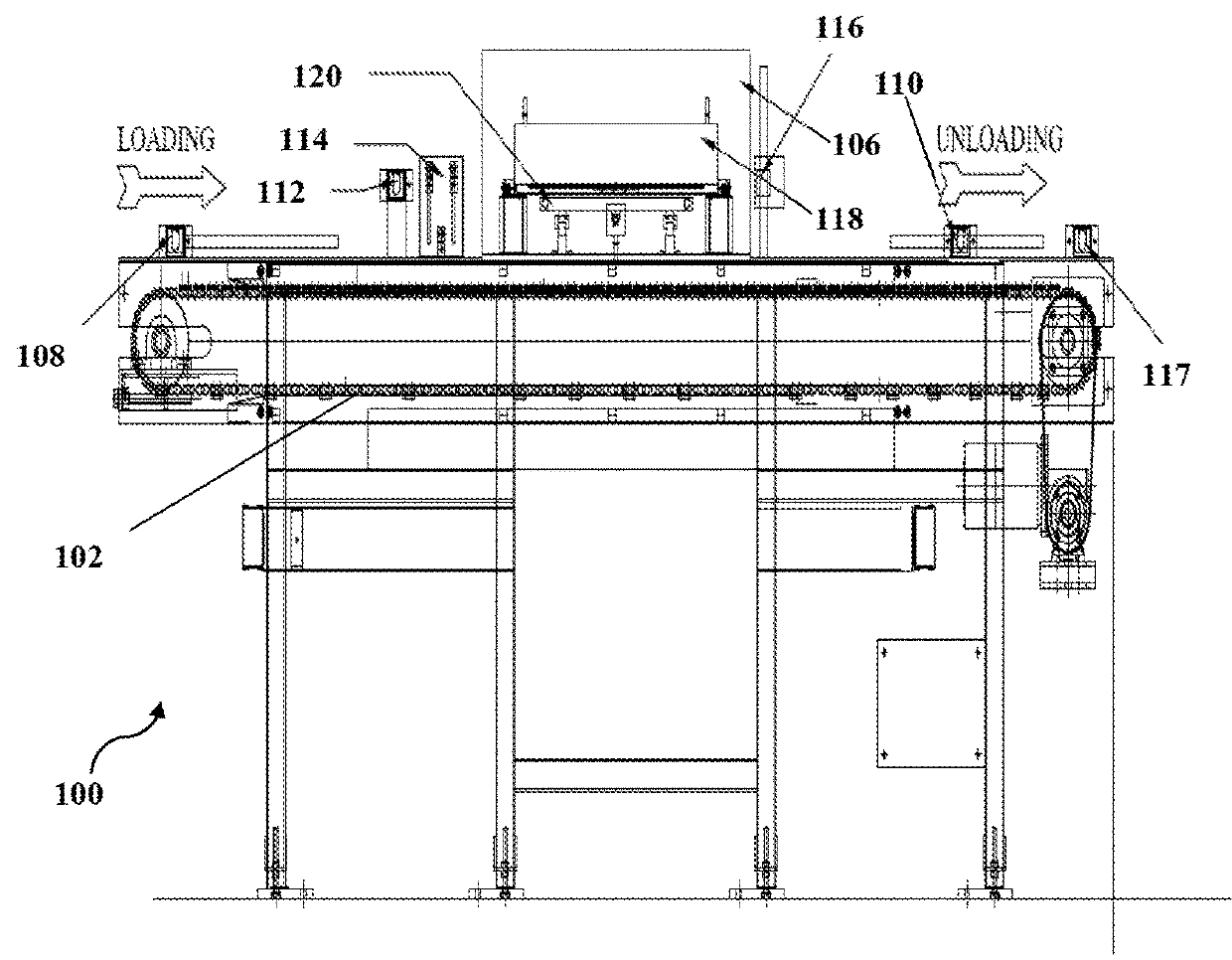

Heat Treatment Method And Equipment For Mass Processing Of Components And/Or Assembly Of Components

