Inorganic filler and dopamine compound inorganic and organic hybrid membrane as well as preparation method and application of membrane

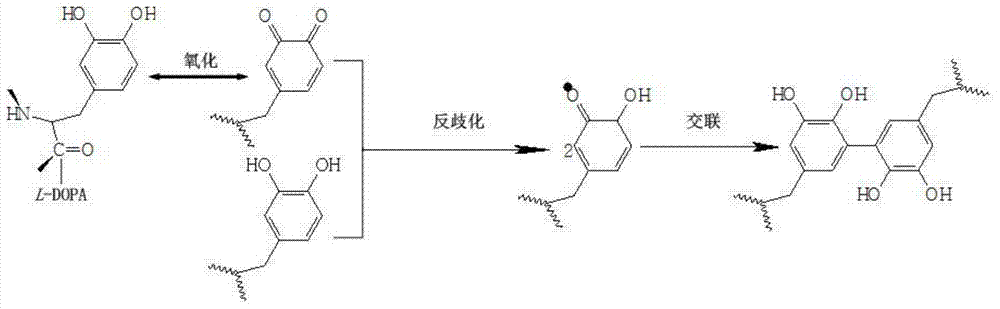

An inorganic filler and organic hybrid technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve mechanical strength, solvent resistance, poor corrosion resistance and heat resistance, and cannot provide sufficient selectivity and penetration Flux, poor film-forming properties, etc., to achieve the effect of increasing hydrophilicity, improving pure water flux, and improving permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) 4mmol / L of CuSO 4 Mix 250ml of solution, 250mL of 28mmol / L NaOH solution, and 500mL of 1mmol / L glucose solution, stir evenly and heat to 85-90°C for 40 minutes. Rinse with deionized water, collect the solid by membrane filtration, and dry to obtain Cu 2 O nanowires.

[0035] (2) Prepare 100mL 10mM Tris (trishydroxymethylaminomethane)-HCl solution and adjust the pH to 9.5, weigh and dry 0.4g Cu 2 O nanowires were placed in it, ultrasonicated for 10 min at room temperature, stirred for 1 h until uniformly dispersed, and an inorganic filler mixture was obtained; 0.2 g of L-DOPA was dissolved in the above inorganic filler mixture, and stirred at room temperature for 5 h to obtain The solid particles were washed with a large amount of deionized water, filtered through a 0.45 μm membrane, and dried overnight at 60°C to obtain composite dopamine inorganic particles, denoted as Cu 2 O-dopa. 0.023g Cu 2 Add O-dopa particles into 20mL DMAC, ultrasonically 30min and stir ...

Embodiment 2

[0039] (1) Disperse 1.5g of titanium dioxide P25 in 140mL of 10M NaOH aqueous solution, mix it uniformly by ultrasonic, conduct a hydrothermal reaction at 200°C for 36h, cool to room temperature after the reaction is completed, filter out the precipitate, and place the obtained precipitate in 0.1M hydrochloric acid dipping in aqueous solution for acidification, then rinsing with deionized water, drying in a vacuum oven to obtain titanate nanowires, placing the obtained titanate nanowires in a muffle furnace, and calcining at 500-600°C for 5 hours to obtain TiO 2 Nanowires;

[0040](2) The operation of preparing the hybrid film is the same as the step (2) of Example 1, the difference is that 0.4g Cu 2 O nanowires were changed to 0.4g of TiO prepared in step (1) 2 Nanowires, other raw materials and operations are unchanged, TiO 2 - dopa-PSF hybrid membrane.

