Composite membrane for water treatment, and preparation method thereof

A composite membrane and polymer technology, applied in the field of membrane separation, can solve problems such as complex membrane making process, and achieve the effects of simplifying membrane making process, good anti-pollution performance, and improved permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of above-mentioned composite film is as follows:

[0034] (1) Take out the polymer support layer after being fully soaked in the aqueous phase solution, the aqueous phase solution includes cyclodextrin amino derivatives with a mass fraction of 2% to 9% and cyclodextrin amino derivatives with a mass fraction of 0.5% to 2%. A catalyst (such as triethylamine or 4-dimethylaminopyridine) used to catalyze the interfacial polymerization reaction between cyclodextrin amino derivatives and polybasic acid chlorides;

[0035] If the concentration of cyclodextrin amino derivatives is too low, the polyamide active layer formed during interfacial polymerization will not be dense enough, and the selectivity of the composite membrane will be low. If the concentration is too high, the polyamide active layer formed will be too dense, thereby reducing the moisture content of the composite membrane Flux: The time required for full soaking is related to the concentrat...

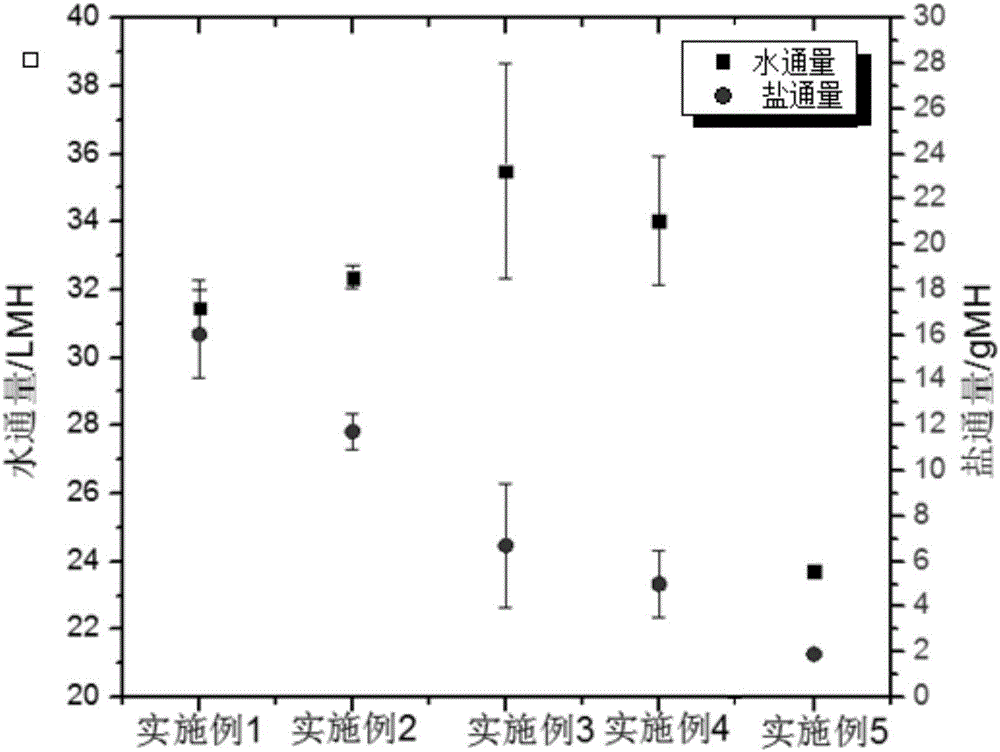

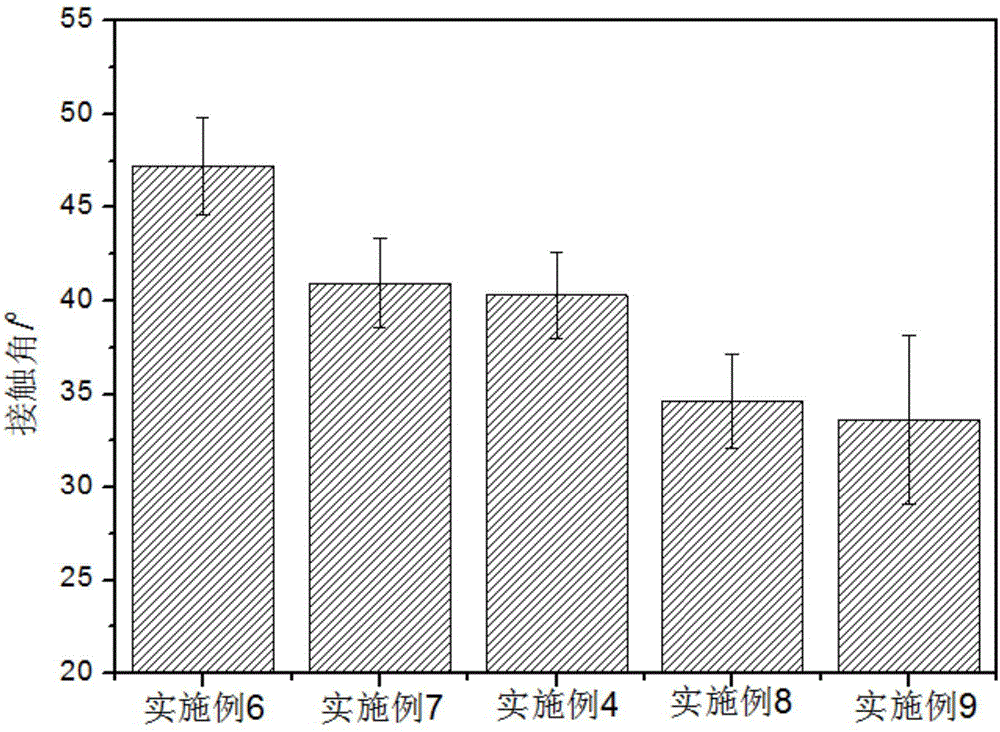

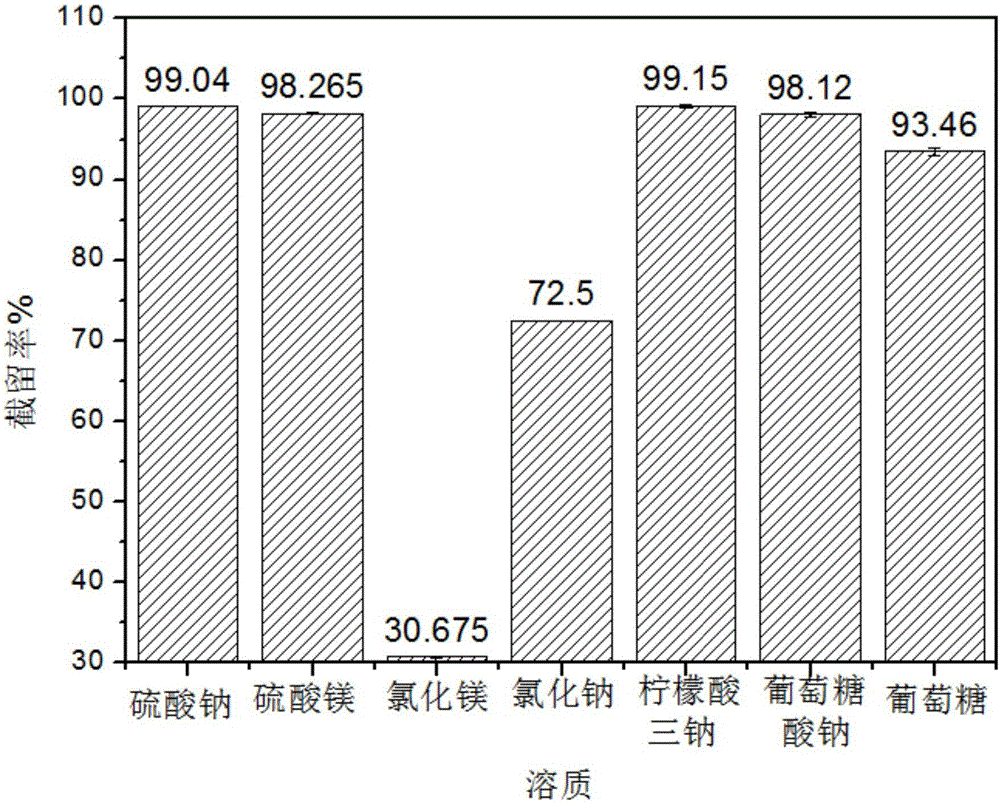

Embodiment 1

