Polyamide film composite membrane and preparation method and application thereof

A polyamide and composite membrane technology, applied in the field of membrane separation, can solve the problems of polyamide thin film composite membrane selection layer not dense enough, large surface roughness, high membrane fouling tendency, achieve good anti-pollution performance, simplify the membrane making process, Effect of low membrane fouling tendency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The present invention also provides a preparation method of the composite membrane, comprising the steps of:

[0043] (1) Prepare a polyamine aqueous solution containing a tertiary amine additive, adjust the pH to 8-11, soak the polymer support layer in the polyamine aqueous solution containing a tertiary amine additive, take it out after fully soaking, and obtain the treated polymer support layer;

[0044] The aqueous phase polyamine solution includes a mass fraction of 1%-8%, preferably 1%-5% polyamine and 1%-8%, preferably 1%-5% tertiary amine additive, if the polyamine concentration is too low, it will As a result, the polyamide active layer formed by interfacial polymerization is not dense enough, and the selectivity of the composite membrane is low. If the concentration is too high, the polyamide active layer formed will be too dense, resulting in a decrease in water flux. When the concentration of the tertiary amine additive is too low, the modification effect is ...

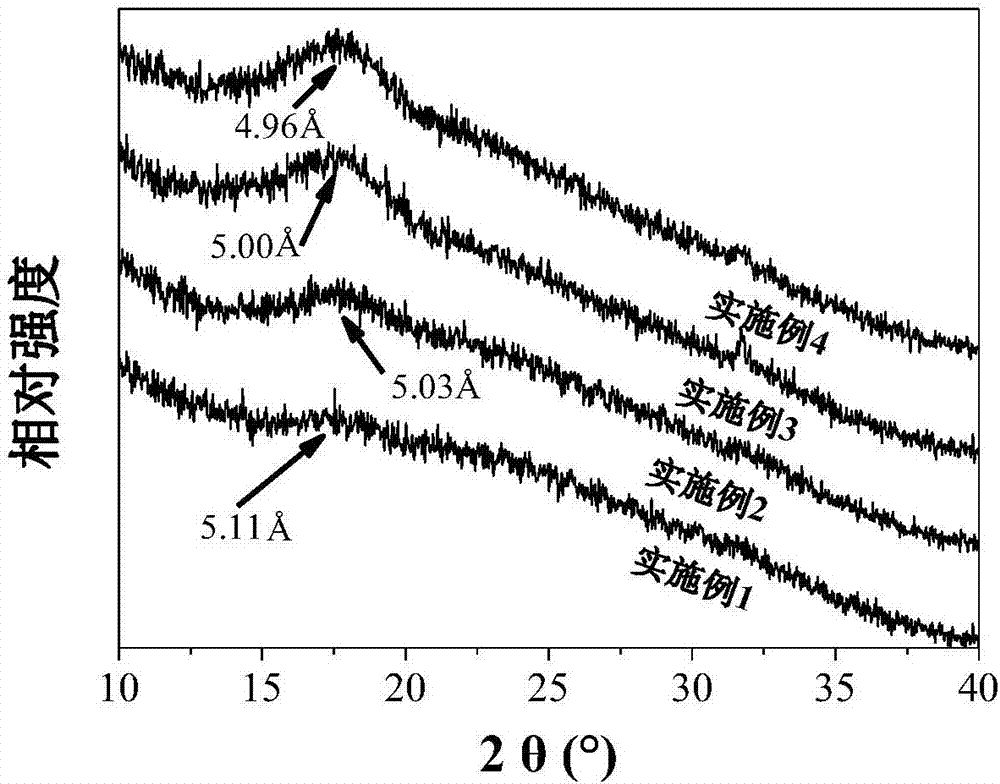

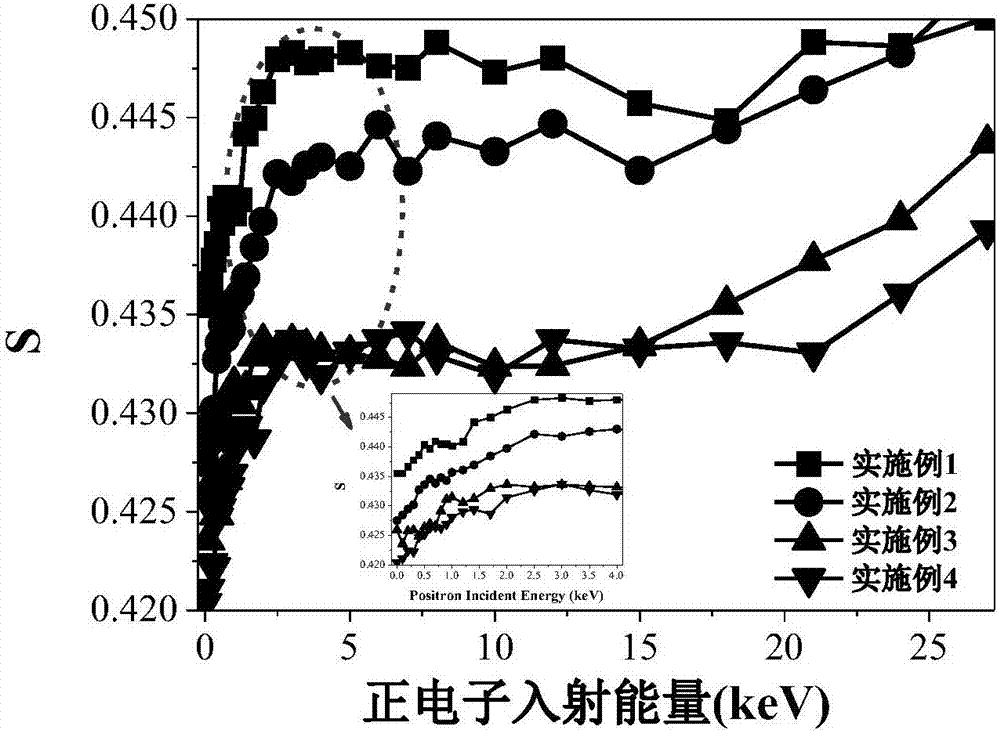

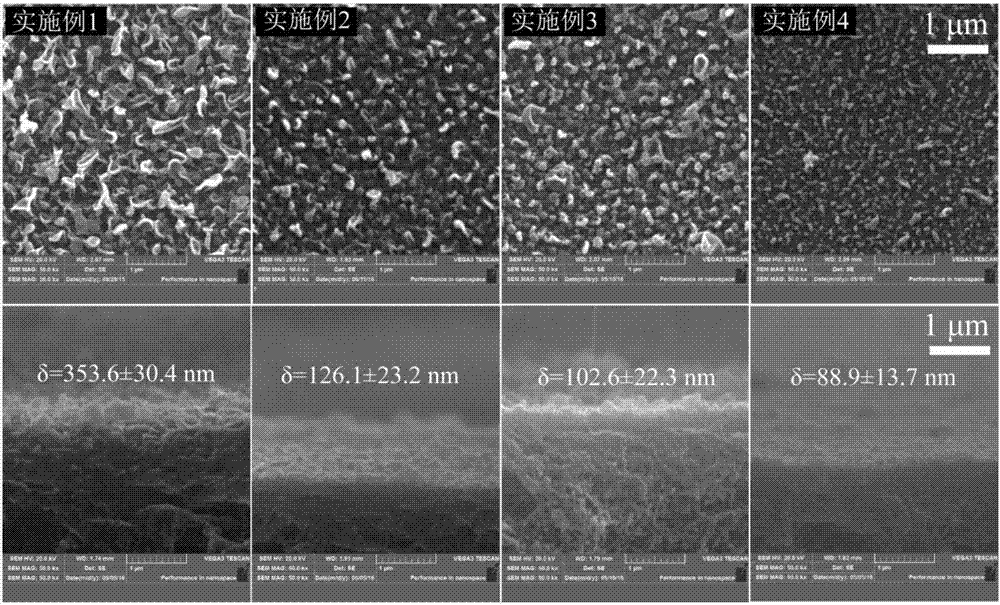

Embodiment 1

[0054] Embodiment 1 (comparative example)

[0055] Example 1 is an example of the preparation of a polyamide composite membrane that has not been modified with a tertiary amine.

