Method for preparing graphene energy storing material through electrochemical cathodic disbonding

A technology of cathodic stripping and energy storage materials, which is applied in the field of new materials, can solve the problems of high cost, reduce the conductivity of graphene materials, and oxidize the surface of graphene, and achieve the effects of low cost, easy industrialization and application, and easy control of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Preparation of graphene by exfoliating graphite rods in acetonitrile (AN) solution at cathode-10V

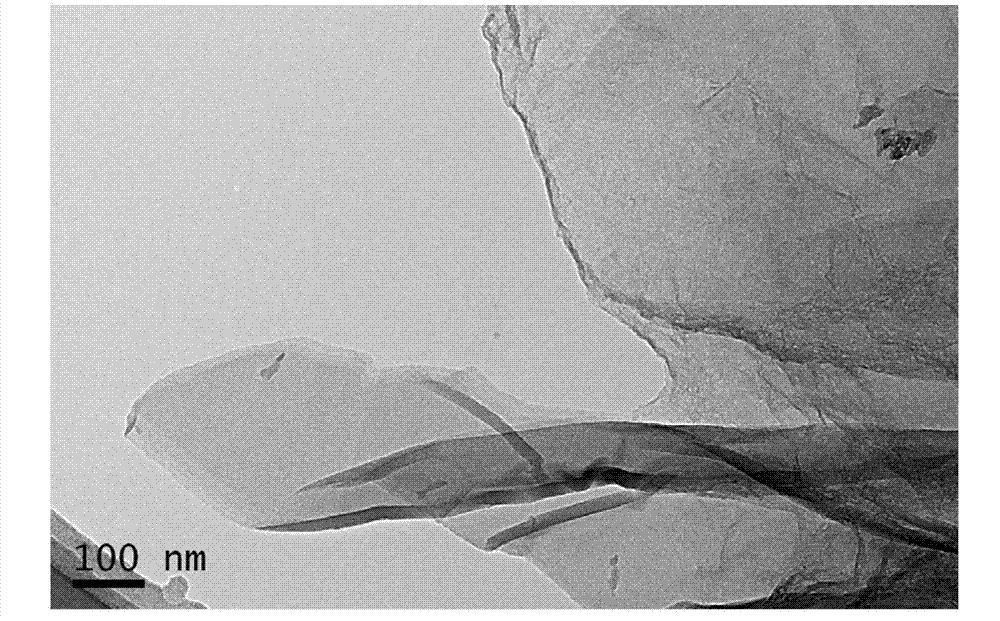

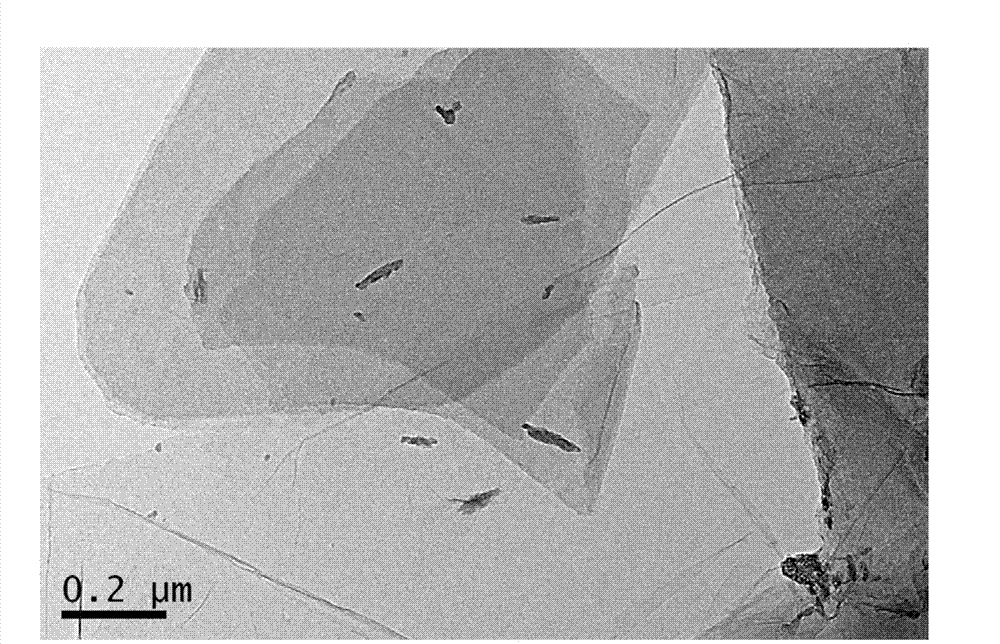

[0028] With Pt sheet as the anode and high-purity graphite rod as the cathode, in the acetonitrile solution of 0.5mol / L tetrabutyl ammonium hexafluorophosphate, constant voltage –10V, DC strong cathodic polarization for 2h, and then the product obtained from the cathode was Wash with water and ethanol for 5 times, disperse by ultrasonic (99W, 30kHz, 5h), centrifuge at a low speed of 1500 rpm, then centrifuge the obtained supernatant at a high speed of 13300 rpm, and finally dry the obtained solid product in vacuum at 40°C to obtain the product . TEM showed that graphite was exfoliated to form graphene material. A uniformly dispersed sol can be obtained by ultrasonically dispersing the dried product in N,N-dimethylformamide (DMF).

Embodiment 2

[0029] Example 2: Preparation of graphene by exfoliating graphite rods in N,N-dimethylformamide (DMF) solution at cathode-10V

[0030] With Pt sheet as anode and high-purity graphite rod as cathode, in DMF solution of 0.5mol / L tetrabutylammonium hexafluorophosphate, constant voltage -10V strong cathode polarization for 2h, and then the product obtained from the cathode was dehydrated with absolute ethanol Wash 5 times, ultrasonically (95W, 30kHz, 5h) disperse, centrifuge at a low speed of 1500 rpm, then centrifuge the obtained supernatant at a high speed of 13300 rpm, and finally vacuum dry the obtained solid product at 40°C to obtain the product. TEM showed that graphite was exfoliated to form graphene material.

Embodiment 3

[0031] Example 3: Preparation of graphene by exfoliating graphite rods in propylene carbonate (PC) solution at cathode-10V

[0032] With the Pt sheet as the anode and the high-purity graphite rod as the cathode, in a PC solution of 0.5mol / L tetrabutylammonium hexafluorophosphate, a constant voltage of -30V is strongly cathodically polarized for 0.5h, and then the product obtained from the cathode is anhydrous Wash with ethanol 5 times, disperse by ultrasonic (90W, 30kHz, 3h), centrifuge at low speed 1500 rpm, then centrifuge the obtained supernatant at high speed 13300 rpm, and finally vacuum dry the obtained solid product at 40°C to obtain the product. TEM showed that graphite was exfoliated to form graphene material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com