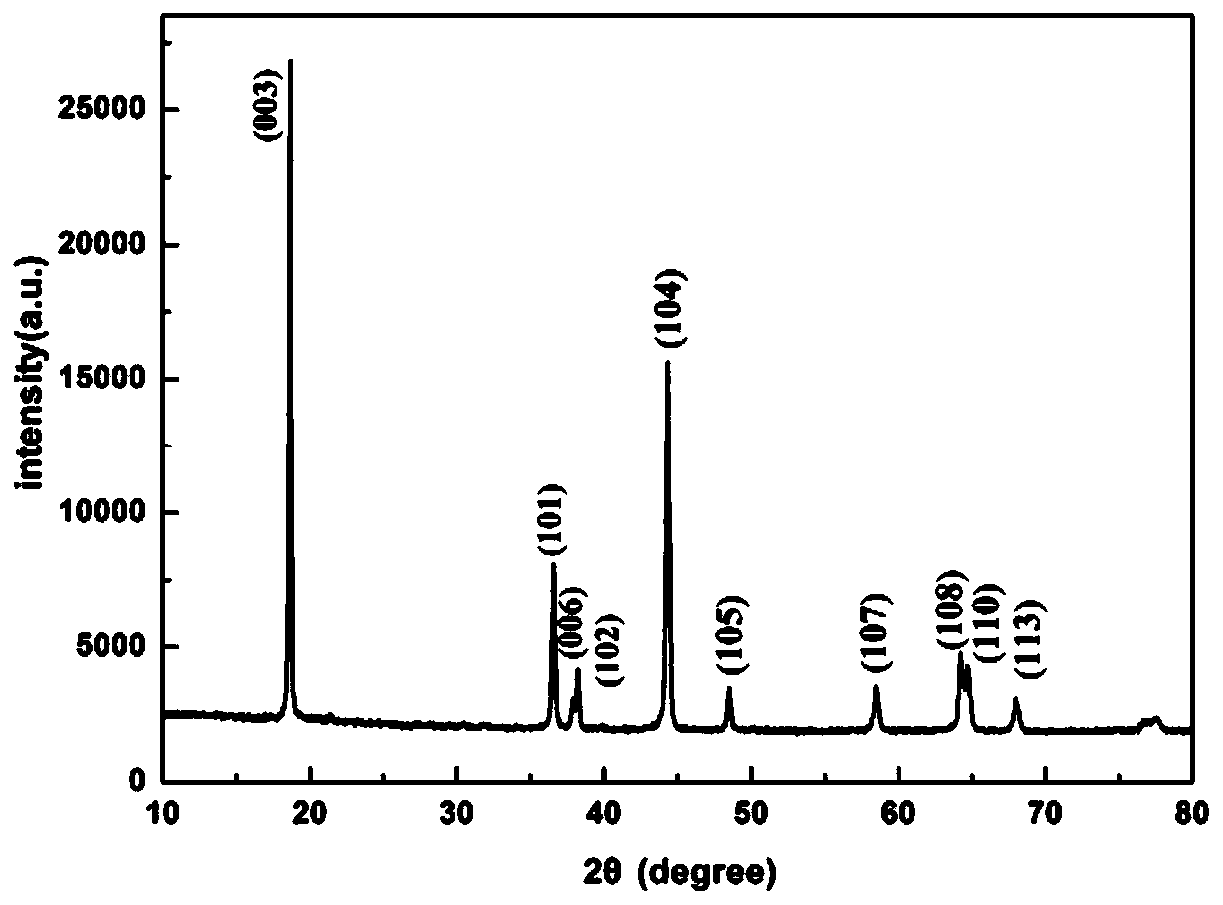

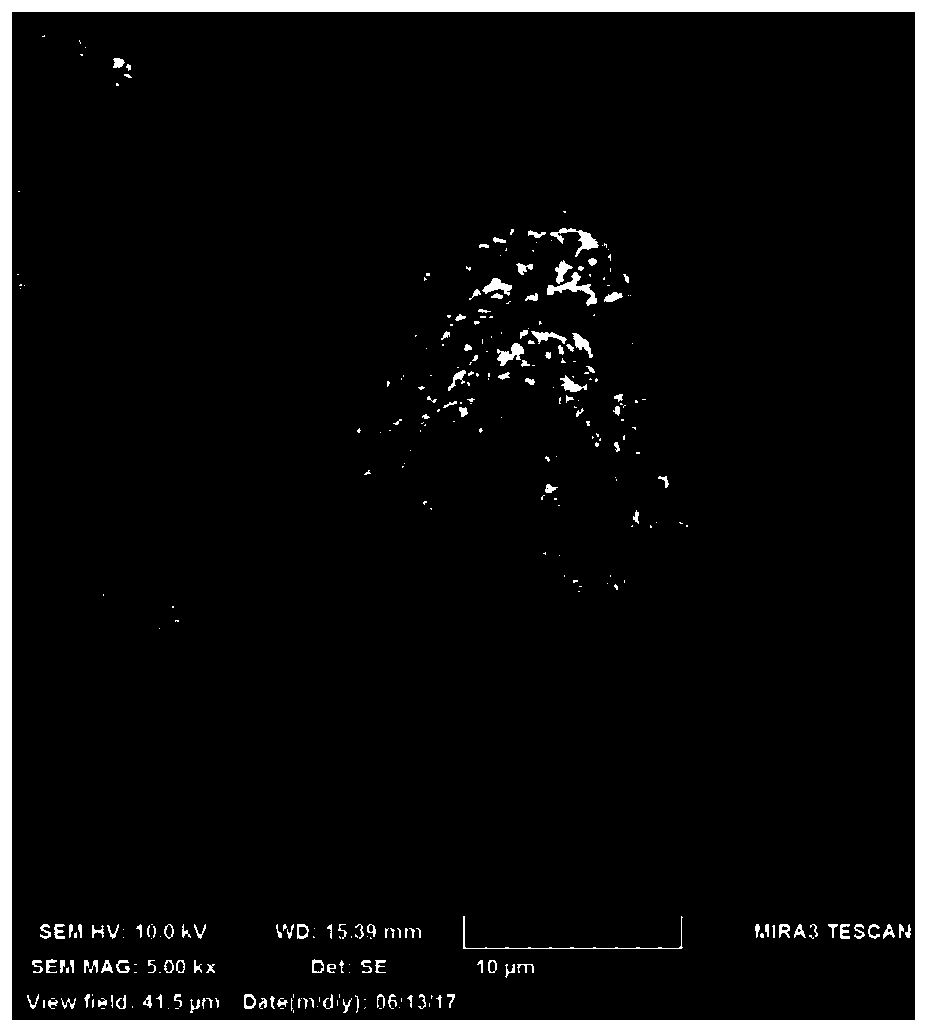

A kind of preparation lini x mn 1-x o 2 Binary Cathode Material Approach

A cathode material, mixed alkaline solution technology, applied in the field of new energy materials, can solve the problems of crystal structure and electrochemical performance, complex synthesis process, high reaction energy consumption, and achieve stable morphology, short process flow, and complete precipitation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Add 2.0 mol NiSO 4 •6H 2 O, 0.5 mol MnSO 4 •H 2 O mixed, at room temperature, add 1.25 L deionized water to configure the binary metal ion mixture. Add an appropriate amount of 25% ammonia water to 2L of 4.0 mol / L NaOH solution to form an ammonia water-NaOH mixed solution.

[0021] (2) Add the binary metal ion mixed solution and the ammonia water-NaOH mixed solution evenly and dropwise at a flow rate of 5 mL / min into a microwave reactor at 55 °C with nitrogen protection at a constant speed, and wait for the binary metal ions to mix. After the dropwise addition was complete, the reaction was stirred for 2 min. Then the reaction solution was transferred into a hydrothermal reaction kettle, and after the reaction kettle was sealed, the reaction was kept at 110°C for 60 min.

[0022] (3) After the above reaction is completed, separate the solid from the liquid, wash with deionized water until neutral, place the filtrate in a drying oven, and dry at 100°C for 24 hou...

Embodiment 2

[0025] (1) Add 1.5 mol NiSO 4 •6H 2 O, 1.0 mol MnSO 4 •H 2 O mixed, at room temperature, add 1.5 L deionized water to configure nickel-manganese binary metal ion mixture. An appropriate amount of 25% ammonia water was added to 1.0 L of 4.0 mol / L NaOH solution to form an ammonia water-NaOH mixed solution.

