Conductive filter membrane and application thereof

A filter membrane and conductive layer technology, applied in membrane technology, semi-permeable membrane separation, water/sludge/sewage treatment, etc., can solve the problems of not being able to couple the electrochemical system well, reducing the effect of electric field, and low pollution rate. , to achieve various system situations, enhance the effect of the electric field, and reduce the effect of membrane fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

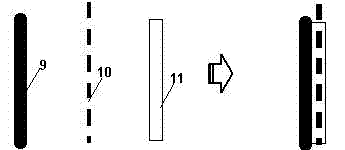

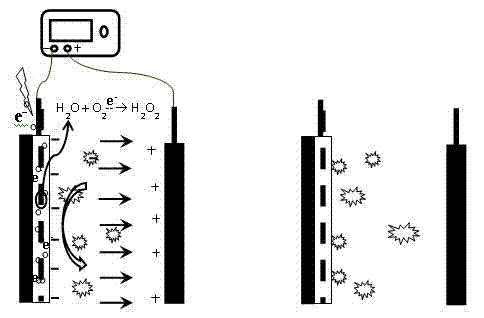

[0025] Conductive filter membrane 4 adopts stainless steel wire mesh 10 to place on non-woven fabric 9, and then scrape coating PVDF and other casting film liquid 11 preparations (such as figure 2 shown).

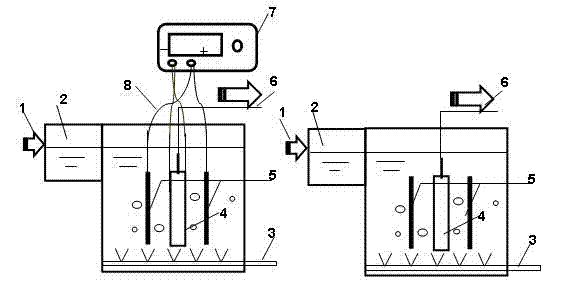

[0026] A membrane bioreactor is a general membrane bioreactor plus an electrochemical system. That is, it includes the MBR water inlet system 1, the MBR water outlet system 6, the MBR aeration system 3, the MBR liquid level control system 2, the power supply system 7, the main biochemical reaction area and the electrochemical system in the general membrane bioreactor.

[0027] The MBR water inlet system 1 is a peristaltic pump water inlet, the MBR liquid level control system 2 is a water inlet tank with an overflow pipe, the MBR aeration system 3 uses perforated aeration, and the MBR water outlet system 6 uses a peristaltic pump to suck out water. The water is distributed artificially, and the transmembrane pressure is measured with a mercury manometer or a pressure gauge...

Embodiment 2

[0030]Utilize the system in embodiment 1 to process actual domestic sewage, the applied voltage is 1 V / cm voltage, and conductive film is 20 L / (m 3 h) Flux operation, when the transmembrane pressure reaches 30 kPa, it is regarded as the end of the operation. The cleaning period of the reactor without voltage is 15 days, while that of the reactor with applied voltage is 28 days.

Embodiment 3

[0032] Utilize the conductive membrane described in embodiment 1, be used in the A / O-MBR system to process high-salinity iron and steel cold rolling wastewater, the applied voltage is 2 V / cm voltage, conductive membrane with 15 L / (m 3 h) Flux operation, when the transmembrane pressure reaches 30 kPa, it is regarded as the end of the operation. The cleaning period of the reactor without voltage is 23 days, while that of the reactor with applied voltage is 41 days.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com