuates a cutoff control valve for closing a steam inlet valve at any time selected to stop the flow of steam to the cylinder. Approaching the end of the exhaust stroke typically 0.12 inch before TDC the cylinder is sealed thereby compressing the remaining residual steam down to a minute clearance approaching zero, for example, 0.020 inch to raise cylinder steam pressure enough to open the steam inlet valve without physical contact between the piston and the steam inlet valve thereby eliminating tappet noise, shock and wear.

Owner:THERMAL POWER RECOVERY

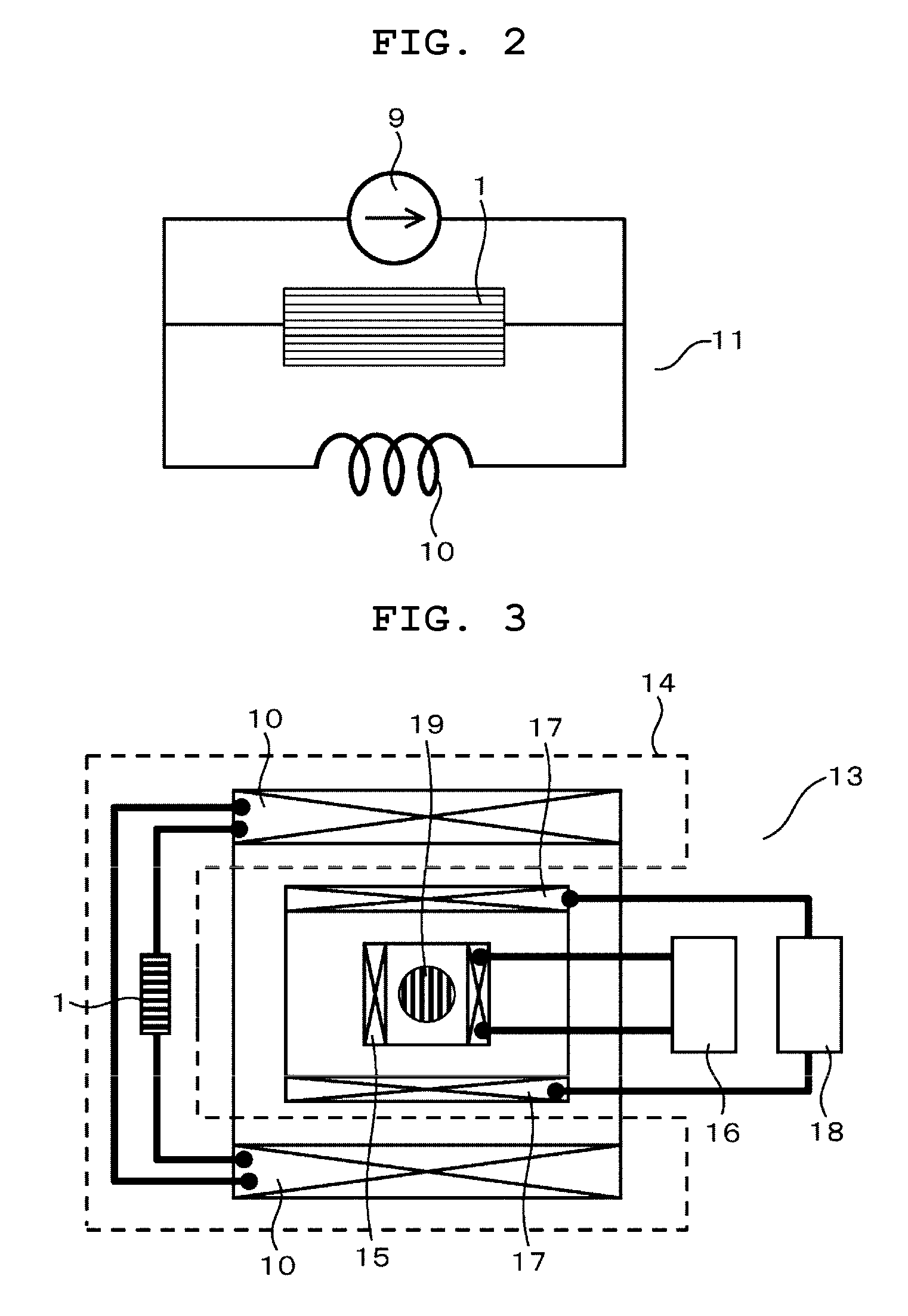

Superconducting switch, superconducting magnet and MRI

ActiveUS8855731B2Thermal efficiencyHigh thermal efficiencySuperconductors/hyperconductorsMagnetic measurementsSuperconducting CoilsThermal efficiency

Owner:HITACHI LTD

Process for high efficiency, low pollution fuel conversion

ActiveUS20120000403A1Harmful emissionImprove thermal efficiencyFuel supply regulationEmission preventionLithiumCombustion chamber

A process for reducing the CO2 and other pollutants produced by the combustion of a fuel in a combustion chamber while maintaining or increasing the efficiency of said combustion includes feeding to the combustion chamber, or preconditioning the combustion chamber, with a catalyst, preferably a lithium based salt Monitoring the energy output and components of the exhaust gas stream to maintain optimum operation allows reduction, during the process, of the catalyst delivery and feed air. The presence of the catalyst results in increased efficiency of operation and reduction of pollutants generated.

Owner:THE TAPLIN FAMILY TRUST

Device for Preheating a Fluid, In Particular Coolant for a Combustion Engine

ActiveUS20160054029A1Improve thermal efficiencySimple and economical structureImmersion heating arrangementsWater heatersCombustionEngineering

Owner:VOLANTE NINO

High efficiency steam engine having improved steam cutoff control

ActiveUS20180223703A1High thermal efficiencyImprove efficiencySteam inlet/outlet valvesEngines characterised by uniflow principleSteam pressureExhaust valve

A high efficiency uniflow steam engine having automatic inlet and exhaust valves rather than camshaft operated valves includes an electromagnet and cooperating armature that actuates a cutoff control valve for closing a steam inlet valve at any time selected to cut off the flow of steam to the cylinder. Approaching the end of the exhaust stroke, e.g., about 0.12 inch before TDC the cylinder can be sealed to thereby compressing the remaining residual steam down to a minute clearance approaching zero, for example, 0.020 inch raising cylinder steam pressure enough to open the steam inlet valve without physical contact between the piston and the steam inlet valve eliminating tappet noise, shock and wear.

