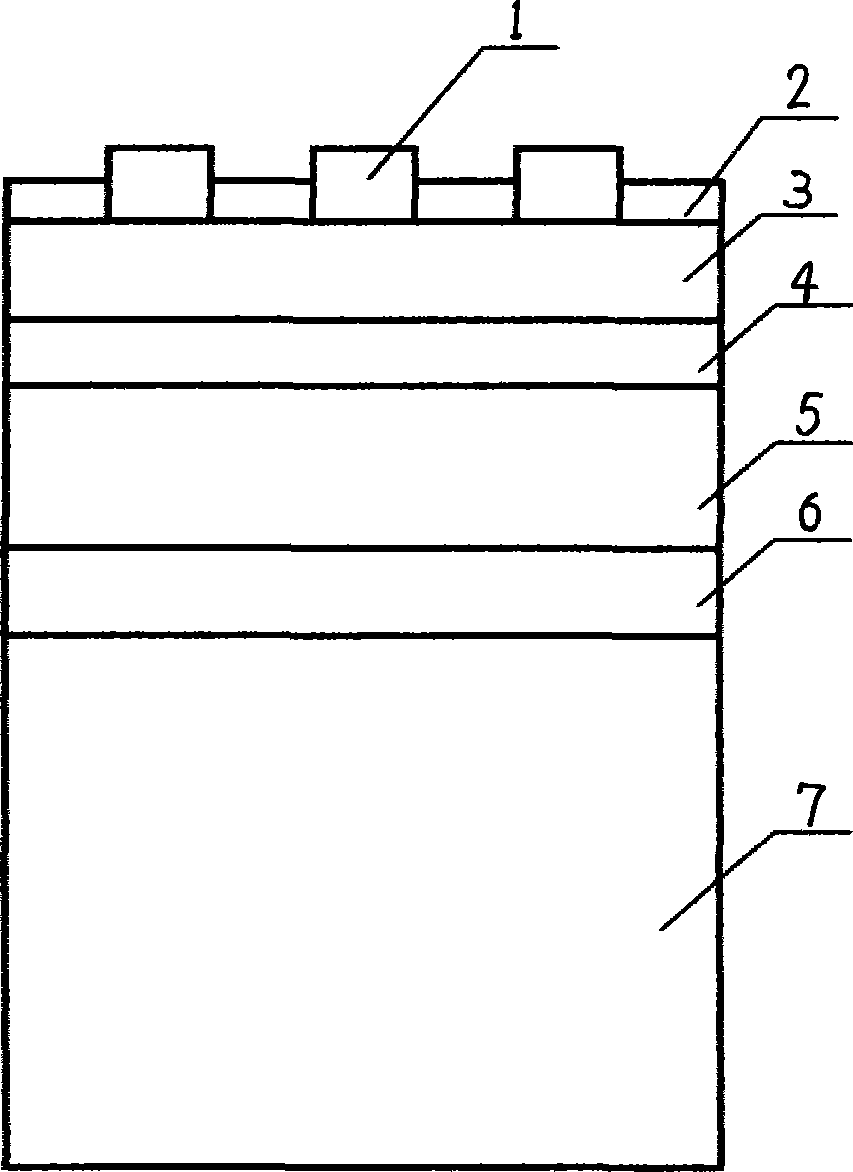

Flexible CIGS thin-film solar cell and absorption layer preparation thereof

A technology of thin-film solar cells and copper indium gallium selenide, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as uncontrollability, poor controllability, and uncontrollable uniformity, and achieve controllable process, simple equipment, The effect of reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: on the 20-100 μm titanium foil, prepare double-layer film bottom electrode Mo with dc magnetron sputtering method, the thickness of bottom electrode is 0.5-1.5 μm, then use CuIn and CuGa alloy target material to magnetize on Mo thin film The metal prefabricated layer is prepared by the controlled sputtering method, and the thickness is 0.6-1.2 μm. The substrate deposited with the bottom electrode Mo and the copper indium gallium metal prefabricated layer is placed in a quartz tube, and at the same time, a 0.5-5g solid selenium source is placed in the tube, and vacuum-sealed. Put it into a tube furnace with segmental program temperature control, and heat up quickly and evenly, so that the temperature of the area where the substrate is located is controlled at 400-590 ° C, and the temperature of the area where the solid selenium source is located is controlled at 180-300 ° C. According to the metal prefabricated layer Thickness, 10-30min of selenization trea...

Embodiment 2

[0025] Embodiment 2: Substrate material is changed into stainless steel foil, other conditions are identical with embodiment 1, make CuIn 1-X Ga X Se 2 Compound semiconductor thin films.

Embodiment 3

[0026] Embodiment 3: change solid-state selenium source into solid-state sulfur source, other conditions are identical with embodiment 1, make CuIn 1-X Ga X S 2 Compound semiconductor thin films.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com