Permeating gasification film used for separation of methanol/dimethyl carbonate azeotropic liquid, and its preparing method

A technology of pervaporation membrane and dimethyl carbonate, applied in chemical instruments and methods, semi-permeable membrane separation, purification/separation of carbonate/haloformate, etc., can solve uneconomical problems and achieve low price , high efficiency and great development potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

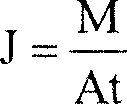

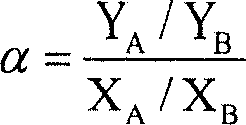

Method used

Image

Examples

Embodiment 1

[0037] Weigh an appropriate amount of PVA and deionized water into a three-neck flask, heat and stir the solution for more than 2 hours to fully dissolve the PVA, and prepare a PVA solution with a mass fraction of 7%. Also prepare a PAA aqueous solution with a mass fraction of 7% for use. Weigh PAA solution and PVA solution of different quality respectively, make PAA / PVA (mass ratio) 50 / 50 casting film solution, stir at room temperature for more than 2h, make the solution mix evenly. After the casting solution is filtered and defoamed, a layer of casting solution is scraped on the polyethersulfone base film. After the solvent is completely evaporated, the composite membrane is put into an oven for heat treatment at 100°C or higher for 1.5h. The separation performance of the prepared composite membrane was measured by a performance evaluation device, and the feed liquid was MeOH / DMC azeotropic liquid, that is, the mass fraction of MeOH was 70%. The separation performance at di...

Embodiment 2

[0041]Weigh an appropriate amount of PVA and formic acid into a three-necked flask, heat and stir the solution for more than 2 hours to fully dissolve the PVA, and prepare a PVA solution with a mass fraction of 7%. Also prepare a PAA formic acid solution with a mass fraction of 7% for use. Weigh PAA solution and PVA solution of different quality respectively, make PAA / PVA (mass ratio) 70 / 30 cast film solution, stir at room temperature for more than 2h, make the solution mix evenly. After the casting solution is filtered and degassed, scrape a layer of casting solution on the polyacrylonitrile base film. After the solvent is completely evaporated, put the composite film into an oven for heat treatment at 100°C or higher for 1.5h. The separation performance of the prepared composite membrane was measured by a performance evaluation device, and the feed liquid was MeOH / DMC azeotropic liquid, that is, the mass fraction of MeOH was 70%. The separation performance at different oper...

Embodiment 3

[0045] Weigh an appropriate amount of PVA and deionized water into a three-neck flask, heat and stir the solution for more than 2 hours to fully dissolve the PVA, and prepare a PVA solution with a mass fraction of 7%. Also prepare a PAA aqueous solution with a mass fraction of 7% for use. Weigh PAA solution and PVA solution of different quality respectively, make PAA / PVA (mass ratio) 90 / 10 film-casting liquid, stir at room temperature for more than 2h, make the solution mix evenly. After the casting solution is filtered and defoamed, a layer of casting solution is scraped on the polysulfone bottom membrane. After the solvent is completely evaporated, the composite membrane is put into an oven for heat treatment above 100°C for 1.5h. The separation performance of the prepared composite membrane was measured by a performance evaluation device, and the feed liquid was MeOH / DMC azeotropic liquid, that is, the mass fraction of MeOH was 70%. The separation performance at different ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com