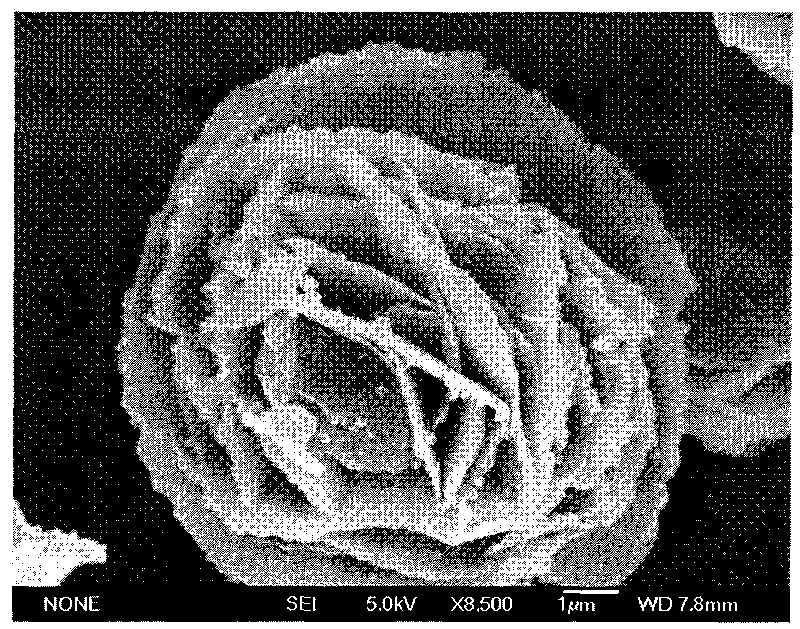

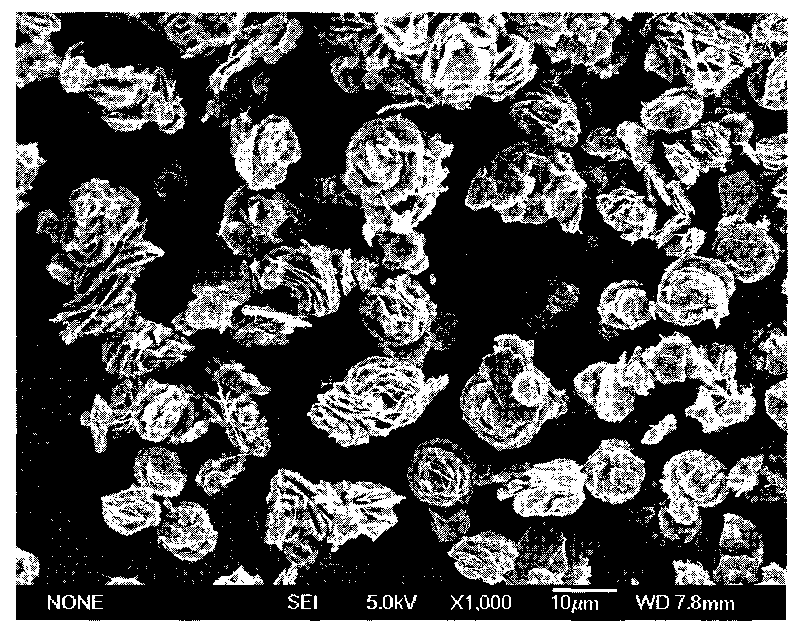

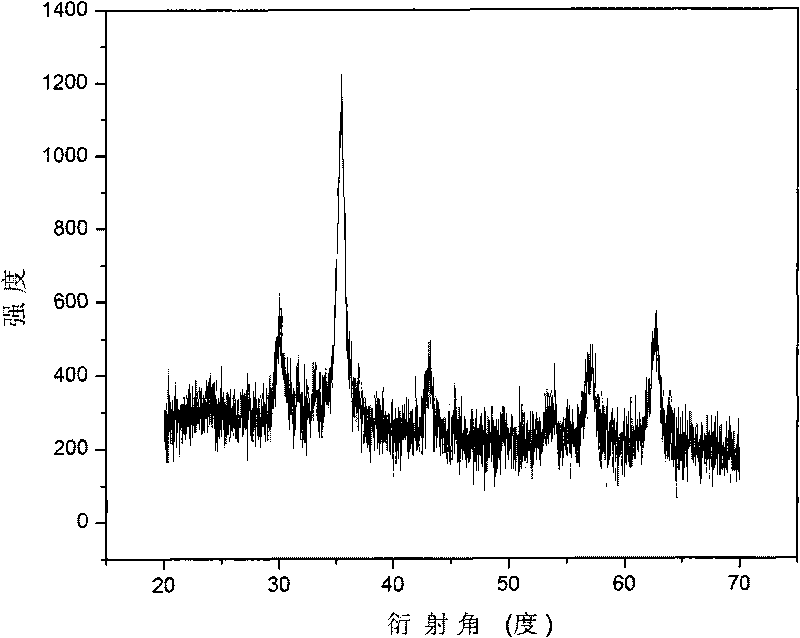

Method for preparing ferroferric oxide nano-piece through microwave method

A technology of ferric oxide and nanosheets is applied in the field of nanomaterials, which can solve the problems of high cost and complicated preparation process, and achieve the effects of short reaction time, simple synthesis route and high purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Prepare ferric oxide nanosheets, the preparation steps are:

[0029] Step 1, adopt ferric chloride as raw material, configure iron salt solution with ethylene glycol, and the content of iron ion in the solution is 0.1mol / L;

[0030] Step 2, adding sodium acetate to the solution configured in step 1 to a concentration of 1mol / L, and adding polyoxyethylene-polyoxypropylene-polyoxyethylene to a concentration of 0.05mol / L;

[0031] Step 3, stir the mixture obtained in step 2 evenly, and set aside;

[0032] Step 4, put the solution obtained in step 3 into a microwave reactor, under the condition of stirring, open the microwave reactor, the microwave power is 500 watts, the temperature of the solution is controlled at 160 degrees Celsius during the reaction, and the microwave is irradiated for 60 minutes ;

[0033] Step 5. After the reaction process in step 4 is completed, the solid product is filtered, and the product is rinsed with distilled water or ethanol for 3 times; ...

Embodiment 2

[0036] Prepare iron ferric oxide nanosheets, the preparation steps are:

[0037] Step 1, adopt iron nitrate as raw material, configure iron salt solution with ethylene glycol, the content of iron ion in the solution is 0.3mol / L;

