Polyamide composite membrane and preparation method thereof

A composite membrane and polyamide technology, applied in the field of membrane separation, to achieve the effect of simplifying the membrane making process, good anti-pollution performance, and good hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

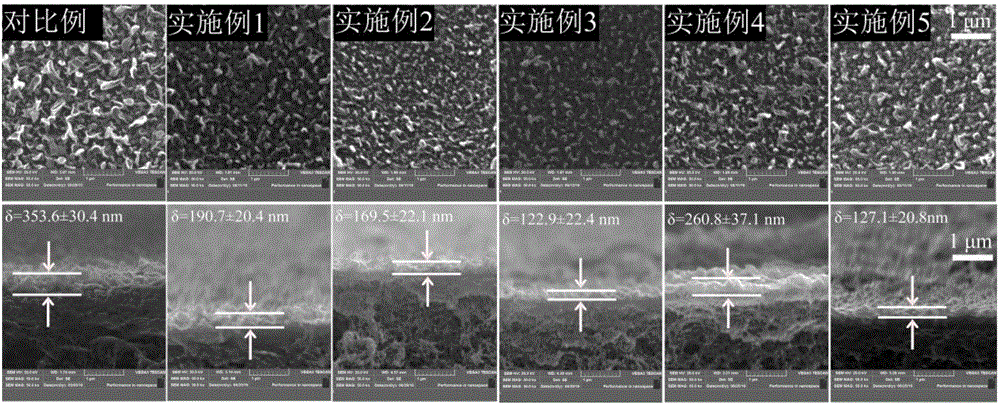

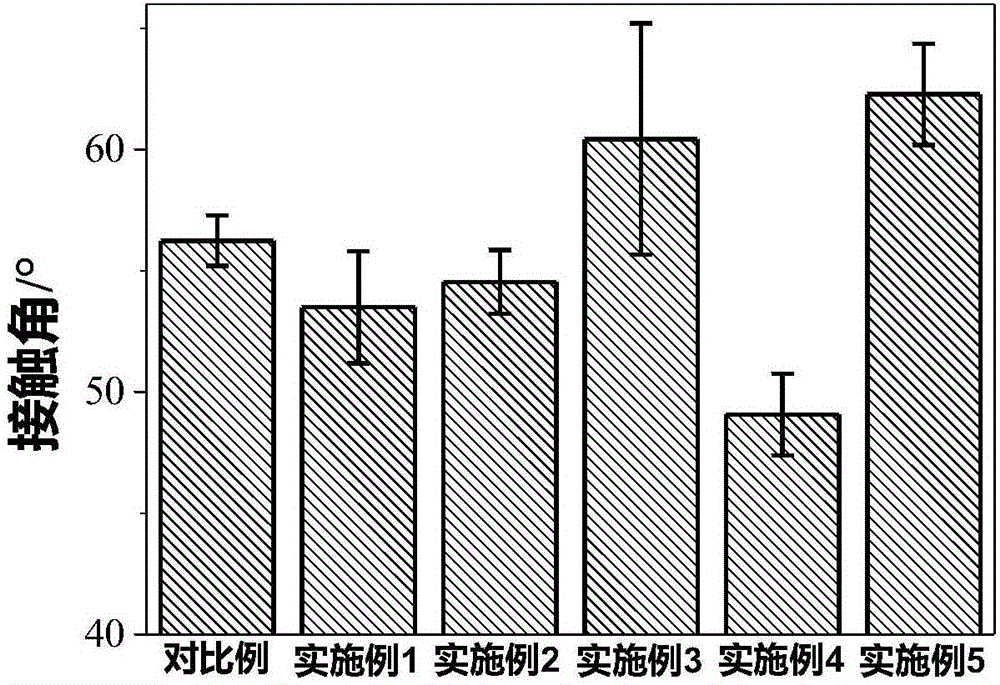

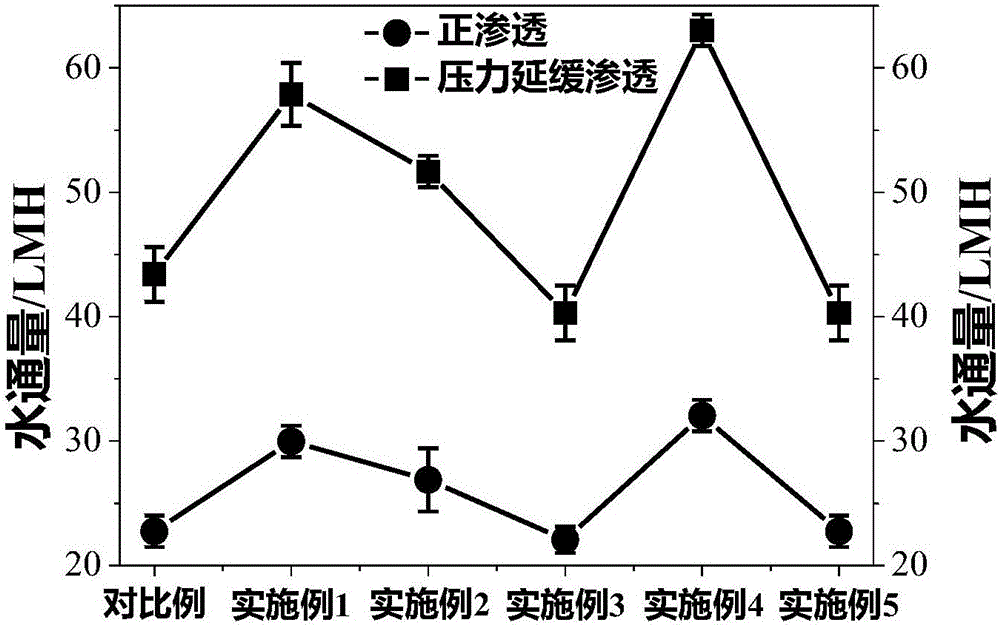

Embodiment 1

[0048] In embodiment 1, tertiary amine additive is three (2-aminoethyl) amine, and structural formula is The polymer support layer of the composite membrane is a polysulfone microfiltration membrane. The preparation process of the composite membrane includes the following steps

[0049] (1) preparation mass fraction is the m-phenylenediamine aqueous solution of 3.4%, is added with mass fraction in this m-phenylenediamine aqueous solution and is 1% tris (2-aminoethyl) amine, the pH of this m-phenylenediamine aqueous solution is used Camphorsulfonic acid is adjusted to 9, the polysulfone-based microfiltration membrane is completely immersed in the m-phenylenediamine aqueous solution for 2 minutes, and then taken out, and the aqueous solution on the surface of the polysulfone-based microfiltration membrane is removed;

[0050] (2) preparation mass / volume fraction is the n-hexane solution of the trimesoyl chloride of 0.15%, this solution is poured on the upper surface of the p...

Embodiment 2

[0053] The experimental operation is the same as that in Example 1, except that in step (1), the mass fraction of tris(2-aminoethyl)amine in the m-phenylenediamine aqueous solution is 2%.

Embodiment 3

[0055] The experimental operation is the same as that in Example 1, except that in step (1), the mass fraction of tris(2-aminoethyl)amine in the m-phenylenediamine aqueous solution is 3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com