Polyvinylidene fluoride hydrophilic modified membrane and preparation method thereof

A polyvinylidene fluoride, hydrophilic modification technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problem of water flux decline, difficult chemical modification of membrane surface, and high cost of disposable equipment. problem, to achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

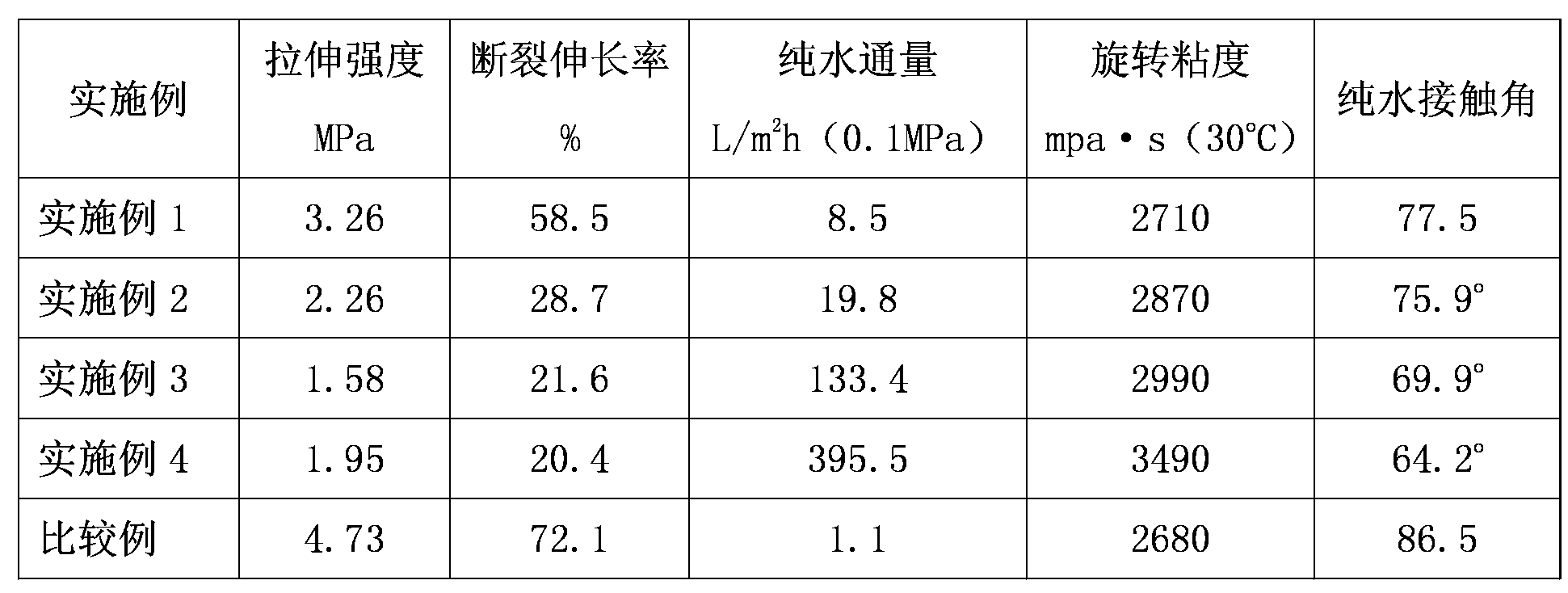

[0043] Accurately weigh 15g of polyvinylidene fluoride, 84.5g of dimethylacetamide, and 0.5g of polymethyl methacrylate, and prepare a blended casting solution with a melting temperature of 55 o C, the dissolution time is 48 hours, and the solution is clear and transparent. Pour the film-casting solution on a glass plate to scrape the film at a constant speed, then soak it in water to form a film, and replace it in water for 24 hours to finally obtain the polyvinylidene fluoride hydrophilic modified film of the present invention. After testing, its tensile strength=3.26MPa, elongation at break=58.5%, pure water flux=8.5L / m 2 h (0.1MPa), rotational viscosity 2710mpa s (30 o C), pure water contact angle = 77.5 o .

Embodiment 2

[0045] Accurately weigh 15g of polyvinylidene fluoride, 84g of dimethylacetamide, and 1g of polymethyl methacrylate, and prepare a blended casting solution with a melting temperature of 55 o C, the dissolution time is 48 hours, and the solution is clear and transparent. Pour the film-casting solution on a glass plate to scrape the film at a constant speed, then soak it in water to form a film, and replace it in water for 24 hours to finally obtain the polyvinylidene fluoride hydrophilic modified film of the present invention. After testing, its tensile strength=2.26MPa, elongation at break=28.7%, pure water flux=19.8L / m 2 h (0.1MPa), rotational viscosity 2870mpa s (30 o C), pure water contact angle = 75.9 o .

Embodiment 3

[0047] Accurately weigh 15g of polyvinylidene fluoride, 83g of dimethylacetamide, and 2g of polymethyl methacrylate, and prepare a blended casting solution with a dissolution temperature of 55 oC, the dissolution time is 48 hours, and the solution is clear and transparent. Pour the film-casting solution on a glass plate to scrape the film at a constant speed, then soak it in water to form a film, and replace it in water for 24 hours to finally obtain the polyvinylidene fluoride hydrophilic modified film of the present invention. After testing, its tensile strength=1.58MPa, elongation at break=21.8%, pure water flux=133.4L / m 2 h (0.1MPa), rotational viscosity 2990 mpa s (30 o C), pure water contact angle = 69.9 o .

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com