[0038] Step 2, adding sodium acetate to the solution configured in step 1 to a concentration of 2mol / L, and adding cetyltrimethylammonium bromide to a concentration of 0.06mol / L;

[0039] Step 3, stir the mixture obtained in step 2 evenly, and set aside;

[0040] Step 4, the solution obtained in step 3 is put into a microwave reactor, and under the condition of stirring, the microwave reactor is turned on, the microwave power is 500 watts, the temperature of the solution is controlled at 160 degrees Celsius during the reaction, and microwave irradiation is performed for 45 minutes;

[0041] Step 5. After the reaction process in step 4 is completed, the solid product is filtered, and the product is rinsed with distilled water or ethanol for 3 times; ...

Embodiment 3

[0044] Prepare ferric oxide nanosheets, the preparation steps are:

[0045] Step 1, adopt iron sulfate as raw material, configure iron salt solution with ethylene glycol, the content of iron ion in the solution is 0.6mol / L;

[0046] Step 2, adding sodium acetate to the solution configured in step 1 to a concentration of 4mol / L, and adding sodium succinic acid (ethylhexyl)sulfonate to a concentration of 0.08mol / L;

[0047] Step 3, stir the mixture obtained in step 2 evenly, and set aside;

[0048] Step 4, the solution obtained in step 3 is put into a microwave reactor, and under the condition of stirring, the microwave reactor is turned on, the microwave power is 500 watts, the temperature of the solution is controlled at 180 degrees Celsius during the reaction, and microwave irradiation is performed for 30 minutes;

[0049] Step 5. After the reaction process in step 4 is completed, the solid product is filtered, and the product is rinsed with distilled water or ethanol for 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com