Owner:THERMAL POWER RECOVERY

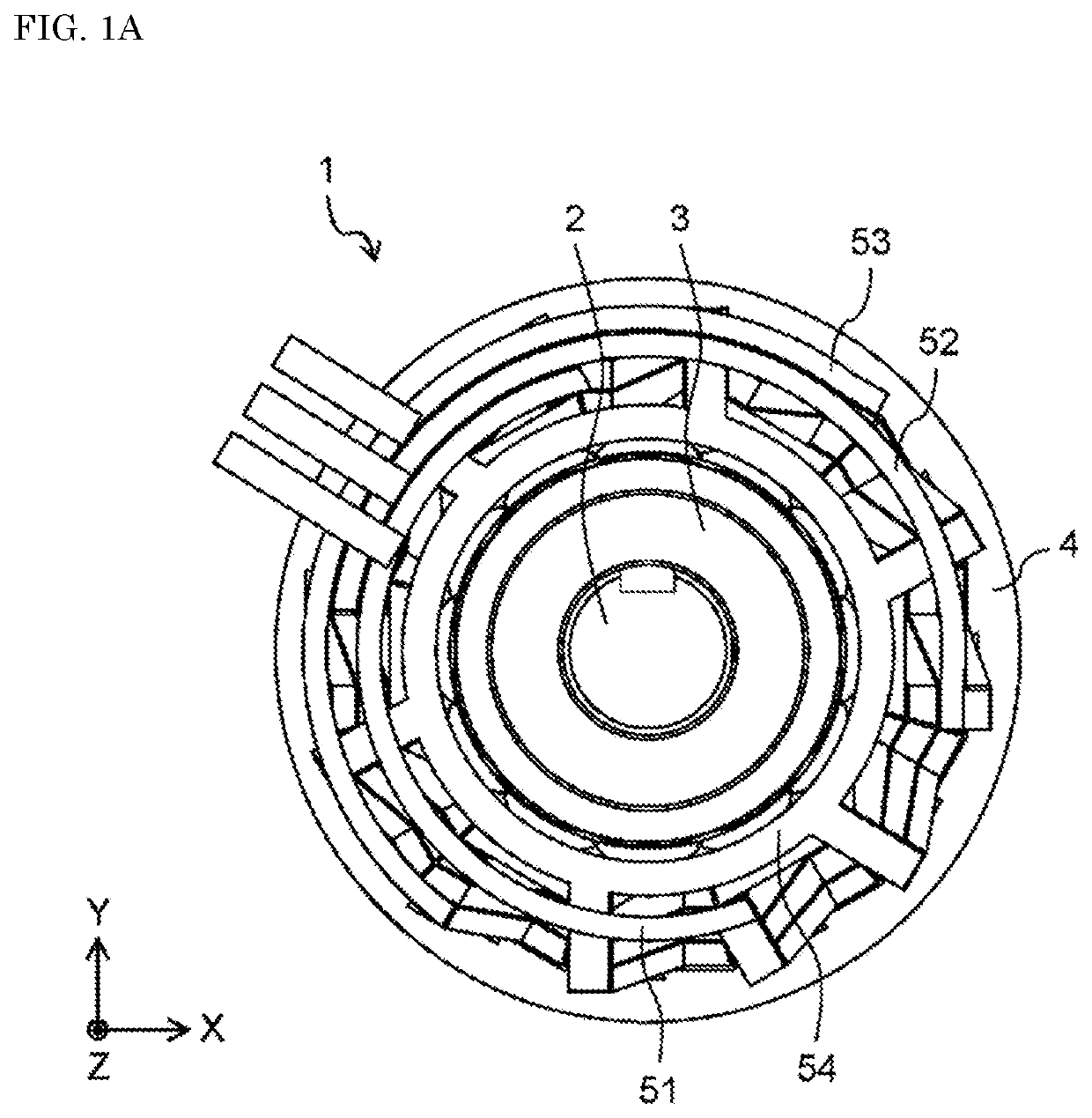

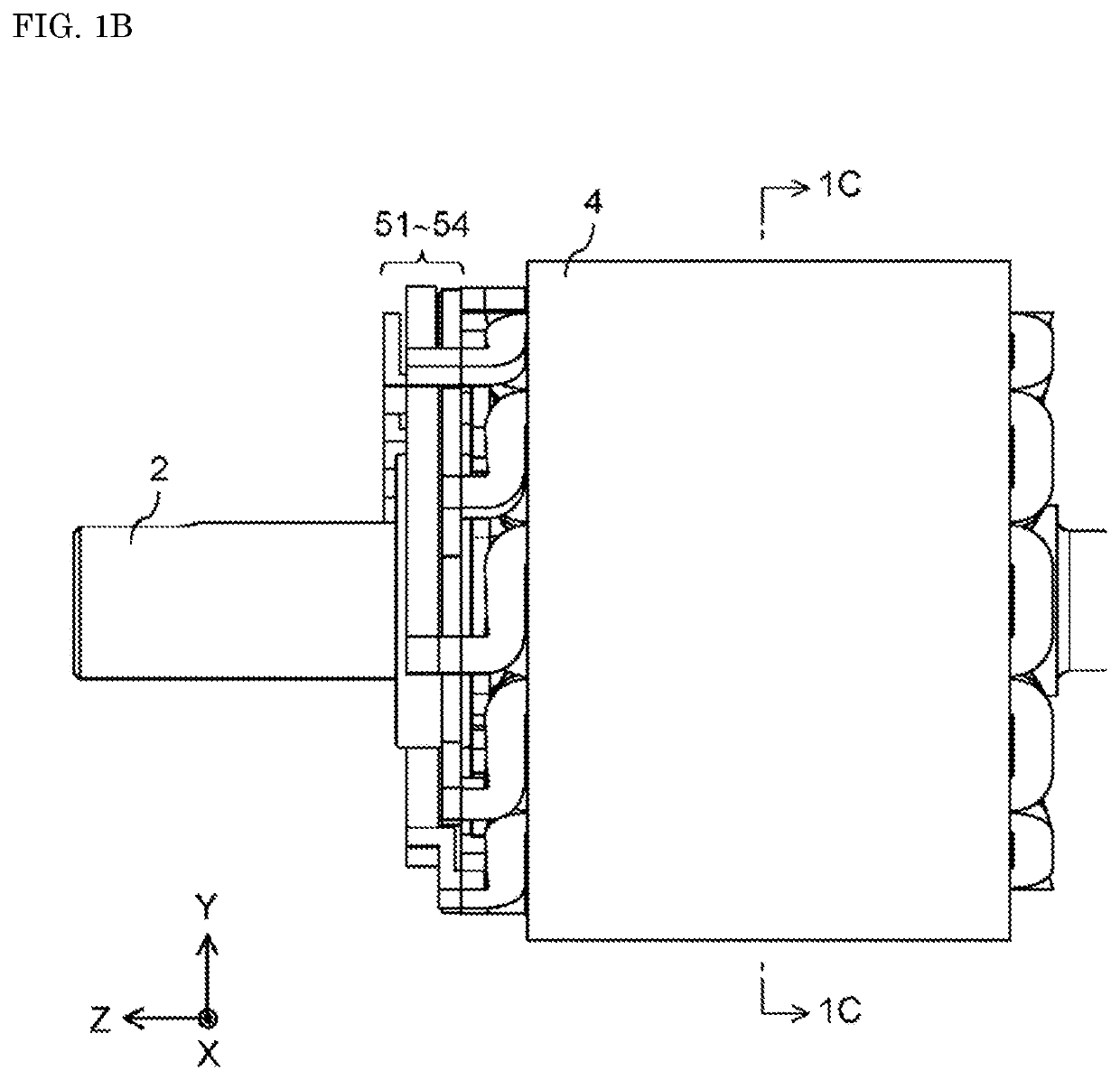

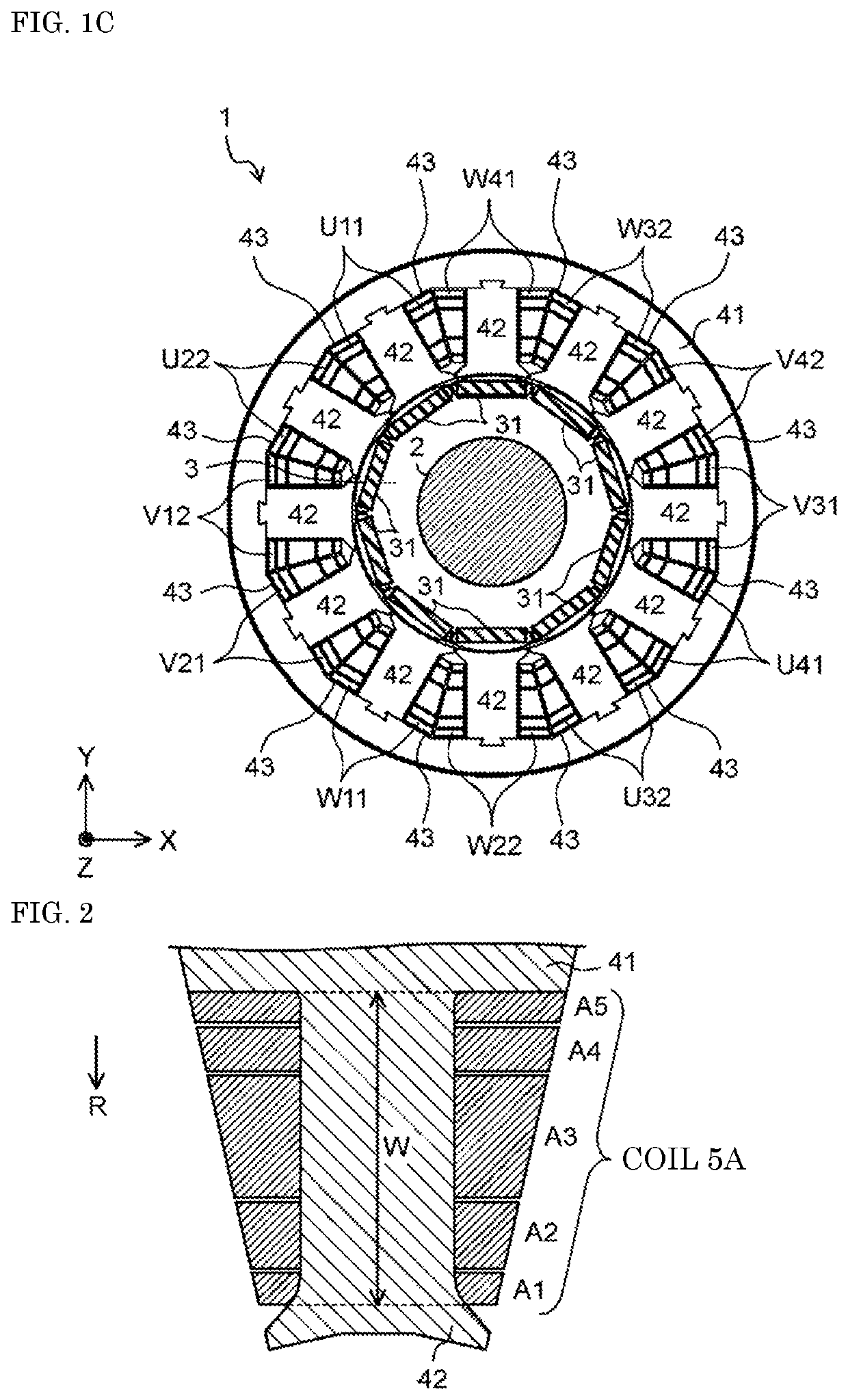

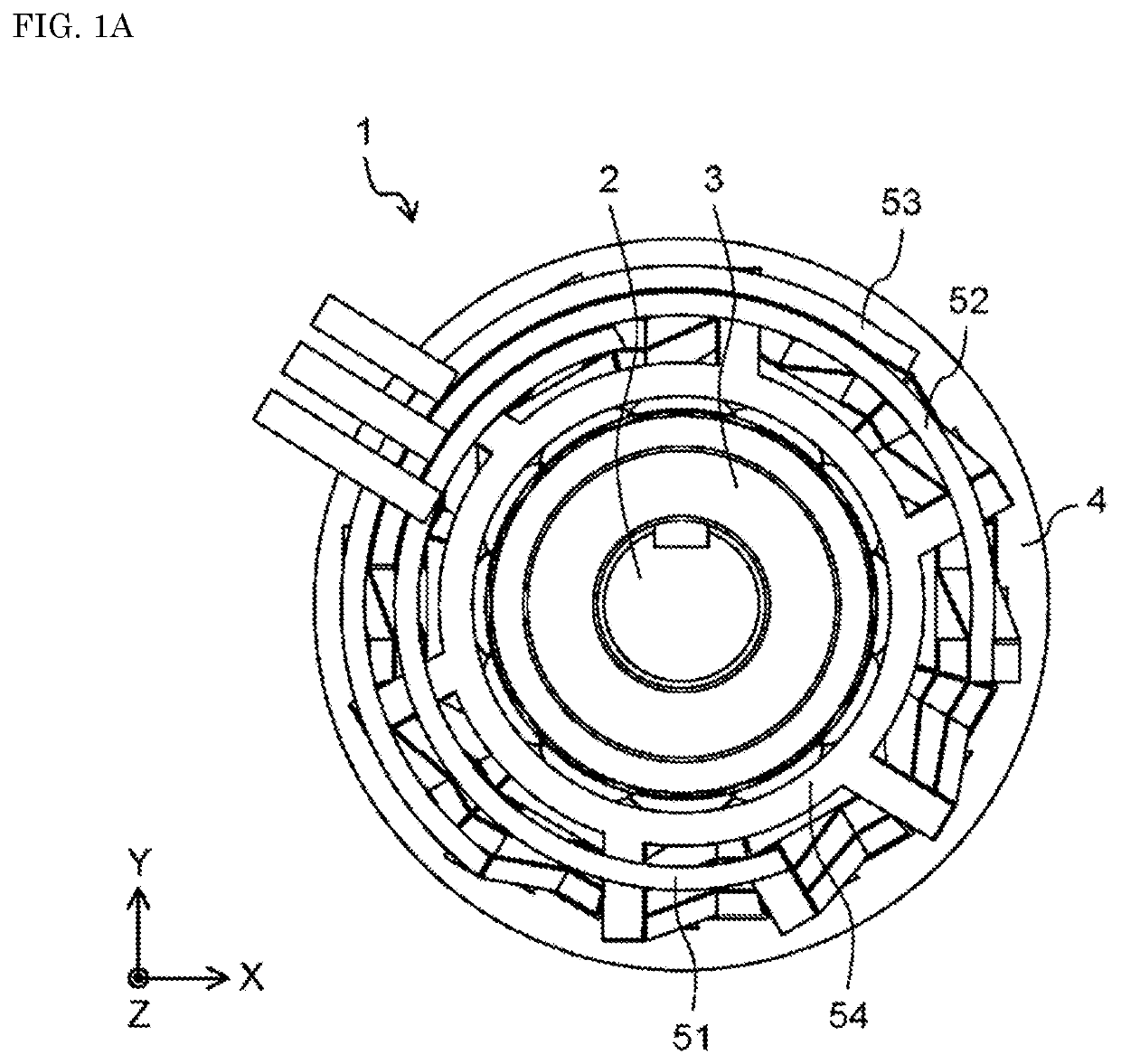

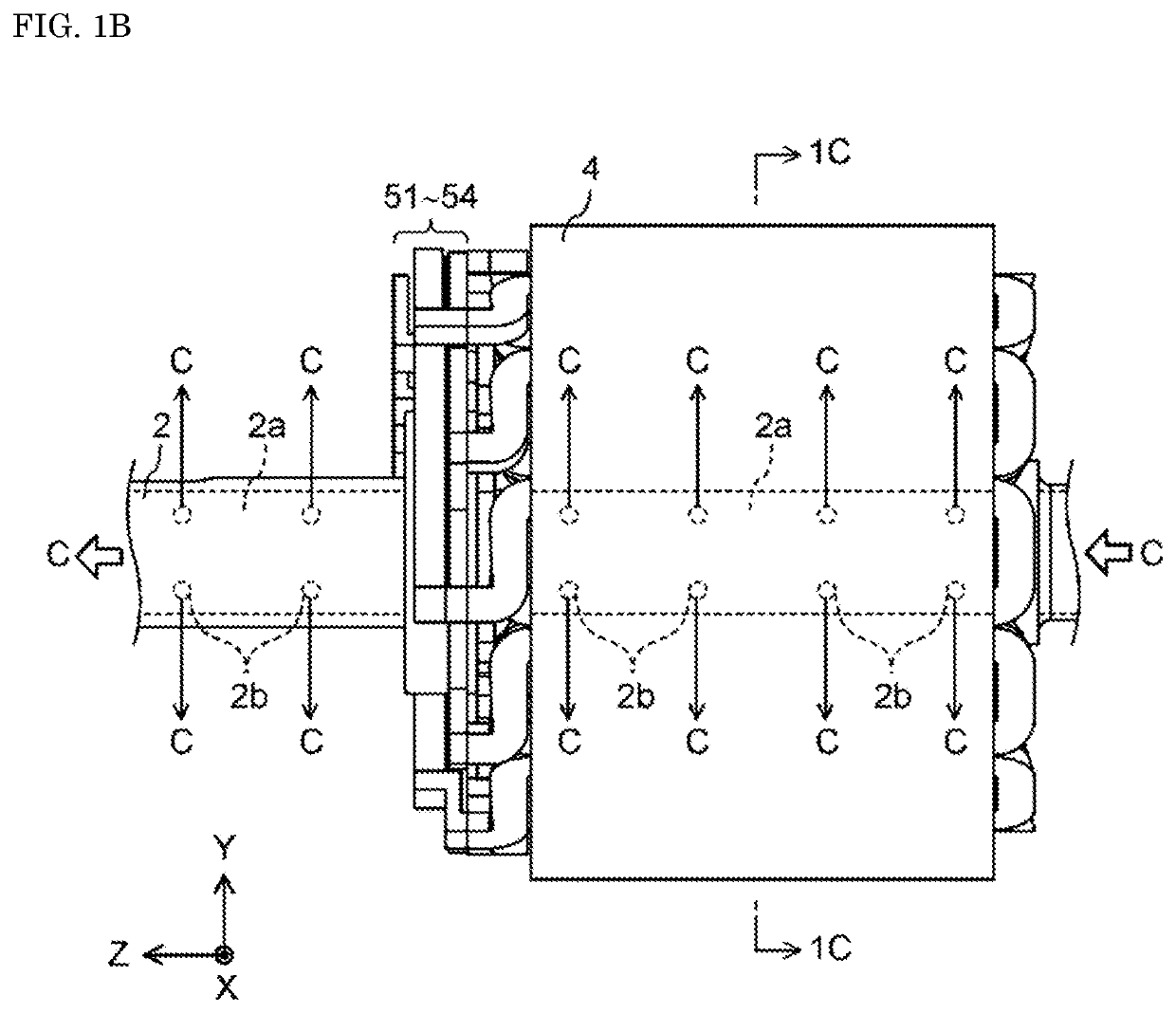

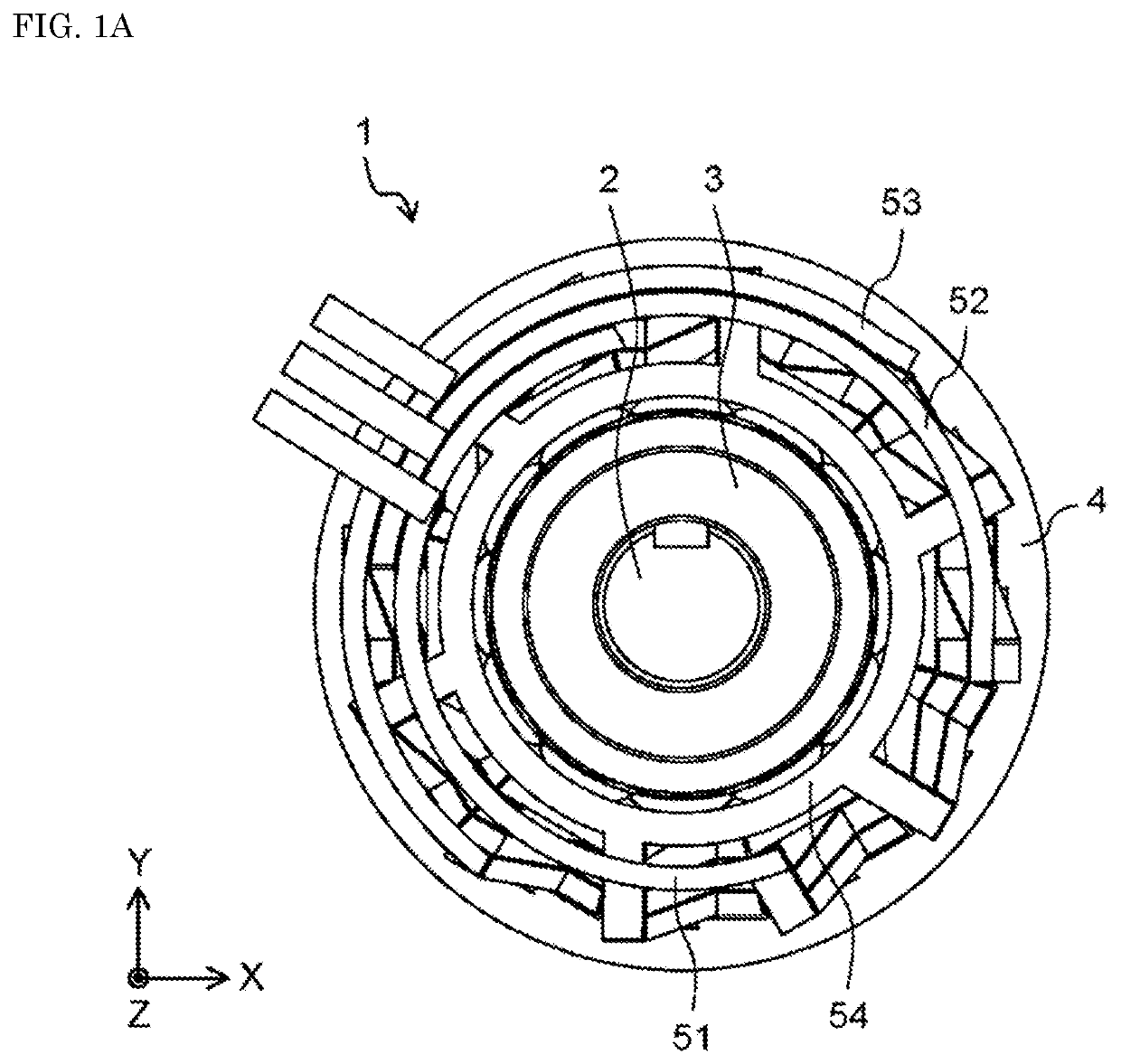

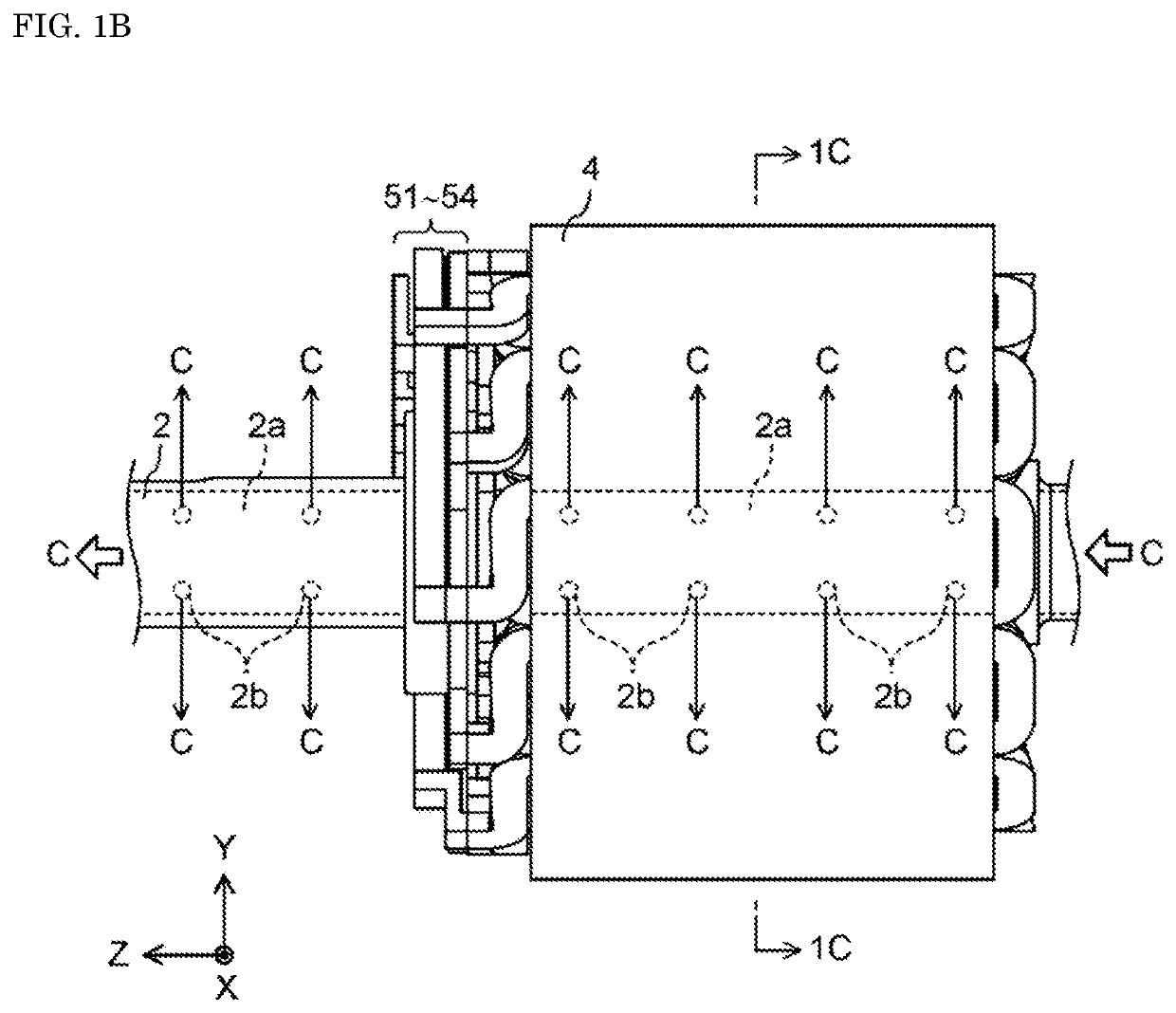

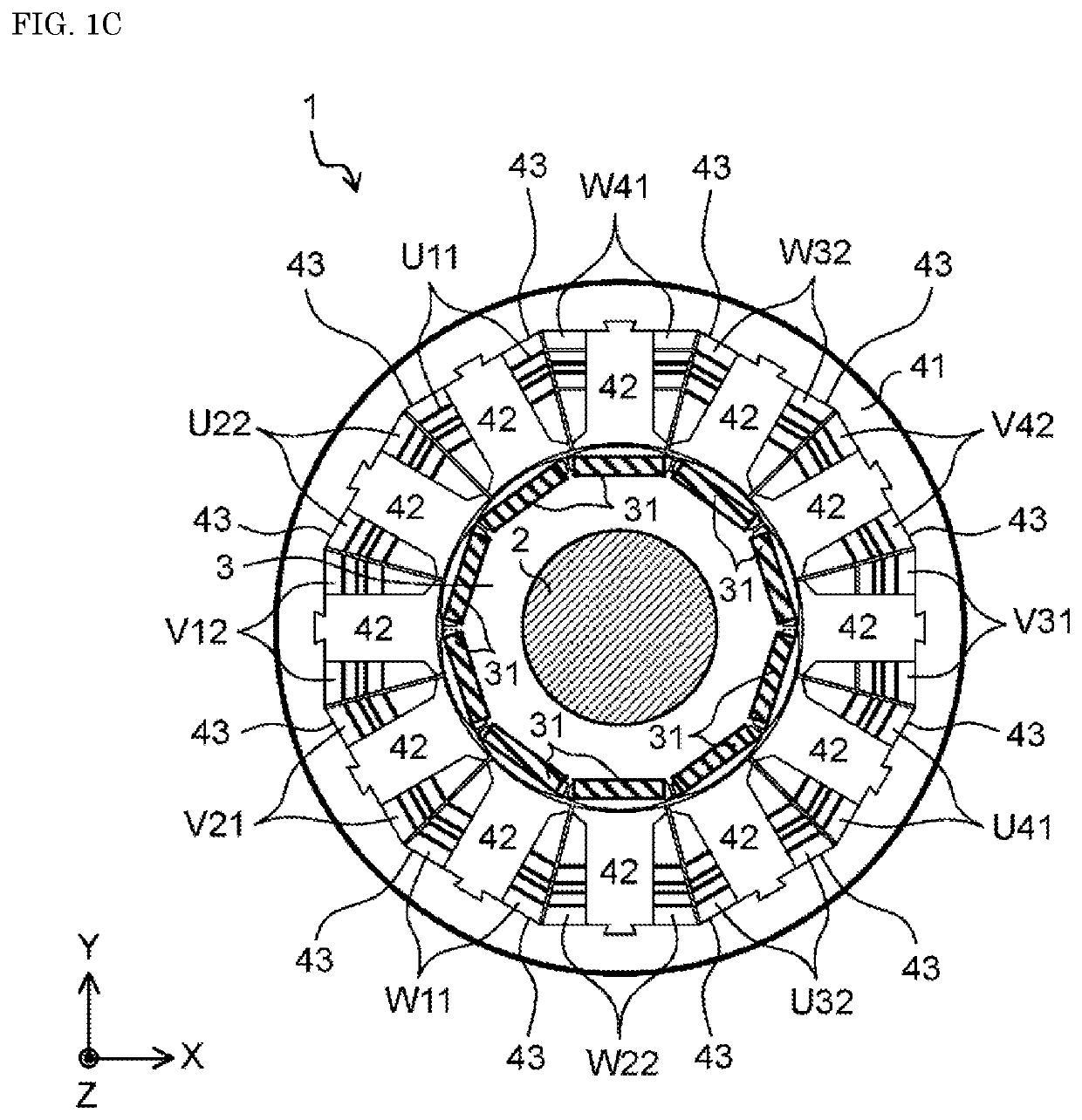

Motor

ActiveUS20200044503A1Highly efficient motorIncrease heat radiationMagnetic circuit stationary partsSynchronous machines with stationary armatures and rotating magnetsEngineeringPhysics

A motor includes a stator including a stator core and teeth respectively protruding from the stator core, and coils respectively wound onto the teeth n (n is an integer of 3 or greater) turns. In a cross section in a first direction representing each of directions of protrusion of the teeth from the stator core, a k-th (k is an integer, 1<k<n) turn of each of the coils lies at a center of a range wound with each of the coils onto the teeth in the first direction. The k-th turn of each of the coils is greater in cross-sectional area than each of a first turn and an n-th turn.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Systems and methods for a cooling fluid circuit

ActiveUS9309801B2Increase temperatureThermal efficiencyCoolant flow controlExhaust gas recirculationExhaust fumesEngineering

Various methods and systems are provided for cooling an engine system. In one example, a system includes an exhaust gas recirculation cooler and an engine. The system further includes a cooling fluid circuit in which the exhaust gas recirculation cooler and the engine are positionable in series with the exhaust gas recirculation cooler disposed upstream of the engine.