[0026] (2) At 20°C, the binary metal ion mixed solution and the ammonia water-NaOH mixed solution were evenly added dropwise at a flow rate of 4.0 mL / min into a microwave reactor at 40°C with nitrogen protection at a constant speed, and waited for two After the metal ion mixture was added dropwise, the reaction was stirred for 5 min. The reaction solution was then transferred into a hydrothermal reaction kettle, and the reaction kettle was sealed and reacted at 80° C. for 2 h.

[0027] (3) After the above reaction is completed, separate the solid from the liquid, wash with deionized water until neutral, put the filtrate in a drying oven, and dry at 110°C for 16 hours. ...

Embodiment 3

[0030] (1) Add 0.70 mol Ni(NO 3 ) 2 •6H 2 O and 0.30 mol Mn(NO 3 ) 2 (50% solution) was dissolved in deionized water to prepare a 0.5 mol / L binary metal ion mixture. Add appropriate amount of 25% ammonia water to 1 mol / L NaOH solution to form ammonia water-NaOH mixed solution.

[0031] (2) At 20°C, the binary metal ion mixed solution at a flow rate of 10 mL / min and the ammonia water-NaOH mixed solution at a flow rate of 10 mL / min were added dropwise to a 60°C microwave reactor with constant stirring and nitrogen protection. After the binary metal ion mixture was added dropwise, the reaction was stirred for 0.5 min. Then the reaction solution was transferred into a hydrothermal reaction kettle, and the reaction kettle was sealed and reacted at 120°C for 10 min.

[0032](3) After the above reaction is completed, the solid-liquid separation is carried out, and the filter is washed with deionized water until neutral, and the filtrate is placed in a drying oven and dried at 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com