Preparation method for novel carbon-nanotube-doped composite membrane with double selective layers

A technology of carbon nanotubes and double selection, which is applied in the field of preparation of new double-selection layer composite membranes containing carbon nanotubes, which achieves the effects of simple preparation method, improved membrane performance, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

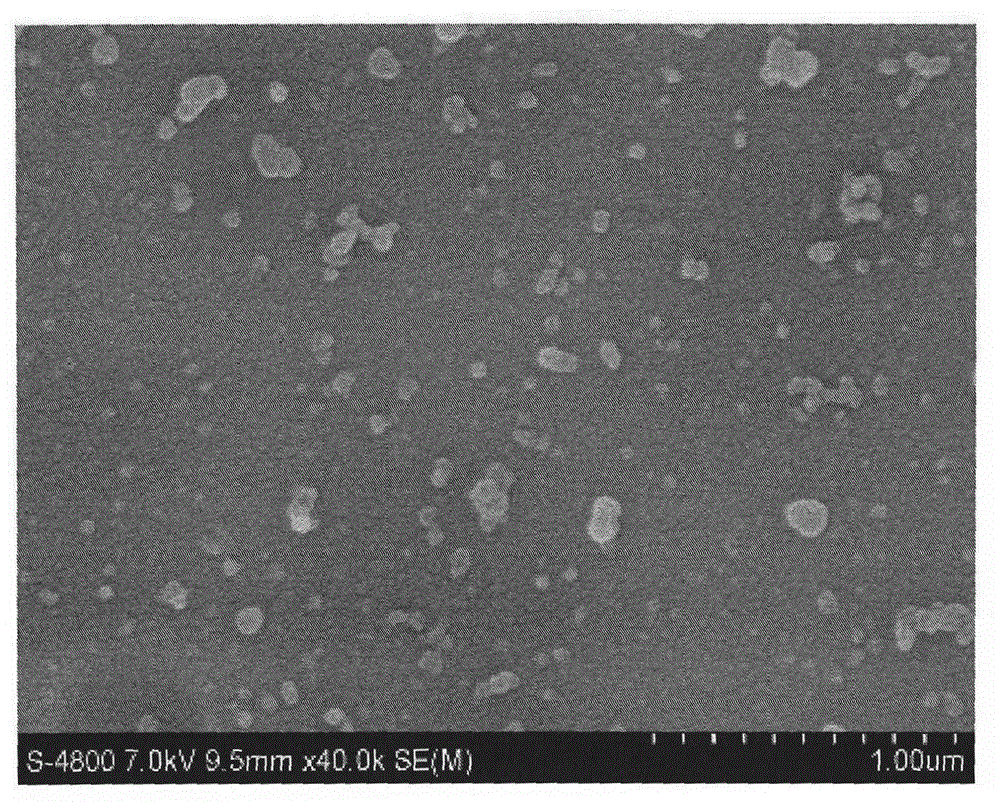

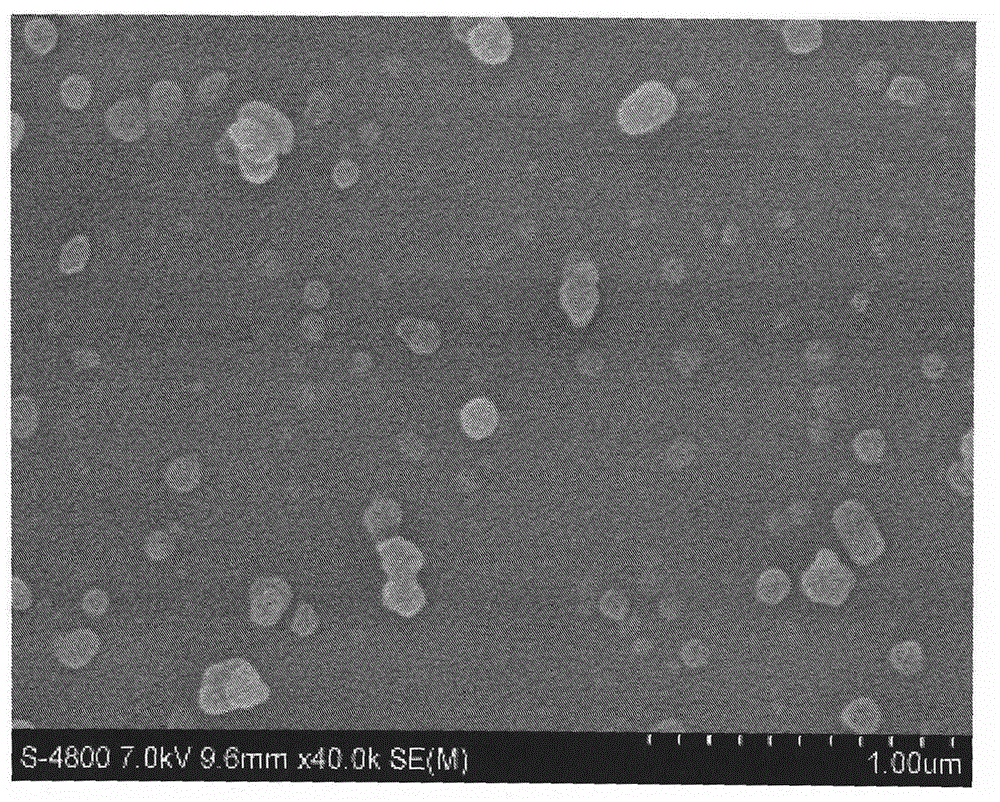

[0028] Put the polysulfone base membrane in 100ml of dopamine hydrochloride (2mg / ml) Tris buffer solution with pH=8.5, react with constant temperature shaking at 30°C for 12h, and let it stand for 6h to obtain the polysulfone base membrane with dopamine attached to the surface; after taking out the base membrane Drain in the air, use the method of interfacial polymerization to immerse the surface (top) of the basement film in the n-hexane solution of 0.1w / v% trimesoyl chloride (TMC), the reaction time is 5min, and then the bottom surface of the basement film (bottom) Immerse in TMC solution for 5min to react, and then treat in 80°C blast drying oven for 5min to obtain a double-selective layer composite membrane. figure 1 It is a scanning electron microscope image of the surface of the carbon nanotube-containing double selective layer composite film prepared in Example 1 of the present invention. figure 2 It is a scanning electron microscope picture of the bottom surface of th...

Embodiment 2

[0030] Add 0.01g of carbon nanotubes (CNTs) to 100ml of dopamine hydrochloride (2mg / ml) Tris buffer solution with pH = 8.5, ultrasonically disperse the CNTs for 1h, place the polysulfone-based membrane in the above solution, and keep the temperature at 30°C Shake the reaction