Method for preparing mesoporous ceramic membrane based on novel two-dimensional material

A two-dimensional material, ceramic membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problem of inability to obtain separation precision mesoporous ceramic membrane, ultra-fine sol particles easily infiltrated into the support, affecting the membrane. Integrity permeation flux and other issues, to avoid cracking defects, reduce capillary suction, and improve water permeation flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

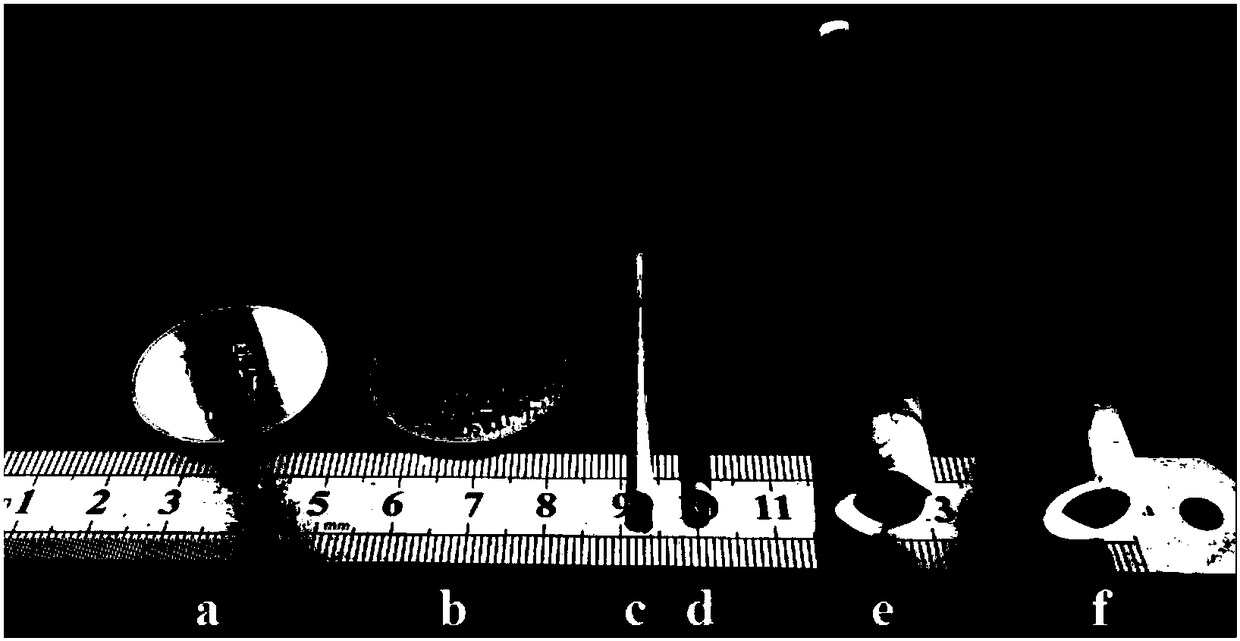

[0027] Add MXene nanosheets with an average particle size of 300nm into the aqueous sol with a titanium content of 0.1mol / L and a sol particle size of 15nm, and disperse it uniformly in the sol to make a coating solution, wherein the MXene nanosheets are in the coating film The content in the liquid is 0.1g / L. Using the prepared coating solution on the sheet-type α-Al with an average pore diameter of 100 nm 2 o 3 The film was coated on the support by the spin coating method, dried in an oven at 40°C, and then calcined in a muffle furnace at 400°C for 4 hours at a heating rate of 0.5°C / min. A pore size of 10 nm can be obtained by one sintering. Pure water flux is 9.9L / (m 2 h bar) TiO 2 @MXene mesoporous ceramic membrane. figure 1 In a is calcined TiO 2 @MXene sheet membrane, b is a sheet support; figure 2 It is the SEM figure of MXene nanosheet in embodiment 1; image 3 It is the AFM figure of MXene nanosheet in embodiment 1; Figure 4 Middle b is TiO after calcination...

Embodiment 2

[0031] Add MXene nanosheets with an average particle size of 300nm into the aqueous sol with a titanium content of 0.1mol / L and a sol particle size of 15nm, and disperse it uniformly in the sol to make a coating solution, wherein the MXene nanosheets are in the coating film The content in the liquid is 0.05g / L. The hollow fiber α-Al with the average pore size of 300nm 2 o 3A film was coated on the support by the dipping and pulling method, dried in an oven at 40°C, and then calcined in a muffle furnace at 400°C for 4 hours at a heating rate of 0.5°C / min. One-time sintering can obtain pore diameters of 6.07nm and pure water flux of 94L / (m 2 h bar) TiO 2 @MXene mesoporous ceramic membrane. figure 1 In c is calcined TiO 2 @MXene hollow fiber membrane, d is the hollow fiber support; Figure 5 is the cut-off curve of the membrane to dextran after calcination; it can be seen from the figure that the molecular weight cut-off of the prepared membrane to dextran is 18566Da, and t...

Embodiment 3

[0033] Add MXene nanosheets with an average particle size of 400nm into the acidic sol with a titanium content of 1.5mol / L and a sol particle size of 6nm, and disperse it uniformly in the sol to make a coating solution, wherein the MXene nanosheets are in the coating film The content in the liquid is 0.15g / L. Using the prepared coating solution on the sheet-type α-Al with an average pore diameter of 100 nm 2 o 3 Spin-coat the film on the support, dry it in an oven at 60°C, and then calcinate it at 400°C for 4 hours at a heating rate of 0.5°C / min in a muffle furnace. A pore size of 2.8nm can be obtained by one sintering. , The molecular weight cut-off to PEG is 2836Da, and the pure water flux is 3.5L / (m 2 h bar) TiO 2 @MXene mesoporous ceramic membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com