Owner:GE GLOBAL SOURCING LLC

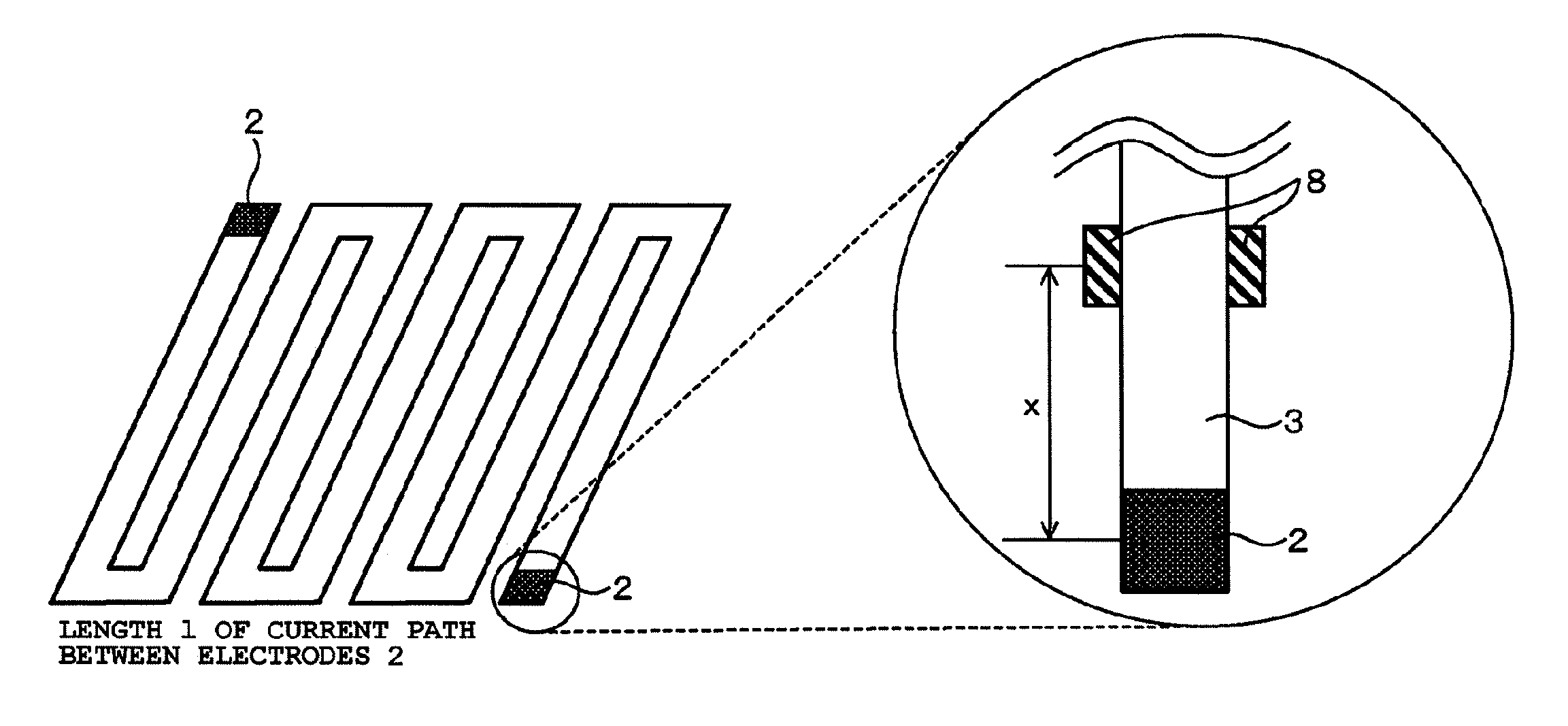

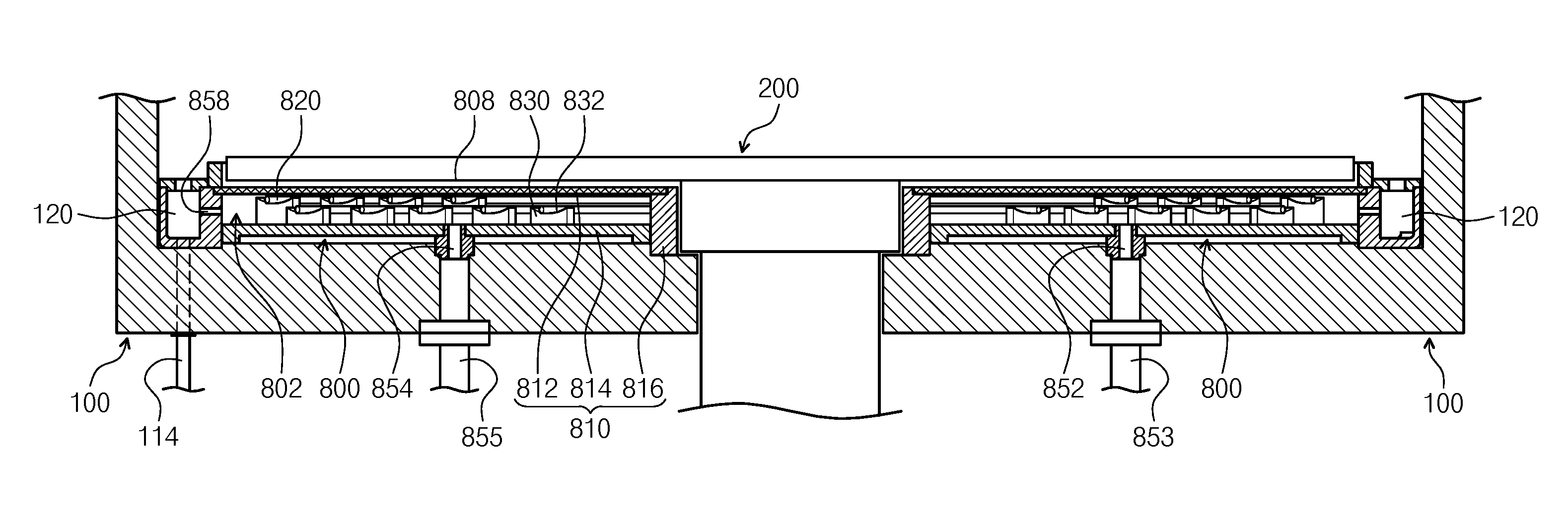

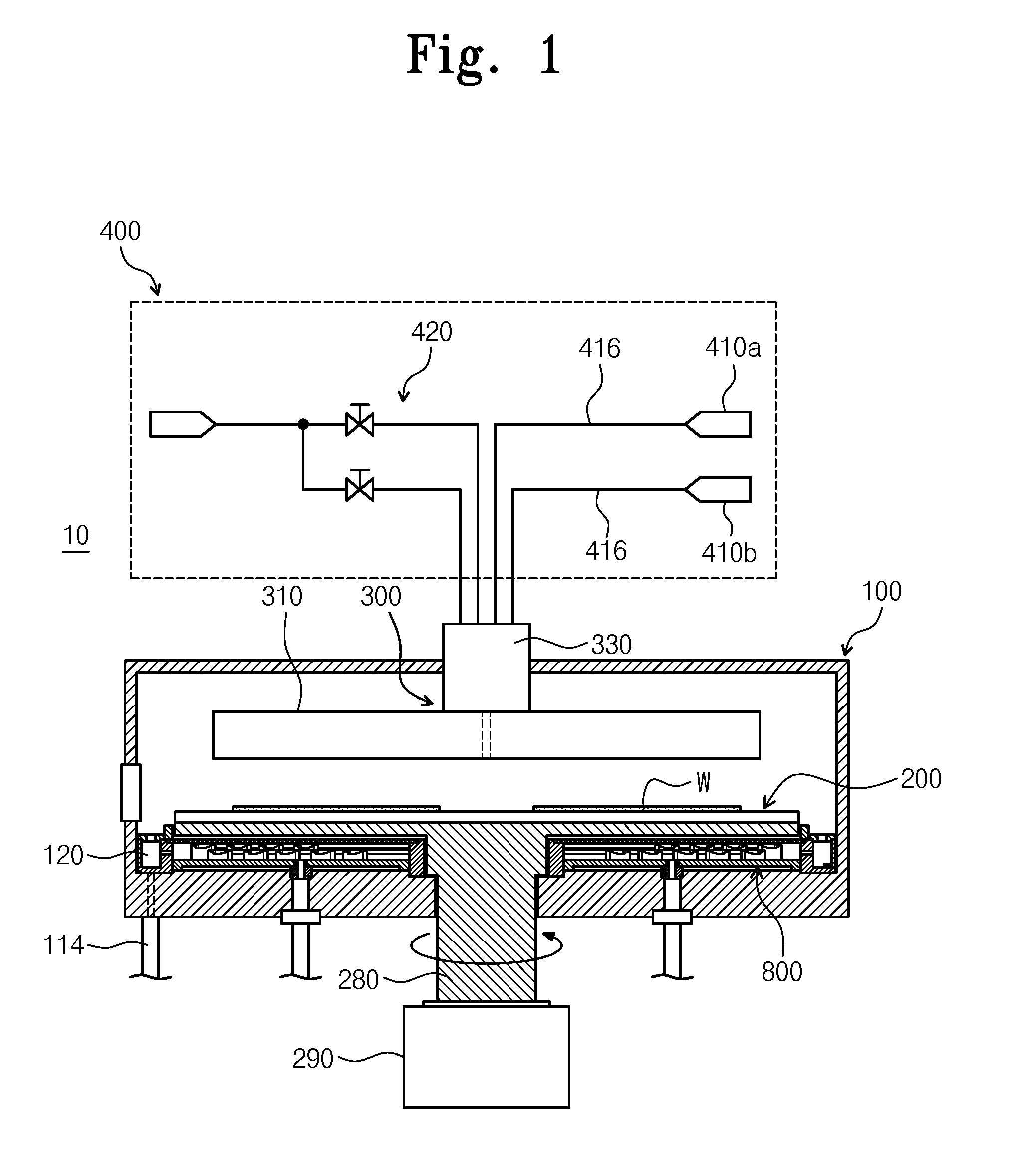

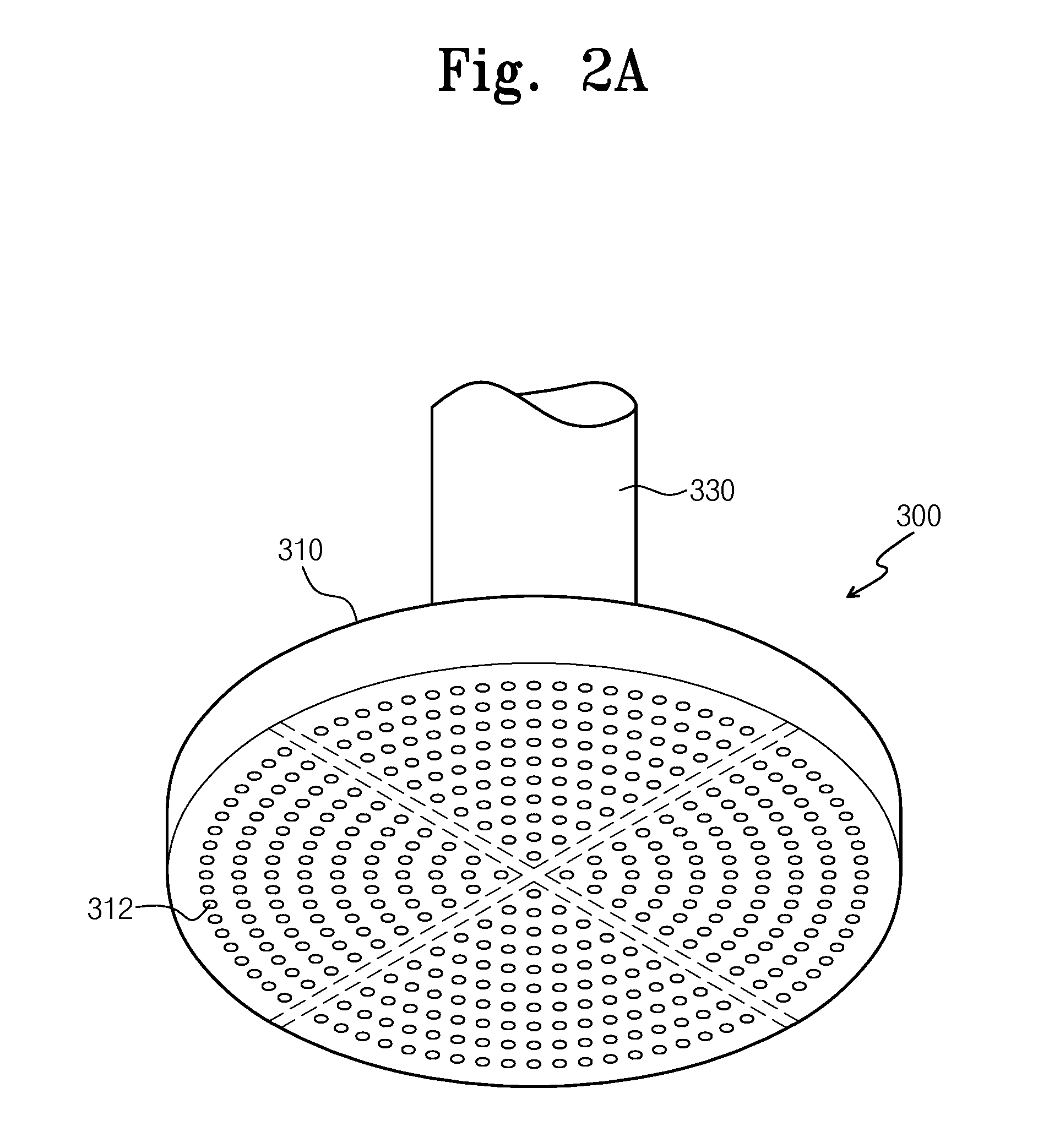

Heater member and substrate processing apparatus having the same

InactiveUS20160230282A1Minimizing temperature variationMinimize changesSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSusceptorElectrical and Electronics engineering

The present invention relates to a substrate processing apparatus. The substrate processing apparatus according to the present invention comprises: a processing chamber; substrate susceptor, installed in the processing chamber, which rotates in connection with a rotary shaft, a plurality of substrates being disposed on the same plane thereof; a heater member located on the lower surface of the substrate susceptor; and a spraying member for spraying a gas onto the entire processing surface of the substrate at a position corresponding to each of the plurality of substrates disposed on the substrate susceptor, wherein the heater member has an inner space in which heating wires for heating the substrate susceptor are arranged in a plurality rows of verticality and horizontality in a concentric circle based on the rotary shaft of the substrate susceptor.

