Preparation method of corundum/mullite light-weight heat insulating material

A lightweight thermal insulation, mullite technology, applied in ceramic products, other household appliances, household appliances, etc., can solve the problems of low application value, difficult to prepare samples, long drying cycle, etc., to avoid sample cracking, Small drying shrinkage and the effect of lowering the sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

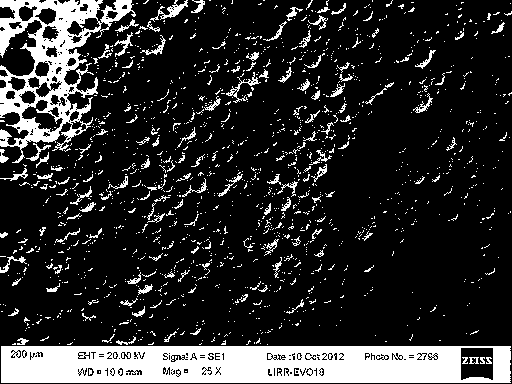

Image

Examples

Embodiment 1

[0027] Aluminum oxide fine powder with an average particle size of 5.0 μm, deionized water with 15% of the quality of alumina fine powder, sodium ion-stabilized silica sol (SiO 2 The mass concentration is 30wt.% (produced by Zhejiang Shangyu Yuda Chemical Co., Ltd.), and 0.4% formamide of alumina micropowder is used for batching, and the pH value of the slurry is adjusted by ball mill mixing and ammonia water to obtain a slurry with pH = 9-10 . Transfer the slurry obtained by ball mill mixing to a mixing tank, add sodium lauryl sulfate with 5% free water quality in the slurry, and foam through mechanical stirring to obtain a foam slurry, and then add it to the foam slurry while stirring NH 4 Cl solution, control of NH in foam slurry 4 The concentration of Cl is 0.10mol / L, and the foam slurry after stirring is injected into the mold, and the foam slurry is quickly solidified and formed; after demoulding, the green body is first dried in a constant temperature and humidity box...

Embodiment 2

[0029] Aluminum oxide fine powder with an average particle size of 1.5 μm, deionized water with 15% of the quality of alumina fine powder, sodium ion-stabilized silica sol (SiO 2 The mass concentration is 30wt.% (produced by Zhejiang Shangyu Yuda Chemical Co., Ltd.), formamide with 0.6% alumina micropowder mass is used for batching, and the pH value of the slurry is adjusted by ball mill mixing and ammonia water to obtain a slurry with pH = 9-10 . Transfer the slurry obtained by ball mill mixing to a mixing tank, add sodium dodecylbenzene sulfonate with 10% free water mass in the slurry, and obtain foam slurry by mechanical stirring and foaming, and then stir in the foam slurry side join NH 4 Cl solution, control of NH in foam slurry 4The concentration of Cl is 0.08mol / L, and the foam slurry after stirring evenly is injected into the mold, and the foam slurry is quickly solidified and formed; after demolding, the green body is first dried in a constant temperature and humidi...

Embodiment 3

[0031] Aluminum oxide fine powder with an average particle size of 5.0 μm, deionized water with 10% mass of alumina fine powder, ammonium ion-stabilized silica sol (SiO 2 The mass concentration is 20wt.% (produced by Zhejiang Shangyu Yuda Chemical Co., Ltd.), ethylene glycol with a mass of 0.2% of alumina micropowder is used for batching, and the pH value of the slurry is adjusted by ball mill mixing and ammonia water to obtain a slurry with a pH of 9 to 10. material. Transfer the slurry obtained by ball mill mixing to a mixing tank, add ammonium lauryl sulfate with 8% free water quality in the slurry, and foam through mechanical stirring to obtain a foam slurry, and then add it to the foam slurry while stirring NH 4 Cl solution, control of NH in foam slurry 4 The concentration of Cl is 0.12mol / L, and the foam slurry after stirring is injected into the mold, and the foam slurry is quickly solidified and formed; after demoulding, the green body is first dried in a constant te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com