Zeolite imidazate-doped polyether block amide gas separation membrane, and preparation method and application thereof

A polyether block amide and zeolite imidazolate technology, which is applied in separation methods, specific gas purification/separation, semi-permeable membrane separation, etc., can solve the problems of separation performance limitation, poor membrane plasticity, and high price, and achieve membrane production The effect of simple process, easy operation and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

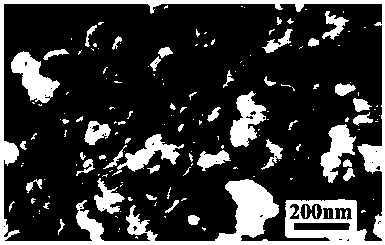

[0045] Embodiment 1: the Zn / Ni-ZIF-8-PEBA mixed matrix membrane that the mass percentage that the additive Zn / Ni-ZIF-8 accounts for matrix is 10wt% is prepared, the steps are as follows:

[0046] Step 1. Preparation of Zn / Ni-ZIF-8: Dissolve 4mmol of zinc nitrate hexahydrate, 4mmol of nickel nitrate hexahydrate, and 60mmol of 2-methylimidazole in 100mL of methanol solution, and then put them into 10g of 4A molecular sieve Let it stand for 10 hours to remove excess water to obtain a methanol solution of zinc nitrate hexahydrate (named product E), a methanol solution of nickel nitrate hexahydrate (named product F) and a methanol solution of 2-methylimidazole (named product G ); then, pour product E, product F and product G into a three-necked flask, stir at 25°C for 24 hours to undergo a chemical reaction, centrifuge the resulting solution at a speed of 10,000 rpm for 50 minutes, and wash the lower precipitate in the centrifuge tube with methanol three times, Dry in a vacuum ov...

Embodiment 2

[0052] Embodiment 2: the Zn / Ni-ZIF-8-PEBA mixed matrix film that Zn / Ni-ZIF-8 accounts for the mass percentage of matrix is 5wt% is prepared, and the steps are as follows:

[0053] Step 1. Preparation of Zn / Ni-ZIF-8: Dissolve 6mmol of zinc nitrate hexahydrate, 6mmol of nickel nitrate hexahydrate, and 60mmol of 2-methylimidazole in 100mL of methanol solution, and then put them into 15g of 4A molecular sieve Let it stand for 20 hours to remove excess water, and obtain a methanol solution of zinc nitrate hexahydrate (named product E), a methanol solution of nickel nitrate hexahydrate (named product F) and a methanol solution of 2-methylimidazole (named product G ); Then, pour product E, product F and product G into a three-necked flask, stir at 40°C for 24 hours to undergo a chemical reaction, centrifuge the resulting solution at a speed of 10,000 rpm for 50 minutes, and wash the lower sediment in the centrifuge tube with methanol three times, Dry in a vacuum oven at 90ºC for 24...

Embodiment 3

[0057] Embodiment 3: the Zn / Ni-ZIF-8-PEBA mixed matrix film that Zn / Ni-ZIF-8 accounts for the mass percentage of matrix is 15wt% is prepared, and the steps are as follows:

[0058] Step 1. Preparation of Zn / Ni-ZIF-8: Dissolve 3mmol of zinc nitrate hexahydrate, 3mmol of nickel nitrate hexahydrate, and 60mmol of 2-methylimidazole in 100mL of methanol solution, and then put them into 5g of 4A molecular sieve Let it stand for 20 hours to remove excess water, and obtain a methanol solution of zinc nitrate hexahydrate (named product E), a methanol solution of nickel nitrate hexahydrate (named product F) and a methanol solution of 2-methylimidazole (named product G ); Then, pour product E, product F and product G into a three-necked flask, stir at 60°C for 24 hours to undergo a chemical reaction, centrifuge the resulting solution at a speed of 8000 rpm for 30 minutes, and wash the lower sediment in the centrifuge tube with methanol three times, Dry in a vacuum oven at 100ºC for 12 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com