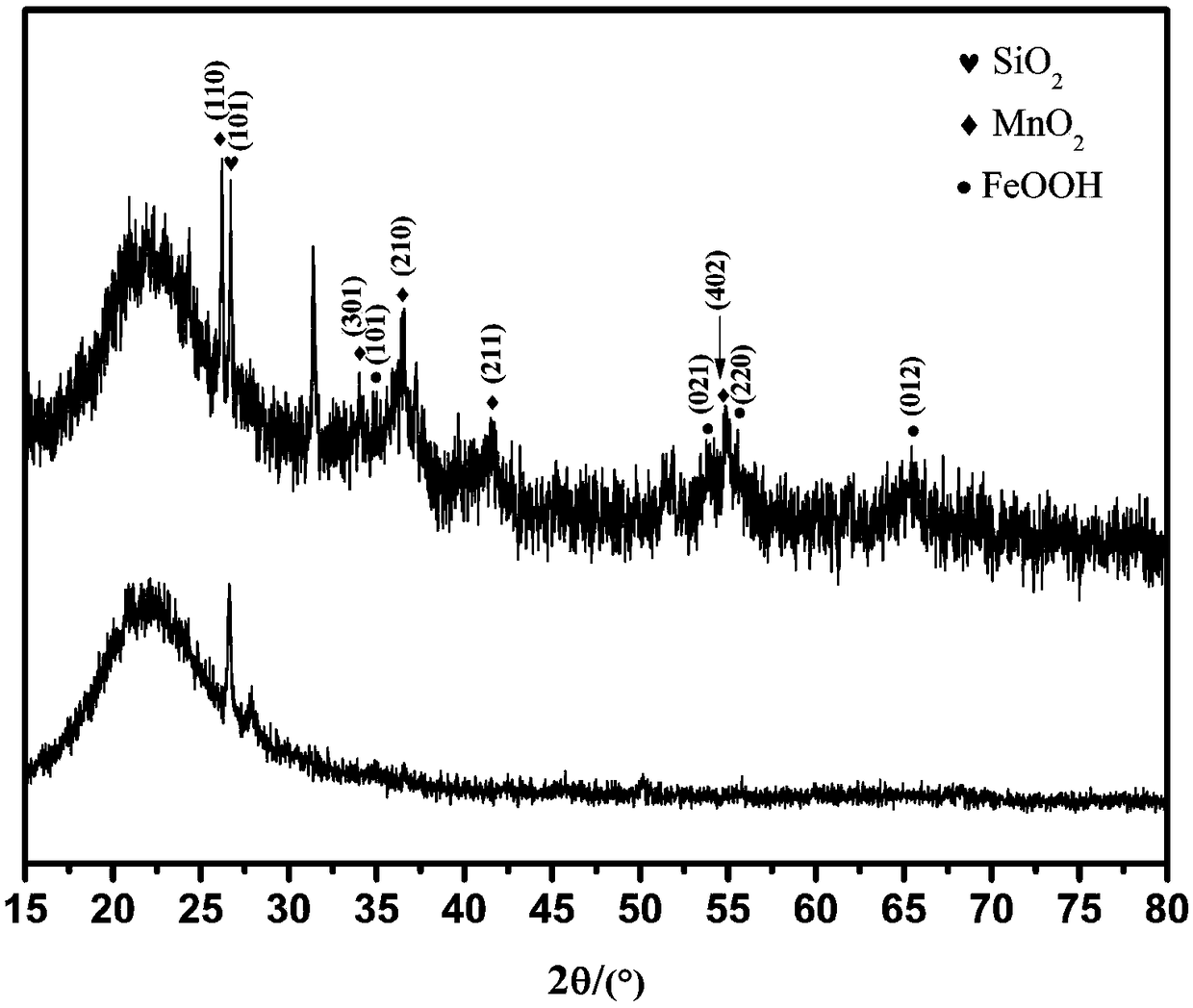

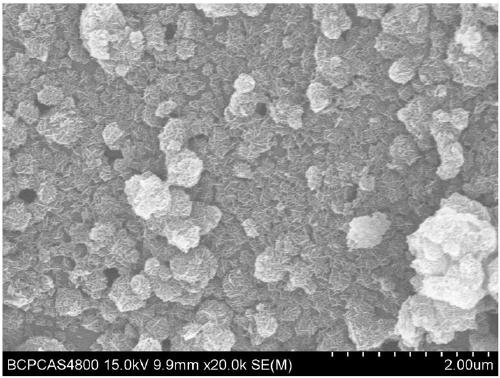

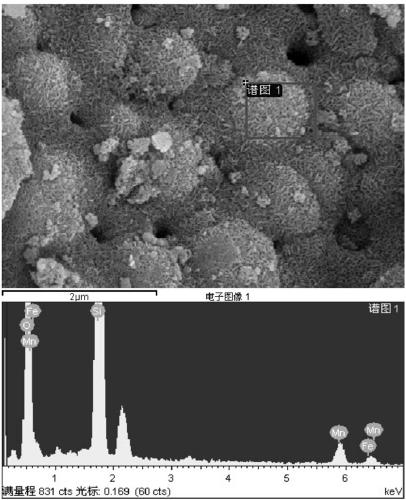

Preparation method of FeOOH/ MnO2@ diatomite composite material

A technology of composite materials and diatomite, applied in chemical instruments and methods, water/sewage treatment, adsorption water/sewage treatment, etc., can solve problems such as preparation methods that have not yet been seen, and achieve great theoretical and practical significance, production equipment Compared with the requirements, the effect of increasing the adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1 of the present invention provides a kind of FeOOH / MnO 2 The preparation method of @diatomite composite material specifically includes the following steps:

[0045] S1. Weigh 20.0g of diatomaceous earth and add it to a 500mL beaker, add 200mL of deionized water, stir magnetically for 10min, then add 5.0g of FeCl 3 Stir to dissolve, and adjust the pH value to 4.0 by adding ammonia water dropwise, then add 0.2 g of sodium dodecylbenzenesulfonate, disperse and dissolve to obtain a diatomite mixed solution;

[0046] S2. Weigh 4.5g ammonium persulfate and 5.0g potassium permanganate respectively, dissolve them in 10mL deionized water to prepare ammonium-manganese composite solution, then add the ammonium-manganese composite solution dropwise to step S1 at a rate of 50 drops / minute In the prepared diatomite mixed solution, stir for 20 minutes, mix evenly, then add 3.6g of urea, stir for 20min, mix evenly to obtain a diatomite composite solution;

[0047] S3. Put...

Embodiment 2

[0051] Embodiment 2 of the present invention provides a kind of FeOOH / MnO 2 The preparation method of @diatomite composite material specifically includes the following steps:

[0052] S1. Weigh 20.0g of diatomaceous earth and add it to a 500mL beaker, add 200mL of deionized water, stir magnetically for 10min, then add 8.0g of FeCl 3 Stir to dissolve, and adjust the pH value to 4.0 by adding ammonia water dropwise, then add 0.3g sodium dodecylbenzenesulfonate, disperse and dissolve to obtain a diatomite mixed solution;

[0053] S2. Weigh 6.5g of ammonium persulfate and 8.0g of potassium permanganate respectively, dissolve them in 10mL of deionized water to prepare an ammonium-manganese composite solution, and then add the ammonium-manganese composite solution dropwise to step S1 at a rate of 45 drops / minute In the prepared diatomite mixed solution, stir for 20 minutes, mix evenly, then add 3.6g of urea, stir for 20min, mix evenly to obtain a diatomite composite solution;

[0...

Embodiment 3

[0058] Embodiment 3 of the present invention provides a kind of FeOOH / MnO 2 The preparation method of @diatomite composite material specifically includes the following steps:

[0059] S1. Weigh 30.0g of diatomaceous earth and add it to a 500mL beaker, add 200mL of deionized water, stir magnetically for 10min, then add 8.0g of FeCl 3 Stir to dissolve, and adjust the pH value to 5.0 by adding ammonia water dropwise, then add 0.3 g of sodium dodecylbenzenesulfonate, disperse and dissolve to obtain a diatomite mixed solution;

[0060] S2. Weigh 6.5g of ammonium persulfate and 8.0g of potassium permanganate respectively, dissolve them in 10mL of deionized water to prepare an ammonium-manganese composite solution, and then add the ammonium-manganese composite solution dropwise to step S1 at a rate of 45 drops / minute In the prepared diatomite mixed solution, stir for 20 minutes, mix evenly, then add 5.0 g of urea, stir for 20 minutes, mix evenly to obtain a diatomite composite solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com