[0056] The polymer support layer of the polyamide composite membrane prepared in this embodiment is a polysulfone microfiltration membrane. No tertiary amine additives were added during the preparation of the composite membrane, including the following steps

[0057] (1) Prepare an aqueous phase solution, which contains 3.4% m-phenylenediamine polyamine in mass fraction. An organic phase solution of polybasic acid chlorides is prepared, and the solution uses n-hexane as a solvent and 0.15% of trimesoyl chloride as a solute in mass / volume fraction.

[0058] The polysulfone-based membrane was completely soaked in the aqueous phase solution for 2 minutes and then taken out.

[0059] (2) After removing the excess aqueous phase solution on the surface, pour the organic phase solution on the upper sur...

Embodiment 2

[0062] The polymer support layer of the composite membrane in Example 2 is a polysulfone microfiltration membrane. The preparation process of the composite membrane includes the following steps

[0063] (1) Prepare an aqueous phase solution, which contains 3.4% m-phenylenediamine polyamine and 1 wt% tertiary amine additive hexamethylenetetramine with a mass fraction of 3.4%. An organic phase solution of polybasic acid chlorides is prepared, and the solution uses n-hexane as a solvent and 0.15% of trimesoyl chloride as a solute in mass / volume fraction.

[0064] The polysulfone-based membrane was completely soaked in the aqueous phase solution for 2 minutes and then taken out.

[0065] (2) After removing the excess aqueous phase solution on the surface, pour the organic phase solution on the upper surface of the wetted polysulfone membrane, and pour off the excess organic phase solution after 1 minute of contact time. The interfacial polymerization reaction between the amine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com