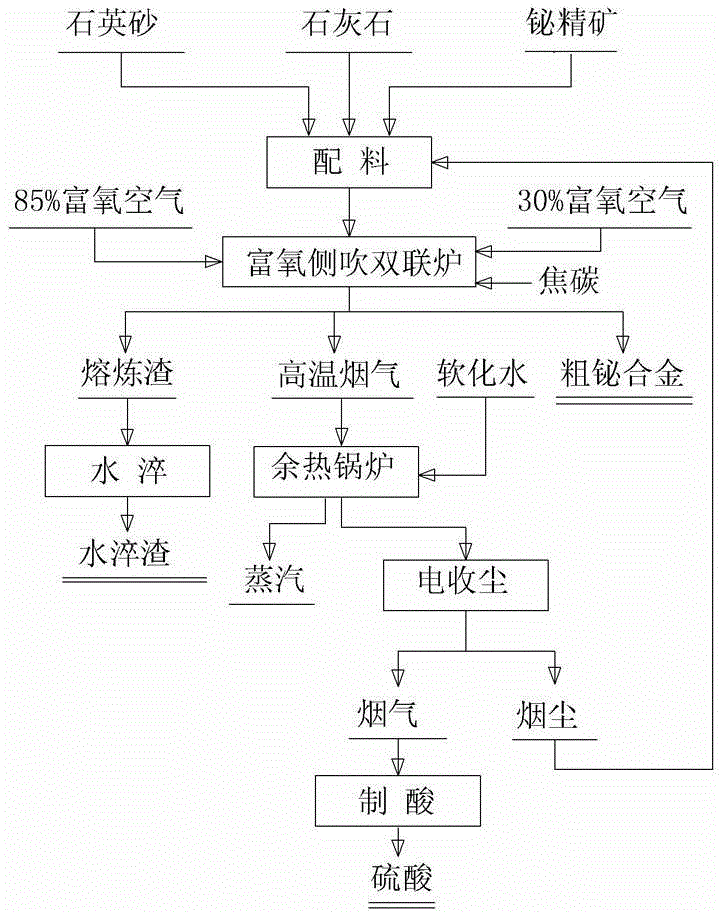

Method for smelting lead-bismuth concentrate in oxygen-rich side-blown duplex furnace

An oxygen-enriched and concentrated ore technology, applied in the direction of improving process efficiency, can solve problems such as increased production costs and energy consumption, failure to meet environmental protection requirements, and long time-consuming metallurgical processes, so as to achieve low production costs and increase hearth index value , The effect of simplifying the smelting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with specific embodiments in conjunction with the accompanying drawings, but it is not interpreted as a specific limitation to the present invention.

[0024] The main components of the lead-bismuth concentrate processed in this example are as follows: Bi36.83; Pb12.24 S19.77; Cu4.08; Fe2.67; Ag0.000921; SiO 2 2.09; CaO0.38;

[0025] A method for smelting lead-bismuth concentrate in an oxygen-enriched side-blown double furnace, comprising the following steps:

[0026] ① Ingredients

[0027] According to the mass ratio of lead-bismuth concentrate:limestone:quartz sand=1:0.07:0.12, the material is weighed, after the disc feeder feeds the material, it is sent to the oxidation smelting section of the oxygen-enriched side-blown double furnace by the belt conveyor Inside;

[0028] ②Coarse bismuth alloy smelting

[0029] For the furnace material entering the oxidation smelting section of the oxygen-enriched side-blown...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com