600MPa grade low temperature high toughness weather corrosion resistant steel and its production method

A technology for atmospheric corrosion-resistant steel and a production method, which is applied in the field of low-carbon and low-alloy steel, can solve the problems of high price, difficult process control, and high production cost, and achieves reduced production cost, easy process control, and reduced steel plate scrap rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

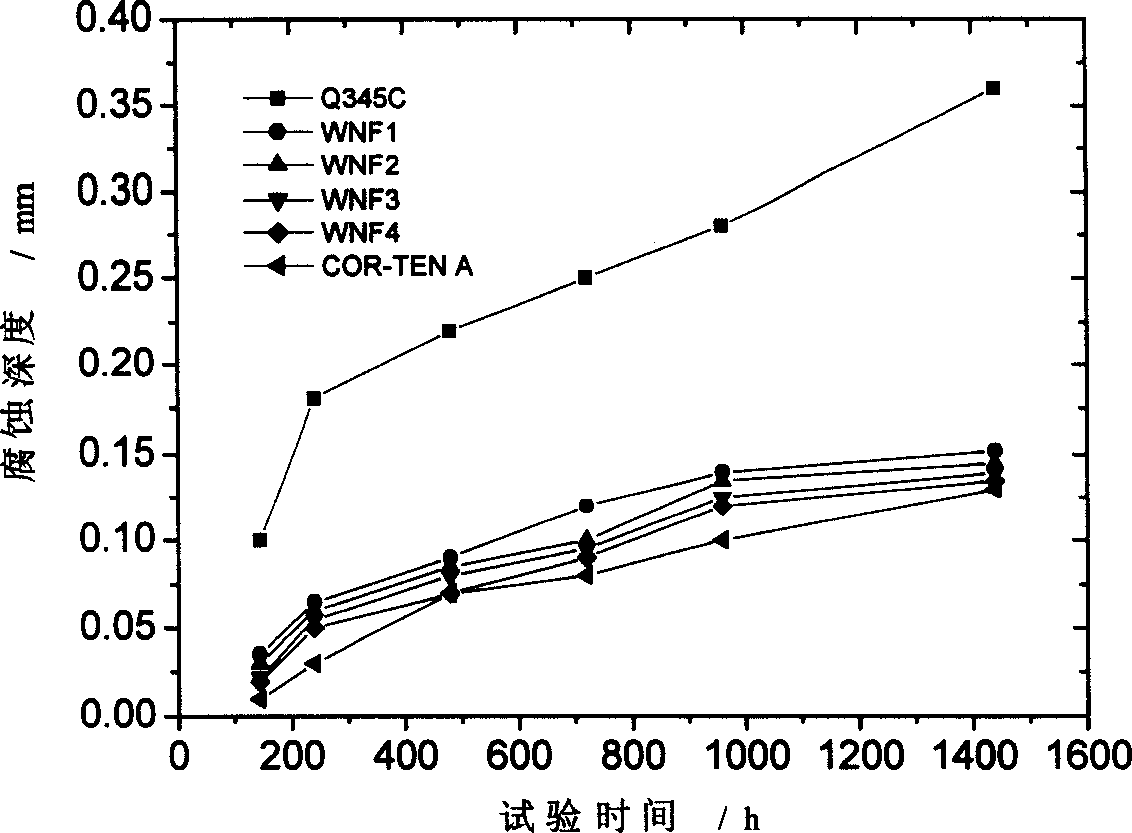

[0037] In the laboratory, 4 furnaces of the present invention were smelted in a 50kg vacuum induction furnace, and the concrete chemical compositions of the 4 furnace steels are shown in Table 1.

[0038] Through the production method described in the present invention:

[0039] The production steps of its specific test:

[0040] 1) Smelting: adopt molten iron desulfurization, dephosphorization technology, converter top-bottom blowing, feed Al wire deoxidation, post-furnace vacuum treatment, calcium treatment and composition fine-tuning smelting process;

[0041] 2) Preliminary rolling: the initial rolling temperature is controlled at 1180°C;

[0042] 3) Carry out finish rolling: the cumulative reduction rate of the last three passes of finish rolling is 60%;

[0043] 4) Final rolling: the temperature is controlled within the range of 850-870°C;

[0044] 5) Cooling: cooling the steel plate to 550-650°C at a cooling rate of 8°C / s;

[0045] 6) Cool the steel plate at room temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com