Preparation method of two-dimensional laminar covalent organic framework membrane

A covalent organic framework and two-dimensional layered technology, which is applied in the field of membrane science, can solve the problems of poor repeatability and low coverage of the film layer, and achieve the effects of improving the quality of film formation, simplifying the film making process, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

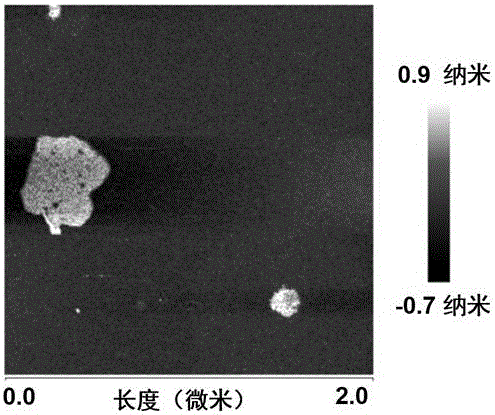

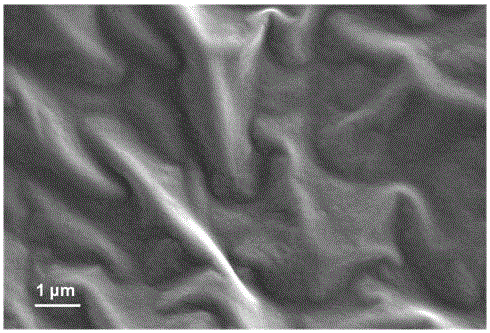

[0031] Mix 40 mg COF-1 powder at room temperature (according to literature Côté et al., Science , 2005, 310, prepared by the synthetic method in 1166-1170) was dispersed in 40 g of dichloromethane, nitrogen gas was introduced to remove the air in the container, and the above-mentioned substances were mixed uniformly by magnetic stirring after sealing. The above COF-1 dispersion was transferred to an ultrasonic water bath, and the exfoliated COF-1 flakes (such as figure 1 shown). The thickness of the COF-1 flakes is less than 1 nm, indicating that the layered structure of the COF-1 powder has been successfully exfoliated layer by layer. The above solution was deposited on flat glass at room temperature by the drop coating method, and then dried at room temperature for 30 min under a nitrogen atmosphere. After repeating the above process three times, a COF-1 film supported by a glass sheet was obtained (such as figure 2 shown). The surface of COF-1 film is continuous and co...

Embodiment 2

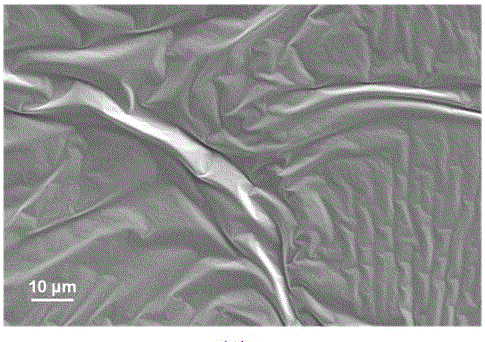

[0033] Mix 2 mg COF-1 powder at room temperature (according to literature Côté et al., Science , 2005, 310, prepared by the synthetic method in 1166-1170) was dispersed in 40 g of dichloromethane, nitrogen gas was introduced to remove the air in the container, and the above-mentioned substances were mixed uniformly by magnetic stirring after sealing. The above COF-1 dispersion was transferred to an ultrasonic water bath, and treated at room temperature for 80 min under the condition of ultrasonic frequency and power of 40 kHz and 40 W, respectively, to obtain exfoliated COF-1 flakes. The above solution was deposited on flat titanium dioxide at room temperature by dipping and pulling method, and then dried at room temperature under nitrogen atmosphere for 30 min. After repeating the above process 6 times, a COF-1 film supported by flat titanium dioxide (such as image 3 shown). COF-1 film has better continuity.

Embodiment 3

[0035] 21 mg ACOF-1 powder (according to literature Li et al. , Chem. Commun. , 2014, 50, prepared by the synthetic method in 13825-13828) was dispersed in 40 g of toluene solvent, nitrogen gas was introduced to remove the air in the container, and the above-mentioned substances were mixed uniformly by magnetic stirring after sealing. The above dispersion of ACOF-1 was transferred to an ultrasonic water bath, treated at room temperature for 30 min under the conditions of ultrasonic frequency and power of 40 kHz and 120 W, respectively, and then peeled off to obtain ACOF-1 flakes (such as Figure 4 shown). The thickness of the ACOF-1 flakes is less than 1 nm, indicating that the ACOF-1 with a layered structure has been successfully exfoliated layer by layer. Finally, the above solution was deposited on the SiO 2 -ZrO 2 Modified porous alumina carrier tube, and then dried at room temperature under nitrogen atmosphere for 100 min, repeating the above process 4 times to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com