[0038] The cyclodextrin amino derivatives in the polyamide active layer of the composite membrane of Example 1 are substituents Obtained by replacing the hydroxyl group in β-cyclodextrin, the average degree of substitution is 5, and the polymer support layer is a polyacrylonitrile microfiltration membrane; the preparation process of the composite membrane includes the following steps:

[0039] (1) configure the aqueous phase solution, the aqueous phase solution containing the cyclodextrin amino derivatives with a mass fraction of 5% and the triethylamine with a mass fraction of 1%; As a solvent, trimesoyl chloride with a mass / volume fraction of 0.1% is used as a solute.

[0040] Soak the polyacrylonitrile microfiltration membrane in the aqueous phase solution for 10 minutes and then take it out.

[0041] (2) After removing the surface moisture, the upper surface is contacted with the organic phase solution for 5 minutes, and the cyclodextrin amino derivative and trimesoyl chlo...

Embodiment 2

[0043] (1) configure the aqueous phase solution, the aqueous phase solution containing the cyclodextrin amino derivatives with a mass fraction of 5% and the triethylamine with a mass fraction of 1%; As a solvent, trimesoyl chloride with a mass / volume fraction of 0.1% is used as a solute.

[0044] Soak the polyacrylonitrile microfiltration membrane in the aqueous phase solution for 10 minutes and then take it out.

[0045] (2) After removing the surface moisture, the upper surface is contacted with the organic phase solution for 10 minutes, and the cyclodextrin amino derivative and trimesoyl chloride undergo an interfacial polymerization reaction in which the amino group and the acid chloride group generate an amide on the surface of the polymer support layer to form Polyamide composite membrane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com