Preparation method for external pressure tubular membrane

A tubular membrane and membrane tube technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of complex production process, easy-to-fall-off hardness of the membrane, and cost of plate-and-frame membrane modules that cannot be recoiled , to achieve the effect of low cost and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

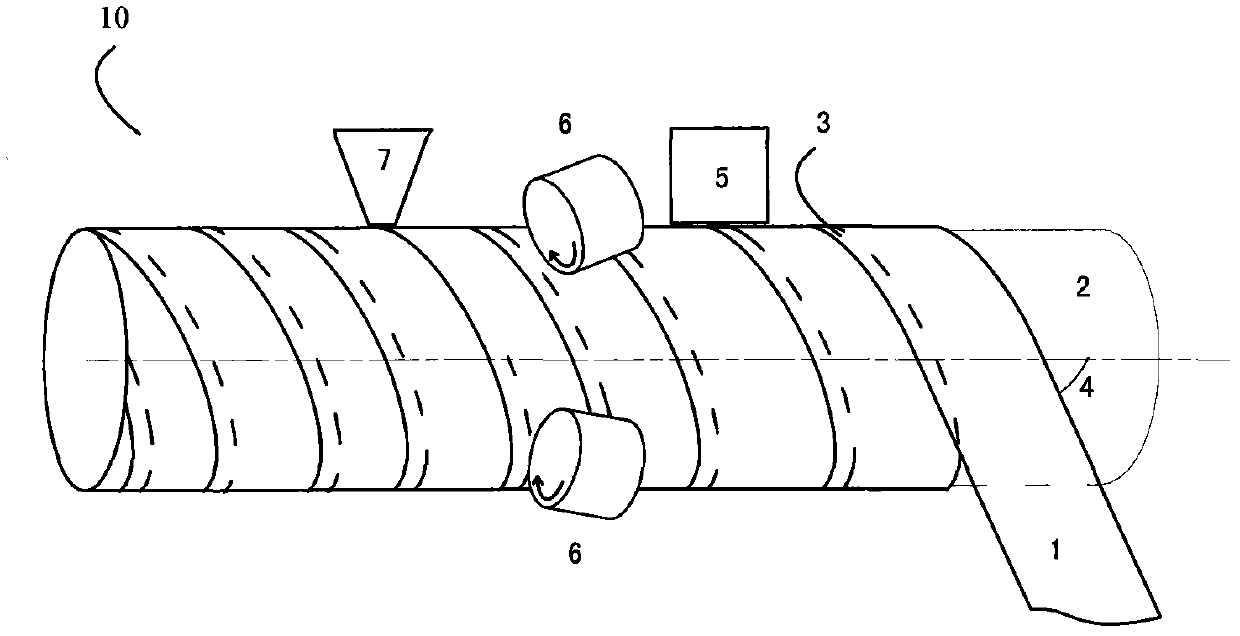

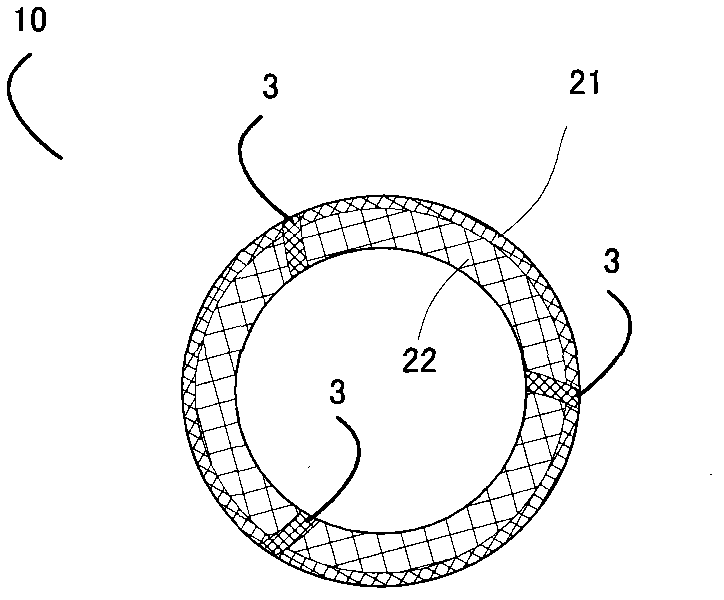

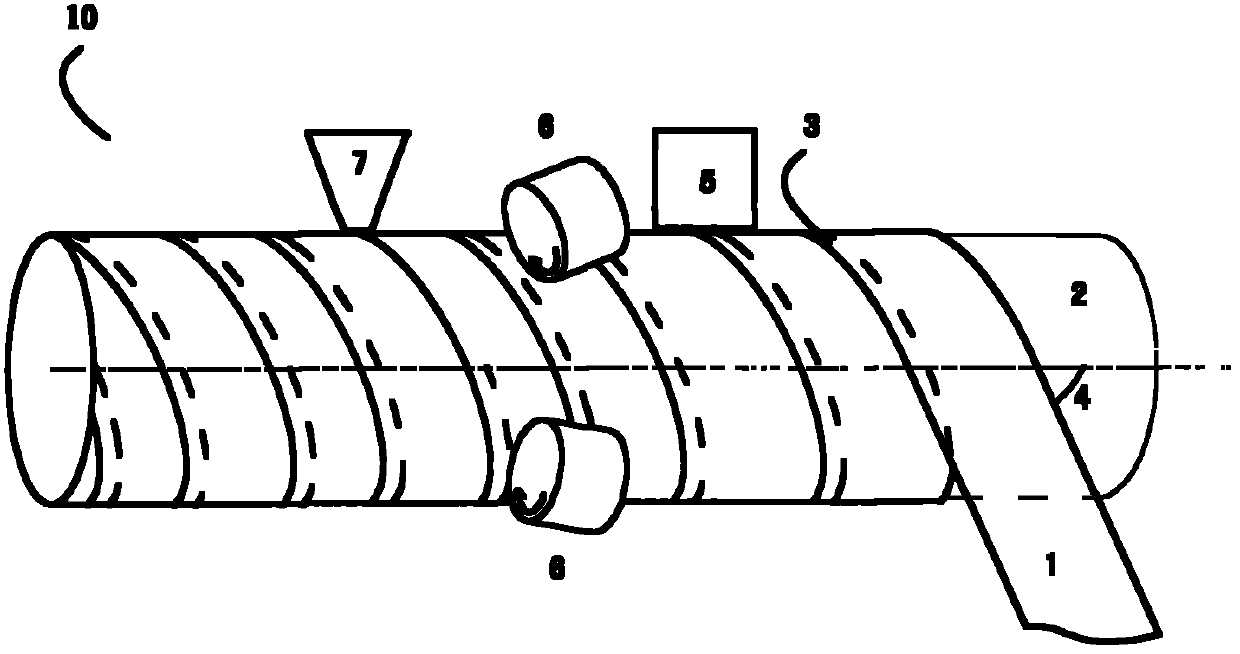

[0016] The preparation method of the external pressure tubular membrane of the present invention comprises that the strip-shaped flat membrane (1) is continuously wound on a central axis (2) at a certain winding angle (4), and the strip-shaped flat membrane (1) is separated from the layer (21 ) facing outwards, when winding, the two sides of the strip flat film (1) overlap each other and this overlapping part is glued or welded to form a joint (3), and the tube is driven by at least one film tube driving wheel (6) The formula membrane (10) is separated from the central axis (2) to obtain the external pressure tube membrane (10).

[0017] The membrane tube driving wheel (6) is tilted in both horizontal and vertical directions, so that when it rotates, it drives the tubular membrane (10) to move in the axial direction and simultaneously rotate in the axial direction.

[0018] The preparation method of the external pressure tubular membrane of the present invention also includes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Winding angle | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com