A kind of high permeability nanofiltration membrane containing zwitterion and preparation method thereof

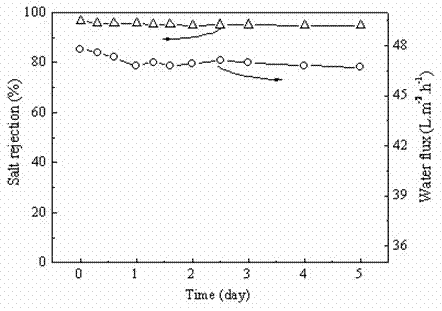

A zwitterionic, high-permeability technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as poor solubility, achieve low cost, simple membrane manufacturing process, and stable separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] The steps of the preparation method of the high-permeability nanofiltration membrane containing zwitterions are as follows:

[0016] 1) Add 2 to 5 parts by mass of monomers containing quaternary amino groups, 1 part by mass of hydroxyalkyl acrylate monomers and 0.06 to 0.6 parts by mass of zwitterionic monomers into water to make a mass percent concentration of 10 to 30% aqueous solution, feed nitrogen, add a water-soluble oxidation-reduction initiator with a concentration of 1 to 3% by mass, at 35 to 50 o Solution polymerization is carried out at C, the polymerization time is 8 to 24 hours, the polymer is precipitated with acetone, and after repeated washing, a terpolymer containing zwitterions is obtained, which is dried in vacuum and used for later use;

[0017] 2) Dissolve 1-2.5 parts by mass of the above-mentioned zwitterion-containing terpolymer and 0.1-0.45 parts by mass of polyaldehyde in water, then add sulfuric acid to adjust the pH of the solution to 2-4,...

Embodiment 1

[0021] 2 parts by mass of methacryloyloxyethyltrimethylammonium chloride, 1 part by mass of hydroxyethyl acrylate and 0.06 parts by mass of 3-[N,N-dimethyl-[2-(2-methyl Prop-2-enoyloxy) ethyl] ammonium] propane-1-sulfonic acid inner salt is added in water to form an aqueous solution with a mass percent concentration of 10wt%, and nitrogen gas is fed into it, and a mass percent concentration of 1wt% water-soluble Sexual oxidation-reduction initiator K 2 S 2 o 8 and NaHSO 3 (1:1), solution polymerization was carried out at 35°C, the polymerization time was 24 hours, the polymer was precipitated with acetone, and after several times of washing, a terpolymer containing zwitterions was obtained, which was dried in vacuum and used for later use; 1 mass The copolymer of 0.1 part by mass and the glutaraldehyde of 0.1 mass part join in water, add sulfuric acid again, adjust solution pH value to be 2; Stir evenly at room temperature, obtain clear and transparent aqueous solution; oU...

Embodiment 2

[0023] 5 parts by mass of methacryloxyethyltrimethylammonium chloride, 1 part by mass of hydroxyethyl acrylate and 0.6 parts by mass of 3-[N,N-dimethyl-[2-(2-methyl Propane-2-enoyloxy)ethyl]ammonium]propane-1-sulfonic acid inner salt is added in water to form an aqueous solution with a mass percent concentration of 30wt%, and nitrogen gas is fed into it, and a mass percent concentration of 3wt% is added. Sexual oxidation-reduction initiator K 2 S 2 o 8 and NaHSO 3 (1:1), solution polymerization was carried out at 50°C, the polymerization time was 8 hours, the polymer was precipitated with acetone, and after repeated washing, a terpolymer containing zwitterions was obtained, which was dried in vacuum and used for later use; 2.5 mass The copolymer of 0.45 parts by mass and the glutaraldehyde of 0.45 parts by mass join in water, add sulfuric acid again, adjust the solution pH value to be 4; Stir evenly at room temperature, obtain clear and transparent aqueous solution; o Unde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com