for 12 hours and let it stand for 6 hours to obtain a polysulfone-based membrane with CNTs and dopamine attached to the surface; take out the basement membrane and drain it in the air, and immerse the surface (top) of the basement membrane in 0.1w / v % in the n-hexane solution of trimesoyl chloride (TMC), the reaction time is 5min, and then the basement film bottom surface (bottom) is immersed in the TMC solution for 5min, and then processed for 5min in an air-blow oven at 80°C to obtain Double selective layer composite membrane containing carbon nanotubes. To measure the performance of the membrane, 4mol / L glucose is used as the draw solution (DS), and 0.1mol / L NaCl is used as the feed solution (FS). When...

Embodiment 3

[0032] Add 0.05g of carbon nanotubes (CNTs) to 100ml of dopamine hydrochloride (2mg / ml) Tris buffer solution with pH = 8.5, ultrasonically disperse the CNTs for 1h, place the polysulfone-based membrane in the above solution, and keep the temperature at 30°C Shake the reaction for 12 hours and let it stand for 6 hours to obtain a polysulfone-based membrane with CNTs and dopamine attached to the surface; take out the basement membrane and drain it in the air, and immerse the surface (top) of the basement membrane in 0.1w / v % in the n-hexane solution of trimesoyl chloride (TMC), the reaction time is 5min, and then the basement film bottom surface (bottom) is immersed in the TMC solution for 5min, and then processed for 5min in an air-blow oven at 80°C to obtain Double selective layer composite membrane containing carbon nanotubes. To measure the performance of the membrane, 4mol / L glucose is used as the draw solution (DS), and 0.1mol / L NaCl is used as the feed solution (FS). When...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com