Owner:KOOKJE ELECTRIC KOREA

Motor

ActiveUS20200006993A1Easily radiatedHighly efficient motorCooling/ventillation arrangementWindings conductor shape/form/constructionEngineeringPhysics

A motor includes a stator including a stator core and teeth respectively protruding from the stator core in predetermined directions of protrusion, and coils respectively wound onto the teeth n (n is an integer of 3 or greater) turns including first to n-th turns. A k-th (k is an integer, 1<k<n) turn of each of the coils lies at a center of a range wound with each of the coils onto the teeth in a corresponding one of the directions of protrusion of the teeth from the stator core. Each of the first turn and the n-th turn when each of the coils is cut in a corresponding one of the directions of protrusion of the teeth is greater in cross-sectional area than the k-th turn.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Device for preheating a fluid, in particular coolant for a combustion engine

ActiveUS11243009B2Improve thermal efficiencySimple and economical structureOhmic-resistance heatingWater heatersElectrical resistance and conductanceEngineering

Owner:VOLANTE NINO

Process for high efficiency, low pollution fuel conversion

ActiveUS9702546B2Harmful emissionImprove thermal efficiencyFuel supply regulationEmission preventionLithiumCombustion chamber

A process for reducing the CO2 and other pollutants produced by the combustion of a fuel in a combustion chamber while maintaining or increasing the efficiency of said combustion includes feeding to the combustion chamber, or preconditioning the combustion chamber, with a catalyst, preferably a lithium based salt Monitoring the energy output and components of the exhaust gas stream to maintain optimum operation allows reduction, during the process, of the catalyst delivery and feed air. The presence of the catalyst results in increased efficiency of operation and reduction of pollutants generated.

Owner:THE TAPLIN FAMILY TRUST

Control apparatus for internal combustion engine

ActiveUS9654041B2Restrains a thermal efficiency of an internal combustion engine from deterioratingAvoid response delaysHybrid vehiclesElectrical controlOperating pointExternal combustion engine

A control apparatus for an internal combustion engine is provided. The control apparatus includes an ECU. The ECU is configured to change, in a stepped manner, an air-fuel ratio of the internal combustion engine so as to change over a combustion mode of the internal combustion engine between lean combustion and stoichiometric combustion, when an operating point of the internal combustion engine satisfies a first changeover condition that is defined by a rotational speed and a torque of the internal combustion engine. The first changeover condition is defined by the rotational speed and the torque that correspond to a predetermined intake air amount at which a thermal efficiency of the internal combustion engine is maintained before and after changeover of the combustion mode.

Owner:TOYOTA JIDOSHA KK

Method for smelting lead-bismuth concentrate in oxygen-rich side-blown duplex furnace

InactiveCN103060578BImprove direct yieldThe melting process is simpleProcess efficiency improvementLead bismuthFlue gas

The invention discloses a method for smelting a lead-bismuth concentrate in an oxygen-rich side-blown duplex furnace, belonging to the technical field of smelting bismuth concentrates. The method comprises the steps of preparing raw materials, and smelting in the oxygen-rich side-blown oxidation-reduction duplex furnace to directly produce a crude bismuth alloy. According to the method, scrap iron is not required to be added, so that the production cost is low; the concentration of SO2 in flue gases generated from oxidizing smelting reaches 10 to 25 percent, and the SO2 can be recycled to prepare acid, so that the problem of environmental pollution caused by the flue gases is solved; and the oxidation-reduction duplex smelting ensures that the direct yield of bismuth is greatly promoted.