- Summary

- Abstract

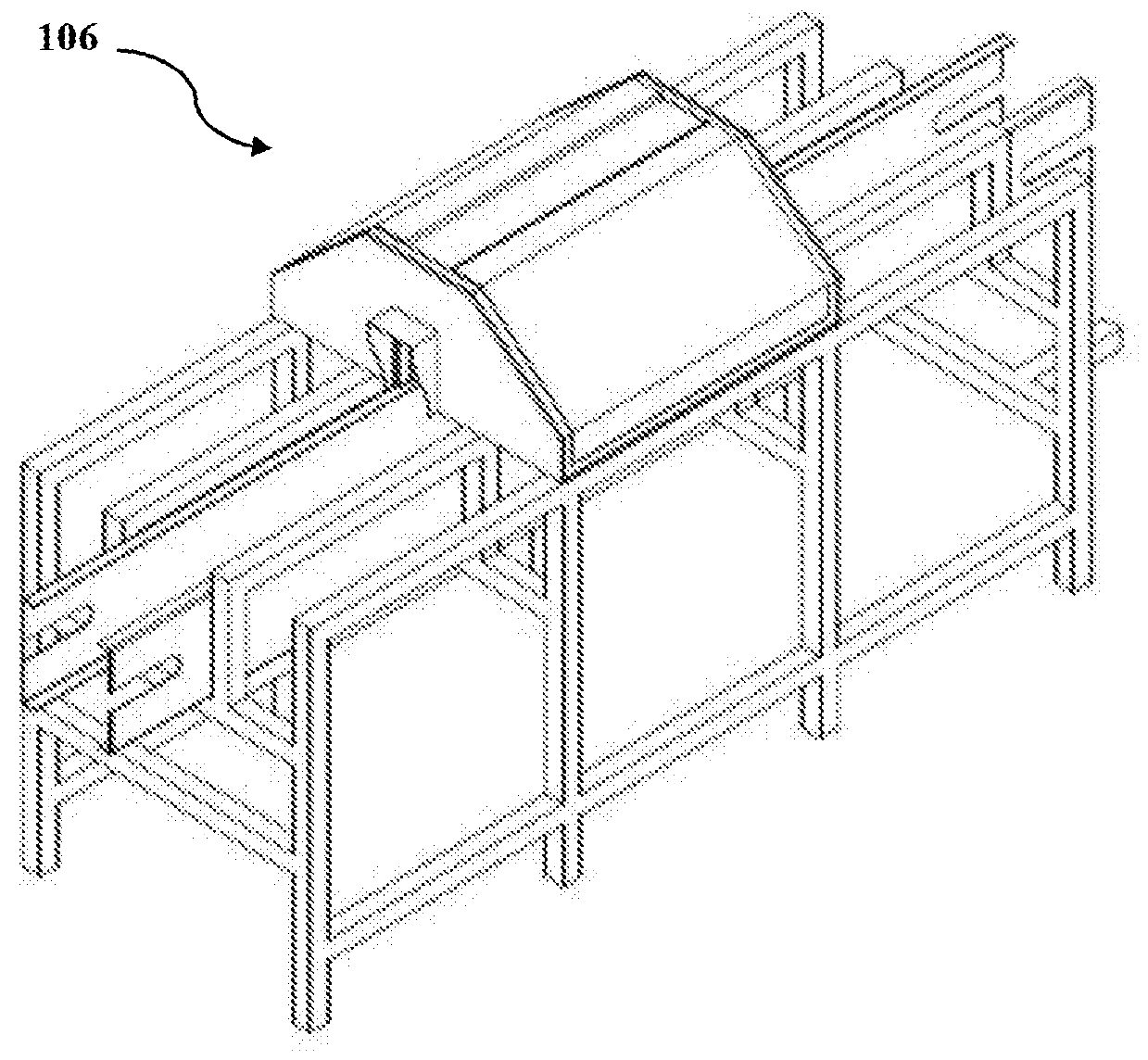

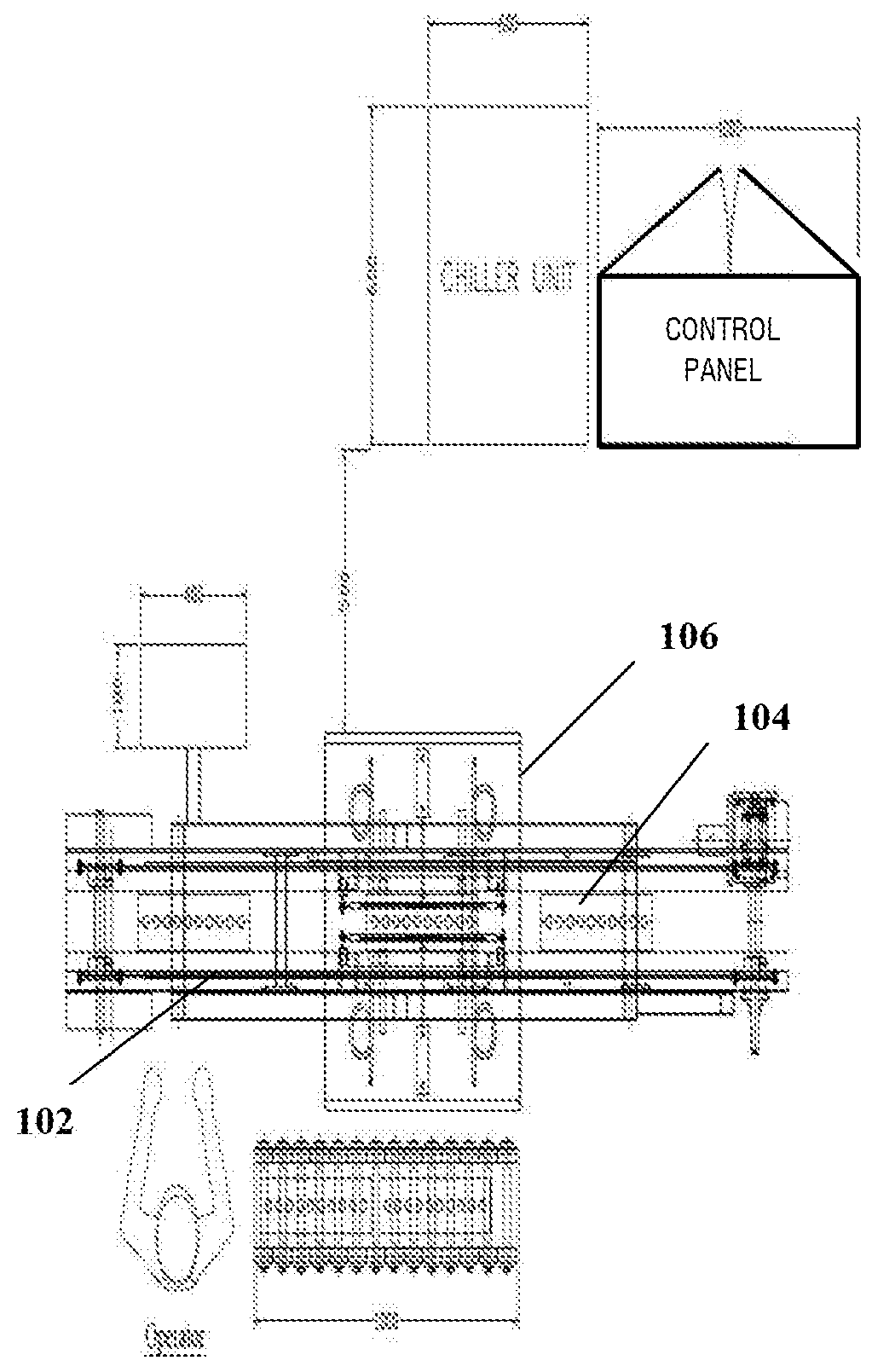

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

[0029]A sample processed components having undergone the above heat treatment method were measured in the lab for softening parameters. It was proven that components processed with the said method exhibit equivalent or better values and reduce the process cycle per component by up to 50%. The contribution of enhanced thermal penetration of infrared heat as designed for the above referenced equipment of the said invention thereby proves that this improved method not only delivers productivity and energy efficiency but also enhanced quality to the heat treatment process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com