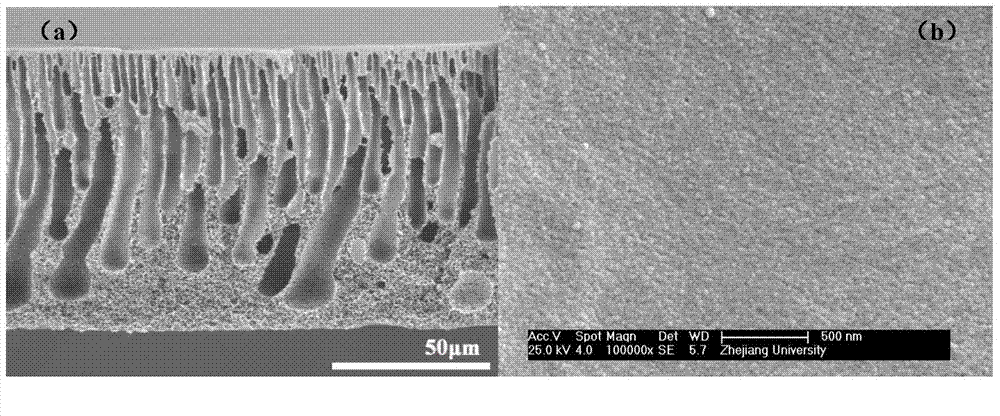

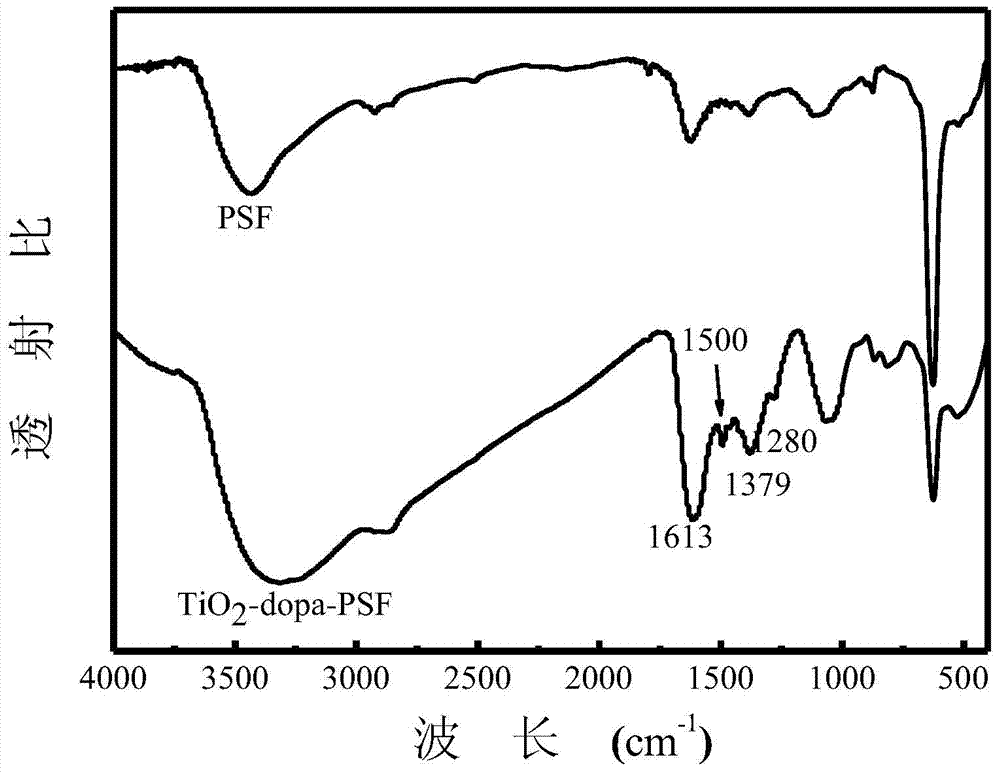

[0041] to TiO 2 -dopa-PSF hybrid membrane for surface analysis such as figure 2 As shown, where (a) is a cross-sec...

Embodiment 3

[0046] Operation is with embodiment 1 step (2), difference is, with 0.4g Cu 2 O nanowires were changed to 0.4g HNT (commercially available commercial products, purchased from Dongming Minghe High Temperature Materials Co., Ltd. Chemical index: Al 2 o 3 37.3%; SiO 2 45.8%; Fe 2 o 3 0.5%; R2O 0.11%; TiO2 0.39%; loss on ignition 14.5% Physical indicators: nanotube inner diameter 10-20nm, length 500-1000nm, specific surface area 60-80m 2 / g, density 2.0-2.2g / cm 3 ), 3.657g PSF was changed into 3.657g PVDF (polyvinylidene fluoride), and other raw materials and operations were all unchanged, and the HNT-dopa-PVDF hybrid membrane was prepared.

[0047] The surface morphology of the HNT-dopa-PVDF hybrid membrane is basically the same as in Example 1, and the pure water flux is 62L m -2 h -1 , The rejection rate of BSA solution is 92.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume usage | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com