Owner:HUNAN JINWANG BISMUTH

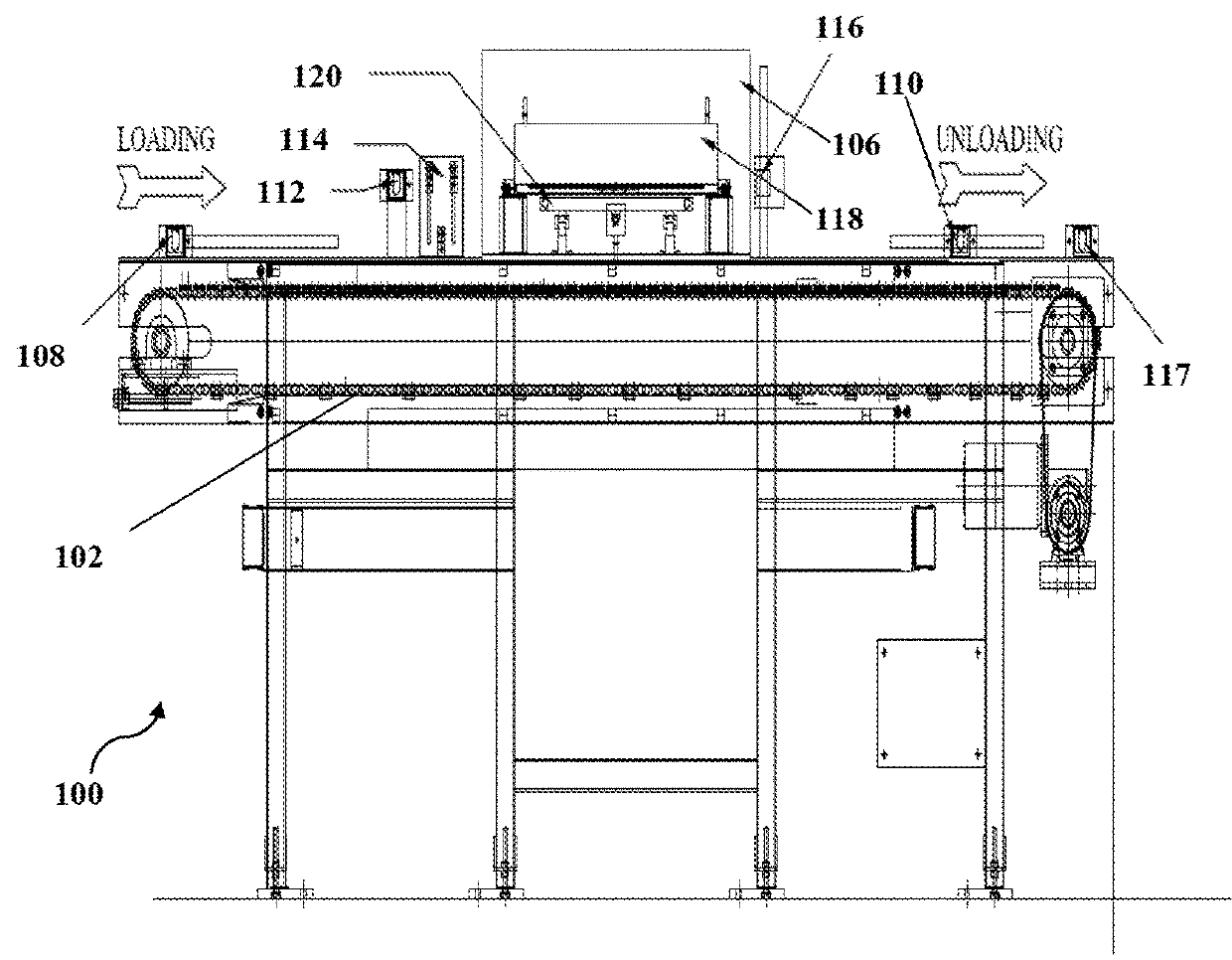

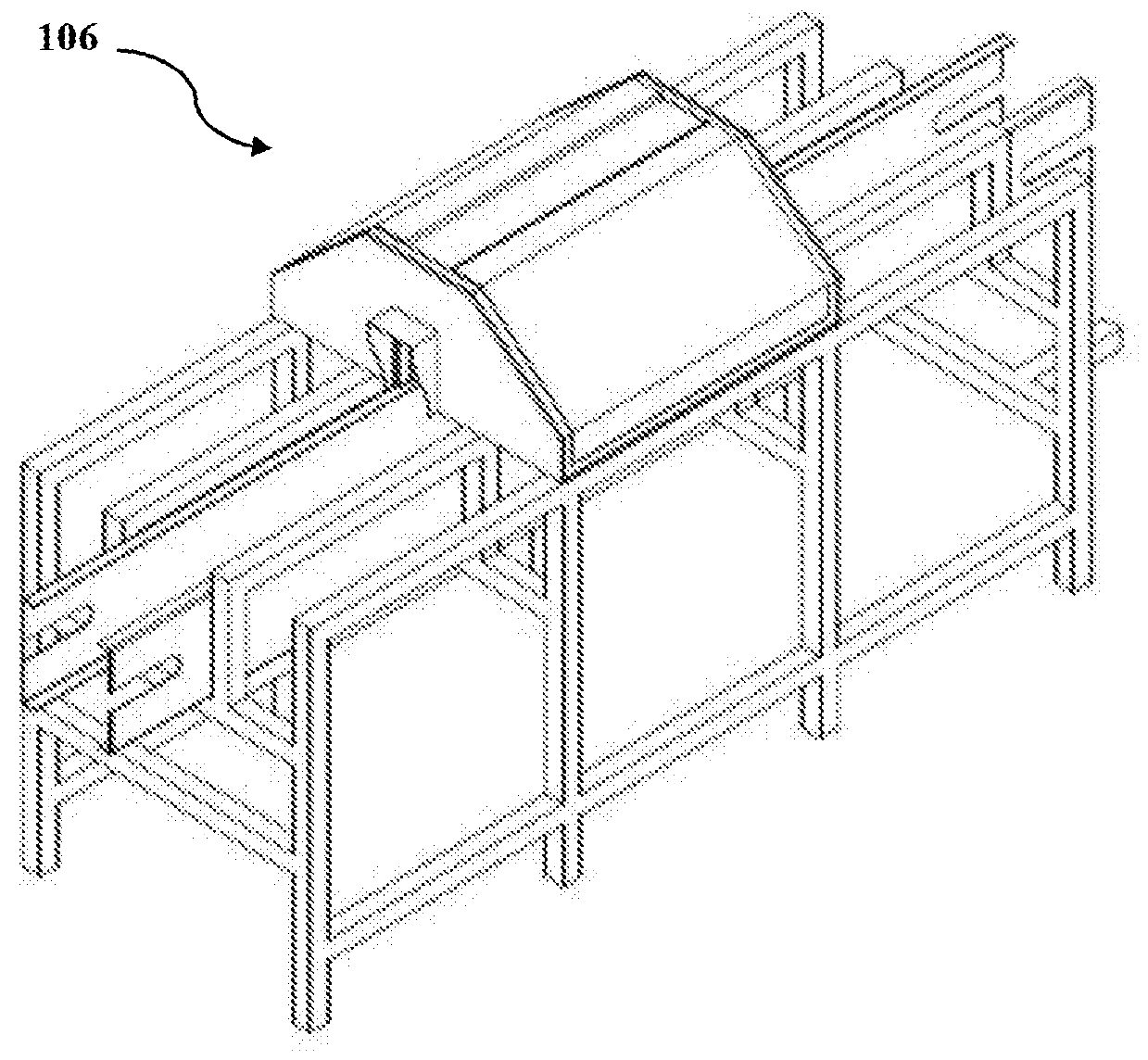

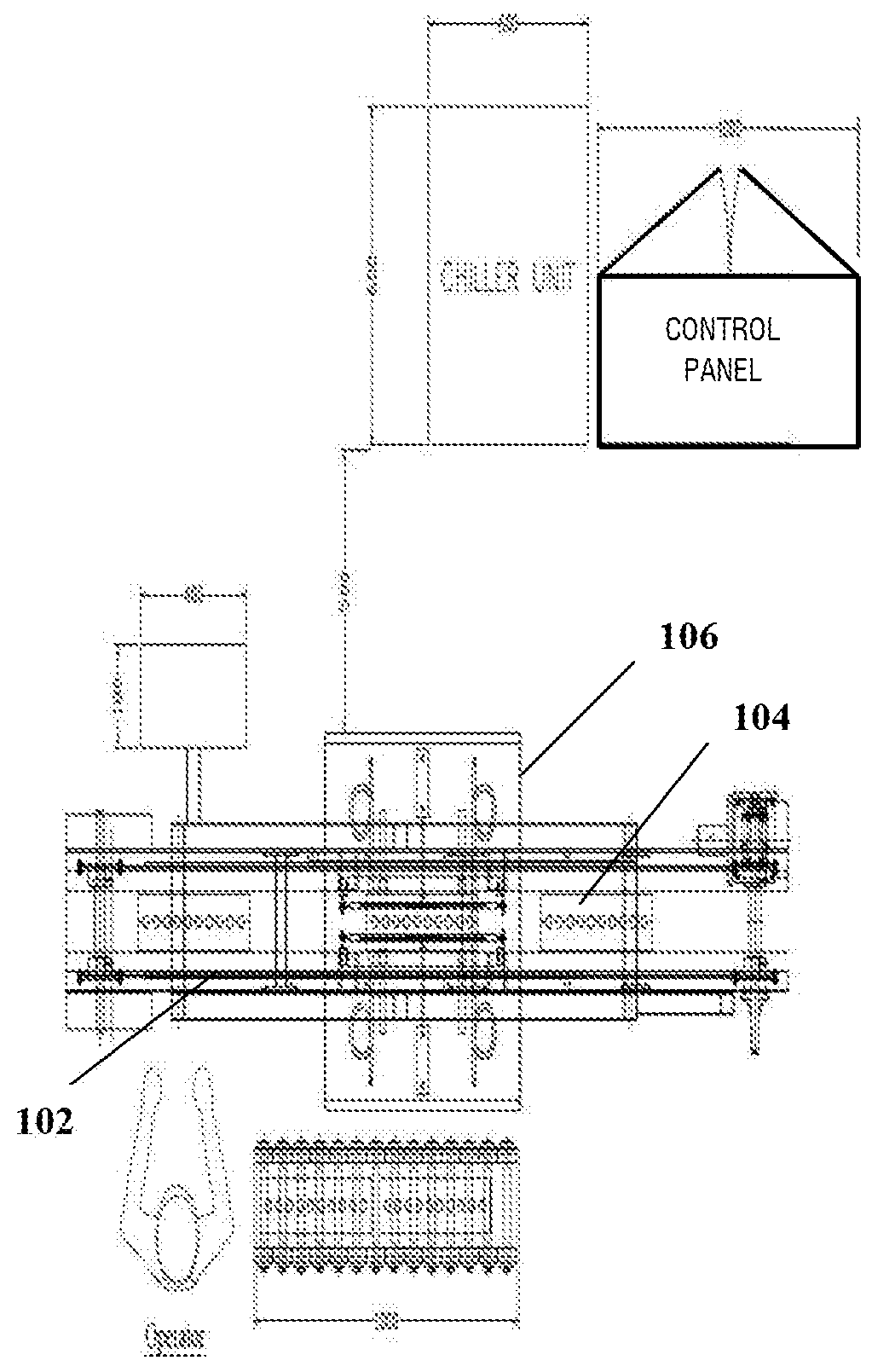

Heat Treatment Method And Equipment For Mass Processing Of Components And/Or Assembly Of Components

InactiveUS20180274048A1Contribute to thermal efficiencyMaximize throughputIncreasing energy efficiencyFurnace typesProcess engineeringHigh intensity

Disclosed is heat treatment equipment and process that facilitates heat treatment process by introducing focused high intensity infrared heating to components on a conveyorized system for maximizing the throughput of heat treated components.

Owner:LITEL INFRARED SYST PVT LTD

Motor

ActiveUS11196312B2Improve cooling effectHighly efficient motorCooling/ventillation arrangementWindings conductor shape/form/constructionEngineeringMechanical engineering

A motor includes a stator including a stator core and teeth respectively protruding from the stator core in predetermined directions of protrusion, and coils respectively wound onto the teeth n (n is an integer of 3 or greater) turns including first to n-th turns. A k-th (k is an integer, 1<k<n) turn of each of the coils lies at a center of a range wound with each of the coils onto the teeth in a corresponding one of the directions of protrusion of the teeth from the stator core. Each of the first turn and the n-th turn when each of the coils is cut in a corresponding one of the directions of protrusion of the teeth is greater in cross-sectional area than the k-th turn.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com